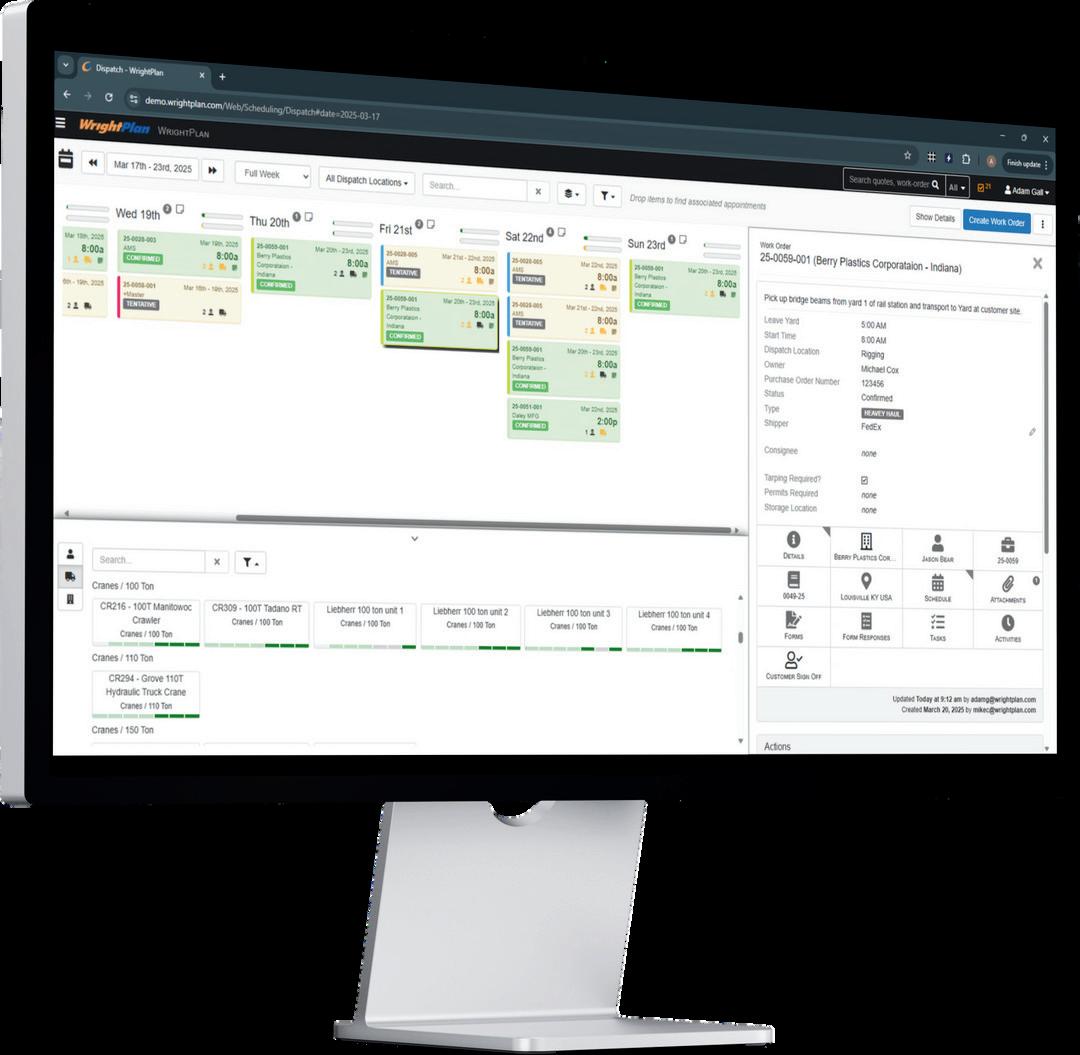

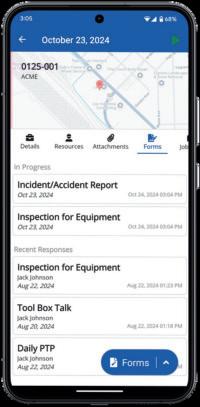

Manage jobs from start to finish

A sneak peek at CONEXPO-CON/AGG 2026 p. 14

Prepare for cyber threats with tabletop exercises p. 10

Industry outlook for future crane regulations p. 22

BY MACENZIE REBELO

Manage jobs from start to finish

A sneak peek at CONEXPO-CON/AGG 2026 p. 14

Prepare for cyber threats with tabletop exercises p. 10

Industry outlook for future crane regulations p. 22

BY MACENZIE REBELO

It seems the New Year has brought on more change than anticipated – as you may have noticed, I am not the editor you are used to seeing in the top left corner.

And since it’s best to strike while the iron is hot, there’s no better time than now to introduce myself. Hello! Some of you may be familiar with me, as I worked alongside Mike Lacey as associate editor on Canadian Rental Service and Rock to Road. I have been working in the construction B2B space for two years and have been a journalist for six.

Since taking over from former editor Jack Burton last November, who left me some big shoes to fill, the crane and hoist industry has welcomed me with open arms. While my time in B2B has been relatively short, I have yet to come across a more dedicated and passionate group than those in the crane and heavy lifting industry. Everyone I’ve had the pleasure of speaking with, whether it be a crane operator, engineer, or technician, have been nothing short of enthusiastic and friendly. The most rewarding part of my role is connecting with the people in the industry and diving into the world of cranes. Looking ahead, 2026 brings no shortage of exciting industry events and trade shows. I look forward to attending them all and meeting many of you in person. Without a doubt, CONEXPO-CON/ AGG is the show generating the most buzz this year. As someone who doesn’t travel much, I’ll admit I’m a bit intimidated. CONEXPO is the largest construction show in North America, and it will be my first trade show outside of Canada. Of course, an extravagant show needs an equally extravagant location–Las Vegas, Nevada. Let’s just say, Las

