The Reality No One Talks About

Why do many RAS projects fail to meet projections?

Very few fail from visible system breakdowns. They fail in the numbers. In the quarterly reports. In the projections you can’t meet due to slower growth, weak FCR, chronic mortality, and delayed harvests.

"Adequate" oxygen is costing you growth.

Not low oxygen. Not system failure. Adequate. The kind of conditions most operators assume are fine. Fish can’t breathe bubbles. Not microbubbles. Not nanobubbles. They breathe bio-available dissolved oxygen.

The cycle you're stuck in.

Fungal treatments. Chemical interventions. Taking fish off feed to treat them or to let water quality catch up. Each cycle delays time to market. Each delay compounds the financial gap.

What Changes When Water Quality Actually Works

Introducing the GasXchanger Technology from Aqua Production

The GasXchanger creates bioavailable and fish-friendly oxygen environment, supporting:

Faster Growth

Fish reach market size sooner

Better FCR

Energy shifts from respiration to growing biomass

Safe Hyper-Oxygenation

High DO with safe TGP...even with onsite generation!

Free Assessment

Scan to find out which water quality factors are limiting your farm's performance.

Systems

Healthier Fish

Less stress, less fungal treatments, less time off-feed

70% Lower Mortality

Fewer losses during critical transitions

Predictable Time to Market Growth projections become reality

COLUMNS

8 | The Fish View

The culture tank is where it all happens 38 | Fresh Tips

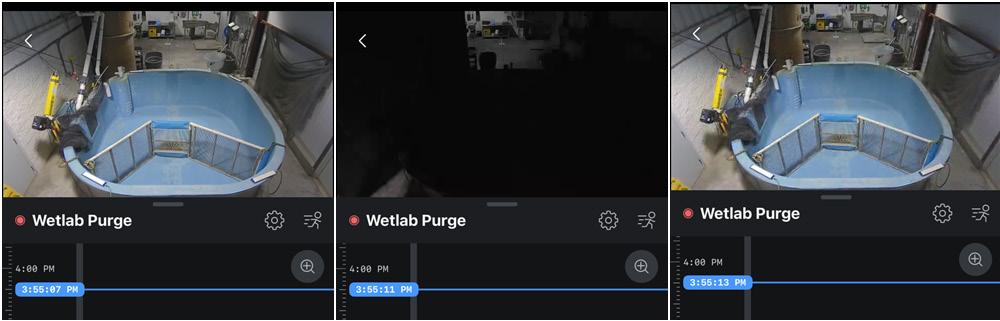

Predictive management made simple through remote monitoring

Haley Rutger, Mote

From the editor

By Jean Ko Din

Expanding our horizons

We are officially taking RASTECH Conference & Trade Fair on the road! Or should I say, across the sea?

If you haven’t heard yet, we’ve officially announced RASTECH Europe which will take place on Sept. 7-9 in Porto, Portugal this year. This is exciting news for many reasons and I hope to share some of our team’s thoughts through this editorial. But, the first thing I’d like to share is that the idea of bringing RASTECH to Europe (and beyond) has always been our ambition. Part of being a global brand is about meeting our audience where they are at and then, being a champion for its growth and progress.

But, as many of you who have developed RAS projects from concept to design to pilot to commerical scale know all too well, we couldn’t expand before we were ready.

When Annex Business Media first launched the conference in 2019, the idea was to bring the international aquaculture community to the budding land-based sector that was starting to buzz in North America. Recirculating aquaculture systems technology was seen as the next frontier in our pursuit to feed the world with nutritious and sustainable seafood.

Today, the annual RASTECH Conference & Trade Fair is the international networking hub that we dreamed it to be. Every year, we welcome about 300 recirculating aquaculture professionals – operators, engineers, researchers, technology providers, investors, regulators, and more – from 15 different countries to share knowledge about the challenges and opportunities that this technology brings.

We talk about market development and deal flow. We talk about ongoing research in fish health, welfare and biosecurity. We talk about the newest technology and engineering innovations that are making land-based technologies even more flexible and efficient.

So much has already happened in these past seven years, not just for our flagship event, but within the global industry we serve. All we’re

doing is trying to grow with it.

So, why go to Portugal? Besides the idyllic landscape of Porto in autumn, our team has always liked the idea of being able to go to our European community. It’ll be a smaller, more local conference that will value more intimate networking experiences.

In developing ideas for the new conference’s program, I’ve been reflecting on deeper explorations on topics make the RAS industry in Europe unique. My initial thoughts would be to have a more detailed look at the growth of smolt and post-smolt production on land. I want to explore the progress being made in Norway, Denmark, Iceland, and the Faroe Islands around this sector.

I want to explore RAS species beyond salmonids that are being produced in the Iberian peninsula versus in the Balkans, in Scandinavia versus in the Baltics, the Alpine region versus the Mediterranean. I’m sure I’m leaving other regions out. But, this is just to say there’s so much potential to explore the unique characteristics of these markets and how land-based technology can bring new aquaculture opportunities there.

And while I’m at it, I’d love your input on this as well, dear Reader, so that we can best serve your own interests. Let’s dream big! Where in the world can we go next?

In Annex Business Media, we talk all the time about being bold and trying new things across more than 60 publications for a variety of B2B industries. Here at RAStech Magazine, this may just be the beginning of what we have in store for you this year. Watch out for our other aqua publications, Aquaculture North America and Hathery International, too. You’ll never know where the next RASTECH-size idea will come from.

We hope to share more as we get further into the development of this conference. You can stay tuned for any updates by subscribing to our free weekly newsletter, checking our website, or following our social media.

And of course, you know how to reach me at jkodin@annexbusinessmedia.com.

Reader Service Print and digital subscription inquiries or changes, please contact Angelita Potal, Audience Development Manager Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Sales Manager Patrick Villanueva 416-606-6964 pvillanueva@annexbusinessmedia.com

Account Coordinator Barb Vowles 416-844-7106 bvowles@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

Subscription Rates Canada – $38.48 (+tax) United States – $49.92 CAD Foreign – $64.48 CAD

All prices are for a one-year subscription and in Canadian currency.

ISSN 2817-7266 - Print ISSN 2817-7274 - Online

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2026 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Made possible with the support of rastechmagazine.com

Argentinian province’s new aquaculture law promotes RAS

Tierra del Fuego, Argentina’s southernmost province, has passed a new aquaculture law that aims to develop its fish farming industry while prioritizing the environment and domestic consumption.

The new law will return salmon farming to the region after a four-year ban, however, maintains the ban on industrial salmon farming in the Beagle Channel.

The province said a highlight of the legislation is encouraging innovation, product diversification, and incorporation of technologies with low environmental impact, such as recirculating aquaculture systems (RAS).

“Fuegian aquaculture is not a risk: it is an opportunity for sustainable development, traceable and under public control,” Diego Marzioni, Undersecretary of Fisheries and Aquaculture, said in a translated news release. “Tierra del Fuego does not renounce its natural heritage: it turns it into knowledge, employment and local added value. Producing while taking care of the sea and water resources: that is the synthesis of the Fuegian model of sustainable aquaculture.”

Marzioni said the new law will incorporate environmental assessments for each project to balance science, production and the environment.

SmartGreen opens India’s first tropical RAS

SmartGreen Aquaculture’s commercial-scale tropical RAS facility and research institute was inaugurated by Indian government officials on Jan. 4.

The rainbow trout aquaculture farm in Telangana is India’s first tropical RAS-based facility. The government called it a “watershed moment in the evolution of Indian aquaculture.”

The company said this RAS project could demonstrate that high-value coldwater species can be farmed year-round in tropical climates.

The facility will also function as a live training and demonstration platform for advanced aquaculture systems, automation, and biosecurity.

“This achievement overturns long-standing assumptions that premium aquaculture species are geographically constrained to specific climatic zones, and it establishes technology – not climate – as the primary determinant of aquaculture viability,” the release said.

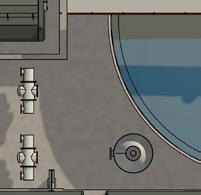

PHOTO:

SmartGreen’s rainbow trout hatchery room finished

Norway’s Bue Salmon is now under construction

Groundwork has begun on what is expected to become Norway’s largest land-based salmon farm.

Bue Salmon, the Norwegian company behind the project, announced in January the beginning of preparatory groundwork at their site in Lutelandet, an island in western Norway.

Bue is collaborating with aggregate company Kvantum AS on the groundworks. Kvantum is managing the entire value chain of the rock materials from extraction to sale.

“Today marks an important step forward in this collaboration,” Bue CEO Knut Eikeland said at the breaking

ground ceremony on Jan. 6. “We are now physically underway at Lutelandet. This enables Kvantum to extract the rock, process it to customer specifica-

tions and ship it onwards for sale in the international market. The plan is for the first vessels carrying rock to depart from the dock here within the first quarter.”

Innovation Beyond Measure

Results Beyond Expectation

The Fish View

By Bendik Fyhn Terjesen

Bendik Fyhn Terjesen, PhD is head of Land-based Innovation in Cermaq Group, where he works with the regions to build new infrastructures and improve operations to give the fish a safe start in life. He has an extensive research background in fish physiology, nutrition, and RAS, and is adjunct professor at Nord University in Norway, where he teaches aquaculture technology. (bendik.fyhn. terjesen@cermaq.com)

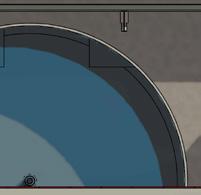

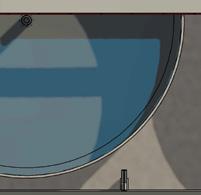

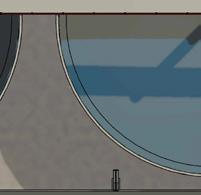

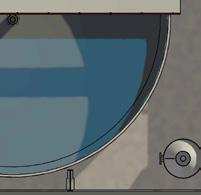

The culture tank is where it all happens

The culture tank is not just a tank, it is the home of the fish and the center of production.

Years ago, RAS suppliers did not include tanks in their scope, which was always surprising to me since it is where it all happens and must be the center of attention. Luckily, this has changed and the culture tank has numerous requirements to fulfill in landbased facilities.

