The Canadian Plastics Impact Awards is an annual must-attend event for members of the plastics industry. The awards luncheon celebrates plastics professionals in Canada who have made a difference in the industry.

2026 AWARDS INCLUDE:

•Leader of the Year: Recognizes an individual for his or her outstanding leadership and for having made a significant, positive impact on their organization and/or the plastics industry at large over the past 12 months.

•Lifetime Achievement: Recipient is recognized for making major contributions throughout his/her entire career that have shaped their field and influenced future generations.

•Innovator Award: Recognizes new and groundbreaking products, services, or processes in the plastics sector.

•Sustainability Award: Recognizes individuals, organizations, or products that demonstrate a strong commitment to environmentally and socially responsible practices.

•Emerging Leader of the Year: Recognizes a relative newcomer to the plastics sector who has already significantly distinguished themself, highlighting their potential for future success.

It’s easy these days to feel apathy – and maybe even some hostility – towards awards shows. Take the Academy Awards, which have devolved from a sophisticated, highly anticipated, and highly watched event where the winners politely thanked the members of the Academy for their awards into a spectacle where vacuous, self-important actors drop f-bombs, use their acceptance speeches to lecture us about politics, and – as comedian Chris Rock found out a few years ago – the host can get physically assaulted on stage for making a joke that an audience member doesn’t like. And I’ll bet this is why Oscar ratings have been plummeting every year for the past decade.

We’re hoping for a better, classier result with our new Canadian Plastics Impact Awards.

The awards – which we’ve launched as an annual program – have been created to recognize and celebrate commitment, innovation, performance, and design excellence in Canada’s plastics sector. There are five categories: Leader of the Year, Lifetime Achievement, Innovator Award, Sustainability Award, and the Emerging Leader of the Year.

We want the Impact Awards to serve as a platform for you – our readers – to celebrate the deserving people in our industry, veterans and newcomers alike, and their achievements. I know from having spoken with many of you that you’re proud of your businesses, your colleagues and employees, and your end products – so here’s a chance to show it. But we need your help to nominate some worthy recipients, either in your own companies or beyond. If you have a person or product in mind for submission, please go to the Canadian Plastics website – www.canplastics.com – and click on the “Awards” link at the top of the homepage. This will take you to the nomination forms for the various award categories and give you more information about each award than I have room to do here (also see our ad on pg. 2 of this issue). All nominations will be treated with the strictest confidence, so don’t be shy. The winners will be selected by our judging panel, honoured in our print and digital editions, and invited to celebrate and collect their awards in person at our upcoming award luncheon, scheduled for May 27 in Mississauga, Ontario. I think I can promise the event will be 100 per cent violence-free, which is more than can be said for the Oscars.

It’s all upside and no downside – an award reinforces your company’s value and builds trust with clients and customers and signals that your people, products, and services are of high quality. And it’s also a fantastic marketing opportunity, as it gives you content to share across your platforms.

And speaking of sharing content, we’ve given our magazine a graphic redesign as of this issue: a new look to make it more visually compelling. We hope you like it.

STEPHEN editor mstephen@canplastics.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Administrator Tel: (416) 510-5113 | Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor MARK STEPHEN 416-510-5110 mstephen@canplastics.com

Associate Publisher STEPHEN KRANABETTER C: 416-561-5362 W: 416-510-6791 skranabetter@annexbusinessmedia.com

Media Designer LISA ZAMBRI lzambri@annexbusinessmedia.com

Account Coordinator KRISTINE DEOKARAN 416-510-6774 kdeokaran@annexbusinessmedia.com

Audience Development Coordinator LAYLA SAMEL (416) 510-5187 lsamel@annexbusinessmedia.com

Group Publisher/Director of Production PAUL GROSSINGER pgrossinger@annexbusinessmedia.com

CEO SCOTT JAMIESON sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 008-4778 (Print) ISSN 1923-3671 (Online) Publication Mail Agreement #40065710 PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

4 issues Canadian Plastics, plus Dec. 2025 Buyers’ Guide: Canada: 1 Year $82.21 plus applicable taxes 2 Years $131.01 plus applicable taxes USA: $186.70 (CAD) / year Foreign: $213.22 (CAD) / year

Occasionally, Canadian Plastics will mail information on behalf of industry related groups whose products and services we believe could be of interest to you.

If you prefer not to receive this information, please contact our audience development department in any of the four ways listed above.

Annex Privacy Officer privacy@ annexbusinessmedia.com • Tel: 800-668-2374

No part of the editorial content of this publication can be reprinted without the publisher’s written permission ©2026 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Canadian Plastics magazine reports on and interprets developments in plastics markets and technologies worldwide for plastics processors, moldmakers and end-users based in Canada.

MEMBER: Magazines Canada, Canadian Plastics Industry Association.

U.S.-based extrusion equipment and converting systems maker Davis-Standard has made a “significant strategic integration” of its Canadian specialty brands.

As of Jan. 1, 2026, Deacro Industries Ltd., Brampton Engineering Inc., and Gamma Machinery have been amalgamated to operate as a single company: Davis-Standard Canada Inc.

“The move consolidates the operational footprint and technical capabilities of these three distinct, market-leading specialty brands,” said Michael Brown, vice president of operations, Davis-Standard. “This integration is designed to leverage combined resources to enhance customer support, drive innovation, and improve operational efficiencies.”

In a Jan. 13 press release, officials with Chicago, Ill.-based Davis-Standard said that key highlights of the amalgamation include continued brand focus based around the core technologies, engineering expertise, and product lines associated with Deacro (slitting/rewinding), Brampton Engineering (blown film), and Gamma Machinery (bag machines/winders); operational consistency, with engineering, sales, and service

contacts remaining unchanged; and global service integration, with customers able to continue to utilize the 24/7 First Responder phone number, 1-844-MYDAVIS (844-6932847), which provides global support across all brands and product lines.

Flexible packaging supplier ProAmpac is acquiring TC Transcontinental Packaging (TCP) from Canadian conglomerate TC Transcontinental for US$1.51 billion.

Headquartered in Chicago, Ill., TCP is the packaging sector of TC Transcontinental. With approximately 3,500 employees, TCP operates 25 production plants located throughout North America, Latin America, the U.K., and New Zealand, which specialize in extrusion, printing, lamination, converting, and recycling.

The combined entity accelerates ProAmpac’s development of next-generation packaging, including barrier films, mono-materials, and fibre-based solutions.

The transaction is expected to close in the first quarter of 2026.

TC Transcontinental is headquartered in Montreal.

Work has begun on Montreal-based packaging supplier Polykar Industries Inc.’s expansion project for its plant in Edmonton, Alta., a C$20-million project that will double production capacity and add 25 jobs.

Polykar – which makes polyethylene film, bags, and packaging – has hired Farmor Architecture, which designed the company’s original Edmonton site, and Dawson Wallace Construction Ltd. as the builder. Both firms are based in Alberta.

Foundation work is now under way, and Polykar expects the project to be complete by the fall. Once finished, the expansion will provide 50,000 additional square feet of production space. Annual production output is expected to increase to 40 million pounds.

“Since opening our Edmonton facility, Polykar has experienced steady growth, and less than three years later we’re ready to expand again,” CEO Amir Karim said in a Jan. 15 statement.

Polykar decided to expand in Edmonton following a minority investment in the company last year by private equity firm MontClerc Capital.

The Plastics Industry Association has released its Q3 2025 shipment data for injection molding and extrusion machines in North America.

$303.2

U.S. dollar amount, in millions, of total shipments.

4.9%

Decrease in single-screw extruder shipments from the previous quarter.

28.9%

Decrease in twin-screw extruder shipments from the previous quarter.

30%

Increase in injection molding shipments from the previous quarter.

Toronto-based Amara Industries, the parent company of Canadian home products maker Gracious Living Corp., is buying Thomson Plastics Inc. (TPI), a large tonnage injection molder in the Southeastern U.S. that currently operates from two locations in Georgia and North Carolina.

The financial terms of the deal have not been disclosed.

In a Dec. 9, 2025 news release, Amara Industries officials said the company is combining TPI’s two plants with its three Gracious Living molding and extrusion plants in Canada and the U.S.

With clamping force capacities up to 3,700 tons – including 30 per cent of its fleet exceeding 1,000 tons –TPI’s technical portfolio includes injection molding, gas-assisted molding, over-molding, insert molding, in-mold labeling, robotic part picking, pad printing, and heat transfer decorating.

TPI was founded in 1975 and is headquartered in Thomson, Ga.

Amara Industries specializes in a range of advanced manufacturing processes, including injection molding, assembly, profile extrusion, decorating, and material compounding.

Amara Industries officials say the company is combining TPI’s two plants with its three Gracious Living molding and extrusion plants in Canada and the U.S.

Germany-based injection molding machine maker

Arburg GmbH + Co. KG has appointed Volker Nilles as CEO.

Houston, Tex.-based nylon 6/6 maker

Ascend Performance Materials has named Patrick Schumache as CEO.

Factory automation maker ATS Corp., based in Cambridge, Ont., has named Doug Wright as CEO.

Germany-based machinery manufacturer KraussMaffei Group has appointed Alex Li as CEO.

LS Mtron Injection Molding Machine, headquartered in Duluth, Ga., has appointed Firaz Sharaf as regional sales manager for Canada.

Westlake, Ohio-based materials distributor Palmer Holland is now supplying impact modifiers and processing aids for Kaneka Corp. in North America. The partnership includes Kaneka’s Kane Ace Modifiers, Kane Ace MX, CPVC, and MS Polymers units.

Atlanta, Ga.-based Tech-Long International Inc. is now distributing thermoforming machines made by Japan’s Asano Laboratories Co. Ltd. in North and South America. Tech-Long supplies blow molding, filling, capping, and other packaging systems for food and beverage customers throughout the Americas.

John Erkert, the CEO of auxiliary equipment maker Piovan Group North America, has now been appointed president of Conair Group, headquartered in Cranberry Township, Pa.