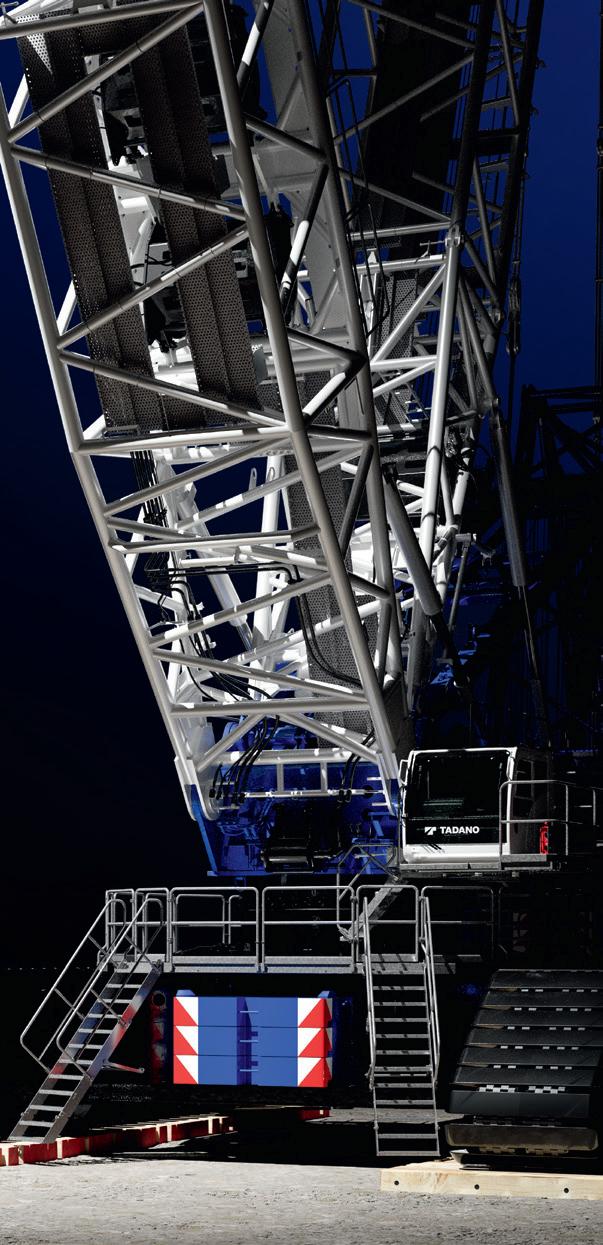

Vegas is very much the Oz to my Dorothy Gale. Regardless, CONEXPO is absolutely the place to be for the crane and hoist sector; the crane lot (which is the cover of this issue) is impressive to say the least. I’ll be attending alongside Crane & Hoist Canada’s national account manager, Laura Goodwin, who I’m sure is a familiar face–or name–to many of you. If you happen to see us, be sure to say hello! The more hands I get to shake, the better.

As the new editor, I’d love to hear about exciting Canadian projects, as well as any issues impacting the industry and its people.

You can also find me at the Canadian Crane Rental Association’s 2026 Annual Conference in Halifax, Nova Scotia, this year. Again, this will be my first trip to Atlantic Canada, and I’m excited to see the stunning landscapes of the eastern part of our country. Not to mention, meet those of you attending who make up such an imperative part of the sector. Above all, I’m eager to learn and listen to the issues that matter to you and explore them further through the pages of this magazine. Speaking of, this edition marks my first with Crane & Hoist Canada and through the process, I’ve already gained insight into both the challenges facing the industry and the innovation that continues to drive it forward. Without a doubt, the heavy-lifting and crane sector is the backbone of all Canadian infrastructure–if something can’t be lifted, it can’t be built.

As the new editor, I’d love to hear about exciting Canadian projects, as well as any issues impacting the industry and its people. Whether you have a story to share or simply want to say hi, please don’t hesitate to reach out to me.

Macenzie Rebelo mrebelo@annexbusinessmedia.com

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | MACENZIE REBELO mrebelo@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | ALISON KEBA akeba@annexbusinessmedia.com

ACCOUNT COORDINATOR | BARB COMER bcomer@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

CONTRIBUTORS | Saul Chernos

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

CEO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues)

Canada: $39.25 (per year + tax)

Canada: $67.36 (2 years + tax)

USA: $50.92 (CAD per year)

Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X Publications Mail Agreement #PM40065710

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2026 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: February 23, 2026. Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: February 23, 2026. For writers’ guidelines and submission requirements get in touch with the editor, Macenzie Rebelo, at mrebelo@annexbusinessmedia.com

MEMBER OF: MEDIA PARTNER:

120 USt| 110 mt Rough Terrain Crane

✓ 38.3’ - 164.1’ six-section pin & latch boom

✓ 261.7’ max tip height

OPTIONAL SMARTFLY:

✓ 35’ - 58’ of stowable fly

✓ SmartFly features

✓ One-person operation

✓ Assembly controls accessed from the ground

✓ Designed to minimize ladder climbs

Mammoet is the first customer of the new Liebherr LTM 1150-5.4E mobile crane with battery-electric drive. While prototype testing is in advanced stages at Liebherr in Ehingen, Germany, the crane has been delivered to Mammoet, where it is also being tested in practical use. The new Liebherr crane supports the company’s sustainability strategy, stated Peter van Oostrom, global projects asset director, Mammoet. Liebherr plans to start series delivery of the LTM 1150-5.4E in spring 2026. Mammoet is pursuing its goal of reducing CO₂ emissions, said van Oostrom. With innovations such as electric SPMT transporters, electric skidding systems and electrically powered SK ring cranes, the company supports its customers on their way to emission-free construction sites. According to Liebherr, with an integrated battery, the crane can operate autonomously for up to four hours without a power connection. A low connection power on the construction site is sufficient to develop the full crane performance, as the battery serves as an efficient buffer.

Sarens is participating in major infrastructure projects that contribute to the development of the potash sector. The expansion of the potash storage building at Westshore Terminals in Delta, British Columbia, a strategic project to transform a coal terminal

into a mixed-use facility that, once completed in 2026, will enable annual potash exports of 4.5 million tons. According to Sarens this expansion, with an investment of over USD one billion and derived from an agreement with BHP to provide port services to the Jansen mine in Saskatchewan, includes the construction of covered storage areas, wagon unloaders, and conveyor systems. To execute the project, Sarens performed the lifting of 33 double arches composed of glulam arches, beams, purlins, support towers, and concrete anchor blocks, each with a 70-foot radius and weighing 80,000 lb. Sarens’ engineering team conducted a thorough site and lift assessment, selecting a combination of 250-ton crawler cranes, 100-ton RT cranes, 250- and 120-ton all-terrain cranes, and a 55-ton truck crane, optimized for capacity, reach, and mobility.

According to Sarens, the Canadian potash sector is expected to grow with a compound annual growth rate of around 5.7 per cent between 2026 and 2035, driven by civil engineering projects.

Bailey International, a provider of hydraulic components and electronic controls, celebrates its 50th year in business in 2026. Bailey’s story began in 1976, when Adrian and Mary Bailey established the company in Owosso, Michigan. What started as a small, family-run business selling overstock and surplus items soon evolved as they recognized a demand for high-quality hydraulic components. Today, the company has over 340 employees in five global locations: Knoxville, TN, Victoria, B.C. Montreal, Que, Grand Rapids, MI and Chennai, India. In preparation for its next 50 years, Bailey has expanded its work truck product lines and bolstered its sales structure with enhanced technical support. According to Bailey, the company is also breaking ground on a new state-of-the-art electronics facility in Victoria, which will unite its electronics teams and accelerate innovation in custom control solutions.