A well-designed tank provides ample three-dimensional space for the fish, is devoid of non-critical equipment, ensures sufficient water flow for supplying oxygen, swimming exercise, sensory stimuli for the fish, and light to control biological processes.

These are demanding and complex tasks, and in this issue of The Fish View, I briefly describe some of the requirements.

The tank set-up

Land-based tank volumes continue to increase. We are now seeing 2,000 m³ tanks are common and sometimes, even 5,000 m³ tanks appear.

The tank set-up must be intimately linked to the production plan over the entire value chain. In traditional salmon farming, there used to be a clear division between the smolt facility and sea cages, with little collaboration. However, this has changed dramatically, partly due to the postsmolt strategies being implemented in most companies.

Nowadays, the focus is on reducing costs, production time in sea, disease risk, sea lice treatments, and improving sea license utilization. The sea cage production plan is therefore made first, and then the work starts to find the supporting tank volume and tank numbers in the land-based facility. The resulting land-based production plan must fit the sea-cage part of the company, in a “pull” and not “push” fashion. Therefore, a tank can be required to accommodate 200,000 one-kilogram post-smolts, to stock one cage

and there must be several such tanks of evenly graded fish to stock an entire sea location within the allotted time window.

I often hear that no production plan survives the first days of real production. The goal must therefore be to design a highly flexible tank set-up, i.e. volume and numbers, which can accommodate many scenarios such as changing harvest plans or stocking plans to sea, delayed wellboat arrival, and lower (or higher) growth rates than expected.

In Cermaq, we attempt to build this flexibility in our facilities by using specialized dynamic simulation software. We first build a simulation model of the sea-based production plan, which then pull the flow of fish groups through the land-based facility. Subsequently, we use AI algorithms to search for the combination of tank numbers and volumes which most efficiently meet production requirements, in several scenarios including storms delaying wellboats and blocking transfer to cages, varying growth rates, and more.

Design for optimization

After the overall tank set-up has been decided, dimensioning and design must accommodate the maximal load situation.

Usually, but not always, maximal load occurs when the fish reach maximum weight, before transferring to the next department, to harvest, or transport to the wellboat. The deciding factor for tank flow (m³/hour) at the maximal load situation is often CO2 production and removal, to maintain CO2 concentration acceptable for fish welfare (<12 mg/L in Cermaq). Subsequently, the number of water inlets, nozzles, their orientation, and design and dimensioning of the drains must be decided to handle the flow and other requirements.

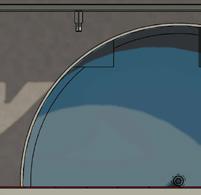

Computational Fluid Dynamics (CFD) are simulations of fluid flows, such as hydrodynamic properties in a fish tank, the water velocity, turbulence, residence time, energy dissipation, self-cleaning, and water quality.

The simulations can be useful to identify problems, such as turbulent vortices in the tank which can be harmful to the fish, and how to place and orient the inlet(s) and drain(s) to avoid such challenges and ensure self-cleaning and sufficient water velocity.

However, CFDs must not be used as the ultimate answer, because they will just approximate the real-life situation. Therefore, the models must be verified and calibrated with actual water velocity measurements, preferably with acoustic Doppler velocimeters.

Water velocity calculations

In Cermaq, we use CFD services for several tasks when planning a new facility or evaluating conditions in existing plants. One important outcome is to find the water inlet impulse force which results in sufficient velocity for fish exercise. Swimming exercise positively influences several physiological processes in salmonids, such as growth rate and disease resistance.

We aim for 1.0-1.5 body lengths per second water velocity, based on several research projects. However, the water velocity must be increased gradually since after transferring into a tank, the fish can be sensitive and affected by high water velocity. Hence, the inlet pipes, which can be huge in large tanks and are often placed out of reach, should be equipped with motors to adjust inlet angle and water velocity.

To arrive at the correct tank inlet impulse force, the fish itself must be accounted for because at common densities they significantly reduce water velocity, with 1/3-1/4 compared to a tank without fish. Hence, the water velocity target in a tank without fish must be correspondingly higher, by optimizing the inlet jet angle(s), or using nozzles that can be individually adjusted, and/or reducing nozzle diameter, which may require pumps giving the same flow at higher pressure.

However, when varying such properties sufficient self-cleaning must still be kept so

no feed or fecal matter sediment, which can have disastrous consequences for water quality. In practice, the final tank design is therefore a compromise made between several important criteria.

Not only do the fish brake water velocity, they also change the velocity distribution and contribute to tank mixing. Unfortunately, today CFD’s cannot accurately model such impacts on the tank flow field of each fish which are present at huge numbers (e.g. 200,000) in commercial tanks.

However, if the fish are incorporated the hydrodynamic predictions will likely be improved. Another challenge today is that the time-duration of simulations is short, but it is instructive to view simulations over longer time than just a few seconds, since in my experience it takes several tank turnovers for effects to manifest in the flow field, of changing flow rates and inlet orientations.

Still, much exciting R&D is ongoing in the field of tank hydrodynamics, and I believe we will soon see better models for aquaculture, incorporating the fish itself. Recently,

Gorle et al. presented a study at Aquaculture Europe 2025 in Valencia, indicating how the future can develop.

Using tank hydrodynamic models, fish distribution and respiration models incorporating swimming speed effects, they simulated how the oxygen concentration varies throughout the tank depending on inlet water impulse force and orientation. Such models can assist in achieving water quality but also limit the gradients (variability) in water quality throughout the tank, thereby increasing the effective tank volume with optimal conditions for the fish.

Plan ahead

If the salmon industry continues to grow, I think tank volumes will keep increasing, but the ideal scale for each life stage is not known. Large tanks bring new challenges, such as difficulties in achieving even feed distribution, light coverage, and self-cleaning. It is then even more critical to develop CFD’s to optimize hydrodynamics, and test equipment at relevant scale, since cor-

recting huge tanks already built is demanding.

Fish welfare must be the main target, and I think we will see welfare innovations also inside the tank, such as environmental enrichment. Several tank enrichments have been studied in fish, such as sensory (e.g. current, bubbles) or structural stimuli (e.g. stones on the bottom), which improve cognitive abilities, increase exploration by the fish, and lower metabolic rate.

Combining a more stimulating environment for the fish, with better control and prediction of the flow field will ensure that tomorrow’s culture tank meets the criteria for fish health, welfare and performance.

References cited:

Gorle J, Gorle A, Terjesen BF (2025). Ensuring optimal water quality in RAS engineering using high-fidelity modeling. In Aquaculture Europe 2025 Abstracts, pp. 724, Valencia, Spain. Sept. 22-25, 2025.

Efficient, Sustainable Air Solutions for your Recirculating Aquaculture System (RAS)

Clean, reliable air technology designed for modern land-based aquaculture about efficiency and protecting fish health www.aerzen.com/ca-us-aquaculture

Clean, stable aeration for biofilters and CO2 stripping, protecting fish health in high-density RAS. High-efficiency blowers built for 24/7 operation, lowering energy use and reducing long-term costs. 160 years of proven worldwide expertise, delivering reliable performance, system stability, and support wherever you operate.

Growing Florida ’ s food system

How

Marine Lab harnesses RAS to support food production and more

By Treena Hein

RAS activities at Mote Marine Laboratory in Sarasota in Florida, USA are a little unusual – and a little amazing.

Here, the recirculating aquaculture system (RAS) doesn’t just support aquaculture for food production. It’s also being harnessed in innovative ways to help improve the environment, protect livelihoods and enhance the recreational activities of people living in this coastal area.

The Lab’s Mote Aquaculture Park (MAP) is situated on a 200-acre campus about 20 miles from the coast. In various buildings that cover about 15 acres of the site, state-of-the-art research is carried out in pilot-scale and commercial-scale aquaculture systems. Director of Fisheries & Aquaculture Nicole Rhody explains that over the last few decades at spawning and rearing technologies have been developed for farming a wide range of species, including Pacific black snook, common snook, mullet, Florida pompano, southern flounder, greater amberjack, red drum, and red snapper.

MAP has a variety of RAS for breeding and rearing marine fish from egg to market size. All of MAP’s RAS and aquaponics systems are marine systems, with a variety of salinities available. In addition, MAP has partnered with other public and private entities such as Georgia Aquarium to explore growing sustainable feeds for their living collections including mullet. Mote also partners with University of Florida IFAS Extension Sarasota County for the Beginning Farmer Education Program, which includes crop/livestock agriculture and fish farming pathways. Five participants have completed the aquaculture pathway so far.

All this aside, Rhody stresses that in recent years, MAP has striven to become – and has succeeded – in serving as a strong regional aquaculture business

incubator hub, helping companies understand the technologies and the biological systems that will get their ventures off the ground or make them an even-bigger success.

Red drum’s multi-faceted success

MAP’s biggest business incubator success to date centers around a fish called red drum. Pine Island Redfish, co-founded by Megan and Tom Sorby, spearheaded red drum farming in Florida, and MAP is currently home to the company’s first production site.

Mote Aquaculture Park partners with industry and research professionals around the world to advance

Mote

The company recently released results from its 2025 production, where they exceeded production targets by 35 per cent and achieved record feed conversion and growth. Their product has achieved strong distribution and sales, positioning them for their next expansion to a second site. “It has been critical for us to have business incubation space to demonstrate our team, our fish and our technology can deliver on all metrics,” said CEO Megan Sorby. “Expansion onto our Pine Island site in the coming months is the result of these initial production years.”

But fish production aside, the company also has big regenerative ambitions and has made great progress already. In

short, in an aquaponics manner, all of the waste nutrients from the fish are processed into fertilizer for growing mangroves and other salt-tolerant plants for restoration of coastal areas.

“So, not only is Pine Island filling an important gap in the U.S. seafood market,” says Rhody, “but it’s also building on preliminary research MAP performed years ago into repurposing its nutrient waste, both solid and dissolved.”

It’s been really exciting for Rhody and others to see Pine Island Redfish grow so much and achieve strong market success across food service and retail across the country, while also making a really meaningful contribution to the

sustainable recirculating aquaculture technologies. PHOTO: HALEY RUTGER, MOTE MARINE LAB

mangrove ecosystems along the coast.

“Their operations in 2025 have resulted in restoration of over 5,000 mangroves and the growth of over 30,000 mangrove seedlings in their nursery,” she adds. “Many of these seedlings are ‘planted’ by volunteers.”

