Manitoba’s plans to invest across southwestern region and beyond

N.W.T. moving Mackenzie Valley Highway project forward.

Ontario’s

Part

Selecting

Manitoba’s plans to invest across southwestern region and beyond

N.W.T. moving Mackenzie Valley Highway project forward.

Ontario’s

Part

Selecting

My last issue on Rock to Road is bittersweet, but at least it's in good hands

At the end of 2011, I moved back to my hometown of Mississauga to accept my first position at a B2B publication after spending about two years working as a newspaper reporter in the Ottawa area. I was instantly attracted to the world of B2B publishing. You were given time to focus on writing longer features (unlike the newspapers), and I really enjoyed the process of editing and putting together magazines. I also discovered that I loved to learn how things are made, no matter what industry I was writing about.

Over time, I moved up in the B2B industry working on various publications until joining Annex Business Media in 2015. Under publisher (now president and COO) Scott Jamieson, I learned a ton about the world of B2B publishing and magazine production. I joined Annex as editor for Canadian Forest Industries, Canadian Biomass and Rock to Road, working alongside fellow editor Andrew Macklin. Working for Annex gave me ample opportunities to expand my knowledge of publishing and travel across Canada and the U.S., meeting all sorts of interesting people across many industries.

When I took over Rock to Road as its sole editor in 2016 (the other Andrew had moved on to other exciting career opportunities), I took this opportunity to reach out to as many people in the industry as possible. Almost everyone I met in the aggregate and roadbuilding sectors welcomed me into the industry, and helped me learn a ton about both sectors.

When I left Annex to start up my own company in April 2019, I was given the opportunity to continue overseeing Rock to Road’s print publications, which I happily accepted. Now, more than 8 years later, I am currently finishing up editing my last issue of Canada's aggreagtes and road-

building magazine – two sectors I knew very little about when I started, but have come to really enjoy covering.

The industry has made some impressive leaps and bounds over the past eight years in terms of sustainable technologies and operations. From electric and hybrid crushing equipment to low-emission asphalt and concrete plants, water-saving washing equipment, creative land reclamation projects, and so much more. I've truly enjoyed covering the latest technologies over the past eight years, and it seemed only fitting that CONEXPO-CON/AGG was my final major trade show to cover in the industry. Shout-out to AEM for always putting on an awesome show!

To all of my connections in the roadbuilding and aggregate sectors, Rock to Road is in the very capable hands of publisher Danielle Labrie, national accounts manager Laura Goodwin, and its new editors Jack Burton and Elizabeth Bate. I have no doubt all of you are in good hands.

As for myself, this past April I started my MFA in Creative Writing and began teaching my second writing workshop for young children, both of which I am finding incredibly fulfilling. I’m also working on a couple of new books (non-fiction and fiction).

As I move on to the next chapter of my career, I’ve got lots to be excited about, and even more to be grateful for. Special thanks goes to everyone I’ve worked with over these past eight years, especially all of the amazing people I’ve spoken with in the aggregates and roadbuilding sectors.

I wish you all nothing but success in all of your endeavours.

Sincerely, Andrew

Sustainable Innovation

As a decades-long leader for asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems.

Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

The Association of Equipment Manufacturers (AEM) has appointed Eric Sauvage, president and CEO of Link-Belt Excavator Company, as the chair of CONEXPO-CON/AGG 2026, running from March 3 to 7 in Las Vegas, Nev.

Sauvage joined Link-Belt in 2008 and has been CEO of the company since 2016. In addition to that role, he has been an active participant in AEM leadership for many years, including his current position as vice-chair of their construction equipment sector board.

“I plan to lean on that strong foundation to further strengthen and grow this world-class industry event, while optimizing the value for our attendees and exhibitors,” Sauvage stated.

Westridge Quarries, an established supplier of construction aggregates and contract crushing services for the Okanagan Valley, has been acquired by Lafarge Canada.

Lafarge will assume control of Westridge’s operations, in addition to two quarries, and one sand and gravel reserve in the Okanagan Region. Westridge’s 70 employees will be joining Lafarge as a part of the deal.

This acquisition is in alignment with Lafarge’s current growth strategy, with the company aiming to expand their presence in the aggregates market by targeting the acquisition of pits, quarries, docks, and depots in strategic high growth markets by 2025.

The Volvo Group appointed Stephen Roy, currently the head of North America for Volvo Construction Equipment, as the newest member of their executive board and new president of Mack Trucks, effective June 1.

Roy has been with the company since 1996 and succeeds Martin Weissburg in the role. Weissburg served as a member of Volvo’s executive board for over a decade and led a number of groups within the company, including Volvo Financial Services, Volvo Construction Equipment, and Mack Trucks. Weissburg will join the board of Novabus, another team under the Volvo Group.

BOMAG revealed the selection of Brian Bieller as the company’s new president of North American operations, effective March 10. Bieller joins the position from his prior role as president and CEO of LeeBoy.

Beyond his tenure with LeeBoy, Bieller has served as president and regional manager for Dynapac’s North American division, which shares a parent company with Bomag in the FAYAT Group. In his new role, Bieller will report to BOMAG’s group president, Ralf Junker, in Boppard, Germany.

“We are happy to have Brian rejoin the FAYAT Group in this new role, and we wish him success as he leads BOMAG Americas into the next season of growth and profitability,” Junker stated.

Rock to Road magazine is circulated free of charge to qualified individuals holding management and supervisory positions with companies engaged in the aggregate, roadbuilding, ready-mix concrete and asphalt production industry in Canada. The Publisher reserves the right to determine qualification. Paid subscriptions are available. Canada: $36.75 per annum including G.S.T. (six issues*); U.S. and Overseas: $60 US. *Includes annual Buyers’ Guide issue. Please send change of address with label from your last issue. All subscription correspondence must include your title/position, company name and address, postal code and telephone number.

