SkyDome engineer Harry Angus is one of this year ,s winners. P. 6

04 | Comment

The Building Show’s first-ever walking tour was a big one: the 7.7-acre, mixeduse downtown Toronto development known as the Well.

18 | Climate Perspectives

This series of columns reaches its conclusion a review of past topics and suggestions for possible solutions to global warming and climate change.

22 | Conversation

Robyn Brown of Arcadis responds to the federal government’s Build Canada Homes (BCH) Market Sounding Guide.

6

COVER STORY

Lifetime Achievement Awards

Meet the winners of Canadian Consulting Engineer’s fourth annual Lifetime Achievement Awards program, whose exemplary careers have helped paved a path forward for younger engineers. This year’s awards go to Harry Angus, Don Bergman and P.K. Chatterji. Read their stories here.

Winter 2026

Volume 67 | ISSUE 1 ccemag.com

05 | 2026 Canadian Consulting Engineering Awards Call for Entries 6 20 16

16

High-rising Responsibly

CTBUH’s recent international conference in Toronto suggested the future of vertical construction is about responsibility just as much as ambition.

20 Pipes, Pumps and People

Beyond issues with aging water infrastructure, North America may face a workforce crisis in ensuring there are enough engineers to build and keep these systems working.

ON THE COVER Harry Angus is a past president, CEO and chair of HH Angus and Associates, who recently celebrated his 50th anniversary with the firm. Among his most notable projects was engineering Toronto’s SkyDome. See story on p. 6.

by Peter Saunders

The Buildings Show, held annually at the Metro Toronto Convention Centre (MTCC), had apparently never offered a local building tour before. On Dec. 5, 2025, I was fortunate enough to join the first one, which involved a short walk west to the Well, a 7.7-acre development that runs west from Spadina Avenue to Draper Street and north from Front Street West to Wellington Street West.

Officially completed in 2024, the Well has added nearly 500,000 sf of retail, more than 1 million sf of commercial office space and more than 1.5 million sf of residential units, across seven mixed-use buildings, interconnected by pedestrian walkways and a concourse. The ‘gateway’ to this new neighbourhood is a 36-storey office building at 8 Spadina.

The Building Show’s tour was led by Michael Conway, associate partner at Hariri Pontarini Architects, who has nearly 20 years’ experience designing large, urban mixed-use projects—but as he put it, he had never worked on anything quite like the Well before and he doesn’t think such a project could happen again today.

Spadina traditionally marked a boundary between Toronto’s downtown financial district and a more industrial district to the west. As the city densified, however, this was no longer the case by the time Hariri Pontarini Architects created the master plan for the Well and designed the aforementioned office building for the site. Condominium towers had already risen along and near Spadina.

While the Well, too, was envisioned as a place to live, it would be much more than that. In fact, Conway and his colleagues looked for inspiration from examples of retail-and-office downtown rejuvenation developments in the U.K., where residential is not part of the mix at all.

They planned a variety of floorplates,

an off-centre core, brick and masonry podiums and staggered façades, all to help the massive undertaking resemble more of a human-scale neighbourhood. They also reused materials from the demolished buildings the Well replaced, ensuring some level of connection to the past even while reinventing the site.

(Among the more daunting artifacts to remove from the previous buildings were the massive newspaper printing presses that used to produce The Globe And Mail Ironically, one of the tenants at 8 Spadina today is that paper's largest competitor, the Toronto Star.)

Hidden below the development is one of its most distinctive features: a thermal energy storage (TES) facility, where a tank equivalent to three Olympic swimming pools stores 2 million gallons of temperature-controlled water, fed by Enwave’s Deep Lake Water Cooling system and a new, high-efficiency hot-water loop. Built in 2020, this installation—which serves not just the Well itself, but also neighbouring buildings—has introduced the first low-carbon heating and cooling option in Toronto’s downtown west district.

The project team for the Well included such consulting engineering firms as RJC (structural), Jablonsky, Ast and Partners (structural), Mulvey & Banani (electrical), TMP (mechanical), Novatrend (mechanical and electrical), EQ Building Performance (sustainability), LRI Engineering (fire code and life safety) and Odan/Detech Group (civil). And in this very issue, RJC has more to say about high-rise projects, including the Well; check out their article on page 16.

Peter

Saunders • psaunders@ccemag.com

READER SERVICE

Print and digital subscription inquiries or changes, please contact: Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR

Peter Saunders (416) 510-5119 psaunders@ccemag.com

SENIOR PUBLISHER

Maureen Levy (416) 510-5111 mlevy@ccemag.com

MEDIA DESIGNER

Curtis Martin

EDITORIAL ADVISORS

Darryl Boyce, Todd Busch, Guy Bruce, Andrew Macklin, Sadaf Parvaiz

ACCOUNT CO-ORDINATOR Cheryl Fisher (416) 510-5194 cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz (416) 510-5182 bolechnowicz@annexbusinessmedia.com

GROUP PUBLISHER

Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CANADIAN CONSULTING ENGINEER is published 5 times per year by Annex Business Media 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 Tel: (416) 442-5600 Fax: (416) 510-6875 or (416) 442-2191

EDITORIAL PURPOSE: Canadian Consulting Engineer magazine covers innovative engineering projects, news and business information for professional engineers engaged in private consulting practice. The editors assume no liability for the accuracy of the text or its fitness for any particular purpose.

SUBSCRIPTIONS: Canada, 1 year $70.01, 2 years $112.44. Single copy $11.22 Cdn + taxes. (HST 86717 2652 RT0001). United States $159.12 (CAD). Foreign $182.46 (CAD).

PRINTED IN CANADA. Title registered at Trademarks Office, Ottawa. Copyright 1964. All rights reserved. The contents of this publication may not be reproduced either in part or in full without the consent of the copyright owner(s). Annex Privacy Officer: Privacy@annexbusinessmedia.com Tel: 800-668-2374. ISSN: 0712-4996 (print), ISSN: 1923-3337 (digital)

POSTAL INFORMATION: Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to Circulation Dept., Canadian Consulting Engineer, 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1.

PRIVACY: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us.

Tel: 1-800-668-2374, fax: 416-510-6875 or 416-442-2191, e-mail: vmoore@annexbusinessmedia.com, mail to: Privacy Officer, 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1.

Member of the Audit Bureau of Circulations. Member of Magazines Canada

Has your firm completed an exceptional project in the past few years? Make sure it’s in the running for Canada’s most prestigious engineering awards!

The annual Canadian Consulting Engineering Awards are presented to projects that demonstrate a high quality of engineering, imagination, innovation and impact. Now in their 58th year, they are the most prestigious mark of recognition for consulting engineers in Canada.