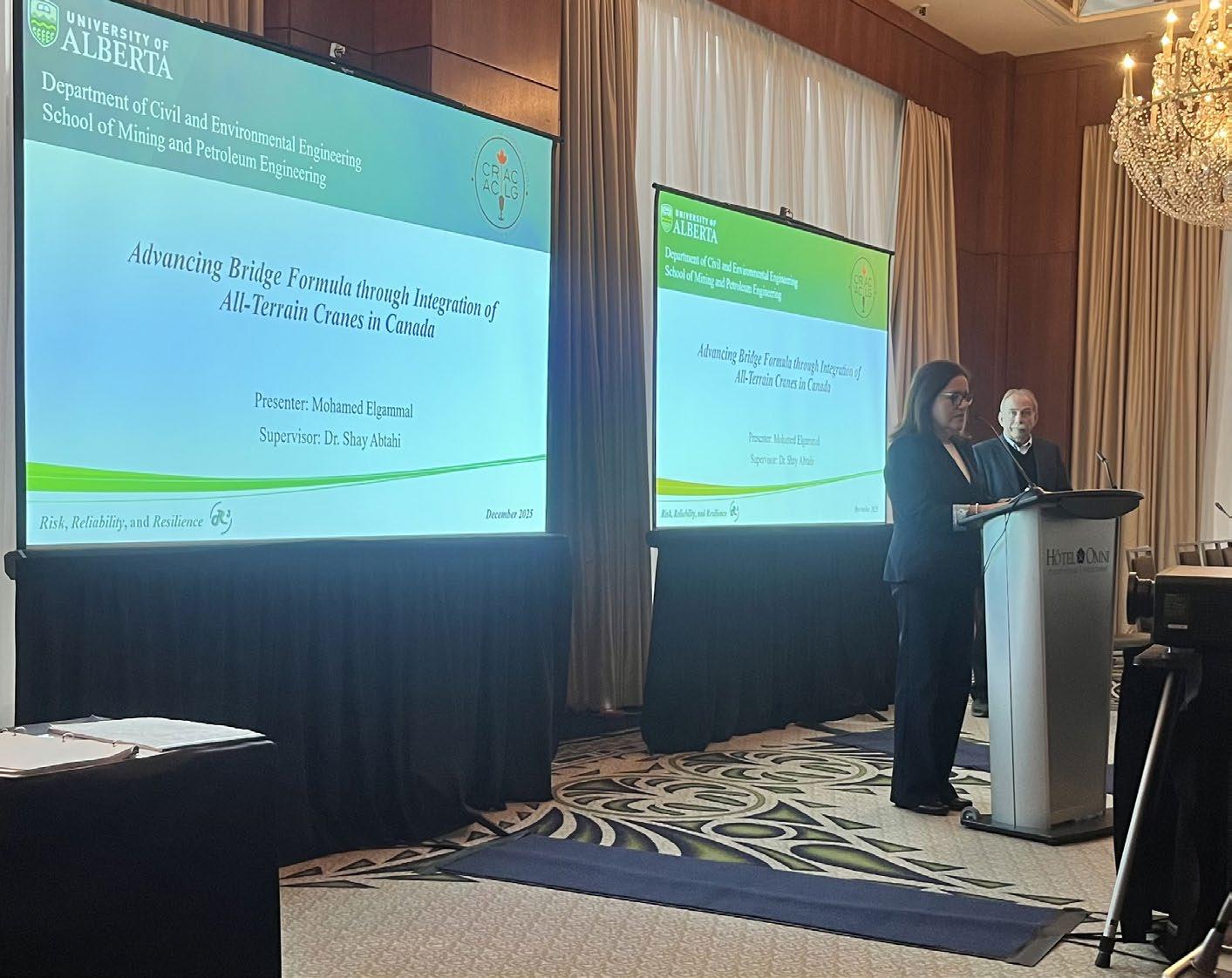

The Canadian Crane Rental Association (CCRA) made an impact at the two-day Transportation and Highway Safety Task Force on Vehicle Weights and Dimensions Policy Meeting, which brought together government and industry leaders to address critical issues affecting the crane sector.

The annual Council of Deputy Ministers Transportation and Highway Safety Task Force for Vehicle Weights and Dimensions Policy was held in Montreal, Que. from Dec. 2 to 3.

For the first time since the foundation of the National Task Force in 1998, an entire day was dedicated to oversize and overweight loads. A highlight of the meeting was the CCRA and University of Alberta bridge formula research project, presented by Mohamed Elgammal, a PhD student from the University of Alberta.

The session provided attendees with valuable insights into the latest research findings from the University of Alberta, emphasizing the importance of consistent, science-based approaches to bridge loading and all-terrain crane operations. The presentation sparked discussion among delegates, underscoring the need to include bridge load rating alongside the current research on the bridge formula.

This presentation was followed by Claire Bélanger-Parker, executive director of the CCRA, Clinton Connell, executive director of BC Crane Safety, and Gijs Verdeijen, vice-president of Mammoet Canada Western, representing the Crane Owners of Alberta. They spoke about the positive impacts that changes to weight and dimension regulations for all-terrain cranes in British Columbia and Alberta have had on the crane sector and provided an update on current efforts in Saskatchewan and Alberta.

Also in attendance were Jason Hanna, representing the Crane Rental Association of Ontario; Guillaume Gagnon, vice president at Guay, representing the Association des proprietaires de grues du Quebec; and CCRA Chair Ryan Long,

CCRA member expanded their knowledge on vehicle weight and dimension regulations, and the development of minimum national standards for oversize/overweight loads.

president of AW Leil Crane & Equipment, who ensured that the respective provinces were well represented. This diverse team brought a wealth of experience and regional knowledge to the table, facilitating productive dialogue on the challenges and opportunities facing the crane industry nationwide.

During the two days of presentations from various stakeholders, CCRA member expanded their knowledge on vehicle weight and dimension regulations, internal trade barriers, and the development

of minimum national standards for oversize/overweight loads. Topics included signage, lighting, escort vehicle specifications, and driver qualifications, which directly impact crane operations and safety across Canada. CCRA delegates engaged with members of the national task force, government officials, and industry peers, fostering stronger connections and mutual understanding.

The CCRA’s participation at the meeting not only advanced technical knowledge and regulatory harmonization but also reinforced the association’s commitment to safety and industry leadership. By sharing expertise and advocating for practical, unified standards, the CCRA continues to promote the future of crane and hoist operations in Canada.

For more information on the CCRA’s initiatives and upcoming events, visit www.ccra.aclg.ca.

Engineered to deliver real-world productivity—Combining a 110-ton capacity, efficient transport,and simplified self-assembly into one versatile crawler crane platform. Built for uptime, backed by Manitowoc engineering, and supported by Nors’ national service network.

Comprehensive crane portfolio from top brands. Strong regional presence across Canada.

Personalized customer support and dedicated account management

Tailored financing solutions and competitive pricing. Expert after-sales services and rapid parts availability. Partner with Nors and discover why industry leaders trust us to lift their businesses to new heights.

Tabletop Exercises (TTXs) help organizations develop strategies and tactics to address potential scenarios before they become reality.

By Brennen Schmidt

Today, technology stands as one of the most critical components of keeping an organization running. But what happens when the technology you rely upon doesn’t work?

For the crane and heavy equipment sector, safety and uptime are critical. Both depend on interconnected systems of people, processes, and equipment. The very thought of such equipment or systems being held for ransom is serious. You might be able to get back up and rolling, for a price, but the result might not be a guarantee. Any response requires careful consideration of operational, reputational, and risk management implications, often under intense time pressure.

Ransomware. It can come in many forms, ranging from system encryption and service disruption to data theft and extortion, and often combines multiple tactics within a single incident. This kind of attack could disrupt safety monitoring systems or halt fleet dispatching; these impacts may arise as part of a cyber incident or as cascading operational effects that intersect with existing safety and reliability dependencies. Depending on their tactics, this could mean locking an organization out of its systems or threatening to release stolen data.

For heavy equipment operators, a single day of downtime in some cases could potentially translate into significant financial losses just from the delays alone, depending on fleet size, contractual obligations, and project timelines; that’s not counting all that might come with the ransom demand.

The aftermath of a ransomware incident often has leaders and boards wondering what gaps were exploited. While discus-

sions often focus on technical causes, zooming out to the strategic side of technology can help leaders determine where to focus their efforts as the organization restores operations.

This can involve investments to shore up gaps in the security of connected cranes, Internet-of-Things (IoT) devices, Operational Technology (OT)–including Industrial Control Systems (ICS)–access control, security cameras, and remote diagnostics. Each of these can expand an organization’s “attack surface.” These systems, connections, and assets may become targets if not properly segmented or governed.