In the same vein, Rhody also points to the integration of multi-trophic recircu -

lating aquaculture systems (MT-RAS), which have emerged as an innovative way to enable intensive production of fish and plants, recycling nutrients and water, and improving fish yields with relatively little effort.

“Supported by outside funding, in recent years, an MT-RAS system was successfully operated at MAP under

LONG-LASTING AQUACULTURE PUMPS

various temperature and salinity conditions, using periphyton, seaweed (Ulva), and a halophyte called sea purslane as biofilters,” Rhody explains. “These biofilters removed and recycled N and P very effectively, enabling the intensive production of red drum at a stocking density of 100 kg/m³, with minimal water and space requirements.”

Specialists in corrosionresistant, reliable and stable propeller pumps, with high uptime and low energy consumption.

Mote researchers worked with shellfish farmers to develop a ‘wet storage’ RAS solution to purge clams affected by red tide season in Florida’s Gulf Coast.

The research also provided extensive knowledge regarding the dynamics of plant-associated microbial assemblies in terms of compositional and functional structure, networking and resilience, says Rhody, as well as their associations with plant growth and nutrient removal performance. “Currently, we are further evaluating the potential of these biofilters in mitigating fish pathogens and off-flavor-producers in MT-RAS in the U.S. and Israel,” she reports.

Problem solving for shellfish

MAP has also completed an applied RAS project to help the state’s shellfish farmers.

The shellfish industry has declined significantly over recent decades along Florida’s Gulf Coast due to Florida red tide. Shellfish farmers are legally required to close their harvest areas when red tide cell counts reach a specific threshold (when the toxin level in the shellfish meat becomes a food safety

risk). But with other stakeholders, Rhody and her team have solved this problem.

“We looked at whether these shellfish can be harvested quickly when a red tide hits and placed in a ‘wet storage’ RAS system to flush out the toxins,” she explains. “Working with industry and government regulatory folks, we developed a system which successfully allowed for the purge of up to 30,000 clams in under 72 hours. The level of

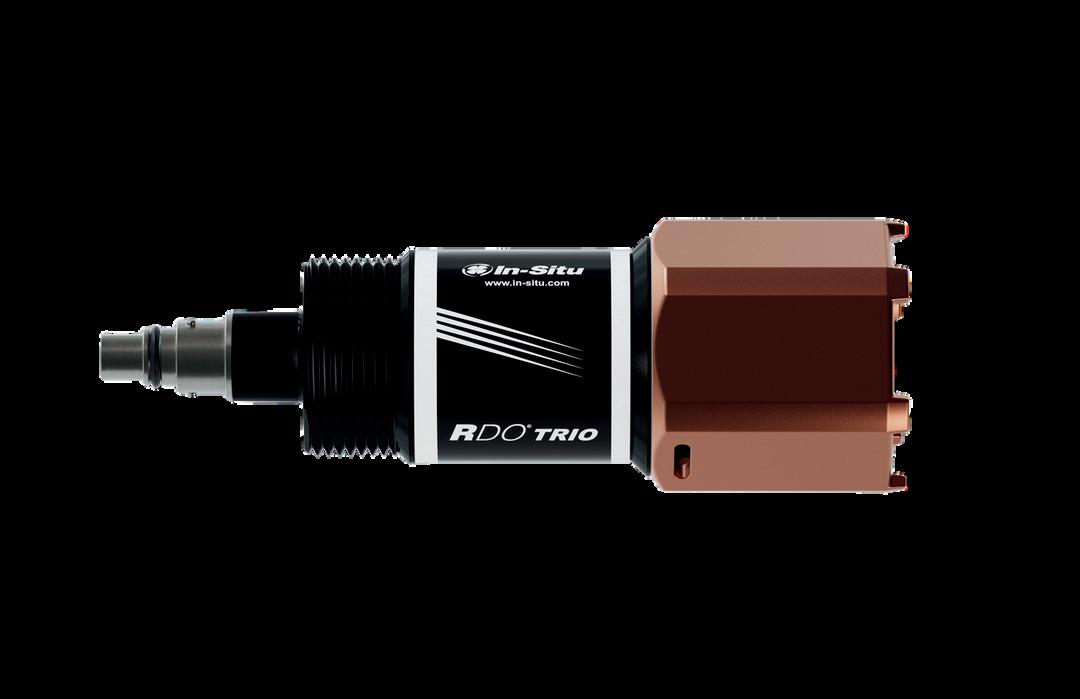

PRECISE DISSOLVED OXYGEN CONTROL

DGI technology uses a proprietary method to infuse gases into liquids, maximizing oxygen efficiency for aquaculture applications. Potential benefits include:

Mote Aquaculture Park hosts a tour of the mangroves greenhouse that is being fertilized by RAS wastewater.

brevatoxin was reduced from 5.4 to 0.2 ppm, so the RAS system performed well. We hope to see this technology to help combat the economic challenges red tide brings to the shellfish industry.”

Best way forward

It’s, therefore, no surprise that in Rhody’s view, the growth of RAS projects in the region is best supported going forward through further business incubator activities.

“In particular, we believe aquaculture businesses that combine food production with restoration activities are smart, with the stability of a dual-revenue stream,” she says. “These operations are also a good news story about giving back. People still have a lot of questions about aquaculture, is it safe, is it sustainable, and combining food production with restoration helps people see that aquaculture is both. It’s a win for food production and for the community and the environment.”

Indeed, Sorby views the restoration aspect of her business as critical to its long-term industry impact.

“We want to be the catalyst for all aquaculture delivering on the environmental good the farming of aquatic foods can achieve,” she explains.

“But we cannot do this work alone. We have built a network of partners and volunteers who dedicate their time to planting and maintaining these mangroves with us. The unexpected result of this has been the opening of communication between

us as fish farmers and community members who do not know our space. They feel comfortable asking us questions, and we can provide real transparency to aquaculture practices, instilling greater public trust. That is the real power of operating with environmental stewardship as a pillar.”

Rhody also wants to stress that now is the time when years of RAS research should be translated quickly into viable commercial seafood production.

“Despite aquaculture being the fastest growing food production sector globally for the past three decades, U.S. production still lags behind this global rate of growth,” she says.

“One of the ways we can help is to support companies which implement technology to demonstrate aquaculture development in this country can lead the world in regenerative practices. We are primed to be an example of protein production that provides for stability and resiliency in our coastal communities.”

She believes that as a research partner, MAP can continue to support research & development that collaborates with companies so that they grow sustainably and efficiently.

“We also hope that our work with responsible companies can assist in bringing capital into the private sector,” Rhody says. “Knowing that new companies have a pathway or research partner contributing to continuous improvement of production should inspire investor confidence and help achieve the growth we need in the U.S. seafood sector.”

•A RASTECH SPONSOR SHOWCASE•

SMART DESIGN IS RELIABLE DESIGN

Reliable blowers are the ‘lungs’ of any RAS operation

Aeration, the process of dissolving oxygen into water and removing excess carbon dioxide, is a critical component of a recirculating aquaculture system (RAS) operation. The continuous and reliable performance of air blowers is essential in maintaining water quality and ensuring fish health is a RAS facility. Failure of an aeration system could mean loss of fish population in just 30 minutes or less.

“You can’t afford to make a mistake in your choice of blower system,” says Kyle Zheng, regional sales manager for Aerzen Canada Inc. The company is a North American arm of the German-based Aerzen Group that has been making high-performance machinery for air and gas handling for more than 160 years.

LUNGS OF A RAS OPERATION

“Air blowers are the lungs of a RAS operation,” according to Zheng. “Since 1864, we have been focusing basically on one thing – making air blowers, and we’re really good at it.”

Air blowers are needed to deliver a constant supply of dissolved oxygen to sustain beneficial aerobic bacteria in the biofilter that break down fish waste.

Proper aeration helps remove from the RAS harmful gases such

as carbon dioxide, ammonia and hydrogen sulfide.

Blowers also create that stream of bubbles that distributes oxygen throughout the tank and prevents the creation of oxygen starved areas called “dead zones.”

RIGHT SIZE AIR DELIVERY

Despite their importance, it is not unheard of for RAS operators to get their air delivery system wrong, according to Zheng.

Among the common pitfalls include incorrect air flow rates that result in not enough carbon dioxide being dispelled; operating blowers beyond their capacity; incorrect sizing of blowers and diffusers, which lead to inadequate oxygen transfer; poor piping layout which forces the blower system to work harder.

“We see a lot of wrong sizing in the industry. This means RAS facility owners are not getting the most out of their air delivery system or worse they are risking catastrophic failure,” explains Zheng. Air blow-

ers and water pumps can account for anywhere from 40% to 60% of a RAS facility’s energy consumption. This is why efficient system design is important for operators that want to cut expenses and reduce their impact on the environment.

Aerzen offers a range of energy-efficient, oil-free air blowers to meet the varying demands of aquaculture. The company’s fully engineered PD blower package – Delta Blower Generation 5, for example, is ideal for applications requiring low maintenance and easy installation.

Aerzen’s screw blower design, the Delta Hybrid combines positive displacement and screw compressor technology for a wide control range and energy savings based on a highly efficient design. Aerzen’s Turbo blower is a maintenance-free, plug-and-play system for medium to large RAS applications.

These easy-to-operate packages are backed by an extensive technical support network that spans the globe.

Above all Aerzen blower’s focuses on fish health.

“Our air delivery systems deliver air that is 100% oil-free. This protects the biofilter and fish health. These systems produce regular and stable flow rate and pressure which reduces stress to the fish,” says Zheng.

WELCOME I Solutions in RAS

Welcome to the fifth edition of Solutions in RAS, RASTECH’s annual resource guide produced in collaboration with our trusted brand partners in the Recirculating Aquaculture Systems (RAS) sector.

In this year’s edition, we share technical insights from landbased aquaculture experts in Norway, Canada, and the USA, covering everything from design and engineering to tank construction, pumping solutions, and smart system technologies.

We also feature our popular Executive Insights pages. This year, we asked industry leaders: “Where do you see the greatest unmet needs in RAS that suppliers should be solving next?” The question generated thoughtful and engaging responses that we’re sure you’ll find valuable.

At RASTECH, we remain committed to supporting industry progress - whether by sharing knowledge and ideas at our events or through our digital and print media. As the sector continues to evolve, we’ll be here to bring you the latest news and developments.