The program offers an unequalled opportunity to gain awareness for your firm and your employees. The list of winners is publicized nationwide, the projects are profiled in the fall issue of Canadian Consulting Engineer magazine and all winners are honoured at an awards gala in Toronto in October.

Entries are invited in English or French, in the following categories:

TECHNICAL

A. Buildings

B. Transportation

C. Water Resources

D. Environmental Remediation

E. Natural Resources, Mining, Industry

and Energy

F. Special Projects

G. Project Management

H. International

NON-TECHNICAL

I. Community Outreach

J. In-House Initiatives

An expert jury will choose the winners of 20 Awards of Excellence. Of these projects, up to five could also earn additional recognition with a Special Award.

The Special Awards are:

• Engineering A Better Future Award – Presented to the project that best showcases how engineering enhances the social, economic or cultural life of Canadians.

• Sustainability Award – Presented to the project that best demonstrates outstanding environmental achievement.

• Philanthropy Award – Presented to the project that be st demonstrates donation of a firm’s time and/or services for the benefit of a community or group.

• Diplomat Award – Presented to the project constructed or executed outside Canada that best showcases Canadian engineering expertise.

• Schreyer Award – Canada’s highest honour in engineering, presented to the best technical entry.

STAGE 1 – TUESDAY, MARCH 19

Notice of Intention to Enter

Entry Fee $425.00 + HST due (non-refundable)

STAGE 2 – WEDNESDAY, APRIL 15

FOR MORE DETAILS

You can find further information and all entry forms at: www.ccemag.com/awards/enter

QUESTIONS?

Contact Peter Saunders, Editor, Canadian Consulting Engineer, tel. 416-510-5119, e-mail psaunders@ccemag.com This is the awards program's 58th year!

Entry Form, Project Outline, Photos, etc.

We proudly showcase this year’s winners.

By Peter Saunders

Canadian Consulting Engineer reached out once again to the consulting engineering community to nominate its leaders for their exceptional careers in—and legacies of contributions to—the fields of construction and infrastructure. And the community again responded strongly, with a wide variety of submissions for these accolades. The following are the winners, selected with the input of our editorial advisory board (EAB).

Harry Angus, 76, is a past president, CEO and chair of HH Angus and Associates, based in Toronto. He was the third-generation Angus to take on management of the firm, which was founded in 1919 by (and named after) his grandfather, Harry Holborn Angus.

“Growing up, I looked at many different fields and felt a bit of rebellion against engineering,” he says, “but I kept coming back to the fact I was good in maths and physics.”

Vision and drive

When Angus joined the family firm in 1974, shortly after graduating

from university, he had a vision and drive focused on both technical insight and business sense.

“My first interview after graduating was with IBM,” he recalls. “After leaving that interview, I realized I had spent about 90% of the time trying to sell the recruiter the services of HH Angus! So, I concluded maybe I should at least give the family firm a try and see how it went.”

He began in its fledgling vertical transportation group. At a time when design in this market was still an emerging discipline, he innovated by helping develop software to simulate elev ator traffic, having studied the programming languages Fortran and COBOL in university.

“The group was small when I started, with two active projects on the books,” he says, “but by 1981, we had expanded to work in five countries and I knew the elevator code backwards and forwards. On average, I was on a plane every week.”

While leading projects in the Calgary office during the early '80s, Angus was entrusted with growing the firm’s presence in Western Canada, particularly in health care and commercial development.

“I was sent out there on a crash

course to learn the mechanical and electrical (M&E) business in-depth and to manage a larger group,” he explains. “Unfortunately, the economy in Alberta badly sagged shortly thereafter and all of our projects were cancelled. I went back to Toronto in '83.”

"I concluded I should at least give the family firm a try and see how it went.”

He became president in 1985, at 34 years old, when his father wanted to retire. Under his leadership, HH Angus expanded both geographically and in terms of its technical depth, growing from a respected local consultancy to a nationally recognized engineering firm.

“I didn’t regard myself as an intricate mechanical or electrical engineer,” he says. “My skill set was running teams and understanding clients.”

Reaching for the sky Angus’ leadership coincided with one of the firm’s biggest projects to date. HH Angus was encouraged to join a design competition for a new sports stadium planned for construction in downtown Toronto.

After delivering a feasibility study, which concluded a retractable roof—the first of its kind in the world—would indeed be possible for what would become known as the SkyDome (and eventually renamed the Rogers Centre), the firm had the option of remaining in an advisory role or joining one of the competing design teams’ bids.

Angus and his colleagues chose the second option, accepting an invitation from Rod Robbie Architects

"My skill set was running teams and understanding clients."

to join EllisDon’s bid team, helping form the alliance that would go on to win the competition. They faced unprecedented technical challenges, such as designing a complete ventilation system for a structure that, at times, would have no roof!

The project proved very technically and logistically demanding for other reasons, as well. The design evolved continuously, but the deadline never shifted.

By way of example, a 350-bed hotel and luxury skyboxes were added to the plans late in the design process, along with a requirement for the baseball-focused facility be adaptable for football games and trade shows.

Angus remained heavily involved through to the end, eventually

serving as the lone engineer responsible for signing off on the SkyDome’s fitness for occupancy just before its grand opening in 1989.

“I was terrified to sign that letter, but it was safe,” he says. “Everything we had noticed while walking the site had been done in time.”

As the project showcased leadership, ingenuity and resilience, it became a prestigious calling card for the engineering firm.

“Our workforce quickly expanded,” says Angus.

With an eye toward the future, Angus led the firm through cycles of growth and reinvention. Recognizing the importance of diversification, he championed new divisions for information, communications and automation technology (ICAT) and digital services. Each such initiative has spawned major business lines.

Angus was also instrumental in the creation of two affiliated firms: facility management technical service provider Angus Consulting Management, which was acquired by Coldwell Banker Richard Ellis (CBRE) in 2024; and building operations management software provider Angus Systems Group, which had its roots in the program he had originally developed and was acquired by MRI Software in 2022.

And he was an early pioneer in joining public-private partnerships (P3s) in Canada, forging relationships with financiers and government partners to position his firm at the for efront of hospital infrastructure delivery. His leadership on such early projects such as the Fort St. John Hospital and Royal Jubilee Hospital in British Columbia paved the way for his firm’s selection to design North America’s largest P3 hospital, the Centre hospitalier de l’Université de Montréal (CHUM).

Angus’ business acumen was instrumental in maintaining long-term

partnerships, such as the firm’s six-decade relationship with commercial real estate firm Cadillac Fairview at the Toronto-Dominion (TD) Centre.

Beyond the business, Angus’ leadership extended to the broader engineering community. He served as president of Professional Engineers Ontario (PEO) in 1992, chaired its committees and contributed to his alma mater, Queen’s University, and Consulting Engineers of Ontario (CEO), now the Association of Consulting Engineering Companies – Ontario (ACEC-Ontario).