Tabletop Exercises (TTXs) offer a potential solution to developing the strategies and tactics to tackle these situations long before they cease to be hypothetical. A TTX is a discussion-based activity framed around a scenario such as ransomware incidents, telemetry outages, compromised sensor data, and more, including scenarios that test decision-making across cyber, safety, and operational domains.

A TTX can complement technical testing and other exercises focused on build-

ing resiliency, while also “pressure testing” incident response capabilities and plans as teams like operations managers, safety officers, fleet supervisors, dispatch leads, and external parties coordinate a simulated response.

Tactically, a TTX can help shed light on gaps in existing processes. For example, you might evaluate how your organization would respond to being locked out of a crane control dashboard or handle corrupted maintenance logs, particularly where safety-critical decisions are required.

The most successful TTX exercises bring together leaders ranging from the CEO to finance, legal, HR, IT, and so on. Engaging experienced incident response and crisis management professionals in the exercise can be helpful, particularly to challenge assumptions and test coordination under pressure. Safety and operations leaders can also play a key role considering the physical risk profile unique to crane and hoist work.

When IT is managed by a third-party, inviting their representative(s) can provide valuable insights into what might happen before an incident occurs, subject to confidentiality and contractual considerations. Establishing clear expectations around roles, decision-making authority, and information sharing during an incident can also help clarify contractual obligations and strengthen relationships before the pressure is on. These partici -

“A TTX can serve as a proactive way of gathering diverse perspectives in a controlled environment–with just enough pressure to keep the dialogue active.”

– Brennen Schmidt, ALEUS Consulting Group

pants may include Managed Service Providers (MSPs), third-party telematics vendors, maintenance software providers, or incident response professionals.

A TTX can serve as a proactive way of gathering diverse perspectives in a controlled environment–with just enough pressure to keep the dialogue active. Introducing “injects,” or plot twists, helps the scenario feel more realistic. Example injects might include a shutdown of operations due to system lockout, or modified sensor data causing safety concerns. While the discussion is essential, leaders often look for practical outcomes. This is where the After-Action Report comes in. A facilitator plays an important role in drawing out feedback through prompts such as: How effectively could our systems be isolated in a real-world event? How can we validate vendor response timelines? Together, these questions can promote meaningful dialogue. Capturing this feedback into a set of strategic and tactical

The aftermath of a ransomware incident often has leaders wondering what gaps were exploited. Utilizing the strategic side of technology can help determine where to focus efforts to restore operations. PHOTO: ©

recommendations can help shape a roadmap for action. Ownership is essential to help promote accountability and sustained progress.

Frame the exercise around goals tied to mission, vision, and values, with executive leadership acting as an active and visible sponsor before, during, and after the TTX.

Typically, a TTX culminates with a report summarizing the exercise, outcomes, and recommendations. Regardless of the format, maintaining momentum is key. Other complementary activities can include control network reviews or riskbased technical assessments with clearly defined safeguards. These approaches can help technical teams identify weaknesses before malicious actors exploit them.

In any case, the best time to conduct a TTX is before the unforeseen happens. If

TTX exercises are already part of IT’s routine, you may want to expand the focus to include Operational Technology (OT), which refers to systems that control physical equipment or infrastructure, including safety and monitoring systems. It’s generally better to test these scenarios proactively rather than reactively.

This article is provided for general information purposes only and reflects the author’s views at the time of writing. It does not constitute legal, financial, or professional advice. Readers should consult qualified professionals regarding their specific circumstances.

By Macenzie Rebelo

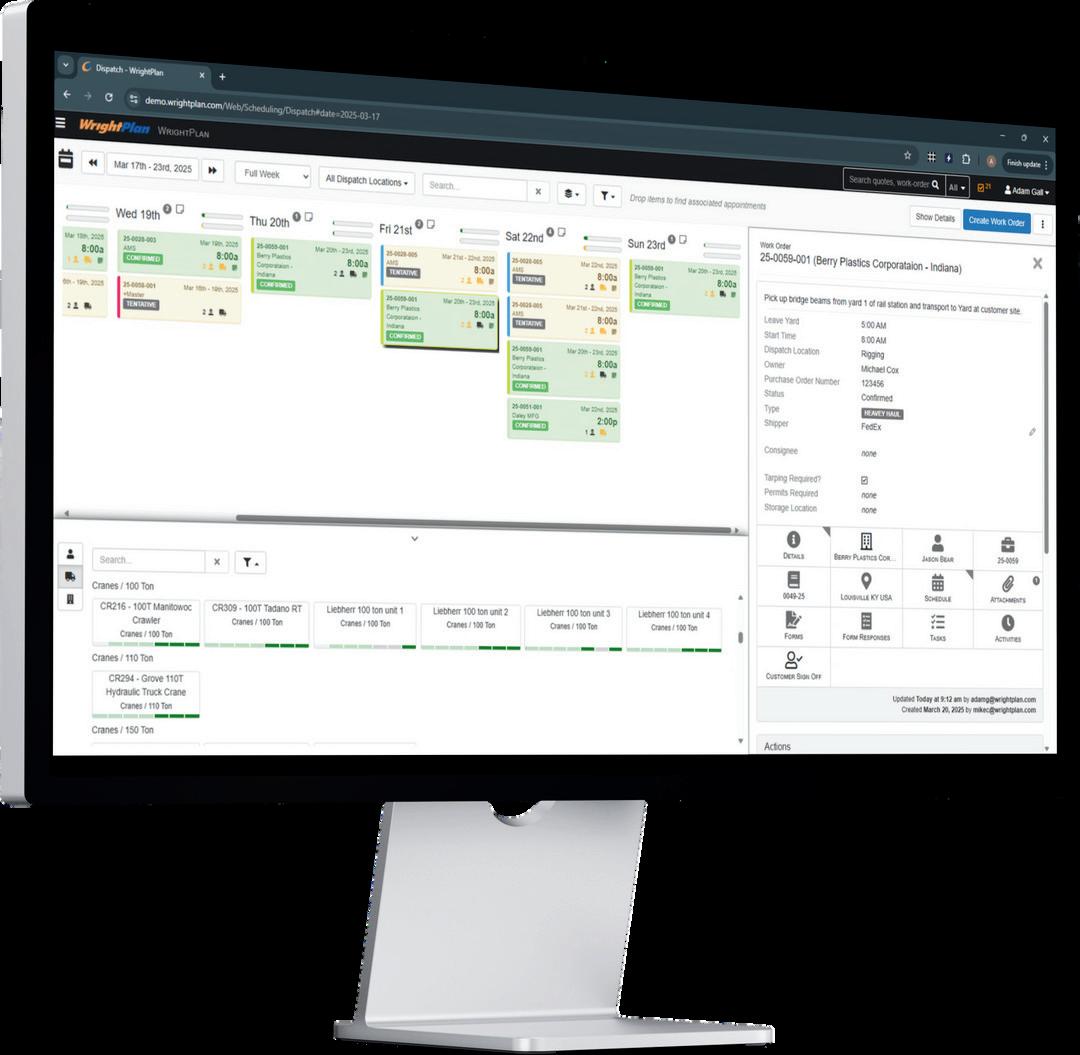

It’s that time of year again, when North America’s largest construction trade show, CONEXPO-CON/ AGG, returns to Las Vegas, Nevada, after three years. With cranes playing such an indispensable role in construction, it is safe to say there will be no shortage of crane and hoist innovations to explore. Here’s a preview of what exhibitors are bringing to the show floor, or in this case, the massive outdoor lot, on March 3-7, 2026.