A big thank you to the sponsors featured in this year’s Solutions in RAS supplement, and to you, our readers, for your continued support.

Jeremy Thain Associate Publisher - Aquaculture Division

Annex Business Media jthain@annexbusinessmedia.com

THANK YOU I TO OUR SPONSORS

MODULAR RAS CONCEPT CUTS COMPLEXITY, BOOSTS EFFICIENCY

Soaring cost of production, potential system failures, and fish health hazards are among the top issues that keep many recirculating aquaculture systems (RAS) operators awake at night.

This is where a standardized, modular RAS that is simple to operate and designed for optimal biosecurity and water quality control can be of help.

One company that offers such a solution is Nofitech AS. The Norway-based fish farming technology firm established in 2011 has been refining its ModulRAS technology for over a decade now. The company delivers turnkey contracts in the

North Sea basin and its engineering, procurement and academy contracts to the rest of the world. Nofitech RAS solutions are now deployed not only in Norway but are also being used at facilities in Faroe Islands, Scotland, and Japan.

“Nofitech aims to deliver good production systems that are easy to operate and nice to work in. We offer modularized RAS and hybrid systems for all stages of production of salmonids with fresh, brackish and seawater,” says Kari Johanne Kihle Attramadal, head of research and development and chief science officer at Nofitech.

“Nofitech’s mission is to enable fish farmers to produce healthier fish with fewer resources, helping address the global challenges of future food production,” according to Attramadal. “At the core of this mission lies a strong focus on fish health and growth.”

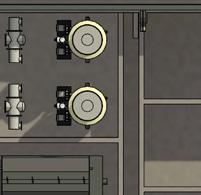

MODULRAS

The ModulRAS and Hybrid modul system provides solutions for smolt, post-smolt, grow-out and broodstock stages.

The company’s concept is based on standardized, prefabricated modules made up of four octagonal tanks built around a

PREDICTIVE ANALYTICS

Nofitech also offers a data collection and analysis system that enables RAS operators to proactively minimize risks. The company’s Mime system, named after a Norse god known for his wisdom, collects, monitors and process facility data.

“Mime also supports operators by providing interactive advice and early warnings as situations develop, helping operators take the right steps at the right time. Mime enables more efficient operational optimization, stronger risk control, and safer utilization of the production systems,” says Attramadal.

TRAINING AND RESEARCH

shared water treatment, explains Hogni Lauritsen, chief operating officer for Nofitech.

“ModulRAS is standardized but flexible. The system can be scaled up or scaled down to meet the user’s needs,” he says. “Our patented design uses short pipelines that take up less space, is cost-efficient, consume less power, and employs renewable energy strategies.”

For instance, a facility in the Faroe Islands uses a Nofitech solution that recovers heat from compressors and reuses it to heat intake water for both fish production and domestic water.

Nofitech invests in continuous innovation, training, and support to help fish farmers gain control, minimize risk, and optimize production. An important part of this is the company’s Nofitech Academy which provides a comprehensive training and support program for managers, operators and anyone using Nofitech products. The model fosters strong bonds between Nofitech and its customers. It also provides the company with a deep understanding of its customers challenges and paves the way for continuous improvements of Nofitech’s products and services.

To improve resource efficiency in production, Nofitech is working on technology that will convert wastewater nutrients into sustainable raw materials.

Nofitech’s Wasteless reactor project focuses on treatment of RAS wastewater, produce microalgae and other microorganisms in bio -

film that can be harvested and used as feed ingredient or fertilizer.

The company is also working on degassing solutions.

“One of the bottlenecks for production and growth in closed systems is CO2. We are developing technology that improve CO2degassing from the production water to increase production capacity, fish welfare and growth,” says Attramadal.

PRECISION FEEDING

Nofitech has also developed a practical sensor for feed detection with real-time data interpretation that can be used in appetitecontrolled precision feeding. “Feed is typically the largest contributor to production costs for RAS,” Attramadal says. “Improved feeding reduces feed waste and improves water quality, translating to better fish welfare, feed conversion ratio (FCR), and growth.”

THE SOLUTION

Patented scalable, modular RAS and Hybrid systems

Easy-to-use system backed by comprehensive customer training and support program

Predictive analytics-driven facility management controls.

CONTACT INFO

Kari Johanne Kihle Attramadal, CSO +47 984 71 328 | kari@nofitech.com

REDUCING ENERGY USE AND OPERATIONAL COMPLEXITY IN AQUACULTURE

As recirculating aquaculture systems (RAS) scale to meet growing global demand for landbased fish production, operators face a common challenge: how to maintain stable water quality while controlling energy use, maintenance requirements, and system complexity. While filtration, monitoring, and feeding technologies have advanced rapidly, water circulation and aeration remain among the most energy-intensive and maintenance-heavy components of modern RAS facilities.

FloNergia is addressing this challenge by re-engineering a familiar concept, the airlift pump, into a modern, high-performance solution designed specifically for the operational realities of RAS.

“In RAS, water movement and oxygen transfer are essential. Treating them as one process opens the door to major efficiency gains.”

RETHINKING CIRCULATION AND AERATION IN RAS

Most RAS facilities rely on centrifugal or axial pumps to move water, combined with separate aeration or oxygenation systems to maintain dissolved oxygen levels. While effective, this approach increases electrical demand, introduces multiple mechanical components, and adds maintenance points that can impact system reliability.