“In 1993, I was asked to deliver the 100th-anniversary lecture of the mechanical engineering department of Queen’s,” he recalls, “which, considering my academic credentials were less than stellar, was a great surprise and honour!”

His volunteerism reached the arts and social causes, as he chaired the McMichael Canadian Art Collection and advised the Yonge Street Mission.

“While I could help them with my expertise, they could help me grow, as well, and obtain new perspectives,” he says.

Angus retired as president on the firm’s 100th anniversary in 2019 and as chair in 2023.

Opening opportunities

Angus’ leadership style combined openness, respect and men -

torship. Known for his open-door policy, he made it clear “management doesn’t have a patent on good ideas” and fostered a culture of collaboration where every employee felt empowered to contribute and grow. His commitment to mentorship led to the establishment of formal programs to connect junior and senior engineers. Through the Don L. Angus Scholarship at the University of Toronto (U of T), where his father and grandfather studied, he created opportunities for financially challenged students to pursue engineering careers. He also launched a financial support program for students at the Yonge Street Mission, who otherwise lacked the funds to continue their education.

“When I joined the firm, I was the youngest employee, which did not bode well for the future,” he says, “so we began to recruit new graduates and train them to take over. Apart from my years in vertical transportation and acting as prime consultant on some specialized projects, my career has been as a manager of people.”

“Harry was a humble leader who quietly and successfully steered the company through the ups and downs of the economy,” says Tom Halpenny, executive vice-president (EVP), who has worked with Angus for more than 45 years. “He was dedicated to providing secure employment for employees, so they could concentrate on serving clients. And he knew the best way to maintain the firm’s collaborative culture was by having it remain independent and employee-owned, not swallowed by a consortium.”

“ The advantage of having a private company is that when workflow slows down, we could deliberately maintain higher staff levels than would be acceptable in a public company,” Angus explains, “knowing that when things improved, we would have the best expertise available.”

“I’ve been with HH Angus for more than 50 years as a Certified Engineering Technologist (CET) and I will always remember the day Harry offered me a partnership role,” says senior associate Steve Smith. “It took me completely by surprise! For a company owned and led by professional engineers, it was a bold move. To me, it demonstrated Harry was keenly aware of the work being produced and by whom and recognized the importance of empowering key staff to take on leadership roles. A big part of Harry’s legacy, in my view, is how HH Angus rose to become the premier health-care consulting engineering firm in Canada.”

Today, the compnay continues to use advanced design tools, such as building information modelling (BIM), digital twins, automation and energy modelling to deliver smarter, more efficient, data-informed projects, both to help clients make better decisions and to provide opportunities for employees to expand their technical expertise.

“Harry’s innate understanding that people are the essence of business success meant opportunities were open to all who were up for the challenge,” says current president Paul Keenan, who has worked with Angus for 31 years. “The result is a foundation of strong leaders at the firm, who have been empowered to build on his legacy.”

Don Bergman, 74, is a senior vice-president (SVP) and project director for COWI, based in North Vancouver. Over the course of his career, he has become a world-renowned expert on cable-stayed bridges, with large engineering teams reporting to him on major bridge projects.

The first degree he earned was a two-year diploma in civil and structural engineering technology at the British Columbia Institute of Technology (BCIT).

“I was interested in physics and my parents expected me to go to university,” he explains, “so I started out studying general sciences at the University of Victoria (UVic), but in the end it wasn’t clear it was leading anywhere. I chose to move over to BCIT, which I’d learned about in high school. I was drawn to civil and structural engineering and creating real things that live on in our built environment.”

That degree led him to a job with BC Hydro as a high-voltage transmission line technician—more structural than electrical, in terms of his engineering work.

“ Working amongst BC Hydro’s engineers for a couple of years, I quickly realized I could do the same

work as them, so I might as well become an engineer!” he says. “I went back to school, at the University of British Columbia (UBC), to get my engineering degree.”

After a one-year stint with C Y Loh Associates as a design engineer on buildings, Bergman joined Buckland & Taylor in 1981 as a bridge engineer (the ‘Taylor’ being one of his former UBC professors, Peter Taylor). He rose to senior designer and project manager before the firm was purchased by COWI in 1998 and became COWI Bridge North America.

Bridges near Bergman’s early career with Buckland & Taylor primarily centred on technical bridge analysis and design, before he took on more significant project leadership roles. He gained experience in the design, construction engineering, retrofitting and rehabilitation of a wide variety of bridges, with much of his focus on long-span cable-stayed.

“Bridges are fantastic structures and really pure engineering,” he says. “As engineers, we get to have a lot of say in how they are designed and built—whereas when I was working on buildings earlier in my career, it felt like the architects dictated the structural solutions.”

“Design-build projects really appeal to me.”

One of his first projects with Buckland & Taylor was the Alex Fraser Bridge connecting Richmond and New Westminster, B.C., for which he served as a designer from 1981 to 1983 and as assistant resident engineer from 1984 to 1986.

“After joining Buckland & Taylor, I very quickly started working with Peter Taylor and a small team on developing an option for the world’s longest cable-stayed bridge to cross the Fraser River,” he recalls.

Bergman helped develop analysis software to support development of the concept and subsequently worked on the design of the steel superstructure. The resulting concept was the world’s first composite deck cablestayed bridge; since then, many of the design details have been copied for other projects around the world. In his on-site role, Bergman monitored and controlled the balanced cantilever erection of the bridge, ensuring safety, stability and control of geometry during construction.

“It was an unbelievable opportunity for me as a young engineer and an amazing start to my bridge career,” he says. “I’ve gone on to work on many cable-stayed bridges, which has allowed me to develop expertise in the form. Modern stay cables provide as much as seven times the

strength of normal structural steel, so they are a super-efficient way to carry loads on a bridge.”

Indeed, Bergman went on to lead the design of some of the most important cable-stayed bridges in North America, including the Golden Ears Bridge near Vancouver, the St. Croix River Bridge over Minnesota’s Stillwater River, the Governor Mario M. Cuomo Bridge (which replaced the aging, structurally deficient Tappan Zee Bridge) over New York State’s Hudson River and the John James Audubon Bridge over the Mississippi River near Baton Rouge, La.

The Governor Mario M. Cuomo Bridge, designed under Bergman’s leadership as engineer of record, stands out as a particularly significant achievement, spanning the Hudson River with twin deck cable-stayed main spans of 366 m each. Super-

“I was drawn to creating real things in our built environment"

vising a team of more than 100 professionals, he guided the design through complex challenges, such as addressing the aerodynamic behaviour of two bridge decks less than 30 m apart. He oversaw wind tunnel testing accordingly, which led to the adoption of open steel barriers, eliminating the need for other, visually undesirable modifications.