Germany-based mold technology supplier

Hasco Hasenclever GmbH + Co. KG has named Markus Büngers as CEO.

Calgary, Alta.-based material supplier Heartland Polymers has named Joanne Swiggett as vice president, petrochemical commercial.

Swiss injection molding machine maker Netstal has named Kevin Green as managing director of Netstal Inc. and president of Netstal Americas, based at the U.S. headquar ters in Hebron, Ky.

Fraser, Mich.-based mold component and hot runner supplier PCS Co. has appointed Patricia Ewald as product manager.

Compounder

Techmer PM, headquartered in CIinton, Tenn., has named Craig J. Foster as CEO.

PROMOTIONS, RETIREMENTS, RECOGNITION • If you have an people in your agency recently promoted or retiring or an individual you wish to have recognized (major award or recently deceased) you can let Canadian Plastics magazine know by emailing: mstephen@canplastics.com.

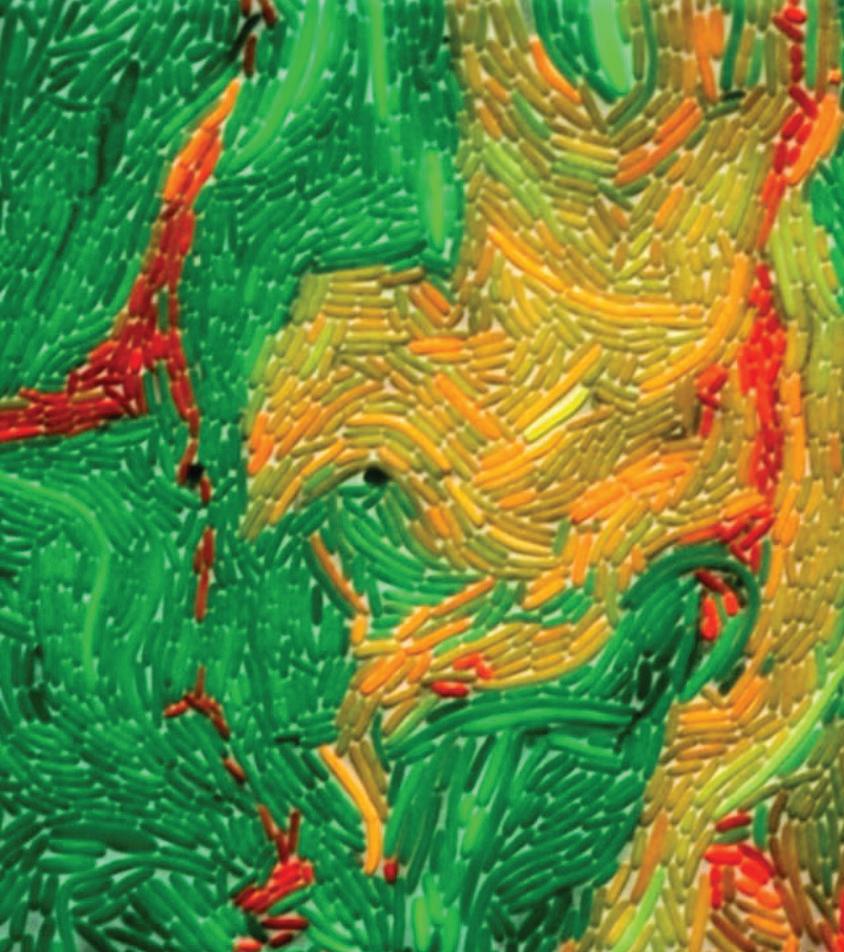

Agroup of chemical engineering researchers at the University of Waterloo (U of W), in Waterloo, Ontario, are working together to use synthetic biology, microbial engineering, and engineering design to degrade and upcycle plastic waste, to turn it into valuable resources.

The problem to be solved is a big one: Estimates say that between 19 to 23 million tonnes of plastic waste leak into ecosystems annually. These plastics take hundreds of years to break down and are now degrading into nano and microplastics.

Biotechnological solutions to plastic waste may be cost-effective in upcycling plastics into valuable products, and since traditional recycling methods rely on harsh chemicals and high temperatures, using synthetic biology to engineer organisms and biological systems offers a gentler way forward.

Dr. Christian Euler, a chemical engineering professor and Waterloo’s lead for the Center for Innovative Recycling and Circular Economy (CIRCLE), is developing novel microbial pathways to enhance the value of plastic waste. In a recent study published in the journal PLoS Computational Biology, Euler’s research group investigated whether feedstocks derived from plastic waste could provide the energy to drive carbon dioxide (CO₂) conversion. The group analyzed how certain organisms metabolize both CO₂ and plastic waste simultaneously – a strategy called mixotrophy, in which “mix” means combining multiple foods and “troph” means eating. This approach may allow micro-organisms to process multiple

In this microscopic view, red and green cells exchange DNA molecules and start to turn yellow as they transfer a plastic-eating gene.

The group analyzed how certain organisms metabolize both CO₂ and plastic waste simultaneously.

carbon sources at once, which is unusual since most microbes typically consume only one type of “food” at a time. The research demonstrated that several waste-derived carbon sources – especially those from plastic – could support the microbial conversion of CO₂ into valuable products, addressing two environmental problems at once. The results served to highlight that developing new methods to break down plastics at their source, such as in wastewater treatment plants, is critical. Degrading plastics before they reach natural ecosystems could significantly reduce environmental contamination.

To address this challenge, Euler’s

U of W colleagues Drs. Marc Aucoin and Brian Ingalls and former PhD student Aaron Yip have developed a process that degrades polyethylene terephthalate (PET) plastic via an enzyme found in nature. Their goal is to spread the enzyme, or the genetic information for the enzyme, throughout a population of organisms found in municipal wastewater.

U of W professor of chemical engineering Dr. Yilan Liu, meanwhile, is taking a different approach by evolving microbes to “eat” plastics as their only food source – her research group is engineering synthetic symbiotic bacterial consortia for the bioconversion of plastic waste.

And finally, Dr. Elisabeth Prince – also a U of W professor of chemical engineering – is approaching the problem by looking at how plastics are designed in the first place. She developed a method to make thermoset polymers and rubbers recyclable using existing manufacturing infrastructure, requiring only minor formulation changes – a strategy that could make currently non-recyclable materials like rubber tires, epoxy coatings, and elastic bands part of a sustainable, circular system.

“Each of us could say our work is a small piece of the solution to the problem of plastic waste,” Euler said. “But when we bring our different expertise together, we’re creating a truly collaborative community to build something new together.”

The multidisciplinary group is working together to review and identify strategies that leverage synthetic biology, microbial engineering, and engineering design to degrade and upcycle plastic waste.

For decades, automation has helped plastics companies gain efficiencies in their production processes. In the newest development, inexpensive collaborative robots are transforming injection molding by automating tedious tasks such as machine tending, part placement, and quality checks.

BY MARK STEPHEN, EDITOR

Injection molding is the primary technology for making mass-market plastic products, creating thousands to millions of identical parts quickly and efficiently with minimal waste. And as such, it’s often the entry point for innovative new technologies in plastics processing, from the all-electric units first developed decades ago to the ongoing adoption of physical artificial intelligence (AI).

The growing use of collaborative robots – usually called cobots – is firmly in this tradition and is the latest development in a flurry of innovations in automation over the past decades that included full servo-controlled Cartesian robots and then six-axis robots. Generally based on articulated-arm technology, cobots are complex machines that work with human beings in a shared work process – often side by side with employees – to both support and relieve the human operator, and are proving to be a flexible automation option for molders attracted by the winning ideas of robotic safety, user-programmability, increased production rates, small footprints, a cure for labour shortages, and a quicker return on investment (ROI) than most industrial robots.

Compared to traditional industrial automation, dexterous six-axis cobots can handle a range of jobs, including machine tending and part removal, secondary processing tasks such as degating and trimming, quality inspection, and packaging and palletizing. Additionally, cobots can perform repetitive or hazardous tasks, reducing the risk of repetitive strain injuries or exposure to hazardous materials. And they sometimes don’t require the heavy, expensive, and space-intensive safety fencing and access doors associated with traditional automation. All of which is why cobots are popping up in injection molding processes in ever-greater numbers, including in many organizations for whom traditional robotics were out of reach.

In short, cobots are a no-brainer for use in many of today’s injection mold shops. But that doesn’t mean that buying and deploying them are also no-brainers. Automating appropriately means carefully evaluating your specific situation to make the best choice, including conducting a risk assessment, implementing safety measures if necessary, and providing appropriate training to human operators. Also, not all cobots offer the same level of functionality or provide the same variety of safety features, so be sure to do the proper due diligence and select a brand with an ecosystem of verified compatible injection molding software and peripherals.

The risk assessment is a crucial part of a good cobot deployment, made necessary by the fact that – although

designed to be safe to work with due to built-in sensors, force/speed limiting, and safety-rated stops – cobots aren’t inherently safe in all scenarios; their safety depends on the application, payload, speed, and workspace analysis. “A cobot setup is only as collaborative as the most dangerous element,” said Jasper Arthur, a research officer with National Research Council Canada, specializing in robotic manufacturing. “You want to avoid going through the procurement process expecting to have a cobot shoulder to shoulder with other workers, only to find out during installation that you actually do need to close off the area with a fence.”

Cobot safety is currently defined by a mix of international and regional standards, each focusing on different aspects of robot behaviour, workspace safety, and human interaction. Together, these frameworks form the baseline for designing, deploying, and auditing safe cobot systems. The most important standards governing cobot safety include ISO 10218:2025 for industrial robots and – in the U.S. –ANSI/RIA R15.06, both of which focus on different aspects of safe deployment and interaction. Canada uses CSA Z434, which is a Canadian adoption of ISO 10218. At present, ANSI/

RIA R15.06 in the U.S. and CSA Z434 in Canada are being updated to align with the new ISO 10218 revisions to ensure consistency in cobot safety requirements across North America.