BY JACK burton

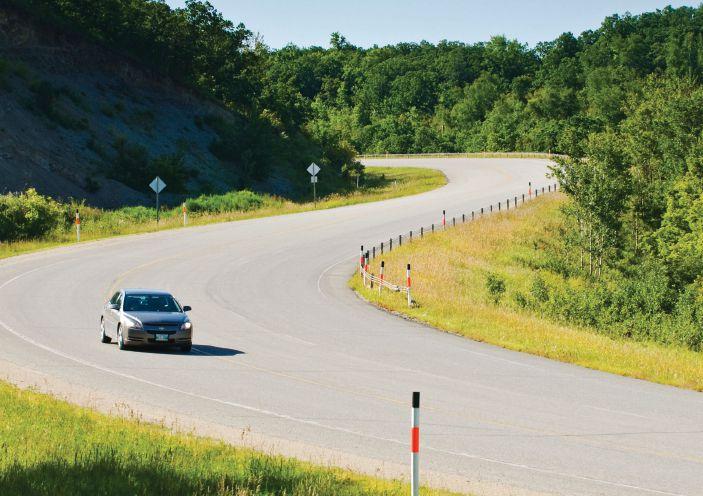

Manitoba’s plans to invest across southwestern region and beyond

> In March, the Manitoba Department of Transportation announced a robust, $50-million plan to target road and highway development surrounding Brandon and the Westman regions. These projects, as part of their overall Multi-Year Infrastructure Investment Strategy, are just one piece of the province’s goal for a healthy infrastructure network connecting all of Manitoba.

A majority of the investment is going toward the Trans-Canada Highway; with a surface rehabilitation planned over the 1.6 km between Provincial Trunk Highway (PTH) 10 and PTH 1A, 0.3 km between the west and east junctions of PTH 10, a stretch between PTH 25 and Provincial Road 270, along with PTH 10 from the Trans-Canada Highway to PTH25; totalling $29.2 million.

The plan also focuses on structure replacements on the Trans-Canada Highway’s westbound lanes at Willow Creek West Branch, and for the westbound lanes at South Boggy Creek for a total of $16.5 million, in addition to $1.36 million in work planned to occur on PR 457 between PR 110 and PR 468.

As the province’s second largest urban centre, it follows that the projects aim to build out provincial infrastructure not only

THE MOBICAT MC 110 EVO2 AN D M OB ICONE MCO 90 EVO2

T EA M PLAYERS THAT WORK TOGETHER INTELLIGENTLY AND STRENGTH EN EACH OTH ER. In linked plant combinati ons, th e MO BICAT MC 110 EVO2 ja w crush er and t he MOB ICONE MCO 90 EVO2 con e c ru sher really flex the ir muscles. SPECTIVE m akes b ot h plan ts easy and intu itive to operate. Also, an adv anced driv e concept ensures greater efficiency with l ow er consumption. Maximum throughput is achieved thanks to the material flow concept coordinated vi a l ine coupling acro ss bot h cru sh in g stage s. Go f or the p erfect team!

www.wirtgen-group.com/evo2-line-kleemann

beyond the Winnipeg corridor, but over the long-term, and also create another commerce centre that can mirror the capital’s economic growth on the western end of the province.

“Our Premier wants economic development in every corner of this province, and that includes the Westman region,” said Doyle Piwniuk, Manitoba’s Minister of Transportation. “As the second largest city and second largest commerce area in the province – in the region, there’s almost a quarter million people that actually use Brandon as a regional centre – we want to ensure the best for the highways that lead into Brandon.”

In the case of the Westman Region, Piwniuk believes that the industries are already there – including the hog industry, oil and gas, and the province’s first potash mine in Russell, set to begin production this summer – it’s just a matter of updating and installing the proper infrastructure to accommodate them.

“Right now, it’s important that we invest in our highways so that we can show outside investment that we’re here, and we’re open for business,” said Piwniuk. “There’s a lot of maintenance needed to rebuild these highways, and that’s what we’re doing. We’re doing that in every part of the province, but especially in the Westman, because there’s a big opportunity

when it comes to agriculture, oil and gas, and just overall economic development.”

A key focus of this initiative, Piwniuk shared, is the forward-looking focus of these projects. For him, it’s about more than just accommodating the current economy of the region on an infrastructural level – it’s about having the foundation

to support the growth and investments in these sectors that these upgrades will bring for years to come.

“You know what they say: the best time to plant a tree was 20 years ago, and the next best time is now,” he said. “So, this is what we have to focus on: how do we move our trade corridor and look at the future of that area, especially through Brandon, as starting to plant that seed right now, and foster it, too, so that we can actually have a freeway going through all of Manitoba?”

Naturally, as these industries grow, so will the movement of goods and commerce between these markets – meaning the simple, future-proof way of achieving this goal begins with the highways.

“We’re looking at long-term planning for the Trans-Canada Highway, because again, it’s going to basically become a freeway in the future, and we want to start working and planning for that,” he said.

In addition to unlocking the full economic potential of the area, these plans are also aimed at optimizing quality of life for residents, specifically in Brandon, with goals of reducing traffic congestion and increasing safety for pedestrians and cyclists surrounding the urban centre’s roadways.

The beginning stages of this significant initiative is already in motion, with the government currently in talks with the City of Brandon on the direction of the plan, before moving into the consultation and design phase.

Regarding the overall timeline, Piwniuk

said that “it’s going to take a number of years to do the consultation and designs, and once we have that, we’ll go out there and start the tendering process, which will allow any contractor to bid on the opportunity to do that range of projects.”

While the project is aimed at extending economic activity across the province, the government is also looking at it as a means of bolstering Manitoba’s heavy construction sector, strengthening the relationship between industry and government.

“When it comes to Manitoba Heavy Construction [Association], they requested that we go to a five-year budget, so that they’re properly informed and prepared for what’s to come,” Piwniuk said. “If they know what is coming, then we can work together to make sure that we bring this province, and the opportunity of investing in infrastructure, forward.”

Part of the changes in how the public and private construction industries in the province operate and interact are in reaction to a number of delays and setbacks to projects awarded over the last several years. By communicating budgets effectively, Piwniuk hopes that contractors across the industry will be best prepared for what’s needed for the incoming wave of projects.

“We don’t want to leave money on the table when it comes to our budgets,” he

said. “A lot of projects have been tendered and awarded, but have yet to be completed. So, this year, we want to make sure that when it comes to the five-year plan, we work with the private sector and contractors to make sure that when we have a five-year budget, it allows companies to invest in the human resources and equipment now, to get ready for what’s to come in the future.”

These delays, Piwniuk noted, were often no fault of the contractors themselves, but rather the unprecedented flooding that numerous regions across the province faced in 2022.

“Last year was perhaps the second worst flood in provincial history, because it wasn’t just that we had it in one region – it came in every direction,” Piwniuk explained. “We had staff, we had contractors, going all over the place, just to repair the highways that were damaged in the 2022 flood.”