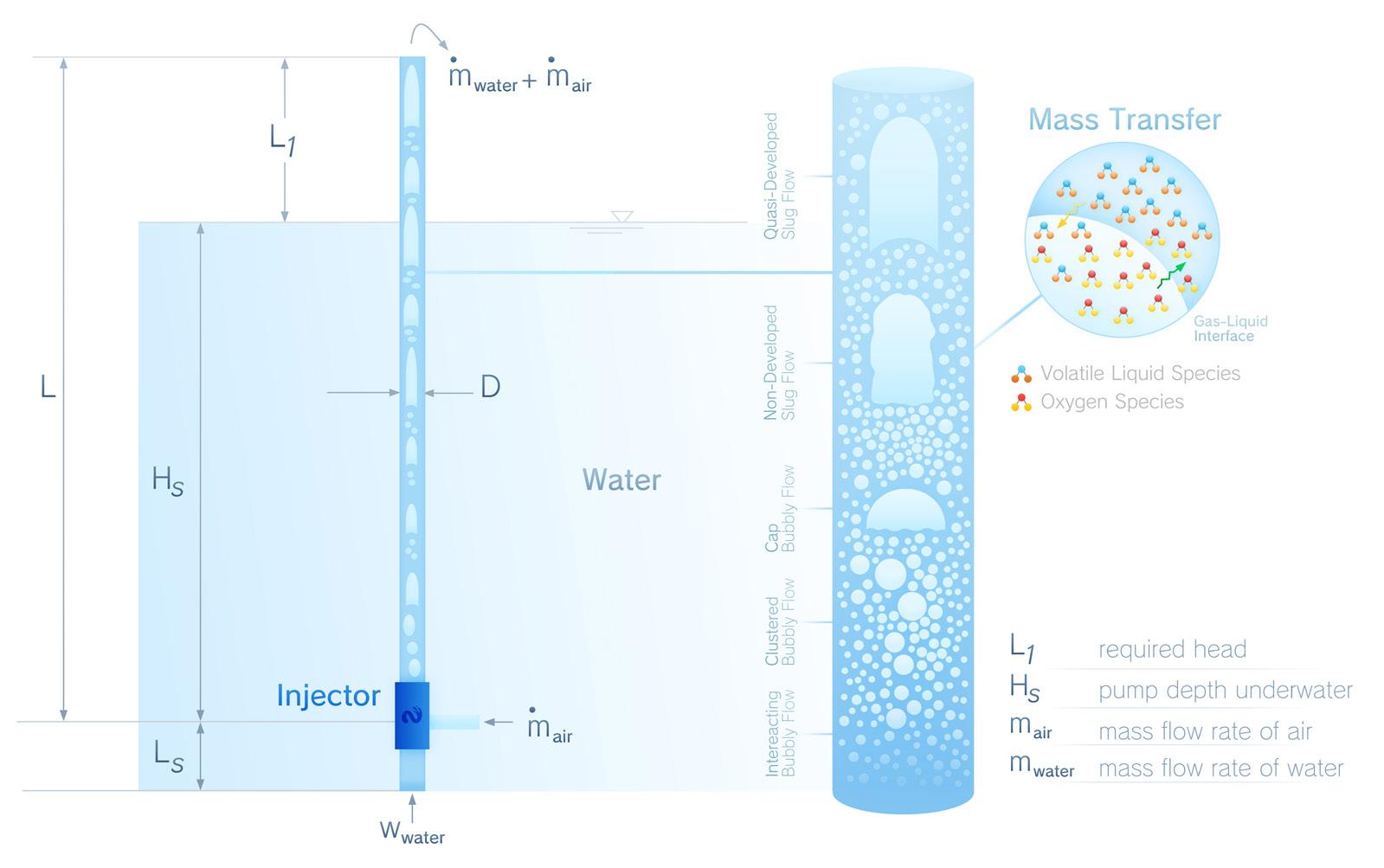

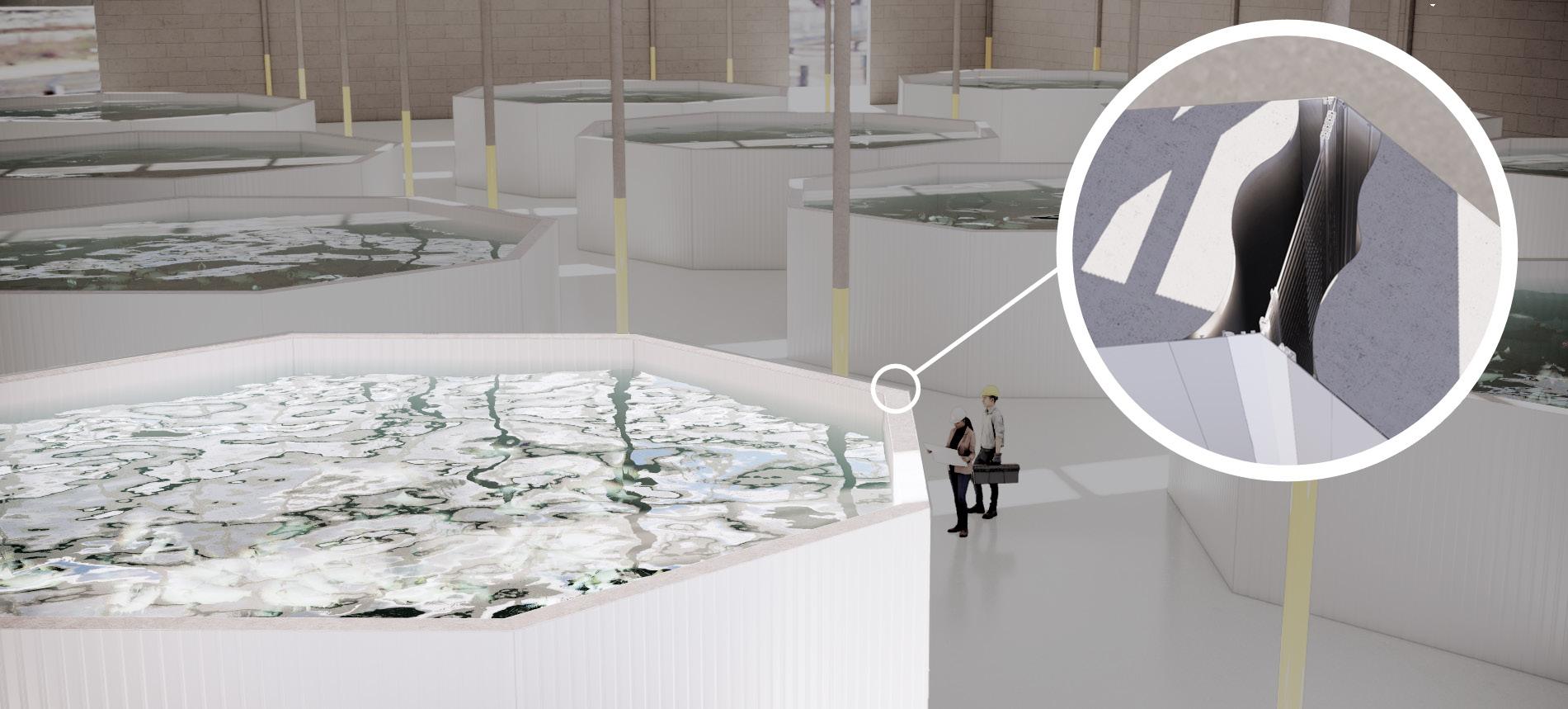

FloNergia’s FloMov™ technology integrates circulation and aeration into a single process (Figure 1). Instead of using mechanical impellers, the system injects air into a submerged riser, lifting and circulating water while simultaneously transferring oxygen. By eliminating submerged moving parts and combining functions, the system reduces both energy consumption and mechanical complexity.

FROM CONCEPT TO THE FIRST ENGINEERED AIRLIFT PUMP

Traditional airlift pumps have been used in aquaculture for decades, but their adoption in RAS has been limited by low efficiency and

poor predictability. FloNergia’s approach transforms the airlift pump into a fully engineered device.

Developed through more than three decades of research in multiphase flow and gas-liquid transport, the FloMov pump is designed around optimized fluid dynamics and mass transfer processes through the pump, submergence ratios, controlled airto-liquid injection, and refined internal geometry (Figure 2). These parameters allow operators to accurately predict water flow rates and oxygen transfer performance – critical for stable RAS operation.

The result is a no-movingparts pump capable of delivering high-volume circulation at low head, while reducing energy use by up to 50-70% compared to conventional pump-and-aerator configurations.

“By engineering the airlift process itself, we can deliver predictable flow and oxygen transfer without mechanical complexity and with less energy.”

DESIGNED FOR REALWORLD RAS OPERATIONS

RAS environments are unforgiving. Pumps must operate continuously, handle suspended solids, and maintain consistent performance across changing biomass loads. FloMov pumps are built to meet these demands.

With no mechanical components submerged in water, the system resists clogging, corrosion, and wear – common causes of downtime in traditional pumping systems. The gentle upward flow generated by the airlift action helps suspend and transport solids, supporting downstream filtration and reducing waste accumulation in tanks.

At the same time, continuous aeration increases dissolved oxygen levels while stripping excess carbon dioxide, supporting fish health, feed conversion efficiency, and overall system stability. The technology is scalable, with pump sizes suited for hatcheries, grow-out tanks, and large commercial RAS installations.

ADDING AI-DRIVEN INTELLIGENCE WITH FLOSYNC™

As RAS facilities become more data-driven, static pump operation is increasingly limiting. FloNergia’s FloSync™ technology builds on the FloMov platform by introducing real-time intelligence and adaptive control. FloSync is an AI-powered digital twin that integrates sensor data –including temperature, dissolved oxygen, carbon dioxide, and ammonia – to continuously assess system conditions. Based on this data, the platform dynamically

adjusts air injection timing and volume, optimizing circulation and aeration in response to real-time needs.

This predictive approach allows RAS operators to move beyond reactive management, maintaining stable water quality while minimizing unnecessary energy use and manual intervention.

“FloSync turns water movement and aeration from a fixed setting into a smart responsive system.”

SUPPORTING LONG-TERM AQUACULTURE SUSTAINABILITY

Energy remains one of the largest operating costs in land-based aquaculture. By significantly reducing power consumption and minimizing maintenance requirements, FloNergia’s technology directly improves the economic viability of aquaculture facilities.

Lower energy demand also supports sustainability goals by reducing greenhouse gas emissions and aligning operations with tightening environmental regulations. Improved water quality and oxygen stability further contribute to fish welfare and production consistency.

FloNergia’s systems are validated through laboratory research

and more than 600 installations worldwide, spanning aquaculture operations in North America, Europe, South America, Australia, Asia, and the Middle East. Performance data from these deployments continuously informs ongoing design refinement, ensuring the technology remains grounded in operational reality.

As aquaculture continues to scale globally, technologies that deliver reliable water circulation, efficient aeration, and intelligent control are becoming increasingly important. FloNergia’s integrated approach supports lower energy consumption while helping operators build more resilient, adaptable, and future-ready aquaculture systems.

THE SOLUTION

FloMov™ is a low-energy, no-moving-parts air-lift technology that integrates water circulation, aeration, and CO₂ removal to improve RAS efficiency and reliability.

CONTACT INFO

Wael Ahmed Wael.ahmed@flonergia.com www.flonergia.com

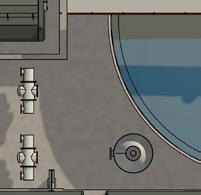

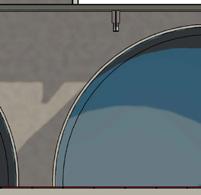

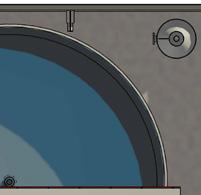

FROM CURVES TO CORNERS: ADVANCING DESIGN FLEXIBILITY IN RAS

No two recirculating aquaculture facility are completely the same.

Factors such as location, topography, fish species, stocking density, flow dynamics, waste management strategies and harvesting needs all play a role in the shape and construction of your RAS tanks.

Will you need a circular tank or a rectangular one?

Whether it’s an oval, circular, rectangular or octagonal tank you’re looking for, or a complex design that incorporates corners and curves, Octaform Systems Inc. of Vancouver provides a highly adaptable tank system that enables owners to construct complex RAS tanks efficiently and with confidence.

Octaform works alongside engineers, owners, and contractors to provide a proven tank system, technical support, and on-site guidance.

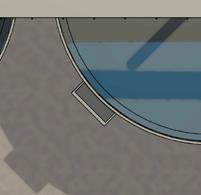

SHIPS FLAT, ASSEMBLES ON SITE

For many RAS start-ups and even for established operators building their land-based fish farm, one of the biggest issues is capital expense.

“Any delay could mean additional cost,” says Callum Graham, director of sales and marketing for Octaform. “The Octaform system is delivered in a flat-pack format and assembled on-site by local contractors, supported by Octaform’s technical team.”

Octaform was founded by Dave Richardson 1997 when he set out to develop durable, energy efficient concrete tanks for wastewater treatment, agriculture, biogass and even car wash applications. The company’s PVC concrete forming technology was later adopted for aquaculture in 2003.

Unlike rigid or precast systems, “Octaform adapts to the engineer’s intent,” says

Graham. “The flexibility of the system allows us to build tanks in any form, shape, height, diameter or wall thickness.”

BENEFITS

The Octaform system is comprised of interlocking PVC components that function as stay-in-place concrete formwork while simultaneously forming a permanently embedded PVC liner.

“The PVC liner becomes mechanically embedded into the concrete wall, creating a continuous, low-porosity, watertight barrier that is integral to the structure – not a post-applied coating. This reduces surface porosity and minimizes areas where dust, debris, or biofilm-forming bacteria could accumulate,” says Graham.

Since the PVC liner is embedded, the liner will not delaminate, blister or peel.

The method also reduces construction time since there are fewer installation steps, and shortening curing, coating or reapplication delays.

Concrete has acoustic dampening abilities which makes for a more tranquil and less stressful environment for the fish. Concrete also has low thermal bridging and high thermal mass. This insulating capability reduce the need for heating and cooling.

“Octaform tanks have been deployed in the harshest of climates. Our first tank was built in the Canadian Prairies, tolerating temperature swings from 40°C to -40°C (104°F to -40°F) with no observed impact on structural integrity or performance over 25+ years,” according to Graham.

DESIGN FLEXIBILITY

Octaform tanks integrate seamlessly with

common and complex RAS elements such as side boxes, integrated channels, doors, gates, removable panels, level controls, large-diameter penetrations, elevated slabs, walkways, and platforms.

NEW PRODUCT

Octaform has further expanded the capabilities of its SnapLockTight (SLT) product line with the introduction of a patented 135-degree SLT panel, extending the same robust, watertight joint technology to octagonal and multi-faceted tank geometries.

Octagonal tanks are becoming an increasingly popular configuration in RAS facilities, offering an effective balance between hydraulic performance, structural efficiency, and space optimization.