“The goal is to prevent people from getting hurt,” said Jerry Perez, executive director for global accounts with Fanuc America Corp. “Even if there’s a one-in-a-million chance of a worker getting injured – even by backing slightly into the wrong space – the risk assessment considers that.”

Cobots are a no-brainer for use in many of today’s injection mold shops.

With a payload of 25 to 30 kg, Fanuc’s CRX-30iA is one of the heavier lifters of its CRX collaborative robot series.

Beyond adhering to the safety standards, a structured risk assessment considers the specifics of each application, ensuring that hazards are identified, ranked, and reduced to acceptable levels. “Factors to consider include proximity to faculty, tooling attached to the cobot, height of the cobot, mold safety if using for press tending, and so on,” said Christopher Buse, application engineering manager with Universal Robots (UR).

“Many risks found in an assessment can be easily addressed in the cobot’s built-in configurable safety settings.”

And unlike traditional robots, cobots require ongoing reassessment since they operate directly in shared spaces.

And despite the popular perception that cobots are safe in all instances, a cobot application for injection molding could require fencing, especially if a risk assessment identifies potential hazards that built-in safety features can’t fully mitigate. In other words, the need for fencing is determined by the application, not by the cobot type itself. “Higher speeds could require safety mechanisms such as area scanners or light curtains, and certain end-of-arm tooling could need to be fully caged,” Buse said. “Other applications may require safety mats or reduced cobot speed.” Importantly, however, some cobot deployments won’t require these safeguards. Fanuc now has 11 CR and CRX cobot model variations to choose from – with payload capabilities ranging from four to more than 30 kilograms (kg) and

reaches ranging from 550 to 1,889 millimeters (mm) – and the company says they’re designed to work in most production environments without fencing or other safety equipment.

Given the importance of smooth interfacing between automation and injection molding machines, it’s vital that a cobot understands protocols – like EuroMap, which is the industry standard for injection molding machine connectivity – that dictate how machines, sensors, and systems exchange data, ensuring seamless communication and coordination in industrial automation and general networking. “Look for brands that provide molding machine interface capabilities, which will help you control and break down every part of the molding sequence while your cobot arm is within the machine,” Buse said. “Having a dedicated EuroMap 67 interface will also enable easy control of the core pullers, air blow, and the timeframes for opening and closing the machine and part ejection.” Moreover, Buse continued, if an injection molder chooses a cobot with an interface module, all the I/O functions of the robot will be automatically prepared by the cobot. “This means that all end users will need to do is intuitively handguide the cobot arm from waypoint to waypoint,” he said. “In this sense, cobots are a radical departure from traditional automation counterparts.” UR offers a plug-and-play EuroMap 67 interface called IMMI (Injection Mold Machine Interface) that allows the robot to directly control all the machine’s mold movements and sequencing while also integrating into its safety system. “Once enabled, the cobot’s software populates all the injection molding machine’s controls directly on the teach pendant,” Buse said. Effective interfacing has an extra dimension of value in injection molding shops that have machines from two or more different vendors – which is probably a lot of them. “Cobots need

some basics in order to be used throughout: Ethernet IP communication, EuroMap, OPCUA, CIP safety, and the other standard communication protocols necessary to communicate within an industrial network,” said Jerry Perez. “OPCUA is the big one – it allows us to bridge all the different communication protocols, giving us our standard start time/job complete interface signals between the injection molding machines.”

The interfacing to molding machines and other peripherals is helped by the fact that leading cobot brands enable relatively quick and easy programming regardless of the processor’s previous level of automation exposure, with no special software language to learn. “Your internal teams can easily pick up how to use cobots, saving on integrator costs and reducing downtime during product and process changeovers,” said Christopher Buse. Again, not all brands are the same when it comes to ease of programming, so look for cobots with features like hand guiding and trusted, human-friendly interfaces.

First-generation cobots proved themselves apt at parts handling and stacking/packing applications. But as the cobots themselves improved, plastics users have tried them out in increasingly challenging applications, such as demolding parts, picking up and placing inserts, and component assembly – anything aside from high-speed removal of parts from a machine, which remains the prerogative of traditional industrial robots. “Cobots are versatile by design, and they can handle specific plastic processes such as quality inspection with a camera, degating sprues and runners, packaging parts from a conveyor belt, palletizing, and machine tending,” Buse said. “Cobots are also excellent at tending value-add machinery such as pad printers, laser engravers, and assembly fixtures.”

Cobots in general also have a much smaller footprint than traditional, caged industrial automation, which sup-

Having a dedicated EuroMap 67 interface will enable easy control of the core pullers, air blow, and the timeframes for opening and closing the machine and part ejection.

ports rapid deployment in fast-moving plastics processing facilities with changing production mixes and schedule demands. Cobots are often mounted on casters so they can be wheeled to different presses to perform different preprogrammed routines stored in the controller’s memory – a cobot could, for example, tend to a press for part of a shift and then be dedicated to finishing or inspection tasks on another shift.

This flexibility – combined with simplified programming and setup, pre-engineered peripherals like grippers and even vision systems, and reduced or no guarding – creates a significantly shorter ROI compared to traditional industrial robots. “The payback on a cobot is typically very fast, often ranging from six to 18 months, and sometimes even shorter,” said Jerry Perez. Which means that smaller companies in particular, which can face challenges in adopting automation due to the high upfront costs and lower production volumes, can now afford to deploy a cobot on tasks that were previously too costly to automate. According to UR officials, its customer Midgard Inc., a custom injection molder in Green Lane, Pa., achieved ROI on a UR cobot after only 1,500 running hours, which is about three months of uninterrupted production.

Custom molder Midgard Inc. achieved ROI on a Universal Robots’ cobot after only 1,500 running hours.

Photo: Universal Robots

On average, cobots typically range from US$35,000 to US$60,000 for standalone models, but the total price of a fully integrated cobot system – including tooling, software licenses, safety features, and integration costs – can run to over US$150,000. Many OEMs offer flexible payment plans that can make a pricier model more accessible.

Another area for savings – of valuable time – is with maintenance. Cobots generally require simpler, less frequent, and less costly upkeep compared to traditional industrial robots, which are built for high speed and heavy duty and have greater cycle demands. “With Fanuc cobots, for example, there’s no grease to change – this is one of the big preventive maintenance differences compared to industrial robots,” Perez said. Even with robust designs, owners should expect to perform regular inspections, check components, and potentially replace items, but some cobot manufacturers advertise extended periods of operation with zero maintenance – such as Fanuc, which advertises its CRX cobot series as offering eight years of maintenance-free operation.

All of this said, there are still bright-line limits to what cobots can do in an injection molding plant. Applications that involve heavy loads, require very high speeds or precision, or involve highly unstructured and unpredictable tasks are still best left to traditional industrial automation. “High-speed industrial robots remain ideal for fast-paced assembly lines,” Perez said. “They’ll continue to dominate in heavy-weight production lines where speed and volume

Leading cobot brands enable relatively quick and easy programming regardless of the processor’s previous level of automation exposure, with no special software language to learn.

are paramount and in tasks that need extreme, unwavering accuracy over long periods.”

A concern with industrial automation decades ago was that it would kick human workers to the curb. But with thousands of baby boomers retiring every day and few millennials interested in joining the manufacturing industry, robots – including cobots – are now welcome additions to almost any molding plant, staffing the repetitive tasks that companies simply can’t fill. Maximizing the interaction between skilled operators and cobots can be more productive than using either robots or human operators alone, and

this is best achieved by consulting with long-time employees about cobot deployment. “If you’re making a palletizing cobot, for example, ask the person doing that job if it’s better to place it at the end of the conveyor or beside it,” said Jasper Arthur. “And figure out early in the process where the human operator will fit in, post-automation –will they be alongside doing a similar operation, or monitoring a fleet of cobots and dealing with any issues?”

For injection molders looking at automation options for their plants, it’s hard to ignore the cobot buzz. With

cobots taking on the repetitive, dangerous, and mundane tasks, human workers can do the jobs that demand a high degree of knowledge, expertise, and creativity – which can’t be provided by a robot. Cobots are one of the primary ways to expand the possibilities and effectiveness of automation.

But do your research first. “There are potential technical pitfalls for each application and use-case, and it can be very helpful to talk to others who’ve gone through a similar adoption to see if the execution matched up with their initial vision,” Arthur said. “Visit other factories, talk to people in your network, watch videos online, and try out a simple mock case or proof of concept if possible before jumping all-in.”

Fanuc Canada Ltd. (Mississauga, Ont.); www.fanucamerica.com National Research Council Canada (Ottawa, Ont.); www.nrc.canada.ca Universal Robots USA Inc. (Novi, Mich.); www.universal-robots.com

• Available with OPC UA EM82.1 communication capability for communication with primary machinery

• Maximum chillers are available with Low GWP (Global Warming Potential) Refrigerants

• Over 47 Years of Dedication to Engineering & Manufacturing Process Cooling & Temperature Control Equipment

• Over 95,000 Units Produced & Shipped Worldwide

• Continually Developing Better Solutions Featuring the Latest Technology

• Customer Service always available to answer application & troubleshooting questions

Scoring against yourself is a disaster in sports and in plastics manufacturing. When it comes to purging, self-inflicted errors will reduce efficiency, increase material waste, and cause unexpected machine downtime, to the benefit of your competition. Here’s how to stop making them.

BY MARK STEPHEN, EDITOR

Using a product in a way that’s not specifically intended by its designer or manufacturer and then complaining about the result is victim-blaming at its worst. And it can happen in the world of commercial purging compounds (CPCs), which are often either not used properly in the most cost-effective manner, or flat-out misused.

To be fair, it’s perhaps become easier to misuse CPCs as various grades become more complex and varied to the point where even experienced technicians can make mistakes. Not only have there been many advances made with general-purpose mechanical and chemical-based products over the years, but there’s also an increasing number of grades designed for specific applications, such as hightemperature engineering resins like PEEK and Ultem; and even tailored to processes such as blown film extrusion, which historically had limited purging options. “When procedures are overly complicated or require excessive labour, companies may struggle with consistent adoption across all shifts and go back to using virgin resin for purging,” said Andrew Reeder, the North American sales manager for thermoplastics at Chem-Trend.