While the conditions created by this incident added difficulty for projects to be completed on time, the flooding illuminated several obstacles, on both an infrastructure and policy level, worth being mindful of as they take a renewed focus in overall provincial infrastructure.

“Sometimes, when it comes to a crisis like a flood, it results in an opportunity for change when it comes to how we look at how things work,” Piwniuk said.

He highlighted a move away from

culverts, and their inefficient modes of maintenance, and toward bridges as one infrastructure lesson the province has put into action after the insights provided by the flooding.

“It’s the definition of insanity, doing the same thing over and over, and trying to get different results,” he said, regarding the government-mandated maintenance on flooded culverts and the resources it requires. “So, what we’re doing now, we’re drawing on a number of examples from last year’s flood that we’ve used as opportunities to put in bridges, to be better prepared should we have major floods.”

The province has learned numerous lessons, whether from current infrastructure, regional industries, private sector relations, or natural occurrences, that have all informed and contributed to the current vision that the government has for unlocking the full economic potential of the province, both now and for years to come.

“Before, we felt with the previous government that we were forgotten in the Westman Region,” said Piwniuk. “And now, this is our time to prosper: we need to put Brandon in focus, and make sure that economically, we’re working together to attract that outside investment because when Brandon grows, the whole Westman, and in turn the whole province, grows along with it.”

BY GRANT cameron

> The Northwest Territories (N.W.T.) is moving ahead, slowly but surely, on the long-anticipated next phase of the Mackenzie Valley Highway project.

The future leg of the thoroughfare will be a 321-kilometre-long stretch of two-lane, all-season gravel road that will run alongside the winding and tree-lined Mackenzie River from Wrigley, a designated authority in the Dehcho Region in the south, to Norman Wells, a town of nearly 700 in the Sahtu Region in the north.

The road will replace a seasonal winter road. In the south, it will link with a 1,150-kilometre-long section of highway that runs to Grimshaw, Alta. In the north, the Mackenzie Valley Highway will eventually be linked to public highways that connect to the Arctic Ocean.

Once completed, the highway will assert Canadian sovereignty in the North by providing an all-season transportation link connecting the isolated central Mackenzie Valley communities with the southern N.W.T..

A spokesperson for the N.W.T. Department of Infrastructure said in a statement compiled for Rock to Road that extensive

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance. BKT is with you, even when work gets tough.

environmental, socio-economic and technical work is being done in collaboration with Indigenous governments and community organizations to satisfy the requirements of terms of reference for an environmental assessment to ensure the project put forward is in the best interest of all area residents.

“All information collected is being compiled into a comprehensive Developer’s Assessment Report, which the Government of the Northwest Territories anticipates will be submitted to the Mackenzie Valley Environmental Impact Review Board in the coming months,” the spokesperson said. “Once submitted, the environmental assessment is expected to take 16 months to complete, followed by a five-month period for the responsible minister’s decision.”

Upon completion of the environmental assessment, the government expects an additional year will be needed to ensure all regulatory authorizations and permits are in place prior to advancing to construction.

“Construction cannot advance until the environmental assessment has been completed, regulatory authorizations and permits are acquired, and construction funding is secured,” the department spokesperson stated.

Completion of the highway has been

talked about for decades. Hopes were raised in 2013, when the territorial government filed applications for land and water licences to build an estimated $1.67 billion roadway in accordance with the Mackenzie Valley Resource Management Act.

But 18 months later, the government shortened the highway by more than half to reduce the cost to roughly $700 million. Instead of linking to the Dempster Highway, the plan was to end it at Norman Wells, 321 kilometres from Wrigley. The Government of N.W.T. has since released a business case for extending the highway.

Terms of reference for the environmental assessment were established by the Mackenzie Valley Environmental Impact Review Board (MVEIRB) in 2015. Funding to advance the environmental assessment was secured in 2018 through an agreement under Transport Canada’s National Trade Corridors Fund. Canada and the Government of N.W.T. committed to cost share $140 million to advance the environmental assessment, and two community capacity building projects along the existing winter road alignment.

The department spokesperson said that, as the environmental assessment process continues, and engineering and design for construction advance, a revised

construction cost estimate will likely be needed. “Large and systemic cost escalations are being experienced across the country and the Mackenzie Valley Highway construction cost is anticipated to have increased significantly.”

A number of smaller projects along the route have already been approved or completed.

In late 2018, the government completed the Canyon Creek Access Road, a 14-kilometre-long, all-season access road from Norman Wells to Canyon Creek. It replaced a winter road that was constructed annually.

Last November, construction began on the first phase of the Prohibition Creek access road, a 6.7-kilometre thoroughfare from Canyon Creek to Christina Creek. Cost of the project is $25.5 million. Right-of-way clearing has been completed and drilling, blasting and embankment construction are in progress. The work is anticipated to be completed in the fall of this year.

A separate budget of $2.5 million has also been approved to cover the plan-ning and design work completed to date, as well as outstanding work required to make phase two of construction project shovelready. Phase two will see construction of

6.3 kilometres of all-season road from Christina Creek to Pro-hibition Creek.

The government is also currently working to complete land acquisition, attain permits and complete the design for the Great Bear River Bridge adjacent to Tulita. Regulatory applications are expected to be submitted this year.

However, there is a wrinkle in a project near Wrigley where a proposal has been put forward to realign a 15-kilometre portion of the highway from Hodg-son Creek to Mount Gaudet.

Regulatory permit applications were submitted to the Mackenzie Valley Land and Water Board in the fall of 2020. However, the Pehdzéh K ı̨́ First Nation (PKFN) has expressed concerns with various aspects of the project.

The regulatory process for the project is currently on pause until additional engagement and technical work is completed to the satisfaction of the PKFN. The government has recently re-engaged with PKFN and is developing an action plan to move the project forward.

When fully completed, the Mackenzie Valley Highway will connect Canadian public highways to the Arctic Ocean. Gravel has been chosen as maintenance costs associated with upheaval and perma-

frost are more expensive for paved roads.

In addition to asserting Canadian sovereignty, the road will mitigate the effects of climate change on current winter road infrastructure and decrease the cost of living for area residents by increasing access to goods and services.

Meanwhile, the road will enable the N.W.T. to incentivize economic diversification and development in the region. Construction of the road will create thousands of new jobs and valuable business and training opportunities.