The panel is co-extruded with an antimicrobial bead that functions as an integral gasket, providing a permanent watertight seal that does not require re-coating or maintenance over the life of the tank. Lab results confirm that the SLT panel will retain water over 68 PSI or 140 degrees of head pressure. The panel reduces the risk of leakage from cracking or capillarization. Independent testing has shown increased surface hardness in concrete formed with the Octaform system compared to tradi-

tional forming methods.

“The development of the 135-degree SLT panel reflects our commitment to evolving alongside our clients’ design needs,” says Graham. “As RAS facilities become more sophisticated, we continue to adapt our systems to support greater flexibility while maintaining the same proven containment performance.”

THE SOLUTION

• Strong and watertight PVC-lined concrete RAS tanks

• Design flexibility to meet any need

• Risk-cutting rapid on-site assembly and installation

CONTACT INFO

Callum Graham Director of Sales & Marketing Callum.graham@octaform.com

C: 236-868-4683

www.Octaform.com

EXECUTIVE INSIGHT

What are the greatest unmet needs in RAS that suppliers should be solving next?

PAUL BIRDI

General manager, Aerzen Blowers and Compressors of Canada Inc.

“In my view, one of the biggest unmet needs in RAS is for suppliers to have a stronger, more practical understanding of how RAS systems are living in biological environments and not just industrial plants.

While many suppliers bring valuable experience and proven technologies from other industries, RAS is fundamentally driven by biology and performance needs to be evaluated and managed differently.

Good equipment alone does not guarantee good outcomes. Fish health, biofilter performance, water quality, energy use, and day-to-day operations are all closely linked. Small mechanical decisions, such as airflow rates, pressure settings, or control strategies, can have a meaningful impact on biological performance

Bridging this gap requires more than incremental product improvements.

Real progress in RAS will come when suppliers, designers, and operators work as true partners.

By combining engineering expertise, biological understanding, and operational experience, the industry can move beyond simply supplying equipment and toward building systems that are more efficient, resilient, and scalable. ”

KARI JOHANNE KIHLE ATTRAMADAL

Head of research and development and chief science officer at Nofitech

“To provide the fish farmers with systems, solutions and tools that increase production and resource efficiency, secure good fish welfare and reduce risk we and other RAS suppliers are motivated to continuously improve our products and services. Important challenges include continuous improvements in reducing use of water, materials, electricity, feed, oxygen, buffer and area. This can be achieved with more efficient technology, smart automation and control and new solutions and materials.

On the output side optimization includes new, smart and sustainable solutions for treatment and use of waste, both sludge and dissolved nutrients and CO2.

Deep knowledge and real time information about fish health and biosecurity can help improve production and fish welfare and reduce risk.

Tools like biotechnology, nanotechnology, materials technology and artificial intelligence (AI) can be used to improve and develop fast.”

WAEL AHMED CEO, FloNergia Systems

“As RAS continues to scale globally, energy use and operational complexity are emerging as the key constraints to long-term economic viability. At FloNergia, we focus on re-engineering water movement itself - integrating circulation, aeration, and CO₂ removal into a single, low-energy process. By engineering the airlift concept into a predictable, no-moving-parts solution, we help RAS designers and operators reduce power consumption, simplify infrastructure, and improve system reliability. This approach supports aquaculture systems that are not only productive today, but resilient, sustainable, and economically viable as the industry grows.”

TONY PANTAGES

, President & CEO of Octaform

“The greatest unmet needs in RAS today are not rooted in equipment performance or automation, they lie in how projects are planned, coordinated, and executed across disciplines.

As an industry, we’ve made tremendous strides in process design, biology, and control systems. However, many projects still struggle at the interfaces: where civil meets process, where structure meets operations, and where early design decisions ripple into construction risk and long-term performance.

What suppliers should be solving next is not just ‘better products,’ but better project outcomes.

This means earlier collaboration that is formalized through clear project charters, shared risk registers, and well-defined scopes of responsibility. It also means wider adoption of BIM and digital coordination tools to reduce rework, improve constructability, and eliminate costly surprises in the field.

RAS projects are no longer experimental, they are infrastructure.

The industry must mature toward standardized execution frameworks that align owners, engineers, contractors, and suppliers around common goals: schedule certainty, cost control, biosecurity, and long-term durability.

That is where the next wave of value will be created.”

DAVE STEVENS

President and Senior Engineer, Silk Stevens Limited

“The greatest unmet need in recirculating aquaculture systems (RAS), in Canada and globally, is closing the cost and risk gap between land-based production and conventional net-pen farming – particularly for salmonids. While the biological, environmental, and biosecurity advantages of RAS are well understood, consistent economic performance at commercial scale remains the primary barrier to broader adoption.

From our experience, this gap is not driven by a single factor, but by the cumulative impact of capital cost, system complexity, operational reliability, and risk management. Many RAS projects struggle not because the core technology fails, but because systems are over-customized, insufficiently integrated, or difficult to operate and maintain over the long term. The next generation of RAS solutions must prioritize simplicity, robustness, and repeatability, while maintaining biological performance.

Suppliers should be focused on standardizing proven design elements, improving system integration, and reducing both capital and operational uncertainty for owners and operators. Equally important is early-stage decision-making - aligning production goals, site constraints, and risk tolerance before design begins. As the industry matures, success will depend less on pushing theoretical performance limits and more on delivering facilities that operate predictably, scale efficiently, and perform as intended over their full lifecycle.

The cost gap has not yet been fully closed, but it is narrowing steadily. Continued progress will come from practical engineering, operational feedback, and disciplined execution rather than incremental technological complexity.”

TOM EPPLE

President & CEO, Structural Armor

“The next decade of aquaculture growth will be defined by who can scale infrastructure quickly, safely, and sustainably—without compromising performance.

Structural Armor is building more than tanks; we’re building the foundation for the next generation of land-based aquaculture.

By combining American manufacturing capacity with worldclass Norwegian engineering, we’re accelerating access to modern aquaculture infrastructure throughout the Americas.

This is only the beginning.”

RIGHT-SIZED RAS DESIGN

High initial capital investment, over optimistic production targets, high operating costs, poorly designed systems, biohazards, permitting hurdles. These are some of the leading hurdles that result in the failure of many recirculating aquaculture system (RAS) ventures.

It is estimated that poor design, improper management, and high operating costs account for 50% of the failure rate of early-stage RAS projects.

That is why it is important that RAS operators seek out dependable system designers, builders and operating consultants.

Silk Stevens Ltd. has been providing end-toend engineering, design, and consulting services for land-based fish farms and hatcheries since the company’s inception in 2006. The New Brunswick-based firm serves the commercial building, industrial building, and civil site design spaces, as well as the aquaculture sector.

“Silk Stevens designs and manages aqua-

culture projects of various sizes and complexity with a focus on excellence in engineering, client service and meeting project objectives,” according to Onassis Sanchez, senior aquaculture specialist for the company. “Our staff of professional engineers, scientists, technicians, and drafters can help you design and build your project on schedule and on budget.”

The company’s past aquaculture projects include hatcheries, grow-out facilities and landbased farms for salmon, char, trout, tilapia, and sturgeon as well as holding facilities for shellfish, processing facilities and research facilities for a variety of aquatic life.

“At Silk Stevens, we design RAS systems that are simple, dependable, and built for real-world operation. Our goal is to help producers lower risk, reduce costs, and grow healthier fish — consistently,” Sanchez adds.

The company specializes in pre-design/ planning, detailed design, drafting, process improvement, automation, environmental protec-

tion, energy utilization and efficiency, regulatory compliance, and facility permitting.

“What truly sets Silk Stevens apart is our engineering-first approach combined with operational experience. We do not sell off-the-shelf systems—every facility is custom-designed to match species, biomass, and production goals,” says Sanchez.

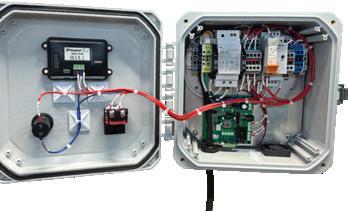

FAIL-SAFE RAS

“In RAS, failure can have immediate and costly consequences, so risk mitigation is a primary design focus. At the same time, it is essential that systems remain simple and easy to operate, allowing fish farmers to focus on production rather than system management,” says Chris Schaerer, design engineer for Silk Stevens.

The company helps reduce risk by designing and supplying proven, robust systems that prioritize reliability and redundancy for a “failsafe” system

“Backup systems and redundancy are funda-

deliver a truly operator-friendly layout. Systems are configured to be self-cleaning and easy to access.

Lifecycle cost is built into the design to lower energy use, and breakdowns.

OCEAN TROUT CANADA PROJECT

These principles and best practices are employed on all Silk Stevens land-based fish farm, hatchery and other aquaculture projects including the company’s ongoing with work with Ocean Trout Canada.

mental to our approach. We design with the assumption that ‘if it can fail, it eventually will’,” says Schaerer. “For this reason, we ensure multiple layers of protection are in place before any failure can occur.”

Right-sized Systems

Silk Stevens also helps RAS operators reduce both upfront capital costs and long-term operating expenses by designing right-sized systems. This means optimizing the scale, capacity, and resources of a systems to ensure they match with the actual needs of a project.

The company’s key process components including radial flow separators, low head oxygenators (LHO, degassers, aeration systems, moving bed biofilters, upwelling biofilters, piping systems, oxygenation systems, wastewater systems, and ozone injection systems. This in-house expertise allows Silks Stevens to optimize performance while maintaining cost efficiency.

Silk Stevens uses energy-efficient equipment to cut power consumption. Low-maintenance components to cut downtime and labor. The company also selects corrosion-resistant components to ensure long service life.

Facilities are arranged to simplify maintenance, monitoring, and daily operations to

Ocean Trout Canada is a Nova Scotia-based producer of premium Steelhead trout for the North American market.

Silk Stevens is currently working with Ocean Trout to design an advanced rearing addition for the Steelhead producer’s Brookvale Fish Hatchery in Brookvale, Price Edward Island (PEI), Canada.

Silk Stevens is providing a full design package, including equipment lists, process flow diagrams, and facility layouts, to support Ocean Trout in achieving these production goals. The Silk Stevens team is using the industry leading data-rich, 3D modelling software Revit from Autodesk for its modelling, equipment sizing, and costing work on the project.

The RAS facility is intended to produce two million high-quality rainbow trout smolts semi-annually, each reaching a target weight of 100 grams.