Success depends on a few things: Selecting the best product for your particular application; understanding the intrinsic properties of your molding resin, including its viscosity, processing temperature range, thermal stability, and whether or not there are additives, colourants or contaminants present; and understanding your machinery configuration and condition – for example, how hot runners can influence the purge product selection due to their tight clearances.

Failing to address these and other issues can lead to the purging equivalent of the own goal – the self-defeating blunder that scores a point for the opposition, which, in this case, is your competition. Purging is one of the most essential maintenance activities in the molding process, and mistakes will reduce efficiency, increase material waste, and cause unexpected machine downtime. Understanding the most common purging errors – and how to avoid them – helps improve production consistency, minimize resin loss, and extend the life of your equipment.

One of the biggest errors comes at the beginning: using the wrong purge product for the application. “Selecting the right product is a critical step that requires close collaboration with the customer to fully understand their needs,” Reeder said. “Most CPC suppliers offer multiple products tailored to different applications and requirements, so it can be confusing to some processors.” For example, the suppliers say, a glass-filled mechanical compound may damage sensitive hot runner gate systems.

First and foremost, Reeder said, it’s essential that a user has accurate baseline data that can be compared to the new CPC that’s being evaluated. “If a company doesn’t have this data, we recommend they collect it before conducting trials with a new product,” he said. “Finding the best product should be straightforward and data-driven, using a cost analysis that identifies which CPC provides the most value by delivering the greatest savings.”

A good baseline data analysis considers factors such as temperature range, type of machinery, and the specific contaminants present. This last category can present a host of potential problems. “All additives – colourants, lubricants, process aids, fire retardants, UV protectors, and more – want to escape from their resin matrix, and that’s a part of the ‘residue’ that we’re challenged with purging,” said Ken Shuman, president of Shuman Plastics, which supplies the Dyna-Purge purging compound line. “It’s far more than just polymer.”

And don’t assume anything. “Making general assumptions for use instead of following outlined procedures specific to each CPC can lead to variable performance overall and/or by shift,” Shuman said. There’s no need to assume, though, since most purge suppliers provide a selection guide on their websites to direct you to the best grade for your application. That’s helpful, but you can go deeper by bringing the CPC maker or supplier into the conversation. “The customer benefits most from our technical staff being involved in making grade selections,” said Doug Bartlett, technical sales manager, Mid-South, for Purgex. “Grade information is available on our website, but we know what questions to ask to identify the customer’s needs and priorities for best results.” And for processors worried about time, a direct conversation with a CPC supplier probably won’t take long. “These discussions are quick, typically between only 10 to 15 minutes,” said Yoko Tanaka, marketing manager with Asahi Kasei Plastics North America, which is the exclusive manufacturer

and supplier of Asaclean CPCs in North and South America. And go one better still by having someone from the CPC supplier on-site to oversee product trialing if possible. “In most cases, we visit the plant to support initial testing and ensure the best results,” Tanaka continued. “There’s not much that our technical sales reps haven’t seen, so there’s benefit for the customer in this.”

A second common error is using the wrong temperature settings during the purging process. One of two things will happen: If the temperature is too low, the CPC won’t melt properly; and if it’s too high, the material may degrade, burn, or leave stubborn residues that are harder to remove later. To prevent this, ensure that your machinery can maintain the required temperature range throughout the purging process and always refer to the manufacturer’s guidelines – especially when switching between resins with different melt temperatures. Related to this, not all CPC products are safe for use with all polymers from the point of view of temperature. “Not all CPCs are heat-stable for use during shutdown and/or startup,” Ken Shuman said. The goal is to stay within the safe processing temperature limits of the production resin to prevent degradation or burning, which causes contamination, manifested in black specks. The appropriate temperature for purging plastic resins depends on the specific resin being processed and the type of CPC being used, so always consult the technical

data sheets or the manufacturer’s instructions. Generally, purging is performed within or slightly above the processing temperature range of the resin currently in the machine, using a compatible purging compound.

A third common error is inadequate material displacement – not getting rid of the old material before introducing the new. “It’s very important that the specified amount be used to remove the purging compound during the ‘rinse,’ otherwise the CPC will appear in the parts when production is begun,” said Doug Bartlett. The solution is simple: Use an adequate amount of the CPC to ensure complete displacement of the old material. Skimping on the CPC to save cost upfront will backfire ultimately, since it can result in insufficient cleaning, leading to contamination and material waste. Again, it’s all about sticking to the program. “CPC suppliers specify recommended usage amounts based on multiple variables, and it’s important that customers follow these guidelines,” Andrew Reeder said. And it happens both ways, he continued. “Overusing purge compounds can reduce cost savings and negatively impact overall efficiency gains, while not using enough of a product can reduce performance,” he said.

Processors that ignore the instructions can make a host of mistakes,

“Making general assumptions for use instead of following outlined procedures specific to each CPC can lead to variable performance overall and/or by shift.” — Ken Shuman, Shuman Plastics

beginning with confusing the properties of mechanical and chemical purges. Mechanical purging uses physical scrubbing for quick colour changes and basic cleaning, and there’s no chemical reaction or soak time. Chemical purging, meanwhile, uses heat-activated agents for deep, thorough cleaning of carbon and residue, especially in low-pressure areas like hot runners; some require no soak time while others require up to 30 minutes. And some “hybrid” CPCs are a blend of both chemical and mechanical. “Each type has specific-use instruction,” said Ken Shuman. “Mechanical purges are typically simple and easy to use directly out of the box. Chemical requires activation – soak or residence time – which is a hidden cost of use, as do ‘hybrid’ products. The mistake is to overlook these distinctions of use.”

Talking with a supplier to find the right CPC for the job might take a maximum of only 15 minutes.

Despite being comparatively simple, mechanical purges can be plagued by a common mistake: “Processors often use too little or too much material with mechanical purges,” said Yoko Tanaka. “So it’s important to follow specific instructions about dosage.”

And deviating from the manufacturer’s guidelines by rushing the process is another common error. Skipping soak periods or shortening purge time may save a few minutes, the CPC suppliers say, but can prevent the compound from fully displacing old resin. The results include black specks, carbon buildup, colour streaks, and resin contamination during the next production run.

For processing shops with both injection molding and extrusion, errors can also be made by treating purging the same way for both types of machines –which is wrong because while the basic physics and chemistry are the same, the procedures will vary. “Each process has its own particular nuances, and advantages and disadvantages,” said Ken Shuman. Injection molding is generally a more involved process compared to other types of equipment, CPC suppliers note, and it offers more processing parameters that can be adjusted to fine-tune purging procedures and enhance performance. “Injection purging can be cycled with short high-velocity air shots to clear the screw tip assemblies, and increased backpressure may also improve purging performance,” Shuman said. In some cases, the CPC suppliers say, injection molders must also mold and eject parts during purging, which requires the correct product selection and procedures. Generally, they continue, applications that require only the extruder to be cleaned tend to have simpler procedures, with fewer machine settings that need adjustment. “Extrusion purging can be improved by using a screen pack/breaker plate combination to drive continuous increased backpressure,” Shuman said. “And varying the screw rpm speed can improve agitation and dislodge carbon and/or colour.”

And there may be variation even within the subset of injection molding – not so much from one brand to another but based on the type of machine. “Some injection molding machines don’t allow purging through the mold while the mold is open,” Andrew Reeder said. “In these situations, the only option for purging the hot runners is to utilize a purge compound that can be molded and ejected from the tool.”

Speaking of the machines, many processors use the default “auto-purge” mode on their injection molding machines during a purge. While convenient,

these preset parameters rarely deliver a complete purge, however, since auto-purge typically runs at lower pressures and screw speeds than what most CPC suppliers recommend, decreasing the compound’s cleaning efficiency. For best results, switch to manual purging, use higher screw speeds, increase the purge pressure, and keep the screw in the forward position for maximum mixing and resin displacement.

The final steps will sound familiar because they’re applicable in all aspects of plastics manufacturing: have a preventive maintenance (PM) program in place and follow it. Purging compounds should complement – not replace – regular maintenance schedules, the suppliers say, so ensure your machinery undergoes routine inspections and maintenance to

www.ccc-group.com/plastics info_cccplastics@ccc-group.com

prevent buildup and mechanical issues that CPCs can’t solve on their own. “A big issue we see is companies that don’t have a PM program in place to eliminate carbon buildup in their equipment,” Reeder said. “Carbon typically accumulates gradually over time, and the most effective way to manage it is through a structured PM program that includes periodic machine cleaning. Trying to remove it later becomes far more time-consuming and less effective, even with a professional grade CPC.” These PM schedules can vary widely depending on materials, equipment, and processing conditions, but creating and following an effective program helps reduce downtime, scrap rates, and the need for screw and die pulls.

In the end, achieving good purges boils down to the primary directive of following the guidelines – carefully read and follow the manufacturer’s instructions for each specific product, including details on dosage, temperature, and purging duration. “Failure to follow the CPC manufacturer’s procedure for the application is the main issue that we encounter,” said Doug Bartlett. Avoiding the own goals of purging will keep you in the game by achieving cleaner transitions between materials and colours, minimizing downtime and maintenance, and reducing scrap.

Asahi Kasei Plastics North America (Parsippany, N.J.); www.asaclean.com

Chem-Trend L.P. (Howell, Mich.); www.chemtrend.com; 517-545-7980

Dyna-Purge Div./Shuman Plastics Inc. (Depew, N.Y.); www.dynapurge.com

Purgex Purging Compounds (Houston, Tex.); www.purgexonline.com

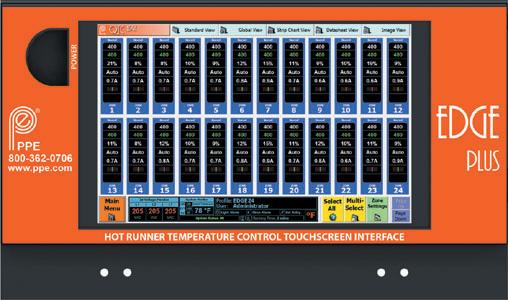

Hot runners have radically transformed injection molding by eliminating waste runners, saving material, and shortening cycles. And the revolution isn’t over yet. From new systems and new controls to new testing devices, the latest innovations keep it going.