Completion of the environmental assessment and regulatory and permitting processes is anticipated to take two to three years, according to the department spokesperson. Construction of the highway itself will take several years to complete. Construction may advance in phases, sequentially or in sections, concurrently.

The project is expected to be challenging due to its remote location. Engineers must figure out how to minimize the impact of the project on the environment and deal with material and labour shortages.

“Advancing a project of this scale is not a simple process and requires careful planning,” said the department spokesperson.

As design for the project advances, it will require land access agreements with

Indigenous land holders, not only for the highway itself, but also to ensure access to appropriate aggregate and other materials. Construction, operation, and maintenance activities will need to factor in waste, water and wildlife management.

“Logistics associated with ensuring equipment and supplies are available and can be mobilized is always a concern, especially given recent inflationary pressures related to the COVID-19 pandemic, which are impacting the construction sector not just in the Northwest Territories, but across Canada,” the department spokesperson said. “Increased material costs, fuel costs, labour shortages, and supply chain issues are all resulting in projects costing much more than originally estimated.”

The Government of N.W.T. is replacing seasonal winter ice roads with all-season roads in order to make the transportation system more resilient to climate change impacts.

“The Department of Infrastructure recognizes the challenge climate change presents and is the taking necessary steps to ensure public infrastructure is more resilient to the impacts of a warming planet and can meet the current and future needs of N.W.T. residents,” N.W.T. Infrastructure Minister Diane Archie said in a recent speech.

Ontario’s top political players talked infrastructure, both present and future, at 2023

> The Good Roads Annual Conference, taking place from April 16 to 19 at Toronto’s Fairmont Royal York, offered Ontario officials a glimpse of what the future holds when it comes to the province’s infrastructure, a major touchpoint between over 2,000 municipal officials, association members, and key thought leaders across politics and industry.

Among the featured voices were some of the top decisionmakers in the province and country at large: After an opening address by federal Minister of Transportation Omar Alghabra on Sunday, April 16, the Monday saw Ontario Premier Doug Ford and his team, along with the NDP’s Marit Stiles, official leader of the provincial opposition, offering informative, if not conflicted, glimpses into the state of infrastructure and municipal relations across the province.

BY JACK burton

Premier Ford began his speech by highlighting the recently-released provincial budget for 2023, speaking to the budget’s goals and how they relate to municipal leaders and provincial infrastructure, both presently and in terms of their impact in the years to come.

“Last month, we introduced our 2023 budget for building a strong Ontario, and that's exactly what we're all doing for all 444 municipalities,” Ford shared. “The budget is a responsible but targeted plan to help people, businesses and communities today, while laying a strong foundation for generations to come.”

Ford expanded on the budget’s focus, commenting both on its future-forward focus and unprecedented scale regarding the investments and improvements it looks to make to infrastructure across the province.

“What we say when we're talking about building roads, transit, and schools, is that we aren't building it for tomorrow –we're building it for the next 50 years,” he said. “Our plan to build includes the most ambitious capital plan in Ontario's history, investing over $184 billion over the next decade. We have the largest infrastructure projects going on anywhere in North America over the next decade to build roads, highways, bridges, schools and hospitals, long-term care homes, and other key infrastructure projects to support the growth of our economy and communities.”

The grand ambition behind this capital plan largely comes from the amount of projects and initiatives across the province to build, expand, and rehabilitate a number of highways, with these projects totalling almost $28 billion over the next 10 years.

Among these projects are the Bradford bypass connecting Simcoe County to York Region, the building of Highway 413, the new Highway 7 between Kitchener and Guelph, and a widening project on southwestern Ontario’s Highway 3.

Ford also noted over 600 highway improvement plans across the province focused on expansion and rehabilitation, in addition to a $400-million contribution to Ontario’s Community Infrastructure Fund to renew and repair critical infrastructure across 425 rural and northern communities.

The budget’s aspiration to provide a large-scale foundation for the future of provincial infrastructure is not an attempt

to make the record books, but rather a necessity, said Ford, highlighting the rapid growth of the province and its industries, and the need to scale up to accommodate this growth that comes with it.

“We're the fastest growing region in North America. Did anyone see the stats that came up from Stats Canada? It’s staggering: 445,000 people landed here in Ontario last year alone,” said Ford. “For the last six months, we've seen growth even as we see turbulent economic times around the world.”

Whether it’s the new realities of Ontario’s present moment or the changes that the government anticipates are set to come, it’s a team-oriented approach that Ford sees as paramount in his goal of building a more connected and growth-prepared province.

“I say, it's a Team Ontario approach: It's not one government, it's not one person, it’s a Team Ontario approach. And because of Team Ontario, we're continuing to grow,” he shared. “I don't care if it's the Liberals, NDP, or PC – if we work together, we're unstoppable. Sure, there's going to be some bumps in the road, but collectively, we all want the same things:

we want economic growth, we want affordable housing, and we want infrastructure built in our communities.”

Another area of the budget that Ford highlighted during his speech was plans to build out skilled training programs with a $224-million investment, in an effort to both deal with the labour shortage and to increase the labour supply to meet the increase in infrastructure projects that this budget is bringing to the province.

“We're making real historic investments in employment and training programs to train the skilled workforce for growing economic needs, whether it's upskilling workers, training new ones, or breaking down barriers to get skilled immigrants into the province,” said Ford. “We're leaving no stone unturned.”

From the numerous projects the government has budgeted for, to the training programs looking to prepare the workforce for the amount of jobs this will create, for Ford, the future of the province’s infrastructure looks bright.

“It's all hands on deck,” he said. “Our population and the economy will grow continuously over the next number of years. We're getting shovels in the ground,

from Thunder Bay, to Kitchener, to Windsor, and everywhere in between.”

Ontario Minister of Labour Monte McNaughton spoke more to the government’s forthcoming strategies for navigating of these labour shortages, including an announcement of a collaboration between the Ontario government and OGRA focused on accessible training and eLearning for rural and First Nations communities.

“Today, I'm pleased to announce that our government is investing $1.8 million to support this project. We're delighted to work with Good Roads to help 625 workers prepare for today's jobs, and to attract the next generation in public works,” said McNaughton. “This idea is exactly the kind of innovative thinking that our government is looking for: cost effective, flexible, and giving workers the skills they need for better jobs with bigger paychecks.”

The courses cover the basics of road construction and maintenance, heavy equipment operations, and leadership training for new supervisors, and will be supported through the provincial government’s Skills Development Fund.