RAS components will include dual Cornell culture tanks, moving bed bioreactors, drum filters, LHOs, foam fractionators, ozone treatment, ultraviolet (UV) filtration, and water management system.

Backup systems, oxygenation, alarms, and biosecurity measures are incorporated in the design to reduce risk.

The project also includes the construction of office and operations spaces, mechanical and workshop areas, liquid oxygen plant, and wastewater management system.

By supporting efficient production close to market, this project will help Ocean Trout plan for both sustainability and long-term operational success. The design also emphasizes fish welfare and maximizing survivability.

“Our focus is on providing a design that helps operators maintain healthy fish and efficient production while planning for future growth,” says Sanchez.

THE SOLUTION

Proven RAS design, planning, automation, environmental protection and regulatory and permitting expertise

Custom-designed, right-sized systems to match species, biomass, and production goals

Engineering-first approach backed by operational experience

CONTACT INFO Dave

507-755-3005

www.silkstevens.ca

PROVIDING CRITICAL SOLUTIONS TO RAS PRODUCERS AND THE AQUACULTURE INDUSTRY

Recirculating aquaculture systems (RAS) offer land-based aquaculture businesses major benefits such as a controlled environment where conditions can be optimized for faster fish growth rates, quicker harvests and water conservation features that recycle as much as 99% of water used in operations.

However, the same efficient and highdensity environment requires increased focus on fish health and welfare.Experts in Fish Health Solutions

As a fish health and welfare solutions

provider, Merck Animal Health offers a wide range of veterinary pharmaceuticals, vaccines, and technology solutions to the Aquaculture industry.vaccines developed to prevent and treat various fish diseases.

“At Merck Animal Health, we develop solutions that combine biopharmaceutical and veterinary innovations with smart technology to help RAS operators run their facilities in an environmentally sustainable yet more efficient manner that support longterm growth for the business,” says Ryan

Vasak, customer manager for the North America Aqua Business Unit of Merck Animal Health. “Our portfolio includes some of the most innovative products for the prevention, treatment and control of diseases in aquaculture.”

The company develops vaccines for a wide selection of aquatic species that include marine fish such as yellowtail and seabass, as well as salmon, trout, catfish, tilapia, and marine fish species such as barramundi, yellowtail, sea bass and sea bream.

HARNESSING DATA-DRIVEN TECH

Merck Animal Health also has an extensive suite of identification, traceability, and monitoring products designed to offer fish farmers an integrated approach to managing aquaculture operations.

Merck Animal Health has acquired some of the aquaculture industry’s leading brands to create a portfolio of technology solutions that empower aquaculture operator to conduct more accurate risk profiling and early disease detection which are critical for achieving a healthy RAS environment.

For example, the company’s acquisition in 2024 of the aqua business of Elanco Animal Health Inc., has given Merck Animal Health access to a robust and comprehensive range of aquaculture vaccines, antiparasitic treatments, water treatment, and nutrition products to complement Merck’s own fish health lineup.

With the move, Elanco’s CLYNAV, a DNAbased vaccine for Atlantic salmon; and IMVIXA, an anti-parasitic sea lice treatment have become part of Merck Animal Health’s vaccine offerings.

By bringing Vaki Aquaculture Systems Ltd., under its fold in 2019, Merck Animal Health broadened its position in the fish handling and real-time monitoring technology space.

Vaki manufactures best-in-class fish counters, fish grades and fish pumps. Vaki products such as its infrared and smart technology-enabled, high-capacity fish counting and image verification machines; high-precision fish graders; and high-capacity fish pumps are now part of Merck Animal Health’s fish handling line-up. New for 2026, Vaki offers

an upgraded and higher capacity 6” Smart fish pump, as well as a new Shrimp Counter that has already been trialed and verified by Shrimp culturists in Ecuador.

Merck Animal Health continues to collaborate with Vaki to further develop the company’s SmartFlow System. The SmartFlow system is the only one of its kind in the Aquaculture industry, and it connects all Vaki fish handling equipment to provide real-time monitoring, control, and data collection during a fish handling event. The system provides users with key insights from data which aid in planning and decision- making.

Biomark delivers best-in-class passive integrated transponder (PIT) tagging and tracking technology for monitoring fish and wildlife. The solution enables fish farmers and conservationists to acquire actionable insights from gathered data so that they can create a healthy aquatic ecosystem.

EDUCATING AQUACULTURE WORKERS

Merck Animal Health also promotes the education of aquaculture works and fish conservation communities through an online training platform called Aqua Care365.

Launched in 2023, the program offers training modules that focuses on fish welfare and operational best practices.

The expert-led training, video-based modules are targeted at aqua communities in developing and delivering improved welfare for aquatic species while supporting a safe, affordable, and sustainable food supply.

Aqua Care365 is dedicated to assisting aqua communities develop and deliver a

culture of care and improved welfare for aquatic species while promoting a safe, affordable, and sustainable food supply. The program was designed to complement and help fulfill the animal care requirements of certification and stewardship programs for aquaculture.

Merck Animal Health’s continuous development aquaculture pharmaceuticals and automated fish monitoring and traceability tools, as well as its promotion of fish welfare best practices, manifests the company’s commitment to innovation and a strong aquaculture industry, according to Vasak.

“Our goal is to ensure that fish farmers have access to the latest advancements in disease prevention, aquaculture technology and data-driven, decision-making solutions,” Vasak says.

THE SOLUTION

Innovative aquaculture pharmaceutical, vaccines and fish health products

Reliable data-driven monitoring and fish management technology solutions

A holistic, sustainable, and affordable approach to fish health and operational efficiency.

CONTACT INFO

Ryan Vasak ryan.vasak@merck.com www.merck-animal-health.com

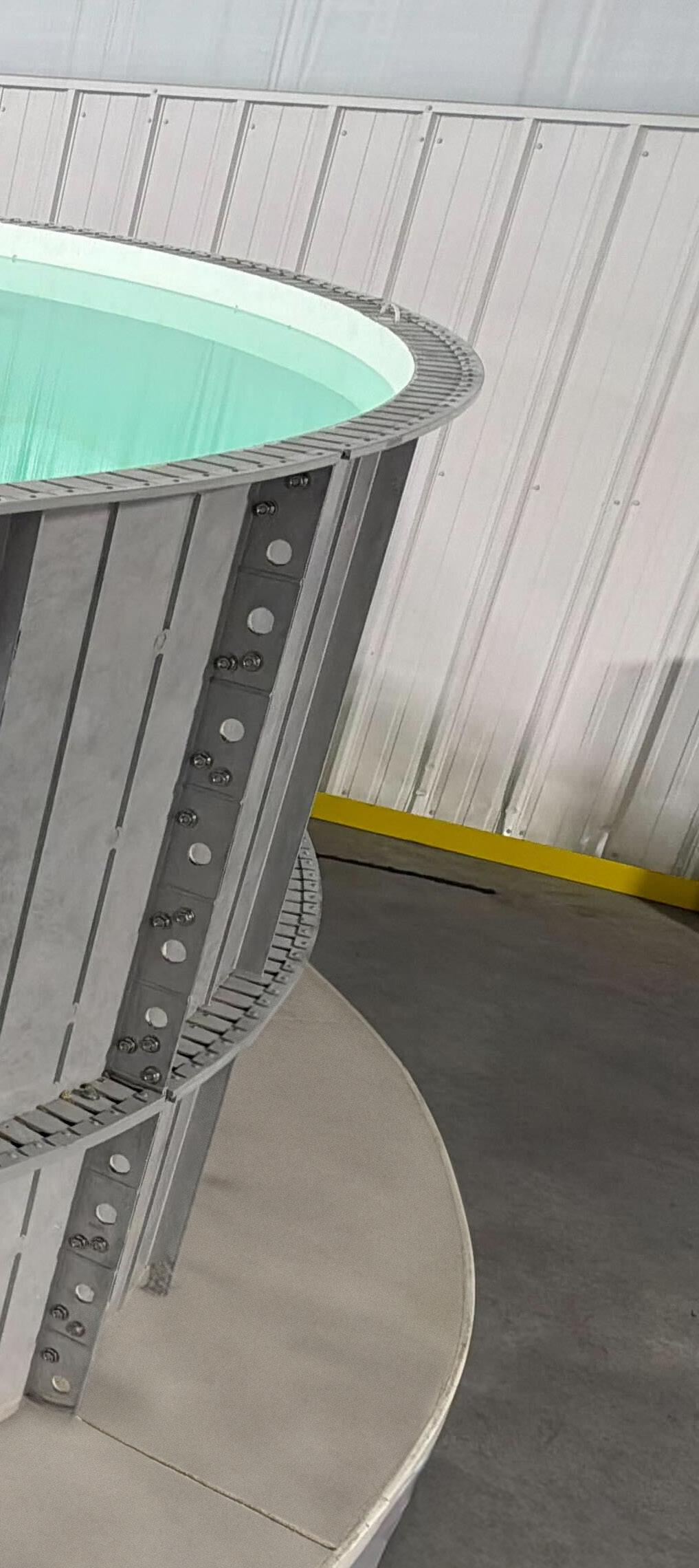

WATER RETENTION TANKS (WRS)

Structural Armor teams with MAT-KULING to support RAS Innovation

Structural Armor WRS, a manufacturer of composite water retention tanks for the landbased aquaculture space, has entered into a strategic co-branding joint venture with Norwegian aquaculture water treatment firm, MAT-KULING AS.

The collaboration focuses on integrating Structural Armor’s modular, engineered tank systems with MAT-KULING’s RAS and water filtration systems to provide reliable and scalable equipment for land-based fish farms and hatcheries.

Both companies will supply the global market using the MAT-KULING-Structural Armor co-brand.

NACA PARTNERS

“Structural Armor WRS is proud to collaborate with MAT-KULING AS to support reliable, high-quality aquaculture solutions,” says Thomas Epple, president and chief exec-

utive officer of Structural Armor.

“This collaboration brings together innovative aquaculture technology and proven tank solutions to deliver dependable, efficient, and scalable results,”

Epple, co-owns Structural Armor with his long-time business partner, Tim Saxer, who is the company’s executive vice-president.

“MAT-KULING is a founding member of the Norwegian Aquaculture in America (NACA), a network of five Norwegian aquaculture technology companies that have banded together in 2025 to offer recirculating aquaculture systems (RAS) solutions to help land-based fish farmers achieve self-sufficiency.