BY MARK STEPHEN, EDITOR

Oerlikon’s Up Nozzle series is specially engineered for tight-space applications with low shot weights.

Hot runners are revolutionary by definition. Developed in the 1950s to solve the then-standard problem of injection molders generating a large percentage of scrap on every shot in the form of sprues and runners, they gained widespread adoption by the late 1970s, revolutionizing injection molding by allowing the process to occur without the need for a runner system – making part cooling the chief element dictating cycle time rather than the sprue. Because they dramatically reduce scrap, hot runners have benefited molders during times of rising resin prices – which is almost always – and have also opened the door to coinjection and multi-component molding within the same machine.

And the revolution isn’t over yet. Hot runner components are usually one of the largest categories of injection molding products exhibited at the major trade shows, including K 2025, which took place in Düsseldorf, Germany just a few months ago. Here’s a look at a few of the new hot runner products exhibited at the big show.

Hasco’s new H1210 hot runner mold testing device is a compact, battery-operated unit that identifies electrical connections – including heating elements, temperature sensors, ground faults, and wiring errors – within seconds, presenting the data both graphically and in table form. This makes it ideal for preventive maintenance, troubleshooting, and quality testing before production begins. The device features a seven-inch colour touchscreen with intuitive menu navi-

gation and can export measurements in .csv or .xlsx formats, offering maximum user-friendliness alongside precise analysis. Data transfer occurs via USB interface. And while developed by Hasco, the testing device works with all common wiring specifications on the market, not just Hasco-specific systems, reliably recognizing and interpreting various cabling standards regardless of manufacturer, making it suitable for universal applications.

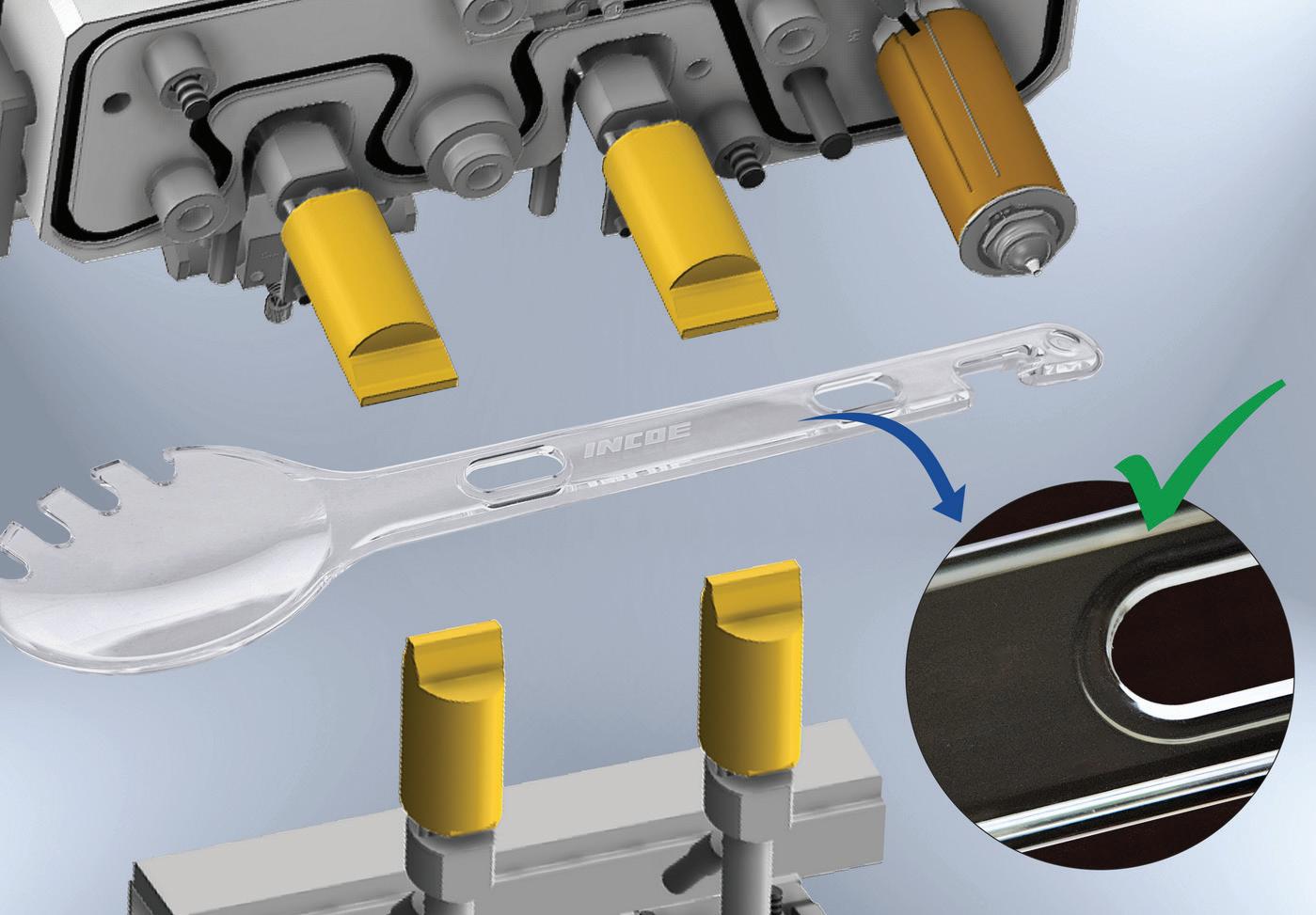

Incoe used the K show to showcase how its compact Heat-Inject system makes weld lines on molded parts –which can’t be avoided altogether, as they occur naturally due to the flow of the melt in the cavity – far less visible. Using localized variothermal temperature control, the company said, the technology delivers precise heat pulses that eliminate surface defects, with minimal energy input and without disturbing the overall molding process. “A heated stamp is briefly pressed against the wall of the cavity from behind and transfers a small amount of heat,” they said. “This amount of heat is sufficient to briefly raise the temperature of the mold surface to a level that prevents the formation of a weld line notch. At the same time, the amount of heat introduced is so small that it’s quickly dissipated via the mold plate without disturbing the heat

Hasco’s H1210 hot runner mold testing device is a compact, battery-operated unit that identifies electrical connections within seconds.

Photo: Hasco Hasenclever GmbH + Co. KG

balance in the mold or the injection molding process.” Heat-Inject units are supplied mounted on the hot runner system and are also available in modules as an extra assembly.

MHS Mold Hotrunner Solutions used K to launch its Rheo-Pro iVG 4 hot runner program, which the company calls the world’s most compact internal valve gate nozzle. With an upgraded internal valve gate design, new fourth generation iVG nozzles allow manufacturers to build extremely compact molds, the company said, while maximizing production capacity and profitability. As a space-saving design, the iVG 4 enables ultra-compact single face molds, back-to-back “short stacks,” and stack molds with a tip-to-tip length of just 285 millimeters (mm) and a pitch distance of 63.5 mm. The new nozzle series features a smaller valve pin diameter than previous iVG offerings, and more powerful internal actuation with a force of 140 psi (10 bar) air pressure, producing 90 pounds (400N) of valve pin closing force at the gate. This allows the iVG to process parts and materials that require a higher packing or hold pressure and time, typically required for thick-wall precision parts with semi-crystalline materials. And unlike electric actuators, the iVG 4 can operate at extreme temperatures of up to 400°C or 750°F.

In the buildup to K, Mold-Masters announced a series of enhancements to its Dura+ hot runner systems that will streamline installation, reduce downtime, and elevate overall system performance. Dura+ systems utilizing F-style nozzles that are delivered drop-in ready (pre-plumbed/pre-wired) are now engineered to be installed and uninstalled at room temperature – in other words, right out of

the box – to reduce installation time, eliminate extra equipment such as a temperature controller, and improve safety conditions during installation and removal. Also, the Dura+ (F) nozzles are now available in customizable lengths up to 1,000 mm and feature more compact nozzle bore cut-outs. And Dura+ actuators now have a more compact height and cut-out than previous actuator designs and have a quick release feature that allows it to be detached from the hot runner system, without having to remove the valve pin with it, to make servicing the actuator quicker and easier.

Finally, Oerlikon HRSflow debuted its new Up Nozzle series at K, which has reduced the gate-to-gate pitch to 15 mm and is specifically engineered for tight spaces with low shot weights. With a 12-mm nozzle cut-out, the series can perform in hard-to-reach gate areas, company officials said, making it well-suited for the beauty and personal care, packaging, beverage, and technical application markets. And it’s compatible with a wide range of materials, they said, including polyolefins.

Hasco America Inc. (Fletcher, N.C.); www.hasco.com

Incoe Corp. (Auburn Hills, Mich.); www.incoe.com

MHS Mold Hotrunner Solutions Inc. (Milton, Ont.); www.mhs-hot-runners.com

Mold-Masters (Georgetown, Ont.); www.moldmasters.com

Oerlikon HRSflow (Byron Center, Mich.); www.hrsflow.com

What does purging perfection look like? Industry leadership, decades of innovation, outstanding customer service, technical expertise and product that’s effective every time. When your work has to be perfect, trust the leader. Trust Dyna-Purge. Request a free sample of Dyna-Purge and see for yourself.

Discover the Difference. 866-607-8743 www.dynapurge.com

DYNAPURGE is a registered trademark of Shuman Plastics, Inc.

XELA Robotics is using plastics to help reach a new level of automation.