The current Conservative government concluded their speeches on the Monday with an appearance by Caroline Mulroney, Ontario’s Minister of Transportation. Mulroney reiterated the budget’s aim to accommodate the province’s growth, in terms of both population and industry, by ensuring that the proper infrastructure is in place to allow the connection of communities and markets that creates this growth to happen in the first place.

“It starts with transportation,” she said. “Think about it: transportation, roads, bridges, buses, subways, is the one government service that every single one of us in this room and every single person across Ontario relies on every single day. We need the transportation network to get us to work, to get our goods to market, to get our kids to school, to get our parents to their medical appointments, and to get us all back home safely at the end of the day.”

Mulroney expanded on the ways in which the infrastructure budget hopes to achieve this, including $99 billion toward the building of transit and transportation infrastructure, and $27 billion for the planning and construction of expansion

and rehabilitation projects for highways.

It’s through investing in achieving stateof-the-art highways and trade corridors that the government believes the province’s economy will come to be state-ofthe-art as well.

“This is critical, because let's not forget that everything, even in this room here today, was brought in by a truck that needed a road or a highway to get here,” she said. “And the rising costs that Ontarians are feeling every single day are impacted by the increased costs to move these goods. Gridlock alone costs our economy $11 billion in lost productivity a year.”

The cost of these investments is one that Mulroney outlined will pay for itself: every $1 billion invested in transit supports 10,000 jobs, she said, and boosts the economy or real GDP by another $1 billion. Jobs such as the construction of Highway 413 will support 3,500 jobs and generate up to $350 million in real GDP, with the building of the Bradford Bypass supporting over 2,600 jobs and generating $274 million annually in real GDP.

An afternoon appearance by Marit Stiles, leader of the NDP opposition, offered a look behind the curtain of numbers and promises that the current government had spoken of earlier that morning. Her concerns focused less on the goals and data of the budget itself, and more on what these current plans and approaches mean for municipal-provincial relations in terms of infrastructure.

“This conversation between us couldn't have come at a more important time. You know this better than anyone,” she said. “Municipalities are the closest form of government for most people. No one understands better than you what's happening day to day, and what will grow stronger communities. And of course, the roadblocks holding you back.”

Stiles highlighted the provincial government’s current approach to be one that is ignorant of the immediate needs of municipalities in favour of large-scale projects and smaller bottom lines.

“You've been asked to adapt at a moment's notice, decades of planning have been overturned because of radical new changes, and after a pandemic that chewed away your funds and your savings, municipalities are looking at the government for more support. But instead, you've been dealt deep cuts and higher costs,” she said.

The primary example of these unfair demands that Stiles looked toward was Bill 23, which she said shows that the system of communication and trust necessary for municipalities to advocate for their needs, especially when it comes to much-needed infrastructure repairs and updates, has been broken and overturned.

“By moving ahead with Bill 23, this government made it clear that they're not interested in hearing from municipalities,” said Stiles. “They sent a very clear message,

[that] they're going to act unilaterally, [and] they're going to propose major changes without a consultation with municipalities. They're willing to cause chaos, and then they're going to leave it to municipalities and taxpayers to fill the financial gap.”

To Stiles and her party, the message sent by Bill 23 is not just a breakdown in order when it comes to municipal and provincial relations, but also a message that communicates a lack of support for municipal governments at a time when their infrastructure requires provincial assistance more than ever – assistance that Stiles reiterated they remain quite capable of providing.

“I felt that in [the] budget, the government sent the message home that municipalities are in this alone,” she said. “And there's no help coming from a government, that I want to be completely clear, ended this year with a surplus. They're flush with cash when municipalities are desperate for money.”

The province’s accessing of these fees creates a $5.1 billion hole over the next decade, Stiles shared, the consequences of which she believes will surely be felt. “We understand the importance of development fees that municipalities rely on to build roads and infrastructure. And we know that by accessing those fees, the livability of our towns and our cities, and ultimately the lives of Ontarians are being put on the line.”

While the truth of Ford’s message of working and building Ontario together is called into question by this, by no means does Stiles see this as the wrong approach – it’s in reliable and collaborative communication between all levels of government that she believes the province’s infrastructure problems can be solved, and it’s something she feels is desperately needed not only at the moment, but to secure an abundant future for the province.

“If we are going to truly attract people to come and live in our province, if we're going to recruit and retain the workers that we need here, we need to build Ontario. It's absolutely essential,” she said. “This is only possible through a strong provincial-municipal partnership that allows Ontarians and people across this province to thrive. It means a provincial government that understands we gain more by working together, instead of offloading costs and responsibilities. That vision, and that dream, of an Ontario for that works for everyone is possible, and it can be the reality.”

BY ANDREW snook

> In the March/April issue of Rock to Road, we looked at several new technologies and OEM initiatives announced during CONEXPO-CON/AGG 2023. The most well-attended edition of the triennial show of all time, this year’s CONEXPO-CON/AGG drew 139,000 to the Las Vegas Convention Centre to check out more than 3 million square feet of indoor and outdoor exhibit space. Here is the continuation of our coverage.

For PPI (Precision Pulley & Idler), the theme of CONEXPOCON/AGG was “How we keep it moving.”

“Part of that is we've increased the inventory in our different locations. We have over one million square feet of manufacturing

capability,” says Dallas Houchins, field applications engineer for PPI.

PPI has a significant Canadian footprint with a manufacturing facility in Surrey, B.C., as well as a dedicated field engineer and sales team covering Canada.

“Our sales force is very seasoned, they’ve got a lot of knowledge. We also have a dedicated field engineering team, which I'm a part of. We assist our sales guys with different issues such as belt tracking, or suggest components that will help solve carryback issues, and increasing the life of the conveyor system. So that's how we keep it moving with conveyors,” Houchins says.

During a tour of the John Deere/Wirtgen Group booth, trade press got a chance to check out Kleemann’s MOBISCREEN MSS 802i EVO. The mobile screening plant features the Spective touchscreen display, which acts as a centralized control system that controls all functions and diagnostics of the machine. This system provides customers with an overview of the complete plant, making it very easy to monitor each component with the touch of a screen, a Kleemann representative told the crowd. They added that the continuous feed system (CFS) optimizes the uniform loading of the machine by allowing the components on board to communicate with each other, which reduces fuel consumption and reduces abnormal wear while increasing overall throughput.