Bergman also led the development of twin V-shaped towers and foundations to accommodate a potential third cable-stayed commuter rail deck, which could be added in-between the twin roadway decks in the future. The design process included delivery of a probabilistic service life design methodology, ensuring the structure would remain durable for all of its planned 100year service life.

Another landmark project was the

Canada Line North Arm Bridge in Vancouver, the first extradosed bridge in North America. As project principal and design lead, Bergman led development of the concept to span a wide waterway with sufficient vertical clearance over a complex marine navigation channel, while keeping the supportive pylons below stringent air clearance limits imposed by the nearby Vancouver International Airport. The design integrated split leg main piers to enhance seismic resilience, precast segmental pylons with composite steel-concrete elements and constant-depth precast and prestressed girders to maximize clearance while simplifying construction. In fact, the bridge was completed ahead of schedule for the Canada Line rapid transit (RT) system, which opened in 2009.

Bridges far Bergman’s overseas experience included serving as lead resident construction engineer for Hong Kong’s Ting Kau Bridge, one of the longest cable-stayed bridges in the world.

“I lived in Hong Kong for two years working on that bridge, which Britain built as a legacy project for the 1997 handover to China, to support the new international airport on the island of Chek Lap Kok, which opened in 1998,” he says. “That was a fascinating experience.”

He also spent time in Bangkok, Thailand, leading design and construction engineering for the Rama VIII Bridge over the Chao Praya River.

“It is right near the Grand Palace, so it had to include culturally significant features,” he says. “We worked with a Thai architect who helped with the details for the bridge’s prominent position in an historic part of the city.”

Though Bergman never lived in Asia again, he did go on to help design the towers for Hong Kong’s Stonecutters Bridge.

“Overall, COWI has had a very prominent role in significant longspan bridges around the world,” he says. “As an organization, we draw on the international experience of our colleagues for the work we do.”

Community involvement

In 2007, Bergman became a member of the Post-Tensioning Institute (PTI) DC-45 committee for cablestayed bridges. Through this involvement, he subsequently helped develop and incorporate requirements into PTI’s Recommendations for Stay Cable Design Testing and Installation, for the seventh and upcoming eighth editions

He has been involved in other professional communities throughout his career. He has led American Society of Civil Engineers (ASCE) courses on the design and construc-

tion of cable-stayed bridges for owners, designers and contractors.

As a participating member of the International Bridge and Structural Engineers Association (IABSE), Bergman was part of Commission 4’s development of ‘Bridge Construction Methods – Essentials and Critical Lessons – Practitioners’ Perspectives’ and contributed through the WC3 Committee to Structural Engineering Document (SED) 17, Extradosed Bridges.

He has made presentations and written papers for IABSE, the Design-Build Institute of America (DBIA), the International Bridge Conference (IBC), the American Segmental Bridge Institute (ASBI) and the Hong Kong Institute of Engineers (HKIE), among others.

Finally, he is a sponsor for industrial Ph.D. investigations that seek to better understand the levels of damping required to safely mitigate stay cable vibrations due to rain-wind excitation and iced cable galloping.

Designed to build

The past 25 years have seen Bergman combine technical leadership with business development to participate in bid designs and continue to secure bridge projects, particularly across North America. He has played a significant role in ensuring COWI is part of many major design-build projects. He has also made staffing decisions, provided independent review, led company initiatives and operational policies and mentored junior staff.

“I’ve worked on a lot of design-build projects and we have several in front of us right now that are really good opportunities,” he says. “I find these very interesting, going through the conceptual design phase with a contractor to determine the most effective and constructible solution. I’m getting late in my career, taking things year-by-year, but I’ll keep going as long as folks feel I have relevant things to contribute!”

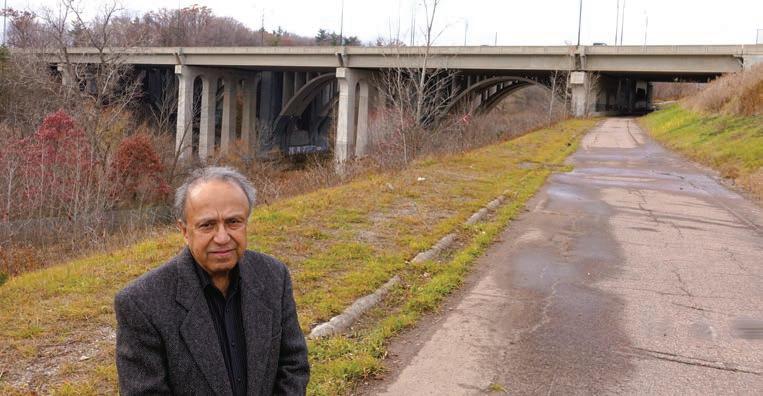

P.K. Chatterji

Pradyot Kumar (P.K.) Chatterji, 80, is a past president and chair of the board for Thurber Engineering, based in Oakville, Ont. He most recently served as principal and senior geotechnical engineer, until retiring at the beginning of this year. He was nominated for this accolade by one of his clients— none other than WSP’s Tony Wing, who has known him for 20 years and who won one of our Lifetime Achievement Awards in 2025.

“I came from a family of engineers, so it’s in my DNA—there was no other choice!”

Chatterji earned his B.Eng. in civil engineering at India’s University of Burdwan in 1965.

“I came from a family of engineers,” he says. “My father was a mechanical engineer and my grandfather and uncle were civil engineers. So, it’s in my DNA—there was no other choice!”

He worked in India as a junior geotechnical engineer for Cementation, a British firm, in 1967 before moving to Canada.

“I started in structural engineering,” he explains, “but soon found I loved geotechnical engineering because so much of it was emerging. The industry was in its nascent state and it was both a science and an art. I never looked back!”

He continued his education in London, Ont., at the University of Western Ontario, where he earned his M.E.Sc. in geotechnical engineering in 1969, and the University of Alberta in Edmonton, where he completed his Ph.D., also in geotechnical engineering, in 1972, the same year he joined Thurber, which to this day remains a specialty geotechnical and environmental engineering firm.

“My Ph.D. was quite a turning point,” Chatterji recalls. “My professor, Norbert Morgenstern, was an extraordinary mentor who taught me a lot besides engineering, including life lessons on how to present myself and deliver as a consultant, which had a great impact on me. I realized in consulting I could learn more hands-on. That was key. And he recommended me to Thurber.”

Chatterji also cites two other geotechnical engineers as his mentors and role models: the late Al Insley, senior partner at Thurber, and Murray Harris, chief engineer at Thurber Edmonton. He says he felt very grateful and privileged to be trained by them.