BY MARK STEPHEN, EDITOR

The rapid development of humanoids – driven by advances in artificial intelligence (AI), sensors, and robotics – is transforming them from research projects into functional systems for industry, with breakthroughs coming almost at a blink-and-you’llmiss-it pace. Nevertheless, it feels like a genuine gamechanger that Japan-based XELA Robotics – a startup launched from Waseda University –has succeeded in providing a human sense of touch for humanoid and industrial robot hands and grippers, in a broad range of manufacturing and other applications. And plastics plays an important role.

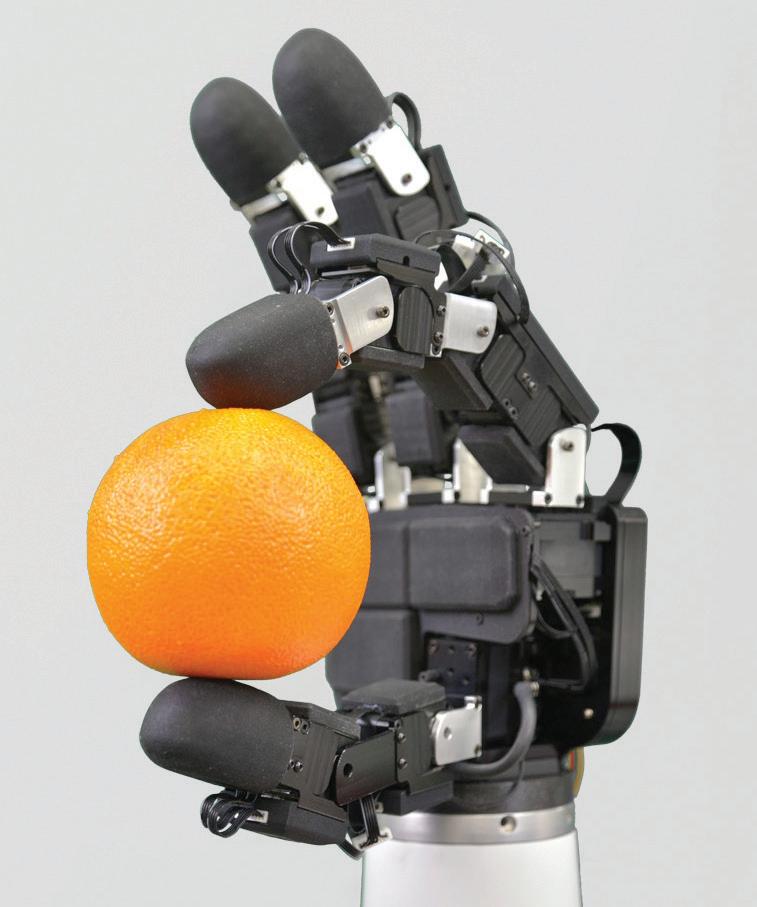

The company recently integrated its uSkin sensor technology successfully into a Tesollo DG-5F five-fingered anthropomorphic robot hand, which is a popular model that’s capable of human-level gripping and manipulation. According to XELA officials, the hardware and software platform enables physical AI, addressing a longstanding limitation in robotics where machines struggle to handle objects with the same care and precision as humans. The system combines XELA’s high-density three-axis tactile uSkin sensors and proprietary software to help robots understand what they’re touching, how tightly they’re

Robotics’ tactile system combines uSkin sensors and proprietary software to help robots understand what they’re touching.

BELOW

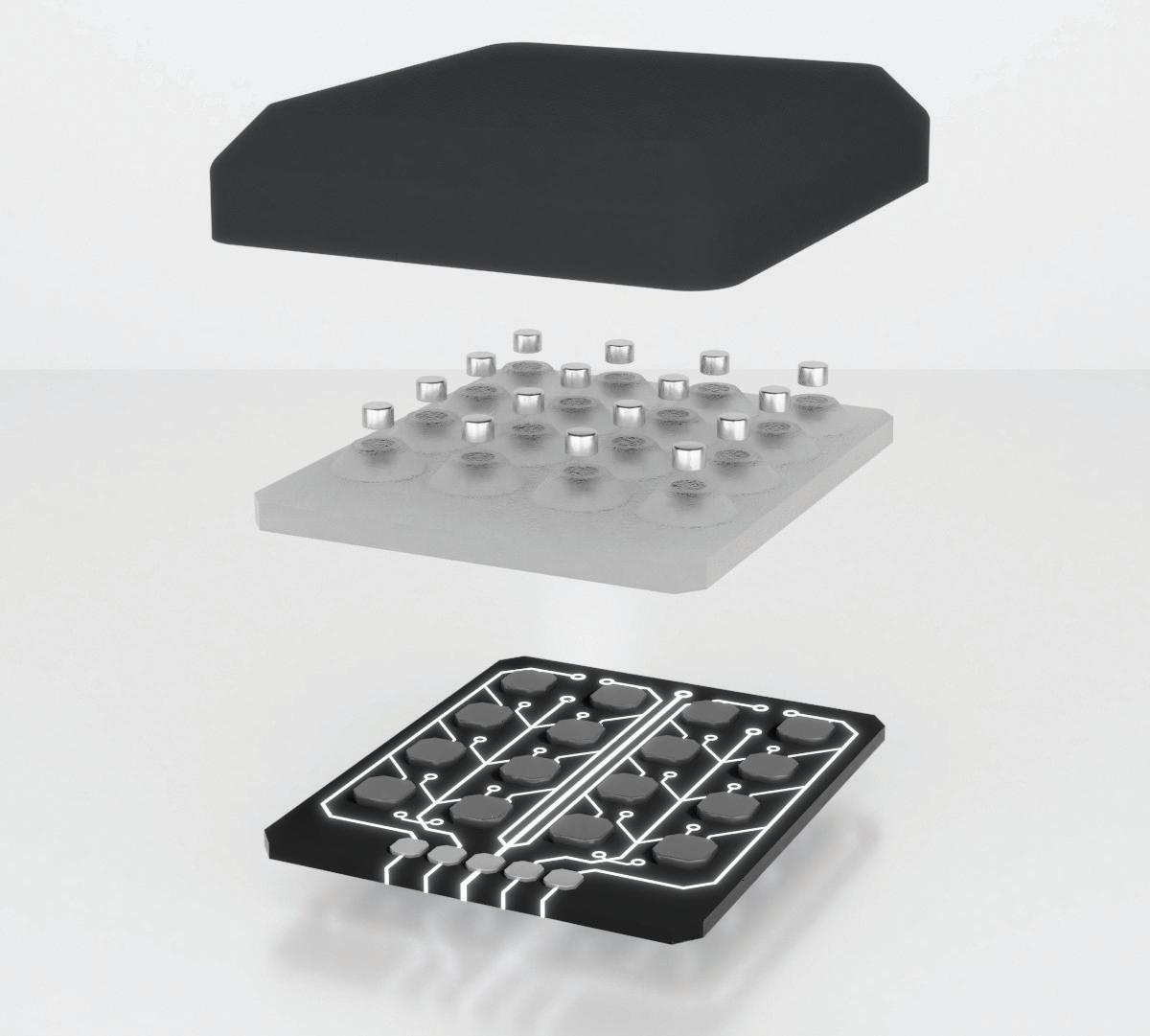

The uSkin consists of three main layers: a protective outer shell, a soft elastomer middle layer, and a bottom layer that’s a sensor module with a multitude of chips.

gripping an object, and how it moves within their grasp. The uSkin consists of three main layers. The outer shell creates a smooth surface and protects the sensors; the middle layer is a soft elastomer that ensures that the sensor is highly resilient to overloading and makes uSkin durable and able to conform to the object being grasped; and the bottom layer is a sensor module which includes a multitude of chips, each of which can measure 3D displacement individually.

While XELA won’t disclose specifics about the elastomer it uses, company officials say they did their due dili-

gence beforehand. “We evaluated a wide variety of elastomers, using customized in-house testing equipment, especially regarding durability and hysteresis,” said Dr. Alexander Schmitz, XELA’s CEO and co-founder. “The material we chose for our sensors performs exceptionally well in those regards. Furthermore, we can customize our elastomer according to user requirements, especially regarding hardness and sensitivity/ force range.”

Unlike most robotic hands, which only have sensors in the fingertips, XELA says it can integrate its sensors in a significantly larger surface area, including fingertips, phalanges, and the palm. The uSkin sensors can integrate into parallel grippers, multifinger adaptive grippers, custom end effectors, and robotic hands, including those that customers may already have in place; and XELA also offers integrations compatible with existing hardware from several robotics’ suppliers – including Wonik Robotics, Sake Robotics, Weiss Robotics, and Robotiq – so customers won’t have to replace their current robotic platforms. “We’ve taken an agnostic approach to commercializing our technology to make it available to all companies seeking to enhance their real-world automation,” Schmitz said.

MARK YOUR CALENDAR for the Canadian Plastics Fall Classic taking place September 10th, 2025.

We are returning to Piper’s Heath Golf Club with their award winning linksstyle golf course. The day will be filled with great networking opportunities, friendly competition, loads of prizes, and lots of great food and beverages.

Want to join the tournament but not ready for a full round?

Our Golf Clinic is the perfect way to participate, learn new skills, improve your game, and enjoy the tournament atmosphere.

SHOTGUN START: 8:45 AM

The fourth generation of Maguire’s Ultra vacuum dryer is designed to be simpler, more affordable, and more accessible than ever.

The Ultra series now includes seven sizes, giving processors a broader throughput range and flexibility to select a right-sized solution for virtually any application. New variants – the Ultra 150E (at left in photo), 300E, and 300+ –extend throughputs to 165, 285, and 440 pounds per hour respectively, or 75 to 200 kilograms per hour, filling critical capacity gaps for polyethylene terephthalate (PET) and extrusion applications.

The new models are designed to provide superior energy efficiency, rapid return on investment, and significant productivity gains.