At CONEXPO, booth W43101 BKT Tires will showcase its latest solutions and innovations for the construction industry. BKT offers a large and updated product range with over 3,600 SKUs sold in over 163 countries worldwide, states the off-highway tire manufacturer. At BKT’s booth, visitors will have the opportunity to see up close some tires, like the AIROMAX AM 27, the ideal road-oriented tire for construction applica-

The CONEXPO-CON/AGG 2023 festival lot from the previous show in Las Vegas, Nevada.

PHOTO: MARY STRATTON / CONEXPO-CON/AGG

tions with cranes. It features extraordinary heat resistance and outstanding riding comfort. AiroMax AM 27 is a highspeed tire particularly suitable for all operations requiring a high level of handling. CONEXPO 2026 will be an important display of innovation and technology, and BKT is looking forward to meeting its visitors in Las Vegas.

Comansa At CONEXPO learn more about Comansa’s

latest innovation, the 6LC85 flat-top tower crane, a highly versatile and compact model designed for urban and confined workspace. The 6LC85 offers a maximum load capacity of 11,020 lb and a reach of 172.2 feet. There are multiple versions available: embedded, supported on bases of 12.5 or 14.8 ft or on top of travelling bases. The crane’s standard mast size of 3.9 ft allows it to fit easily in very small areas. Its modular jib can be configured from 65.6 to 172.2 ft, with in -

crements every 8.2 ft, providing maximum flexibility for various projects. The crane features a minimum working radius of 5.8 ft and a counterjib radius of just 41.0f ft, making it ideal for congested job sites. The 6LC85 is equipped with Comansa’s compact head design, which integrates the slewing and hoist mechanisms, electric control panel, and safety limiters into a single compact unit. Nearly all connections are pre-assembled, significantly reducing installation time. Compact components simplify transport and handling, reducing on-site logistical challenges and resource requirements while all components are located close together within the compact head, allowing for quick inspections and easier maintenance access.

1

3

Elliott Equipment Company At booth number S60430 Elliot Equipment Company, will showcase it

latest equipment like the Elliott E160 Aerial & Eline Platform designed for high-stakes work in hard-to-reach places.

The Elliott E160 is a 160-ft-

material handling aerial work platform engineered specifically for utility transmission construction and maintenance. With a maximum working height of 210 ft, 30 mph wind rating, full compliance with ANSI A92.2 structural, stability, and hydraulic standards, and control precision, the E160 delivers the height, performance, and peace of mind transmission crew’s demand. Elliott’s new E-Line platform transforms the E145, E160, and E190 aerial platforms into advanced utility solutions. With industry-leading capacity, material handling, and safety features, the E-Line platform gives crews the flexibility and performance needed to take on today’s most demanding utility projects. Visit Elliot Equipment Company at CONEXPO 2026.

2

3

4

Liebherr-Werk

Ehingen GmbH

Liebherr is not only using CONEXPO 2026 to showcase new machines, but also to demonstrate what modern crane operation will look like in the future. The focus will be on a combination of high-performance technology and intelligent digital services, with clear practical benefits for operators, dispatchers and

crane drivers. Visitors can expect to see a representative mix of the latest mobile and crawler cranes, including the world premiere all-terrain crane. Among the crawler cranes, there will be an exciting spectrum ranging from compact powerhouses to heavy lattice boom models. Together, they paint a picture of machines that combine high lifting capacities with econom-

ical transport solutions worldwide, an aspect that is becoming increasingly important for operators and dispatchers. Overall, the exhibits reflect key trends in the Liebherr portfolio like state-of-the-art assistance systems for greater safety, economically optimized transport solutions and digital tools that make day-to-day work on the construction site more efficient.

4

5

5

Link-Belt Cranes

Link-Belt Cranes is proud to exhibit at CONEXPO this year. Located at booth number F35029, Link-Belt will showcase several standout models across all product lines, including the 300-ton (275-metric ton) 300|AT, the 225-ton (200-metric ton) 225|AT, 120-ton (110-metric ton) 120|HT, as well as two all-

new models it will premiere at the event. CONEXPO is a great opportunity for LinkBelt to demonstrate its world-class products and interface with customers across North America. All models on display will be equipped with the latest features, including cameras, telematics, lighting packages, and fall protection.

Make sure to stop by Nelson Manufacturing’s booth F43085 in the festival lot at CONEXPO, where the company is excited to unveil its lightweight boom launch trailer. This innovative trailer not only upholds Nelson Manufacturing’s commitment to safety and efficiency in boom launching operations, but it also features optimized empty weight, axle spacing, and weight distribution. The straightforward design allows for a quick and simple changeover for various crane booms and crane boom configurations making it incredibly versatile for any operation. In addition, the Nelson Manufacturing will have its advanced boom dolly on display, equipped among other features with user-friendly outrigger pad holders for added convenience. Don’t miss the chance to check out the bi-fold ramp trailer, perfect for transporting fork trucks, industrial cranes,

• Type 304 Stainless Steel Construction

• Food-Grade Grease Meets NSF H1 Standards

• Enclosed Gearing & Sealed Roller Bearing

• Weston-Style Braking System

• Ergonomic Handle with 360-Degree Rotation

• Twin Pawl Design

8

and other rigging equipment. Stop by to learn how Nelson Manufacturing can enhance your operations with our stateof-the-art transport solutions!

SANY America will debut three new cranes at this years CONEXPO, expanding its lineup across key high-growth segments of the market. Headlining the launch is the SCA3300A, a 330-US-ton lattice-boom crawler crane

engineered for today’s most in-demand applications, including the rapid expansion of data centers across North America. Continuing its product strategy, SANY will also introduce the SCA1100TB telecrawler, a long-reach, high-capacity machine designed for maximum versatility and simplified transport between jobsites. Rounding out the launches is the SCD150A, marking Sany America’s entry into the carry-deck crane market and further broadening its lifting solutions portfolio.

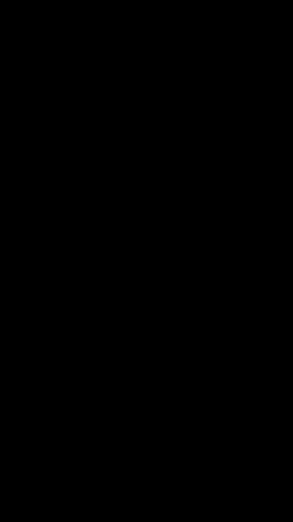

At CONEXPO, Tadano is inviting attendees to see what ‘reaching new heights’ really looks like. Visitors to Tadano’s booth will find one of the most complete lifting lineups in the industry, strengthened by the integration of former Manitex Group brands into the Tadano portfolio, giving customers access to aerial work platforms, pick-and-carry cranes, truck-mounted cranes, boom trucks, and more under one trusted name. Alongside Tadano’s all terrain, crawlers, rough-terrain, and truck cranes, the company will showcase how its expanded

9

product range and global manufacturing footprint help contractors tackle more jobs. Several models will be making their U.S. debut at CONEXPO 2026, giving attendees an early look at what’s coming to jobsites across North America. Attendees will also be able to learn about Tadano’s growing suite of digital tools that support smarter planning, fleet optimization, and efficient service, making our booth a must-visit for anyone looking for where lifting technology is headed next.