After joining Thurber, he gained consulting experience across six provinces and territories, starting in British Columbia for six months before moving on to projects in Alberta, Saskatchewan, Northwest Territories, Ontario and New Brunswick, living variously in Victoria, Edmonton and Mississauga, Ont. He held P.Eng. designations in each of the provinces where he worked, including those where he was never a resident.

In a career that has now topped 50 years with Thurber, Chatter ji has primarily applied his geotechnical engineering expertise to highways, railways and transit systems. The latter have included the Toronto Transit Commission’s (TTC’s) Sheppard subway line and stations and Edmonton Transit Service’s (ETS’s) light-rail transit (LRT) network, for which he provided geotechnical design of tunnels and stations. He provided geotechnical input for On tario’s Highways 407 and 413 and New Brunswick’s Route 1 Gateway and Fredericton-to-Moncton Highway. Another area of focus was foundation engineering for major petrochemical plants, which he completed in Alberta for Esso Resources and Petro-Canada.

Rising through the ranks

Within Thurber’s corporate operations, Chatterji became a partner and director in 1976, manager of the Edmonton office from 1979 to 1983, managing director from 1989 to 1993, manager of the To ronto office from 1993 to 2002 and, as mentioned, president and chair of the board from 2002 to 2008. Over time, his focus shifted back and forth between engineering and management.

“From the beginning, I must have shown some ability to manage people,” he says. “I was made manager of the Edmonton office early on, which exposed me to further opportunities. And the office expanded quite rapidly when Alberta was booming.”

When Chatterji moved from Edmonton to the Greater Toronto Area (GTA) in the ‘90s, it marked Thurber’s expansion into Ontario, where the firm now has offices in St. Catharines, Cambridge, Oakville, Pickering and Ottawa, with a total staff topping 150 (out of nearly 500 across the country).

central Canada. There’s no oil patch, but the highway network is extensive! Transportation, including public transit, became our main area of business here.”

Working with MTO

Fittingly, over the past 30 years, Chatterji has largely been involved in Ontario ministry of transportation (MTO) projects, across the province’s central, east, west, northeast and northwest regions. He has been heavily involved not only in the design stages of such projects, but also in resolving problems during various stages of construction.

Chatterji became Thurber’s MTO principal contact and, through his involvement, the firm achieved ‘high complexity status’ for them. The work continues today.

For Highway 407 and now the planned Highway 413, he acted as the co-ordinating geotechnical engineer to support collaborative approaches between MTO and several geotechnical service providers. A series of meetings helped develop and standardize cost-effective foundation recommendations for similar soil conditions between adjacent sections of the new highways handled by different

“At the time of the move, I was a senior partner in the company,” he says. “We knew that if we wanted to expand, we needed to go to

We are deeply grateful for your 50+ years with Thurber Engineering - your time with us is a testament to the legacy you inspired and the foundation you helped build.

Street Bridge, which involved load-testing two sacrificial piles. He has researched the use of diaphragm wall (barrette) foundations for major bridges planned along Highway 413. And he undertook a pioneering study at the Greenock Creek Bridge on the reuse of H-pile foundations.

All of these projects were initiated by Tony Sangiuliano, MTO’s head of foundations, to whom Chatterji says he is very grateful.

Supporting others

Chatterji’s associates at the Canadian Geotechnical Society – Southern Ontario Section (CGS-SOS), in which he has been involved since 1970, have lauded him as an inspiring mentor of younger practitioners. He has enthusiastically served as a role model as a consultant for both junior and senior colleagues. And his recommendations of post-graduate training for junior engineers have extended to Thurber providing financial support for them.

This dynamic directly reflects Chatterji’s management roles at Thurber, through which he has hired, worked with and contributed to the growth of more than 100 engineers and technicians over time. Many of them are now partners in the firm, which has seen very low staff turnover.

“Our staff stays with us for a long

time, so they grow loyalty to the company,” he says. “There’s a family environment and we strive to maintain it. Our resources are our staff!”

Chatterji is known for providing calm, sage advice to his teams and his clients. He has encouraged Thurber’s engineers to use advanced computational tools, such as Finite Element Methods to refine their geotechnical predictions, and has promoted to his clients the benefits of undertaking pile and caisson load tests during their projects’ design phases to optimize capacity and, as a result, cost savings.

“Solving the client’s problem is the most important goal,” he says. “That’s what leads to repeat business.”

Speaking of CGS-SOS, Chatterji was a key member of its professional practice committee, which successfully advocated for a regulatory distinction between geotechnical boreholes and drinking water wells, ensuring the boreholes were exempt from originally proposed regulations under O Reg 903. Without his behindthe-scenes contributions, geotechnical practitioners would have faced difficult barriers in advancing boreholes.

The CGS-SOS community has also relied on Chatterji to help invite world-renowned and distinguished geotechnical experts to visit Toronto to present lectures, including the

aforementioned University of Alberta professor emeritus Norbert Morgenstern, University of Illinois professor Gholamreza Mesri, the late professor James K. Mitchell from Virginia Tech and, for a recent cross-Canada tour, Imperial College London professor John Burland, who oversaw the remediation of the Leaning Tower of Pisa.

Chatterji’s long working relationship with Ontario’s ministry of transportation involved geotechnical engineering for many bridges and highways throughout the province.

Chatterji has encouraged strengthening CGS-SOS, which has resulted in an increase in membership and attendance at its chapter events and annual conferences. He has also contributed to the geotechnical industry by authoring numerous technical papers.

In 2019, Chatterji received a CGSSOS award for contributions to the geotechnical community across the region through his participation, service to the advancement of research, improvement of design and development of construction.

He has also been a member of the International Society for Soil Mechanics and Geotechnical Engineering (ISSMGE), the Geotechnical Society of Edmonton (GSE) and the Engineering Institute of Canada (EIC).

“From the beginning, I must have shown some ability to manage people.”

Right up until his retirement, Chatterji continued to direct projects, mentor staff, provide high-level reviews and keep in touch with long-time clients.

“The greatest highlight of my career was expanding the firm in Ontario,” he says, looking back. “It took more than 20 years to establish the presence we maintain today, but it was worth it. Ontario has been good to us. To maintain this position in the marketplace, the firm needs to continue to do high-quality, complex geotechnical work and not get greedy. Our niche has served us well so far. I also thank my very supportive and loving family, without whose constant support and encouragement I would not have been able to embark on this marathon journey.”

The Advance: Women in Engineering virtual summit will be held on June 23, 2026, International Women in Engineering Day. This is a key opportunity to promote greater gender diversity in one of Canada’s most celebrated areas of expertise, as consulting engineering firms seek to recruit and retain more women for roles at all levels of seniority.