All the models in the series enable Maguire’s signature 15-minute “pit stop” material change – a dramatic improvement that slashes downtime from hours to minutes and delivers average energy savings of 60 per cent versus desiccant dryers. And with load-cell monitoring of the vacuum chamber and retention hopper, operators can stage and preheat the next resin while continuing to run the current job.

www.maguire.com

The Model TSF twin-screw feeder from Best Process Solutions (BPS) is designed for precise batching and weighing applications.

The feeder’s dual-helix design combines fast, high-volume filling with accurate dribble flow at the end of the cycle, and its compact design is ideal when limited space prohibits multiple individual screw units.

Two helixes – 1.5 and 4 inches in diameter – are mounted on an 18-by-22-inch hopper and are rated at 17 cubic feet and 283 cubic feet per hour respectively, at maximum rpm with 100 per cent efficient conveyable product and no slippage.

TSF is well-suited for batching to weigh-hoppers, low loss-in-weight scale-monitored flow, low loss-of-weight batch applications with scales; drum and pail packout lines; and recipe-type batching by multiple computer-controlled units.

Many options are available.

www.bpsvibes.com

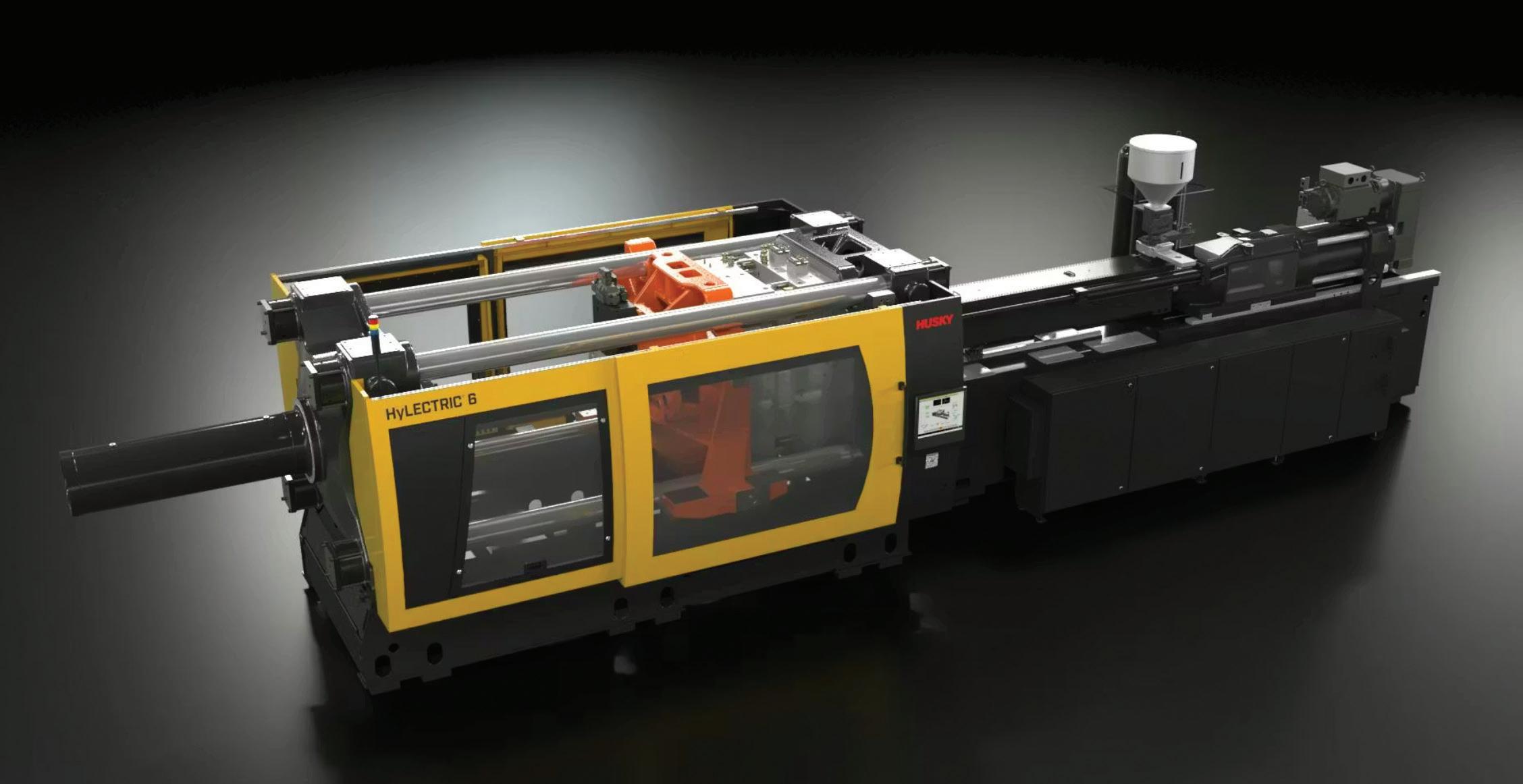

The new Hylectric6 injection molding machine platform from Husky Technologies is designed to produce packaging molding, including industrial pails, thinwalled food containers, closures, and medical devices.

Offered as a unified ecosystem that’s digital, integrated, and designed to support a more sustainable industry, the new system features increased energy efficiency, enhanced user experience, improved performance via reduced non-process time, and optimized feeds screws that yield boosted throughput and recovery capabilities.

And the machines are connected to Husky’s Advantage+Elite 24/7 proactive, predictive monitoring system, which tracks more than 70 new packaging performance parameters in real time, alerting and supplying customers with proactive, actionable insights that help maximize efficiency, reliability, and overall performance management.

www.husky.co

New from Pixargus, the ProfilControl 7 XLine inspection systems for plastics and rubber extrusion quality control are designed to help users reduce scrap by detecting even very small surface defects and geometrical deviations, delivering maximum precision and reliability with minimal system complexity.

Consisting of the ProfilControl 7 PlastX system for plastic extrusion (pictured) – which is targeted at industries such as window profile production – and the ProfilControl 7 RubberFleX for rubber extrusion, the 7 XLine has optimized software architecture and smart assistance features, with up to 700 high-performance LEDs.

Both PlastX and RubberFleX can be configured as dimension measurement systems, surface inspection systems, or combined all-in-one solutions. www.pixargus.com

PCS Co. has launched corrosion-resistant stainless steel ejector pins in inch and metric sizes, designed to be ideal for medical and polyvinyl chloride (PVC) molding applications and cleanroom environments.

These new pins feature a close pin diameter tolerance of +0/-0.005 millimeters (mm) and annealed heads and are through-hardened for superior wear resistance, making them well-suited for molding corrosive plastics.

Metric JIS stainless steel ejector pins are offered in standard diameters starting from one to six mm, and lengths from 100 to 200 mm.

Inch varieties are available in diameters from one-sixteenth to one-half, and lengths of six to 10 inches.

Both inch and metric versions are made of SUS440C stainless steel with hardness of 56 to 60 HRC. www.pcs-company.com

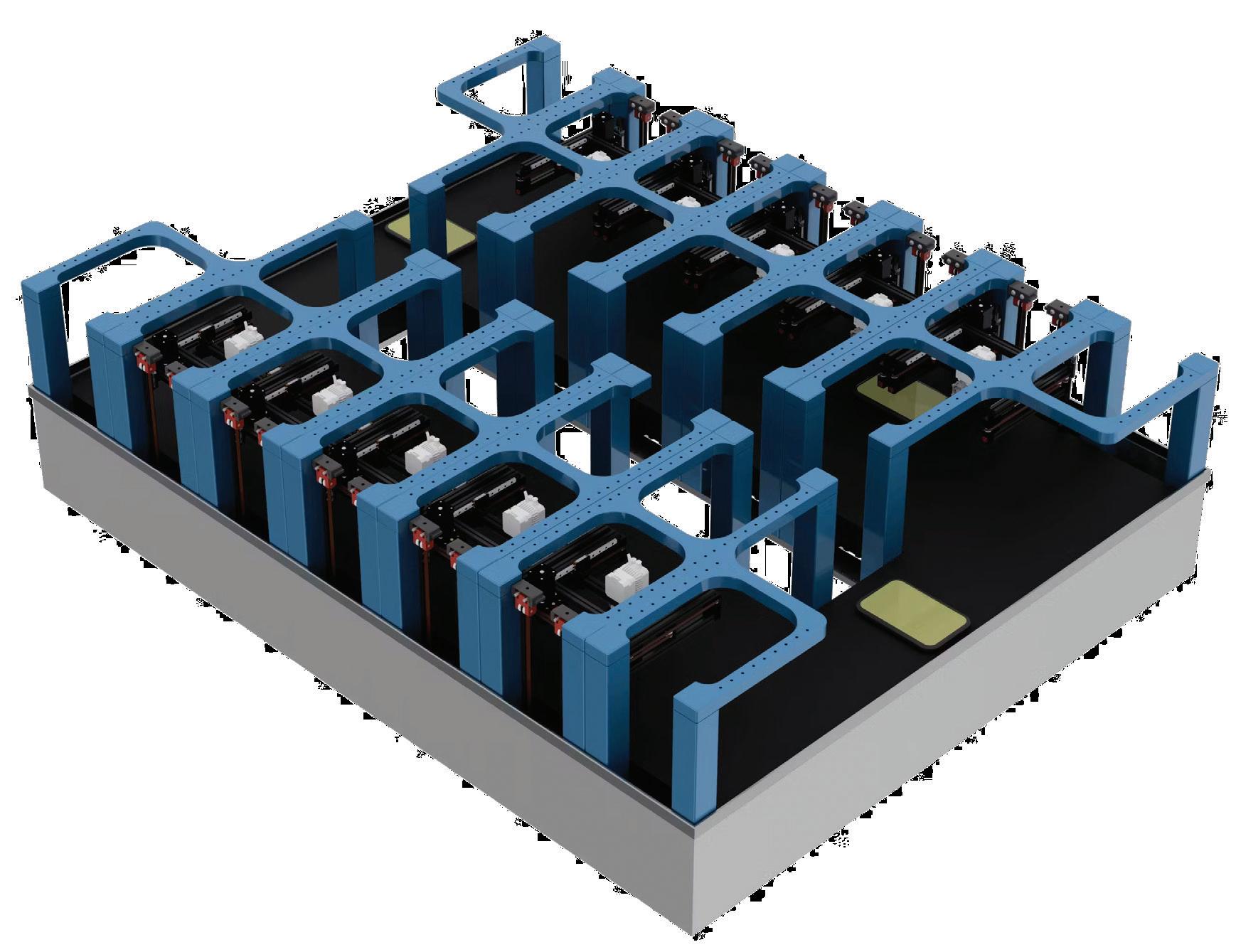

The Matrix6D modular, multi-tool-station additive manufacturing system from Advanced Printed Electronic Solutions is designed for manufacturers looking to scale up production from prototyping to large volumes.