At CONEXPO, Tele Radio will showcase its wireless remote-control solutions designed for cranes,

lifting equipment, and mobile machinery operating in demanding jobsite environments. Visitors to the booth can explore the Panther, Tiger, and TEQ product lines, offering flexible configurations for everything from compact applications to complex, safety-critical systems. Tele Radio’s experienced U.S. team will be on site to discuss real-world applications, customization options, and integration support for OEMs and operators. With a strong focus on reliability, safety, and long-term partnership, Tele Radio helps customers find the best control solution for each machine–not just the right remote.

MR. FIX IT

BY SEBASTIEN GIRARD-PAGE

We prepare our cars for winter, why should it be different for your cranes?

As we equip our cars for colder months, it is crucial to ensure that your cranes are also properly prepared. These powerful machines, designed to operate in a variety of climates, require special attention to avoid cold-weather issues. For cranes used in the Canadian climate, winterization is essential.

The importance of preparing your cranes for winter to ensure their performance

Based on our experience, we know that the northern climate has a significant impact on the electrical and hydraulic components of cranes, lifting systems, and related equipment. Although manufacturers are increasingly aware of our climatic conditions, there is still much progress to be made in developing components that can withstand them.

It should be noted that we are sometimes called to a job due to a hydraulic oil breakdown that, unfortunately, is not suited to the northern climate. In such cold environments, the oil literally freezes, affecting all components of the crane or lifting system’s hydraulic system (pump, valves, hoses, etc.). This causes a significant loss of profit due to inefficiency when a crane is not operational.

Here are some best practices to follow, in the form of a checklist, to ensure that your cranes are ready to face the rigors of winter:

1 Check oils and fluids:

Make sure your oils and fluids are suitable for the conditions your cranes will face at the deployment site. It is also strongly recommended that you take a sample of the used oil to detect any anomalies, premature component wear, or contaminants in the oil or fluids.

2

Auxiliary heating check:

Ensure that the auxiliary heating system is working properly to maintain an optimal temperature inside the machine. Don’t forget to empty and clean the aux-

iliary heating fuel tank to remove any water and prevent freezing.

3 Testing engine heaters and hydraulic compartments:

These components must be operational to ensure efficient starting and proper functioning in cold weather.

4 Changing air dryer cartridges: These cartridges must be replaced to prevent moisture buildup, which could freeze and cause damage.

5 Check the windshield wipers: Make sure they are working properly for optimal visibility. It is important for the operator’s driving safety that the wipers not suddenly fail due to cold weather or poor preparation. Checking them can help prevent unpleasant surprises and delays on the job site.

6

Proper operation of the cab heater:

It is imperative that the cab heater be operational for the operator’s comfort. Test it before the temperature drops to

avoid unpleasant surprises and to ensure that the person in charge of operating the crane is not forced to endure our cold climate. Again, this can cause delays and stoppages in operations due to frost that accumulates on windows, significantly obstructing vision.

7 Installation of radiator covers:

These devices help reduce heat loss from the engine, thus protecting the internal components.

8Testing coolant density:

This prevents the product from freezing, which could damage the engine head. In summary, it is vital to prepare your cranes for winter. The weather can vary considerably, and a well-maintained machine is the key to avoiding inconvenience.

9Operational test:

After completing winter preparations, it is essential to perform an operational test before departure. This test will allow you to identify minor adjustments that need to be made and, sometimes, even breakdowns that could not be detected in the workshop, but only when operating the crane.

Regardless of where your crane comes from, it is important to conduct the necessary checks to ensure it is ready to withstand our specific climate. Even if the machine is designed for North American temperatures, our weather can vary considerably from region to region–don’t assume it will be ready to withstand the local winter without an assessment. Maintaining a construction schedule depends, among other things, on equipment in perfect condition. Proactive maintenance and appropriate inspections of your cranes can significantly reduce the risk of breakdowns and damage, ensuring optimal productivity.

Sebastien Girard-Page is the owner-technician of SGP Crane Repairs, bringing over 20 years of technical expertise to delivering reliable, high-quality crane repair services across Canada.

By Claire Bélanger-Parker

The network of companies across Canada’s crane rental industry is a cornerstone of national efforts in infrastructure and innovation. The Canadian Crane Rental Association (CCRA) is driving these efforts to strengthen the industry and, by extension, the country, while offering a platform and voice for the diverse array of companies across the sector and the issues they face.

Advancing research and development

Innovation is at the heart of progress. The CCRA retains active collaborations with the University of Alberta Faculty of Engineering, alongside experts in the engineering space, to tackle research on bridge load rating and bridge formulas. These efforts aim to provide scientific research and data that will be used to support advocacy toward regulatory changes in the areas of weights and dimensions legislation for those in the heavy equipment and infrastructure sector.

Influencing policy through government relations

As the federal government prioritizes removing Canada’s interprovincial trade barriers, the CCRA is maintaining close government relationships to inform efforts to ensure the country’s heavy lifting sector has a voice at the table.

Representing Canada’s crane rental industry, the CCRA is advocating for fair and practical regulations at municipal, provincial, and federal levels. Aiming to replace barriers to growth with new opportunities, the CCRA’s efforts include the harmonization of vehicle weights and dimensions across provinces and further shaping apprenticeship pathways.

To help move these issues forward, the CCRA maintains a presence at national

forums and on consultative committees to ensure that the industry’s concerns are heard where decisions are made.

In addition to the association’s research and advocacy efforts, the CCRA has an active and wide-ranging member network, which provides crane rental companies across the country with features including:

• Networking and knowledge transfer

opportunities between crane rental companies, manufacturers, and suppliers across Canada.

• Educational resourcesincluding technical toolkits and workforce development programs.

• Industry visiblity through the Member Portal, annual conference and annual recognition programs such as the Canadian Lift of the Year and Safety Awards.

• Opportunities to contribute to the sector through participation in committees and task forces that influence industry standards.

• Influencing career paths by attending Skills Canada Compétitions and connecting with thousands of youth in the prime of their career selection process.

Want to learn more? Visit ccra-aclg.ca or contact claire@ccra-aclg.ca.

The new Professional Engineers Ontario standard means it’s even more critical to plan and get your paperwork in order, states Jason Brown, technical project lead at

By Macenzie Rebelo

The Canadian crane and heavy lifting industry is not new to the ever-changing regulations and requirements in place for safety. Despite these changes, compliance remains an uphill battle. In 2024, the Notice of Project - Tower Crane (NOP-

TC) requirement came into effect in British Columbia and requires every employer responsible for crane activity to submit a NOP-TC to WorkSafeBC at least two weeks before crane activity begins. Similarly, in 2025, new mandates for tower crane inspection schedules came into

effect across Ontario. These mandates introduced new scheduled inspection requirements and compliance measures aligned with the most recent CSA standards for the design, erection, and dismantling of tower cranes and other crane types. What do these changes mean? And how

should the industry comply with these new standards?

Jason Brown, technical project lead at Kova Engineering Ltd., and Clinton Connell, executive director at BC Association for Crane Safety, joins Crane & Hoist Canada to discuss the future of crane safety and answer these questions.

CHC: Could you summarize what these new regulations look like and what is required to achieve compliance with them?