Kleemann also introduced Spective Connect, an extension of the Spective technology, which offers the operator an extension of the Spective screen via an app on their smartphone. Operators can essentially view the same screen while inside the cab of a wheel loader or excavator. Spective Connect also allows operators to send reports of productivity throughout the day, providing customers with a much more sustainable and ecofriendly operation.

During CONEXPO-CON/AGG, Dynapac introduced its SEISMIC technology, already successfully used for its soil compaction equipment, on the company’s new line of tandem asphalt rollers.

“We've had very good success on the soil side, so we wanted to bring that into the asphalt field as well,” explains Dynapac marketing and digital solutions

manager Dormie Roberts.

The intelligent SEISMIC system improves compaction performance significantly compared to conventional compaction carried out at fixed frequency. SEISMIC automatically detects the optimum compaction frequency and continuously adjusts accordingly.

For tandem asphalt rollers, since the drum and the asphalt act as one dynamic system, several benefits can be found from the system’s natural frequency. At the natural frequency, the drum amplitude is enhanced significantly, since energy is automatically fed to the system at exactly the right time. This, in turn, maximizes the contact force between the drum and the surface layer, yielding maximized compaction and energy efficiency. The best compaction parameters guarantee an optimal output.

BKT showcased its EARTHMAX SR 45 H2 OTR tires for standard haul trucks for quarries.

“It’s a new product for us. It’s got the sight down the centre that allows for better heat dissipation,” explains Chris

Rhodes, vice-president for BKT.

EARTHMAX SR 45 H2 is an All Steel radial tire specifically designed for rigid haul trucks. The E-4 tread depth and the unique tread pattern ensure excellent wear minimizing vibration and noise. EARTHMAX SR 45 H2 is ideal for all operations requiring traction and stability. The All

Steel casing provides excellent resistance to snags and punctures and a long service life. Available in standard, heat-resistant and cut-resistant compounds.

On display at the Polydeck booth was the screen manufacturer’s new RUBBERDEX ULTRAMAX synthetic media and METALDEX ULTRACLEAN.

Polydeck’s Demi Agresta says the ULTRACLEAN product was reconfigured and redesigned.

“We found that doing this design makes it way better in the field,” she says.

ULTRACLEAN is built with an easy pin-style fastening and 30-mm panel thickness. The modular screen media is available in 3/32”; 1/8”; 3/16”; 1/4”; 5/16”; 3/8”; 1/2”; 9/16”; and 5/8” aperture sizes. The screen features a zigzag wire design oriented across the flow of the screen to enable smaller apertures while providing secondary movement that prevents entrapment of material to eliminate blinding and plugging.

The ULTRAMAX is how Polydeck directly competes with wire cloth, Agresta says.

“It has up to 57.6 per cent open area, whereas, wire cloth sits in that 40- to 45-per-cent range most of the time,” she says. “So, a lot more throughput going through.”

The ULTRAMAX also features easy pin-style fastening. It is currently available in 19mm (3/4”) and 14mm (9/16”) aperture sizes. It features square apertures for clean cut sizes, and a 40-mm panel thickness. The modular design results in reduced labour costs and maintenance needs.

Safety device leader Brigade Electronics showcased its AI intelligent detection with its new VBV-2220C-AI-D04 front-facing AI camera and its VBV-2230C-AI-D04 rear AI camera for heavy equipment.

“The software is written into it to specifically detect people,” explains Brigade’s Jason Davis. “It differentiates the people from other small objects.”

Using AI, the cameras detect and recognize the human form within the pre-

defined detection zone and reliably warn the driver visually and/or audibly before a possible collision occurs. Image processing is built-in to the cameras.

The cameras’ features include:

• High definition image;

• Recognizes and alerts the driver to people in the front and rear blind-spot;

• Detected people are shown in a coloured box overlaid on the HD camera image on the driver’s monitor;

• Image processing and detected-personoverlay directly from the camera unit;

• Plug and play: AI camera connects directly to the Brigade monitor and/or optional buzzer

• Brigade Select range connectors;

• Compatible with all brigade HD monitors and MDR recorders.

The company also showcased its Brigade Fusion solution.

Brigade Fusion uses sensor fusion technology to combine Brigade’s range of safety devices, including its 360-degree camera, radar obstacle detection and M2M RTLS (Real Time Location System) technology. This allows the system to predict high risk events, providing the operator with appropriate and prompt alerts and, if required, signal the machine to prevent movement, slow down or stop entirely if its operator is unable to react in time.

The new system, which has been trialled by several customers in the U.S. and the U.K., adds EMESRT (Earth Moving Equipment Safety Round Table) Level 8 and Level 9 collision avoidance to its existing Level 7. This delivers the highest standard in worksite safety for off-road construction and mining mobile equipment.

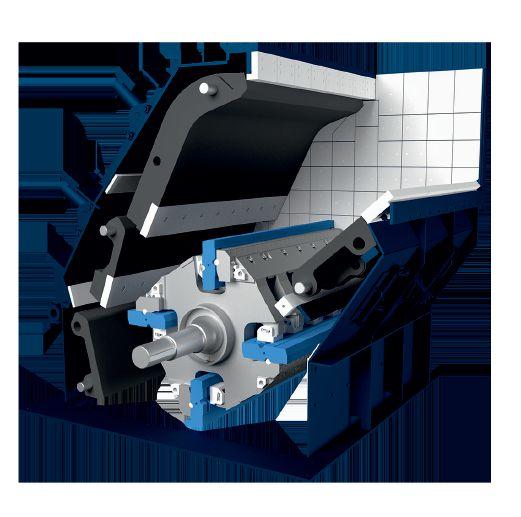

Superior Industries debuted its two new cone crushing models at CONEXPOCON/AGG 2023: the Endeavor Cone and the Dakota Cone. Both models join the bulk material processing system manufacturer’s overall line of aggregate production solutions, including their previously released Patriot Cone Crusher.

The Endeavor sports a spider bushing design, which Superior reported are historically known for accepting the largest range of feed sizes and simplified operation and maintenance. The crusher also includes what the company are calling the strongest shaft style the industry has

designed to date, supported on a cast top and cast bottom shell.

A top access chamber makes the Endeavor both safer to access and simpler to maintain, the company released in a statement, while a range of multiple strokes and liner configurations adds flexibility when it comes to the model’s applications.