It allows multiple manufacturing recipes to run in parallel, making it ideal for semiconductor and electronic device packaging, additively fabricated circuit boards, metamaterial optics, and other applications. www.advpes.com

Featuring a proprietary blend of fatty acid derivatives and vis-breaking technology, Struktol’s VMO series is an advanced family of melt flow modifiers designed to optimize polypropylene processing, quality, and versatility, allowing compounders, processors, and recyclers to accelerate throughput rates, enhance manufacturing efficiency, lower overall costs, and support circular manufacturing models and closed-loop recycling efforts.

Available in an easy-to-handle off-white to beige pastille form, the modifiers feature a low-odour formulation that includes an odour neutralizer, allowing for high-quality, neutral-smelling finished compounds.

Additionally, the series is effective at low addition levels, has a storage stability of at least two years, and is available in 50-pound bags and 2,000-pound skid packaging formats. www.struktol.com

Avient has added non-PFAS (Per- and polyfluoroalkyl substances) processing aids for low-density polyethylene (LDPE) and low-linear-density polyethylene (LLDPE) to its Mevopur healthcare functional additives portfolio. These non-fluorinated alternatives can help reduce common processing issues such as die buildup, melt fracture, and shark skin in extruded tube and film applications – including catheters and pharmaceutical packaging – while maintaining performance levels on par with conventional processing aids that use fluorinated substances.

The Mevopur portfolio offers colour and additive masterbatches and compounds formulated with bio-derived materials, including polypropylene, polyethylene, polycarbonate, acrylonitrile butadiene styrene (ABS), and styrenic polymers; and its raw materials are pre-tested to ISO, USP, and ICH Q3D protocols. www.avient.com

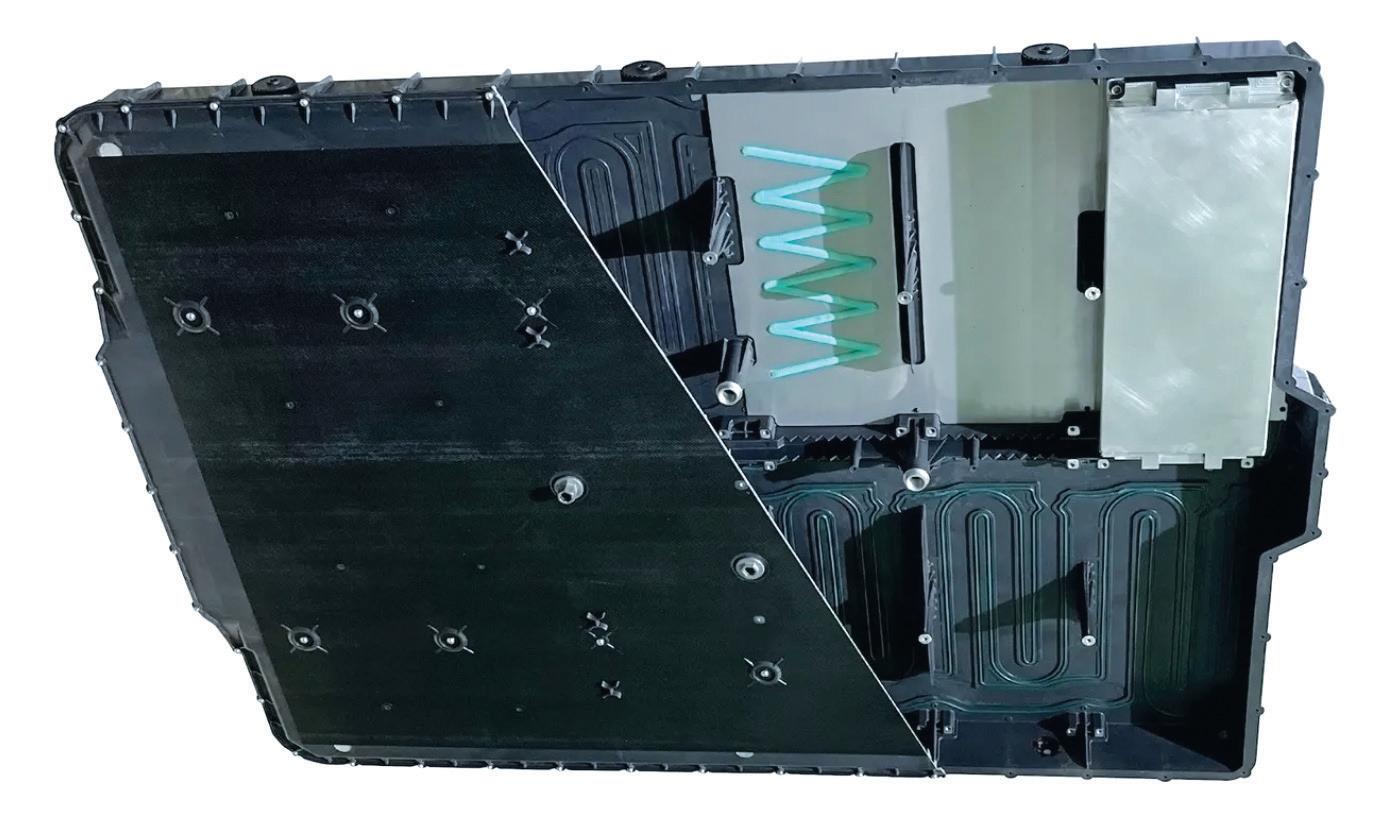

Sabic recently introduced its Megamolding platform, which consolidates the company’s data, tools, and materials to help make production of large thermoplastic parts more accessible and efficient across a variety of sectors.

The platform’s benefits include cost and process efficiency by using competitive tooling, consolidating parts, and simplifying manufacturing, post-processing, and assembly steps; faster injection molding cycle times compared to metal casting or thermoset processing; greater design freedom for more complex geometries and functional integration that’s difficult with metal stamping or casting; and weight and mass reduction while meeting strength and stiffness requirements.

The technology is well-suited for a wide range of industries and applications, including automotive, energy and infrastructure, industrial equipment, consumer goods and electronics, and building and construction.

www.sabic.com

By Bob Reese, RJG Inc.

Following up on my last article on testing to maintain injection mold part quality, here are nine common injection molded part defects and some practical solutions for addressing them. This is not an exhaustive list but simply some techniques to try regardless of your available equipment.

Sink marks are depressions or indentations on the surface of molded parts, caused by insufficient cooling time, inadequate packing pressure, improper gate design, and/ or poor part design. Solutions include increasing the cooling time to ensure complete solidification, adjusting the packing pressure, and redesigning the gate to improve material flow and pressure distribution.

Warping is the distortion of a part, caused by uneven cooling rates, mold temperature imbalance, material shrinkage, and/or non-uniform part thickness. Solutions include ensuring uniform cooling by optimizing the cooling channel design, balancing mold temperatures to prevent differential cooling, using materials with lower shrinkage rates, and adjusting processing parameters to control shrinkage.

Flash is excess material that extends from the edges of a part, caused by filling the mold too full during fill, worn or damaged mold parts, and/or improper clamping force during molding. Solutions include decoupling the process to ensure the mold isn’t being over-filled during

This is not an exhaustive list but simply some techniques to try regardless of your available equipment.

filling, regularly maintaining and inspecting molds, and adjusting clamping force to ensure the mold halves are properly sealed.

Short shots occur when the mold cavity isn’t completely filled, resulting in incomplete parts. They’re caused by insufficient material supply, low injection pressure or speed, and/or blockages in the gate or runner. Solutions include ensuring adequate material supply and proper feeding, increasing injection pressure and speed, and/or clearing any blockages in the gate or runner.

Weld lines are visible lines on the surface of parts where two flow fronts meet and fail to bond properly, caused by low melt temperature, slow injection speed, poor venting in the mold, and/or gate location and part design. Solutions include increasing the melt temperature to improve flow front bonding, increasing injection speed to reduce cooling before meeting, and improving mold venting to allow gases to escape and prevent weak bonds.

Air traps are pockets of air that get trapped within the part, leading to voids or bubbles, and are caused by inadequate venting in the mold, high injection speed, and complex part geometry. Solutions include improving mold venting to allow air to escape during injection, reducing injection speed to prevent air entrap-

ment, and redesigning part geometry to minimize areas where air can become trapped.

Burn marks are dark discolourations or blackened areas on the part, caused by high injection speed, excessive melt temperature, and/or poor venting. Solutions include reducing the injection speed to prevent overheating, lowering the melt temperature, and enhancing the mold venting to release trapped gases and prevent burning.

Surface delamination is the separation of the surface layer from the underlying material, and is caused by contaminated material, incompatible material blends, and/or improper material handling. Solutions include ensuring material purity and proper handling to avoid contamination, using compatible material blends and verifying supplier quality, and implementing thorough material inspection and handling procedures.

Voids are internal pockets caused by the material shrinking away from itself. The causes include insufficient packing pressure, uneven cooling, and/or high melt temperature. The solutions include increasing packing pressure, ensuring uniform cooling to prevent differential shrinkage, and lowering melt temperature to reduce gas formation within the material.

BOB REESE is a senior consultant at RJG Inc., a Traverse City, Mich.-based training and consulting company that specializes in the injection molding industry. Visit www.rjginc.com for more.