BROWN: The Ontario regulation requires not only the structural inspection of the crane to be approved by an engineer, but also the electrical, mechanical and hydraulic components to be inspected in accordance with this Professional Engineers Ontario (PEO) standard. Ontario has also introduced some requirements for 10-year breakdowns on cranes as well, which is new. One of the big changes is the fact that they reference the PEO standard, which has been lumped into being part of legislation now, and a law you must follow and abide by. The PEO standard itself goes a bit more in-depth than just the general regulation, which has definitive benchmarks for tower cranes to hit, such as a pre-inspection document review to ensure all your documents are correct and complete to provide the engineer with enough information to make all the decisions they must make.

This means it’s even more critical to plan: communicate early, make sure everyone on the project understands new timelines and expectations all the way from the developer down to the crane operators and users, and get your paperwork in order.

CHC: Are there any events that inspired these changes to be made?

CONNELL: Unquestionably, what drove this was the Seattle, Wash. and Kelowna, B.C., tragedies in 2019 and 2021, which collectively took nine lives. One of the recommendations that arose from the

“As with the introduction of any new regulation, it takes time to adapt. In a perfect world, there would be a one-size-fits-all certification, but that’s just not the case.”

– Clinton Connell, BC Crane Safety

aftermath was multiple industry consultations. There were about four basic ones, and the NOP-TC is the one that came through the policy stream. It was agreed that a central registry, similar to crane operators in B.C., should be created or adopted. As you know, it’s quite specialized, and it’s quite small: there are about 100 individuals in B.C. that are active in that type of work, so this creates a database where that list of qualifications, credentials and training could be accessed and listed.

BROWN: Similarly, in Ontario, it goes back to some serious crane incidents in Toronto from the late 2000s that sparked a push to bring in more stringent regulations related to do with tower cranes. In Ontario, it was realized that, while the owner has always been responsible for maintaining these cranes, is anybody really checking prior to an incident happening? That gap was identified, as people were relying on the honour system for compliance.

These new regulations are striving to add additional thirdparty oversight to the maintenance programs being enforced on tower cranes. In the PEO standard, there is a very heavy emphasis on maintenance, including very detailed requirements for something like slew ring maintenance, which one of the incidents in Ontario had to do with.

CHC: What did tower crane regulations in both Ontario and B.C. look like before each of these respective changes?

BROWN: The Ontario inspection requirements hit a lot of main points and followed a lot of the CSA guidelines. The only real involvement required by an engineer was to certify any foundation or shoring

used to support the crane, and a structural inspection of the crane prior to it being erected and every 12 months thereafter. The Ontario Ministry of Labour (MOL) realized they left the door open for non-compliance by leaving it in the hands of equipment owners to ensure maintenance. These new regulations really push responsibility to an engineer to help close this gap,

leveraging the legal duty of engineers to safeguard the public and use them as an impartial third party. I believe this approach makes sense in theory and is a step in the right direction, but it also presents some practical challenges. Engineers are ever-increasingly asked to play a quasi-enforcement role, effectively overseeing the actions of the very clients who have retained us to help them achieve compliance. This can create tension, especially if there is a disagreement between the parties, with no real fallback.

CONNELL: The introduction of NOPs is new to the heavy lifting industry, but they have existed for a long time for things like major construction projects, asbestos work, forestry and underground operations. What is significant is that the regulator receives advanced notice of the types of work they classify as high-risk activities, allowing them to engage the necessary parties if they have any questions or concerns. When they receive the NOP, they go into a sort of triage system. WorkSafeBC has a crane team, so they look at the NOPs, ensuring qualified individuals are listed with the registry, and look at some of those work procedures. This allows them to engage parties ahead of time and ensures they have the available resources to deploy or visit the job site before work begins.

CHC: Have there been significant impacts or obstacles stemming from these changes?

BROWN: It’s created a bit of uncertainty in Ontario at the moment about what people need to do, and it has required a certain amount of adjustment from across the industry – there’s been a bit of scramble

by organizations to integrate the new requirements. The MOL understands how much work is required to implement such a big change in regulation, so they’re currently taking the approach of education rather than enforcement, which I believe is the right direction.

CONNELL: I don’t want to sugarcoat it. While I’m pleased with the 80 per cent compliance rate we’re currently sitting at, it’s been tough on the industry. As with the introduction of any new regulation, it takes time to adapt. In a perfect world, there would be a onesize-fits-all certification, but that’s just not the case. There are so many different types of equipment, configurations, and manufacturers, especially in our region, to capture all that takes time. The idea behind the registry was to have an inventory of those in the province engaged in this type of work, collect their various types of credentials and the employer’s due diligence. It really is specialized work, and crews that are specialized in certain makes and models may not be familiar with other makes and models.

CHC: What are some of the shared impacts these changes might have on the industry nationwide?

CONNELL: The changes to the EGBC document for mobile crane inspection took place between roughly 2009 to 2013 for large mobile crane equipment, and that’s exactly the direction it’s headed for tower cranes. It’s not a matter of if, but it’s a matter of when that level of inspection diligence will be applied to tower cranes. Ontario and B.C. typically lead the country with the introduction of new OHS regulations, so I think it’s very safe to expect and assume

other provinces or even municipalities may jump aboard and start implementing some of these requirements. Even if it’s not part of the provincial legislation, a specific municipality may wish to see certain things. A quick example of that would be following the Kelowna tragedy, we ran the City of Vancouver Pilot Project, which involved the traffic control plans, the safety personnel and the various subtrades involved in the erection and dismantling of cranes. A checklist was developed, and multiple municipalities, including Kelowna, Vancouver, and some on Vancouver Island, implemented it as a requirement for the issuance of crane permits. Ultimately, that’s since morphed into the NOP-TC, which is now legislation and law for all of B.C.

“The MOL understands how much work is required to implement such a big change in regulation, so they’re currently taking the approach of education rather than enforcement, which I believe is the right direction.”

– Jason Brown, Kova Engineering

CHC: What direction do you see the provincial tower crane sectors moving toward?

BROWN: Ontario’s inspection requirements for tower cranes are still in a bit of a transition-

al phase, but the intent behind the new PEO standard is very clear: to raise the bar on inspection and quality, improve consistency and ultimately support safer crane operations across the board. Organizations and stakeholders have a

huge role to play in helping the standard deliver on its goal. It starts with taking ownership and implementation – not waiting to be told what to do, but actively working with engineers to build out practical, repeatable processes.

The crane, hoisting, and rigging industry faces rapid change in 2026, but one principle remains constant: competence saves lives. While new technologies and initiatives are reshaping worksites, the core of lifting safety still depends on qualified and certified people. With cranes operating on increasingly complex projects, one mistake can injure workers or halt multimillion-dollar jobs. British Columbia and most other jurisdictions require more than just “experience” or “common sense.” Workers must be competent and qualified. In 2026, competency means more than passing an exam, it includes continuous learning, strong supervision, and adapting to evolving standards.

Why competence still matters

Competence remains the foundation of lifting safety because it blends technical skill with judgment, hazard recognition, and adherence to procedures. When competence fails, consequences follow. WorkSafeBC Regulation reinforces this expectation:

• WorkSafeBC Occupational Health and Safety Regulation Part 14 Section 14.34.1

Operator certification: Cranes must be operated by certified operators.

• WorkSafeBC Occupational Health and Safety Regulation Part 15 Section15.2

Qualified riggers: Rigging and slinging must be done by qualified workers.