Structural Armor WRS is a U.S.-based corporation and affiliate member of NACA. To lead the charge, the NACA Members in conjunction with Structural Armor WRS recently welcomes the lifelong aquaculture expert,

Alex Tsappis, to represent NACA’s and Structural Armor WR’s presence in the Americas.”

The other members of NACA are Simona Stadpipe AS, a piping system company; Helland Silosystems AS, a maker of silo feeders; Silikal Nordvest AS, a developer of coating for aquaculture tanks; and Dynamic FishEye, a developer of AI-driven monitoring and data analytics tools for fish health.

Through the collaboration with NACA, Structural Armor serves as a bridge for Norwegian expertise entering the Western Hemisphere.

FROM SWIMMING POOLS TO FISH TANKS

Prior to entering the aquaculture space, Epple and Saxer have been manufacturing building materials for the swimming pool industry for over 36 years.

After 20 years of working for a leading

manufacturer in that industry, the two started Trivector Manufacturing, a precision equipment manufacturing firm. Next, Epple and Saxer launched the company’s subsidiary, Only Alpha Pool Products which made swimming pools.

Only Alpha Pools Products was followed by the launch of Structural Armor.

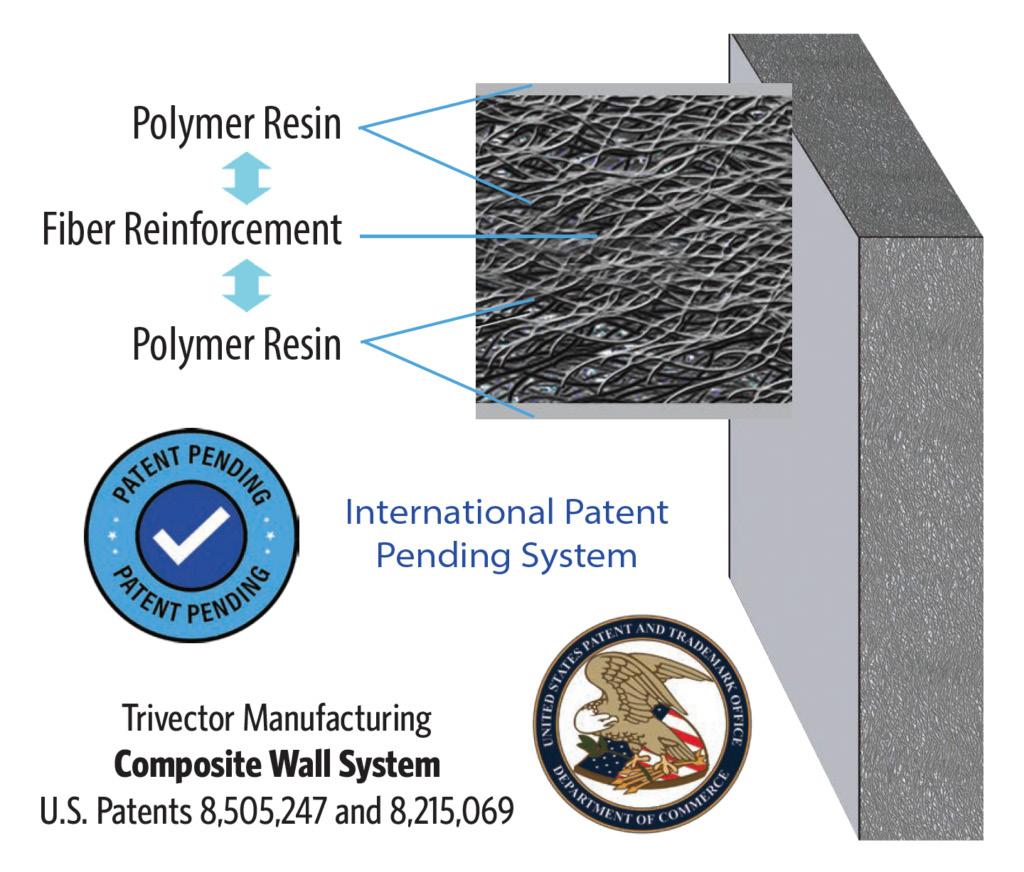

One of the products Epple and Saxer sought to develop was an extremely strong, lightweight, non-corrosive material that would be resistant to salt.

Their work led to the creation of a “componentized,” lightweight retaining wall system with the physical properties of concrete.

Epple and Saxer later realized that their product could be of use in the growing RAS industry.

Today, Structural Armor is now known for its panel-based, modular tanks that are food and fish-safe. The tanks are adaptable for both small and large-scale commercial and aquaculture applications.

Structural Armor paneling system offers straight or radius panel options, making them adaptable to any shape requirement.

Structural Armor employs a compression molding process using the same technologies employed by the National Aeronautics and Space Administration (NASA) and leading auto and aircraft manufacturers.

The fibre-reinforced composite panels of the tanks are easy to ship since an entire tank system can be palletized. This reduces equipment footprint, cuts shipping costs, this avoids packing delays and shaves transit time.

Structural Armor turned to its sister company Only Alpha Pool Products for help in developing its waterproofing technology.

Structural Armor’s corrosion resistant panels and can be finished-to-purpose. The company offers a variety of options, including patented, easily replaceable options such as polyethylene scrim reinforced liners, PVC liners, and Structural Armor’s own Evolution Epoxy Coating. Most importantly, Structural Armor WRS specifies high performance coating technology from NACA member, Silikal Aquaculture Solutions.

SHARED COMMITMENT

Structural Armor and MAT-KULING share a commitment to innovation and excellence in the aquaculture industry.

MAT-KULING designs and manufactures and supplies equipment for land-based farming for different saltwater and freshwater species like salmon, trout, sea urchin, and eel. The Norwegian company has clients in Australia, Canada, New Zealand, and the United States. The company also provides fish farmers with RAS treatment equipment

like protein skimmers, moving bed biological reactors, ozone and UV-C units, degassing towers, overflow launders, oxygen cones, plastic tanks, gate valves, and dissolved air filtration systems.

MAT-KULING and its fellow NACA members believe that North America is on the move towards seafood self-sufficiency.

The alliance also recognizes that the continent has the potential for becoming a global leader in aquaculture production. NACA wants to engage and support that growth.

Epple believes Structural Armor’s strategic ties with NACA and MAT-KULING has a part in building that future.

“Our joint efforts reflect a shared commitment to innovation and excellence in the aquaculture industry,” says Epple. “Alongside our partners at MAT-KULING AS and through NACA, we are strengthening collaborations that are driving the future of aquaculture.”

THE SOLUTION

• Strong, modular water tanks engineered for aquaculture applications

• Robust partnerships with international leaders in RAS technology

• Proven research and development

CONTACT INFO

Caitlin Raupp Business Development

Structural Armor WRS/Trivector Manufacturing

c.raupp@structuralarmor.com 800-873-9906

www.structuralarmor.com

2026 CONFERENCE SCHEDULE

12:30 PM - 2:00 PM Exhibit Hall set up & Registration opens

BUSINESS TRACK - Session details to be confirmed

DAY 1 (May 19)

DAY 2 (May 20)

2:00 PM - 4:00 PM

BIOLOGY TRACK - Early rearing Session Chair: Yonathan Zohar

TECHNOLOGY TRACK - Partial, hybrid or full? Session Chair: Huy Tran

4:00 PM - 6:00 PM Welcome Reception at poolside!

7:30 AM - 8:30 AM Breakfast & Exhibit Hall opens

8:30 AM - 9:30 AM Keynote The Future of RAS in Traditional Salmon Farming - Cermaq, Grieg Seafood & more

9:30 AM - 10:30 AM Networking Break in Exhibit Hall

10:30 AM - 12:30 PM

BUSINESS TRACK - System readiness & completion Session Chair: James Tuller

BIOLOGY TRACK - Smolt & post-smolt Session Chair: Bendik Terjesen

TECHNOLOGY TRACK - Artificial intelligence Session Chair: Rakesh Ranjan

12:30 PM - 2:00 PM Networking Lunch & Exhibit Hall visits

2:00 PM - 4:00 PM

DAY 3 (May 21)

BUSINESS TRACK - New Projects Session Chair: Justin Henry

BIOLOGY TRACK - Growout Session Chair: Chris Good

TECHNOLOGY TRACK - Sludge & by-product processing Session Chair: Christine Lepine

7:30 AM - 8:30 AM Breakfast & Exhibit Hall visits

8:30 AM - 9:30 AM Round Table discussions

9:30 AM - 10:00 AM Networking Break in Exhibit Hall

BUSINESS TRACK - Telling the RAS Story Session Chair: Dianna Fletcher

10:00 AM – 12:00 PM

BIOLOGY TRACK - Fish Health Strategies Session Chairs: Kathleen Hartman & Bill Keleher

TECHNOLOGY TRACK - Off-flavour & finishing Session Chair: John Davidson

12:00 PM – 1:00 PM Networking Power Hour

1:00 PM -3:00 PM Exhibitor Teardown. Afternoon at leisure - an opportunity to socialize with your industry peers!

Hotel:

World Golf Village Renaissance - St. Augustine Resort

• Full access to all conference sessions including keynote, round table discussions and three daily content tracks: Business, Biology, Technology

• Access to Exhibit Hall of 50+ RAS-related industry suppliers

• Welcome Reception

• 2x hot buffet breakfasts (Day 2&3)

• 1x hot buffet lunch (Day 2)

• Coffee & snacks during networking breaks in Exhibit Hall (All 3 days)

• Swag bag of sponsored RAS goodies

• Printed copy of RAStech magazine + Solutions in RAS + 1 Year digital subscription

Incredible value for only $785 USD + tax & services charges!. Check conference website for any early bird savings!

500 South Legacy Trail St. Augustine FL, 32092

Group rate available for nights booked between May 15 – May 25, and subject to availability. Bookings must be made by no later than April 28.

Purpose-built for coho salmon

Inside Invermar Aucha, Chile’s first RAS smolt farm for coho salmon

By Christian Pérez-Mallea

Invermar, one of Chile’s leading salmon producers, is making history with ‘Aucha’, the country’s first recirculating aquaculture system (RAS) specifically engineered for coho salmon (Oncorhynchus kisutch).