The Dakota features a roller bearing design, which the company reported typically offers the most efficient use of horsepower per ton of crushed rock.

Additional features include a steel threaded bowl, a single-piece cast mainframe, a tramp relief system designed with fewer accumulators to minimize maintenance, and a hydraulically-operated anti-spin system that aims to eliminate additional labor such as the installation of individual gears.

Both models are designed for high performance in primary, secondary, or tertiary applications. Each model is also suited for both portable and stationary settings. Maximum feed opening is up to 18 inches (450mm) with horsepower ranging from 200 to 800 hp (150-600 kW).

Schurco Slurry showcased its range of heavy-duty slurry pumps and had a pump on display in an exploded view at its booth at CONEXPO-CON/AGG 2023.

“This pump can take replaceable liners and impellers. As the pump wears out, whether it's pumping sand or any sort of aggregates, it will wear out over time. So, this design allows you to replace the commodity components rather than replacing big metal cast pieces,” explains Oliver Nobels, director of engineering at Schurco Slurry.

Nobels showed off the company’s urethane liners and explained their advantages.

“Urethane is much more comparable to a natural rubber than a high chrome pump, but the benefits with urethane is it's a little bit harder. So, it can handle a little bit higher pressures than our natural rubber, but also show some of the main wear characteristics. Whenever we're talking any sort of sand that has some sort of silica content, it is not good for a metal or a high chrome pump, so we have to look at some sort of elastomer. We have seen that urethane has been a good option, especially in the case where we need to hit a little bit higher pressures where

we wouldn’t be able to do that with the natural rubber.”

The pump also features Schurco Slurry’s Expeller Seal.

“It's a dynamic shaft seal that does not require seal water, which for the aggregate industry is ideal, because a lot of the plant water is not very clean. And if you're using a stuffing box that will require seal water, it will wear out over time. So this is a good option if you don't have much available seal water or the seal water is

not very clean.”

The next edition of CONEXPO-CON/ AGG will take place from March 3 to 7, 2026 at the Las Vegas Convention Center in Las Vegas, Nev. The Association of Equipment Manufacturers has appointed Eric Sauvage, president and CEO of Link-Belt Excavator Company, as chair for CONEXPO-CON/AGG 2026.

To read Part 1 of our CONEXPOCON/AGG 2023 coverage, visit: www.rocktoroad.com.

BY TROY GEISLER

Determining which deck configuration will be the best fit is a question for the professionals, as there are pros and cons to each. Custom trailer manufacturers have the experience and knowledge to determine what style would be best overall.

Selecting the right trailer isn’t a decision to be taken lightly

Transporting paving equipment to and from the jobsite safely and efficiently can be a logistical and financial challenge. That’s why selecting the right trailer for hauling paving equipment isn’t a decision to be taken lightly. Many hours of research are required to find the trailer that fits an operation’s needs. It’s a long process, but the end result is — hopefully — an implement that will provide safe, efficient hauling for years, benefitting the operation’s bottom line for the long haul.

Just as there are many considerations to make when investing in paving equipment, selecting the ideal trailer to fit all of an operation’s hauling needs means taking a critical look at several key variables.

Keep these five factors in mind when sizing a trailer for paving equipment loads.

1. Equipment weight and dimensions

The first step in sizing a trailer for any hauling job is determining the weight and dimensions of the load. Identify the length, height, width and weight of your most challenging machines. Keep in mind that the information on the spec sheet might not include the dimensions and weight with added accessories.

When making initial calculations, ensure you have a suitable truck that is capable of handling all or most of your equipment before moving on to the trailer. A three-axle tractor and a four-axle tractor

will have different hauling capabilities and that varies by state.

There is a wide range of machinery used in the paving industry — such as pavers, rollers, milling machines and screeds. Each of these machines are different by design, so proper research on the specific requirements of each intended machine is highly recommended. Certain paving equipment will require a lower load angle as opposed to other equipment.

After determining the weight and dimensions, it’s time to look at trailer deck designs. Manufacturers usually offer three deck configurations — flat, raised center and beam. For the most part, operators looking to haul paving equipment will find a flat deck meets the majority of their needs. It offers the most versatility for moving a variety of equipment, from rollers to milling machines. However, it also has the highest deck height and might not be ideal for those also looking to haul taller machines. For this reason, discussing the pros and cons of different deck designs with a professional is recommended when spec’ing a trailer.

Custom heavy-haul trailer manufacturers have the experience and knowledge to determine what style would be best overall. While the primary focus might be on paving equipment, a trailer often hauls a variety of equipment types. Backhaul equipment should also be included in calculations. An expert can determine the best trailer to meet all hauling needs.

In addition, companies today tend to specialize in a wider variety of equipment moves that might require special considerations when it comes to selecting a trailer. For instance, operators looking to haul excavators in addition to paving equipment should research configurations that accommodate the boom. In these cases, operators need to consider the length of the boom, where it will sit on the trailer and how it will be cradled in addition to hauling needs for their paving equipment. Some top-tier manufacturers offer customizations to make mixed-load transportation safer and easier. Knowing all the types of equipment that might be hauled will help ensure purchase of a suitably versatile trailer.

2. Trailer capacity rating

While knowing the overall weight of the equipment is imperative, it is also important to know where that weight is concentrated. Failing to be mindful of this

Working with an experienced manufacturer will ensure a wealth of knowledge and expertise when it comes to making sure trailers and loads are safe and compliant for each area of operation.

can lead to overloading the trailer, which can result in stress fractures and ultimately trailer failure.

Just because a trailer is rated at 50 tons does not mean it can be loaded with 50 tons of cargo in any configuration; operators need to consider the deck length used in the capacity rating to determine if the trailer is suitable for the proposed load. This varies between man -

ufacturers. One trailer might need the entire deck length for that 50 tons, while another handles that same weight in half the deck length. Similar-sized paving equipment can have drastically different load concentrations. If the majority of the equipment’s weight is concentrated in 8 or 10 feet, a trailer with a half-deck load concentration rating offers the best solution.

3. Loading configurations

Today’s trailers offer a variety of loading configurations. While tag-a-long trailers that unload off the back are an accepted option for small paving in tight spaces, safety can be a concern. Driving equipment over the back of the trailer is no easy feat and requires a careful and experienced driver to prevent damaging the trailer and minimize the risk of tipping equipment. Reputable manufacturers are safety minded and have implemented designs to minimize certain risks, such as roller stops at the rear of the trailer or extended ramps for lower-approach angles.