These requirements aren’t just legal obligations; they are the baseline for safe work. As cranes grow more sophisticated companies must reinforce competence with ongoing skill verification.

WorkSafeBC has increased oversight following recent incidents, and the industry has also taken proactive steps to strengthen competency in B.C. Key developments include:

• WorkSafeBC: Mandatory Notice of Project for Tower Cranes (NOP-TC)

• Industry-led: Proctoring of the online provisional exam for crane operator cer-

• Industry-led: Expanded crane operator exams with additional rigging content Industry discussions for future actions include potential licensing or certification models for assembly/disassembly crews.

Advancements in technology are reshaping lifting operations, but they are not replacements for skilled workers. Artificial intelligence (AI), smart sensors, and connected equipment can enhance decision making but they cannot compensate for poor judgment or lack of training.

AI driven load monitoring systems and Internet of Things (IoT) enabled cranes now provide real-time data on wind, radius, ground conditions, and structural stress. Predictive maintenance tools alert crews to issues before failures occur. Virtual reality (VR) simulators continue to improve training outcomes by offering realistic, consequence-free environments to practice critical skills. A strong example comes from ABC Supply, which adopted Hiab’s HiSkill VR training program. Their first-time NCCCO pass rates rose from 65 per cent to 85–90 per cent. This demonstrates how technology can strengthen competence when used as part of a broader training strategy.

But the core remains unchanged, technology enhances competence but does not create it.

Sustainability continues to influence equipment choices. Manufacturers such as Liebherr are releasing hybrid and fully electric models such as the LTM 1150-5.4E which combine battery powered or electric operation with conventional drive for road travel. These machines may reduce emissions, noise/hearing conservation and fuel costs, advancing both environmental and operational goals.

Parallel to equipment innovation is the ongoing challenge of workforce development. As experienced workers retire and younger workers enter the trade, structured

training, mentorship, and periodic refresher/renewal programs are essential. Regulations, equipment, and best practices evolve; training must evolve with them. Competent crews are not built once they are built continuously.

Ensuring competence is not the job of one person or one role. It requires coordinated effort across the entire project team:

• Owners and prime contractors: Set expectations, verify subcontractor qualifications, and ensure pre-planning reflects site conditions and risks.

• Employers: Provide proper training, supervision, documented evaluations, and refresher programs. Competence should never be assumed based on tenure.

• Supervisors: The critical link between policy and field practice. They must verify credentials, understand the strengths and limitations of their crews, and stop work when competency is in doubt.

• Safety professionals: Audit lifting operations, conduct thorough risk assessment and process analysis, identify training gaps, and reinforce compliance through coaching and continuous improvement.

• Workers: Comply with regulatory requirements, report hazards and incidents to supervisors, protect the health and safety of themselves, and the public. In an environment where equipment is more capable and jobsites more complex, the human factor remains the most decisive element of safe lifting.

In 2026, lifting safety is about balance, which means competence first and technology second. The crews that combine strong foundational skills with smart tools will continue to set the standard for safe and efficient lifting in Canada. The safest jobsite is the one where people are trained, qualified, competent, and supported by innovation that makes every lift smarter and safer.

Safety.

BROWN

Canada’s construction crane industry is operating in a regulatory environment that no longer reflects the complexity, pace, or scale of modern lifting. Our cranes have evolved. Our wire ropes and synthetic materials have advanced. Our projects have grown larger, taller, and more demanding. But the guidance governing rigging products like wire rope, and below-the-hook devices remains fragmented, inconsistent, and out of date.

Across Canada, there is a renewed push to reduce friction between jurisdictions and harmonize in areas that touch public safety, workforce mobility, training, and industrial performance. Whether it is codes, qualifications, procurement requirements, or operational guidance, many sectors are recognizing that national alignment improves outcomes without erasing provincial authority. The construction crane and rigging community should follow suit.

A patchwork system that doesn’t serve construction cranes

Canada’s safety landscape is decentralized. Only a small portion of the workforce falls under federal occupational health and safety rules. That structure creates a reality crane owners and contractors know well: requirements vary by jurisdiction, and the references used to define ‘acceptable’ rigging practice differ from one province to the next.

The impact on construction cranes is immediate. Tools and practices that are considered compliant on one job may be questioned on another, especially across provincial lines. Some jurisdictions reference ASME standards but may not keep pace with updates. Others rely on legacy guidance and local interpretation. At the national level, Canada has only a narrow set of standards touching crane operations, while whole categories of essential rigging products lack Canadian standards altogether. When the rules are unclear or inconsistent, the industry pays the price in delays, and elevated risk. In a discipline where clarity saves lives, that

should concern everyone.

Over the last two decades, construction crane work has become more engineered and more demanding. Lift plans are more common. Loads are more complex. Schedules are tighter. Meanwhile, rigging technology has changed rapidly. Wire rope can no longer be viewed through the lens of a few legacy constructions. Today’s market includes a wide range of rope designs and technologies, each with distinct operating behavior. Synthetic crane ropes that are addressed internationally through established guidance bring new benefits and new inspection challenges. Sling technologies have also advanced, including high-performance synthetic products that can deliver extraordinary capacity with minimal weight. Yet the guiding documents many people rely on have not kept pace with these changes. That mismatch puts pressure on everyone.

harmonization matters to crane owners and contractors

First, it improves safety through consistency. When crews, supervisors, and inspectors share the same baseline criteria for inspection, retirement, and use, the probability of critical misunderstanding drops. Second, it strengthens training and competency. Standardized guidance supports standardized training. That matters in a market where labour mobility is necessary and where competent riggers and operators are in high demand. Third, it reduces jobsite friction and administrative risk. Harmonized references reduce debates, creating smoother pre-lift planning and fewer mid-project interruptions. Fourth, it supports engineering rigor. Clear, consistent guidance on sling angles, reduction factors, multi-leg behavior, and hardware limitations helps engineering teams produce better lift plans and helps field teams execute them with confidence. Fifth, it can align Canadian construction practice with global best practice, in an industry where products are sourced internationally. Just as importantly, harmonization supports the broad-

er national objective Canada is pursuing in many areas. Rigging may be a specialized field, but it sits at the centre of the construction economy.

A practical path forward for Canada Canada’s decentralized OH&S model does not prevent harmonization. It simply requires a practical approach.

Step one is to recognize a national reference point. Provinces can adopt guidance by reference without rewriting entire regulations. This is a proven model in other sectors, where a national reference document becomes the common baseline and jurisdictions adopt it in whole or in part. Step two is collaboration. A cross-provincial working group, bringing together regulators, technical experts, industry associations, and end users, can drive consistent terminology, consistent criteria, and consistent interpretation. Step three is the alignment of referenced standards. Where provinces point to ASME or other standards, they should reference the same editions and updates on a predictable schedule. Out-of-date references create uncertainty and undermine enforcement. Step four is training alignment. Training providers, crane programs, and employer competency systems can adopt harmonized guidance quickly, building consistency from the ground up even before regulations evolve.

The time for action is now. Canada is moving through a period where harmonization and alignment are being recognized as practical tools to improve safety, efficiency, and mobility across industries. Harmonization will not eliminate provincial autonomy, and it does not require a slow political process. For crane owners, contractors, and working crews, the payoff is real: fewer inconsistencies, clearer expectations, better training, and ultimately safer lifting. That is a future worth building.