Our goal is to spotlight the accomplishments of successful professional engineers, encourage more women to join the industry/community and raise awareness of organizations that are already taking a leading role in this effort.

WHY SUPPORT WOMEN IN CONSULTING ENGINEERING?

z Recognize the careers of successful women in the industry

z Build your reputation as an industry leader in diversity

z Amplify brand visibility among Canada’s top consulting engineering firms

z Position your organization as progressive

z Increase exposure to key audiences across multiple media platforms, including email; website; social media; and the live virtual event.

ONE BUY REACHES CANADA’S TOP CONSULTING ENGINEERING FIRMS • Print distribution: 6,000+ copies • Email distribution: 12,000+ • Website exposure: 26,000+ monthly page views

By Daniel Snodgrass

Every year, the Council on Tall Buildings and Urban Habitat (CTBUH)—now rebranded as the Council of Vertical Urbanism (CVU)—has brought together people who shape the world’s skylines with its international conference. Engineers, architects and developers from across the globe gather to share insights, challenge conventions and explore what’s next in tall building design.

At the most recent conference, which was held in Toronto from Oct. 6 to 9, 2025, and titled ‘From the Ground Up: Tall Buildings and City-Making’, one message stood out: the future of vertical construction is about responsibility as much as ambition. Building tall is no longer just about reaching new heights, it’s about ensuring every meter of structure contributes positively to the environment and the urban fabric of our cities.

Building up, building better

‘Responsible density’ was a recurring theme throughout the sessions. As cities continue to grow, tall buildings are becoming essential to sustainable urban development by using efficient, existing infrastructure and transportation, but their impact must be carefully managed. From embodied carbon and materials to resilience and livability, engineers are being asked to think more broadly about what ‘better’ really means.

For Canadian engineers, the conversation hit close to home. Cities like Toronto, Vancouver, Montreal and Calgary are growing vertically, rapidly, and the role of structural engineers has evolved accordingly. We are not just solving for safety and stability anymore, but also designing for low-carbon, high-comfort, growing communities.

One of the most-discussed topics at the

conference was the global push to measure and reduce embodied carbon, i.e. the emissions associated with building materials and construction. The shift toward whole-life carbon analysis is changing the way projects are conceived and delivered.

RJC Engineers has seen this transformation firsthand with tools that allow us to assess carbon impact during the earliest stages of design, when the biggest reductions can be achieved. Much of what we are asked to design are reactions to different requests by owners or architects for massing changes, city requirements or transfers.

Transfers can increase a building’s embodied carbon by 10% to 20%, while creating a watertight tanked basement increases embodied carbon by about 10% for a 10-storey mid-rise development. By quantifying the footprint of different structural systems before construction begins, engineers can make smarter, data-driven choices about materials and methods

Across the industry, real progress is being made. International case studies presented at the conference showed embodied carbon reductions of 20% to 30% are achievable

without compromising performance. Comparable outcomes are being realized here in Canada on high-rise projects like One Bloor West in Toronto and M3 in Mississauga, where design teams have prioritized efficiency and resilience from the outset.

The more slender and expressive towers become, the more critical it is to control their movement. Another major focus of this year’s conference was damper design for motion and deflection control. While the public viewpoint focuses on safety, most of our structural systems are actually governed by control of building motions and deflections, such as slabs and lateral systems.

Engineers from around the world presented next-generation dampers that use fluid dynamics, space-age materials or tuned mass systems to manage motion. These are not just feats of physics, but also enablers of greater design freedom. By reducing the impacts of wind and seismic loads, they allow architects and engineers to explore lighter, slimmer forms that would have been impractical prior to the current building boom. They can also lower both cost and embodied carbon.

The aforementioned M3 is an 83-storey building that includes Canada’s largest tuned mass damper (TMD), allowing it to lean dramatically off-axis while maintaining comfort and performance. It is the country’s tallest tower outside Toronto.

RJC presented a 10-year anniversary retrospective on the Viscoelastic Coupling Damper (VCD) developed by Kinetica. Recent building monitoring validated the system continues to perform as intended, protecting occupant comfort while preserving saleable area. Such technologies illustrate how close collaboration between engineers, architects and builders can turn complex ideas into tangible results.

The conference also highlighted major advances in material science. The next generation of tall buildings will be shaped by new approaches to concrete, steel and hybrid systems that blend the best attributes of each material.

Beyond technology, the conference reinforced, tall buildings are ultimately about people. The best towers do more than solve engineering challenges; they contribute to livable, resilient cities.

Panels on urban well-being explored how vertical design can promote connection and community through shared amenities, green spaces and adaptable layouts. These discussions reflected a shift from pure efficiency to experience, in terms of how tall buildings can make city life more inclusive, engaging and sustainable.

This mentality was showcased on a tour of Toronto’s King Street West, which included such projects as The Well, Portland Commons and Bjarke Ingel’s KING Toronto, each of which aims to enhance livability and community connection with large public spaces, pedestrian connections and active courtyards. The Well received a CVU Urban Habitat Award.

High-strength steel and ultra-high-performance concrete were central to many discussions, with presenters showcasing their ability to achieve the same performance with less mass, directly reducing embodied carbon. Hybrid structures combining steel, concrete and timber are also emerging as a powerful option, delivering flexibility and sustainability without sacrificing structural integrity.

Adoption of these materials is growing in Canada, but innovation still depends on local context, code requirements, supply chains and construction methods. The takeaway from CVU is clear: progress is optimized when designers, fabricators and regulators collaborate early and often.

RJC, for example, has been partnering with concrete suppliers to better optimize designs with existing cement mixes. Last fall, the firm conducted mix-design trials with EllisDon, Master Builders Solutions and Votorantim Cimentos North America (VCNA) to evaluate new accelerator admixture technology that reduces embodied carbon and optimizes slab designs, all while maintaining speed of construction.

No single discipline can tackle these challenges alone. True progress happens through integration between architecture and engineering, between analysis and intuition and between global research and local application.

For Canadian engineers, that means staying connected to international conversations while continuing to lead through our own innovations. We are developing tools, testing materials and sharing data that are already shaping the next generation of design standards.

Leaving the conference, the path forward for structural engineers is both technical and philosophical. It’s about refining how we measure success, valuing carbon reduction as much as capacity and viewing collaboration as not optional, but essential. The next era of tall buildings will not be defined by their height so much as by their integrity: structural, environmental and social.

Daniel Snodgrass is an associate at RJC Engineers. With a focus on structural design for tall and complex developments, he is passionate about innovation, collaboration and sustainable engineering practices. For more information, visit www..rjc.ca.