Removable goosenecks reduce the danger by eliminating the need to drive up and over the trailer axles. This configuration saves time, hassle and expense while also extending trailer life. However, a removable gooseneck requires ample space for loading and unloading.

4. State and federal regulations

Knowing where a trailer is headed is as important as knowing what it’s hauling.

In general, operators should not need additional permits for loads up to 102 inches wide and under 13 feet, 6 inches tall. However, weight and height regulations vary for bridges and between states, especially trailers hauling in California and the surrounding areas. Operators must also consider state kingpin laws. Working with an experienced manufacturer will ensure a wealth of knowledge and expertise when it comes to making sure trailers and loads are safe and compliant for each area of operation.

It’s important to consider the quality of a trailer, not just the price tag. Working with a custom manufacturer offers the best results when it comes to safety, value and peace of mind. A trusted manufacturer will work to understand the client, not just the load. They will consider not just the equipment, but everything the client needs to haul, the territories of operation and the specific challenges they face. The manufacturer will use that information to

design a trailer that offers maximum flexibility, versatility and strength.

Also consider the construction materials. Look for materials like heavy-duty T-1, 100,000-psi minimum yield steel for extreme durability and longevity. Apitong flooring is another good choice because it stands up better than traditional oak and pine decking. Investing in higher-quality materials and components can double the life of the trailer.

Trailers from a respectable manufacturer may also include positive camber in the design. The amount of camber can be customized based on the estimated usual load to ensure the flattest loaded deck possible.

Choosing the right trailer is a job best left to the pros, but with these tips, operators can get a jump start on the process.

Troy Geisler is the vice-president of sales and marketing for Talbert Manufacturing. He has more than 15 years of experience in the trailer industry, including 10 years with Talbert.

CAMBRIDGE, ONT. ossga.com > JUNE 22-24 CIQS

CALGARY, ALTA. ciqs.org > SEPTEMBER 26-28 The Utility Expo LOUISVILLE, KY. theutilityexpo.com > SEPTEMBER 26-28 SC&RA Crane & Rigging Workshop OKLAHOMA scranet.org > NOVEMBER 17 MHCA 2023 AGM WINNIPEG, MAN. mhca.mb.ca > NOVEMBER 29-30 SHCA

saskheavy.ca

> NOVEMBER 29 TO DECEMBER 1 The Building Show TORONTO, ONT. thebuildingsshow.com

It takes many people by surprise that Canada is home to approximately 25% of the world’s wetlands. Most of Canada’s wetlands are in the north, part of the circumpolar boreal forest, known as peatlands. These include wetlands classified as bogs, fens, and swamps. For those of you that have had the pleasure of experiencing the north, you may know these areas fondly as ‘muskeg’ or ‘skeg’. These areas are uninviting, mosquito-ridden hellholes for the average human, but they provide valuable ecosystem services for the species that depend on them. In fact, one square metre of peatland in northern Canada stores around five times the amount of carbon compared to a square metre of tropical rainforest.

Regulators, scientists, and environmental groups also place an incredible value on non-peatland wetlands across Canada. For example, from mid-April to the end of August, prairie pothole wetlands support a vast array of biodiversity such as plants, birds, and amphibians, also serving as the habitat they require to reproduce and cultivate their species.

Wetland regulations and permitting

The regulations and policy pertaining to wetlands across Canada are largely varied. Some provinces have rigorous regulations and policies for wetland removal that include financial disincentives in the form of inlieu wetland replacement fees, while others have little to no protection. One thing that is consistent is that identifying and adhering to applicable regulations and policy pertaining to wetlands can help operator’s from incurring unnecessary costs, and potential litigation.

Several provincial pieces of legislation across the country specifically pertain to the protection and preservation of wetlands and can impact aggregate operations significantly. Any permanent impact to wetlands will usually require approval under the various provincial water legislation from the regulators. Provincial wetland policies, legislation and associated directives provide guidance on wetland identification, classification, and delineation; mitigation hierarchy; and wetland replacement options for unavoidable permanent impacts to wetlands. Most regulatory submissions for wetlands must be supported by a wetland assessment. The wetland delineations and classifications are often

reviewed, and sometimes scrutinized, by regulators, so most submissions require designated wetland professionals to complete the assessments.

Another thing to consider is that if a wetland is semi-permanent or permanent (i.e., it holds water throughout the year most years), the bed and shores of the wetland may belong to the Crown under provincial lands legislation. Any activity within a crown-owned waterbody requires the prior approval of the Crown and may trigger additional regulatory requirements.

Additionally, birds and amphibians also have protections of their own under other regulations, such as the federal Species at Risk Act or the Migratory Birds Act. If unauthorized disturbances of wetlands take place in advance of securing the necessary approvals, the regulator will usually require the impacts to wetlands to be reported and that the wetland be restored to its pre-disturbance condition before any regulatory submissions will be considered going forward (operations can be suspended until such time as all remedial actions have been undertaken).

The entire permitting process can often take anywhere between six months to two years to complete, a timeframe that some developers need to remember to account for when planning their projects. Early identification and assessment of the potential impacts on wetlands along with understanding and adhering to applicable regulations and polices for wetlands in your jurisdiction, is the best way to mitigate long permit wait times, avoid unnecessary costs, and prevent potential regulatory anguish.

Bill Gowdy is the technical director of aggregates for SLR Consulting. He has 35 years of experience in the geology and environmental fields, including 22 years based in Edmonton managing aggregate resource assessments, geological modeling, permitting, reclamation, environmental management systems, groundwater monitoring, community relations and biodiversity projects. Alana-Rose Lynes is a senior wetland specialist with 16 years of experience in Canada and internationally. She prepares regulatory applications, conducts technical environmental assessments, and completes wetland research. Alana is a subject matter expert who has appeared as an expert witness in Environmental Appeal Board Hearings.

244 X-TIER

Our new electric lineup made a lot of noise in Vegas. Which is impressive, since they cut noise in half while keeping the same power That means you can work overnight or indoors. And we also built them to fast charge at a station, or recharge directly on the jobsite, because even small machines should deliver big results.

We help build the roads that connect goods to markets, people to communities and families to one another. Astec aggregate processing equipment and road building machinery yield innovative and reliable Rock to Road solutions that create value and connection. We are inspired to connect with our customers through inventive design and productive machinery. Find your solution.