By Stan Ridley

Stan Ridley, C.Eng., MICE, BSc (Eng), MSc (Eng), DIC, is president of West 2012 Energy Management, based in Vancouver. He is also a member of United Nations (UN) groups of experts on gas and coal mine methane and just transition.

Over the last few years, I have written a series of articles and columns for Canadian Consulting Engineer about energy in relation to global warming and climate change (GW&CC). This article, the last of the series, will review my past topics, address other current developments (such as ammonia and methanol) and share some of the ideas today’s bright young women and men are investigating as antidotes to the climate crisis.

According to the Energy Institute (EI), fossil fuels—i.e. coal, oil and natural gas, including fracked shale gas and liquefied natural gas (LNG)—represented about 80% of global total primary energy consumption (TPEC) in 2024. Wind and solar represented about 4% and 3%, respectively.

While fossil fuels are very convenient, their life-cycle processes—including extraction, processing, transportation, storage, distribution and conversion to useful energy—release enormous quantities of greenhouse gas (GHG) emissions annually, which have formed an increasingly thick ‘blanket’ around the planet and have mainly caused the climate crisis.

Solutions to this growing crisis need to be viably scalable to significantly reduce emissions. They must meet stringent scientific, engineering, environmental, commercial and social requirements.

While we do have a number of solutions already, none has been able to make a significant difference yet in fossil fuels’ share of TPEC. Instead, emissions continue to increase year over year.

We desperately need major technological breakthroughs. These will require one or two orders of magnitude in increased research and development (R&D) efforts and expenditures.

The following are some of the topics I have previously addressed in this series.

Our present ‘fission’ nuclear power plants suffer from a few major constraints: (a) they use about 1% of the input fuel, while the remaining 99% is removed and considered spent fuel; (b) that spent fuel entails dangerous, long-lasting radiation; and (c) while the probability of a nuclear meltdown is low, its consequences are high.

On the positive side, nuclear plants provide reliable baseload power, with capacity factors of more than 80%, and their life cycles are associated with very low GHG emissions. Breakthroughs in nuclear fusion have tantalized, but still seem elusive.

The notion of carbon capture, utilization and safe sequestration (CCUSS) is to trap emissions before they are released into the atmosphere. Unfortunately, such systems are not presently scalable to capture a significant portion of our GHG emissions.

The costs of electricity generated by wind and solar have declined remarkably, to the point where they are not only two of the least GHG-emitting forms of energy generation, but also among the least expensive

They are intermittent sources, however, and generally deliver direct current (DC) electricity. As such, they require energy storage systems, smart transmission grids and backup from other, non-intermittent sources. Most storage today is provided by hydroelectric pumped storage and reservoirs, while other options are more limited or still in their infancy.

Solutions need to be viably scalable to significantly reduce emissions.

Hydropower offers a low carbon footprint and, as mentioned, reliable storage for energy from intermittent sources. Significant new developments, however, are constrained by the availability of suitable sites, the need to meet geological and hydrological requirements and socioeconomic pushback from millions of people who can be adversely affected by such developments.

Although the use of biomass as an energy source has mainly fallen from our collective consciousness, its commercial and non-commercial total exceeds the combined TPEC of wind and solar. Globally, we could double this total, but this would involve emitting considerable carbon unless replanting and regeneration were also undertaken at sufficient scale to approach carbon neutrality.

Human-made hydrogen (as opposed to more limited natural hydrogen) must be produced using energy. As such, it is not an energy source, but rather a carrier of energy—and a very inefficient one. So-called ‘green hydrogen,’ produced using

renewables, typically loses 55% to 75% of input energy. It is thus a non-starter relative to much more efficient types of energy.

Other countermeasures

What other technologies could become viably scalable and significantly reduce global carbon emissions? Unfortunately, the list is not ver y long.

Ammonia and methanol have been proposed as ‘green’ alternatives to fossil fuels and could be particularly useful for maritime and aviation applications. Despite claims of near-zero emissions when they are produced using renewables, however, they are actually typically based on input hydrogen, with low overall life-cycle efficiency. By contrast, our present use of renewable

energy sources, while limited, is nearly 100% efficient in directly displacing or replacing ‘dirty’ energy (in terms of GHG emissions) produced using fossil fuels.

Other possible areas of improvement include geothermal plants that exploit heat energy below the ground; tidal and other wave energy systems; novel CCUSS systems that rely on biological processes; smarter transmission grids; geoengineering the atmosphere; and using artificial intelligence (AI) to control and optimize energy systems beyond human capabilities.

You could say the climate crisis has put our civilization on the Titanic with very few lifeboats—and no ‘Plan B.’ It is very difficult to see

how we can reach net-zero goals by 2050 and wean ourselves off fossil fuels by 2100.

We can only end the fossil fuel age by finding cost-effective, environmentally friendly and viably scalable alternatives, which will require massive increases in R&D. Another overarching solution that could make a significant difference is limiting growth, which seems to be societal anathema.

Given the limited natural resources in almost every area of consumption, our fossil fuel ‘party’ that has been under way since the early 1800s is unsustainable. If we do not make the necessary corrections, then nature—as it has always done—will make the corrections for us, across the board, in a very non-discriminatory manner.

The challenge facing our water future is human.

By Arun Parsons

In North America, we are looking at a future of uncertainty regarding the long-term safety of our water supply. A lot of factors contribute to this issue, but one is more apparent now than ever.

Our water infrastructure—including the pipes beneath our feet, aging water treatment plants and critical flood protection measures—is easy to take for granted, but there is a problem brewing. The true crisis is emerging not in concrete and steel, but in the ranks of the skilled engineers and technicians needed to design, build and keep these systems working.

In other words, North America is entering a workforce crisis. Who will maintain our water infrastructure in 2035 and beyond?

A problem with a price

Multiple forces are driving unprecedented demand for professional talent in the water sector. Much of our infrastructure, from major reservoirs to local water mains, was constructed between 50 and 100 years ago. Now, many of these structures are reaching the end of their design life, all at once.

Meanwhile, population growth and urbanization demand new or upsized systems.

And climate change is both limiting the availability of safe water and increasing the risk of floods, requiring new engineering approaches.

In response, historic public infrastructure investments represent billions of dollars ready to be deployed, lying in wait for projects and the people who can deliver them. So, why are we facing a shortage?

The water market’s needs are rapidly outpacing the available engineering work-

force. University enrolment in civil and environmental engineering programs is not keeping up, partly because other industries offer higher salaries and the perception of greater prestige.

Becoming a licensed engineer is a journey that takes years to complete. Even if there were a major surge in interest now, it would take a decade or more to bear fruit. Further, a concentration of experts in big cities and coastal hubs has left small towns and rural districts struggling to tap into essential skills locally.

The workforce shortage comes at a real price. When there are few well-staffed teams, competition flags, project costs rise and opportunities for innovation shrink. Overstretched, less-experienced teams risk project delays or shortcuts, where quality potentially could be compromised. Engineering firms may even be forced to turn down work, reducing the industry’s capacity to solve the very problems the public is funding. Communities, large and small, will lack safe and reliable water, not for lack of money or materials, but for lack of people.

There are strategies to address this challenge, but we must act with urgency and innovation.

First, we must normalize integration with remote and international teams. We already have the collaboration tools to connect talent globally; now is the time to fully embrace this model. Remote work should be seen not as a stopgap, but as an enduring solution, both in terms of allowing firms to tap experts wherever they

are and to offer a better work-life balance, which will attract more people to the field.

Next, we need to expand cross-training and streamline pathways for engineers from adjacent disciplines. With focused corporate investments and support from professional organizations, engineers who specialize in transportation, geotechnics or structures could pivot to designing water infrastructure far faster than starting from scratch. Clients must be brought along to value this flexibility.

Finally, streamlining immigration for skilled foreign engineers is a necessity. Our infrastructure is at stake and we must welcome talented professionals who ar eager to build in North America.

With a culture of adaptability, we can cultivate remote, diverse project teams, not only to fill the project needs of the moment, but also to plant the seeds for a more resilient, robust workforce in the future.

The bottom line is evident. No matter the funding levels of various projects or the merits of different technologies, every water project ultimately depends on people, for their skills, flexibility and creative problem solving.

Addressing the workforce crisis is our greatest infrastructure challenge and opportunity. If we commit to bold, collaborative strategies today, we can ensure our w ater future is not undermined by a shortage of engineers and technicians whose ingenuity is needed to keep the taps running and the pumps humming for generations to come.

ACO Qmax has been developed to satisfy the demand for a versatile, high capacity slot drainage system for a wide range of applications to any load class. The system is specifically designed to form an integral part of modern, sustainable surface water management solution requiring effective collection, storage, or attenuation. ACO Qmax is also economical compared with traditional drainage methods.

Email: info@acocan.ca

For over 35 years, electrical engineers and contractors have trusted Champion Fiberglass® conduit on thousands of underground utility transmission and distribution projects across the US and Canada. Champion Duct® fiberglass conduit offers durability, mechanical strength and no burn-through elbows that minimize repairs. spec.championfiberglass.com/utility-project-guide-canada

CANADA LIFE

The Engineers Canada- sponsored Financial Security Program is exclusive to engineers and geoscientists, as well as their families, across Canada. Group savings products give you a real advantage: you’ll pay typically lower fees compared to retail investment options, and this can add up to more future savings. Plus, you get free investment guidance when you join. For more information please visit: welcome.canadalife.com/engineers-canada

Canadian Consulting Engineer magazine provides high quality editorial coverage of the most pertinent and timely issues that affect engineers across Canada. The magazine reaches the consulting engineers who make the critical decisions on building and construction projects. This is exactly the audience you need to reach. Advertise your product or service with us. Be seen and be specified! To order your 2026 media kit contact: Maureen Levy (416) 510-5111, mlevy@ccemag.com or visit www.canadianconsultingengineer.com/advertise/

After the federal government announced the Build C anada Homes (BCH) agency last year, it invited feedback from industry experts across the country about how to develop affordable communities. Robyn Brown, principal of consulting engineering firm A rcadis’ Canada East placemaking g roup, was among those who responded to the call.

With more than 20 years’ experience in urban planning, economics and development, including involvement with Canada Lands’ master plan to add affordable housing in Ottawa through the Tunney’s Pasture redevelopment, she suggested (a) delivering small to medium-size developments quickly, (b) supporting Indigenous-led housing projects in northern and remote areas and (c) accelerating funding to increase industrial capacity for modular construction and prefabrication.

What would you like to see BCH accomplish?

We understand the federal government’s focus on large projects to address the housing crisis—they want bang for their buck—but many communities don’t have the sites or the infrastructure capacity for them. There’s an opportunity over time for smaller and medium-scale developments to add up. That’s where a lot of developers are more comfortable and where capital may be.

Encouraging modular housing is another opportunity, but it faces different building codes in each province. By harmonizing the building code at a national level and streamlining how new materials and

make them easier by addressing regulatory challenges.

methods are incorporated, BCH could encourage companies to invest and innovate, as they could apply one process across the country.

How can you help make modular housing more feasible?

We can bridge the gap between clients, builders and municipalities. We have already created innovative designs and used new materials, but an increased focus on modular will help enable easier implementation, reduce timelines and promote further innovation.

Modular housing offers advantages in terms of speed (and speed is money!) and environmental sustainability. We have experience delivering them quickly, including in First Nations communities, and we understand why these projects can be very efficient in terms of lifecycle costs. We are also talking to municipalities about how they can

I’m on the board for Mohawk College, where I can help students make connections with the industry. There’s a well-trained workforce ready to build houses in a whole different way than we’ve done historically. New grads know a lot more that I do!

What role do you see for engineering firms, going forward?

BCH is in its early stages as an agency, but we’re already seeing how it’s accelerating change and we expect that to continue. The question is how can we be part of the solution?

Engineering firms have a big role to play in interpreting BCH’s objectives and using them to inform designs. Beyond regulatory expertise, we can act as strategic problem-solvers, bringing forward solutions ba sed on our understanding of community needs and budgets, to help accelerate housing delivery while ensuring quality.

Engineers know the importance of a solid foundation. That’s why the Engineers Canada-sponsored Group Savings and Retirement Program offers tailored financial solutions to help you build and grow your savings. Whether you’re saving for that next trip or planning for a confident retirement, build on what you’ve earned with a financial approach as intentional and forward-thinking as you are.

Why join the plan?

• Lower-than-retail fees* mean you pay less and keep more, helping your savings go further

• Access to a variety of plan options including a registered retirement savings plan (RRSP), tax-free savings account (TFSA), non-registered savings plan (NRSP), registered retirement income fund (RRIF) and life income fund (LIF)

• Free personalized guidance from licensed advisors who understand your goals and help you stay on track

• Retirement support from a dedicated licensed consultant offering expert, non-commissioned advice to help you understand your options and retire with confidence

• Easy plan management from anywhere through My Canada Life at WorkTM, Canada Life’s intuitive member site and mobile app

A plan built just for you.

The Engineers Canada-sponsored Group Savings and Retirement Program is exclusive to engineers, geoscientists, students and their families across Canada.

No burn-through eliminates elbow repairs

Lower material and installation costs

Mechanical strength protects conductors

Low coefficient of friction for smooth pulls

Operable in temperatures of -40° to +230°F