MACHINERY AND EQUIPMENT

29, No. 4

SPECIAL REPORT

INDUSTRIAL LUBRICATION

Understanding friction regimes

How lube affects machine performance

What’s new in lubrication

29, No. 4

SPECIAL REPORT

INDUSTRIAL LUBRICATION

Understanding friction regimes

How lube affects machine performance

What’s new in lubrication

Are your maintenance records backed up?

Pumped for action: 8 hands-on tips for keeping pump costs down

Maintaining the flow of engine-driven pumps

Canada’s industrial safety a guide for the world

Report from PTDA’s Canadian Conference

WHAT’S NEW SEALS & GASKETS SEVERE SERVICE TOOLS

Work glove offers the wearer comfort while keeping out winter cold

Designed, engineered and tailored to withstand Canada’s harsh winter climate, the ActivArmr 97-201 personal protective glove from Ansell offers a balance of protection and dexterity for the real-world extremes of the oil and gas and mining industries. The glove features a flame-resistant construction, along with good impact protection. The reinforced Kevlar stitching supports a waterproof PU barrier, while Thinsulate insulation keep hands warm and dry in the most aggressive conditions.

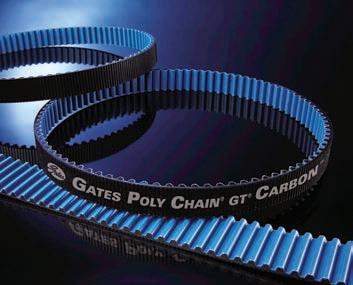

Carbon belt outperforms roller chain in demanding high-torque applications

In today’s high-performance driven world, parts that need to be incredibly strong and lightweight are often made of premium-grade carbon fibre.

Gates’ Poly Chain GT Carbon belt offers very high power transmission capacity, strength, flexibility and durability, packing a lot of power into a small space, matching the capacity of roller chain drives width-for-width in most pitch

sizes. This maintenance-free drive is said to outlast roller chain 3-to-1 and accommodates the use of backside idlers, while compact drive components provide versatility to drive designers.

Gates Canada Online Reader Inquiry No. 473

On-line monitoring system checks on machine condition round the clock

SKF’s robust and programmable Multilog IMx on-line 24/7 monitoring systems for a wide range of machine condition monitoring applications provide timely and true simultaneous measurements of various operating parameters. All systems are engineered to detect faults early and integrate automatic recognition to correct existing or impending conditions. The technology additionally offers an

Motor-driven pump systems represent 30% of all motors used in North America.

Baldor Electric Company recognizes

the need for robust, energy efficient motors for this application and offers a wide range of motors for practically any pump application:

• 56J

• Close-coupled

• Explosion-proof

• Vertical P-base with solid shaft

• Submersible and immersible designs

…plus, an unlimited number of custom designs.

With low and medium voltage motor horsepower ratings to 15,000 and stock motor voltages in 115/230 and 230 for single phase and 200, 230/460, 460, 575 and 2300/4000 volt for three phase designs, there’s a Baldor•Reliance® pump motor for your next pump system design or retrofit replacement need. For special applications and strict industry specification requirements, IEEE 841-2009, API 610, API 541 and API 547 compliant designs are

available. ABB brand IEC metric motors are offered in standard or ATEX configurations for export or replacement on imported equipment through 100,000 Hp.

OEM pump manufacturers and pump assemblers will find a wide range of Baldor•Reliance stock and custom motor configurations to meet your specific application requirements. For OEMs that manufacture their own submersible pumps, Baldor can supply stator-rotor sets in many different frame sizes and ratings for low and medium voltage use.

All Baldor•Reliance motors are made in America and distributed through 32 stocking warehouses in North America, giving you the fastest stock motor delivery in the industry.

In a motor-pump system, the life cycle cost of the motor is about 2% of the total expense with electricity consumption comprising over 97% of the motors total cost. By upgrading to a Super-E® NEMA Premium® efficiency motor, substantial energy can be saved… immediately. Since most pump systems are oversized for worst case conditions and are operated well below that point, adding an adjustable speed drive to operate the motor at a lower speed (instead of using a valve) can, in most cases, save over 60% of the energy used.

These applications can pay for the cost and installation of the drive in less than a year with rebates available from most utilities, while reducing energy consumption for many years afterwards. Both the U.S. Department of Energy and Natural Resources Canada accept Baldor’s Super-E motors as an energy-saving upgrade.

opportunity to convert and upgrade outdated systems, and interface with compatible SKF @ptitude Analyst and Observer software. Included are units for extremely tough industrial environments and models for turbo machinery, wind turbine, vehicle, or railway applications, as well as portable versions suited for temporary installations and troubleshooting The systems can run on an existing LAN or WAN and network, or over the Internet.

SKF Canada Online Reader Inquiry

Affordable shaft alignment system features wireless communication Hamar Laser has introduced the durable, light- weight and mobile Stealth series S-660T three axis wireless laser shaft alignment system. This entry-level system features Couple6 software, which runs on a PC industrial tablet with a Microsoft Windows 7 Professional operating system. The S-660 Dual-Fan measurement technology enables highly accurate measurement of offset and angle simultaneously using two laser fans and two PSDs, providing full operating range between laser and target. An internal Bluetooth transmitter sealed in IP67 housing has a range of up to 10 m (33 ft) from the target to the Windows-based 10.1-in. high-resolution tablet display. Using Dual Arc technology, spans of 3.05 m (10 ft) can be achieved with the use of a fantype laser.

Hyatt Industries

Online Reader Inquiry No. 471

Linear spring series comes in a wide range of sizes Smalley’s linear springs, available from RotoPrecision, are produced from spring tempered wire material that is shaped into waves along the length of the wire. They act as load-bearing devices, having approximately the same load and deflection characteristics as circular wave springs, but designed for straight-line applications. This means a linear spring may be located in an axial direction, yet still provide a radial force. The springs are available as a standard part in more than 200 sizes, with stock in carbon and stainless steel. Custom sizes and exotic alloys also are available. There are no tooling charges on special designs. The springs are available cut to length or as a continuous coil, for the user to cut as needed.

RotoPrecision

Pumped for action / 10

Eight tips for keeping costs down at the pumps.

Keeping the flow flowing / 11

Performing preventive maintenance helps reduce downtime with engine-driven dewatering pumps.

Generator repair requires perseverance / 13

Old machinery and tight spacing make retrofit of

What’s new in lubrication / 19

Products, components, systems and services for industrial lubrication.

Mr. O, the Practical Problem Solver / 9

Explaining the strange and unusual Hollow Ball Phenomenon in bearings.

Improving worker safety everywhere / 15

Safety File: If safety standards like Canada’s were introduced worldwide, it would save thousands of lives each year.

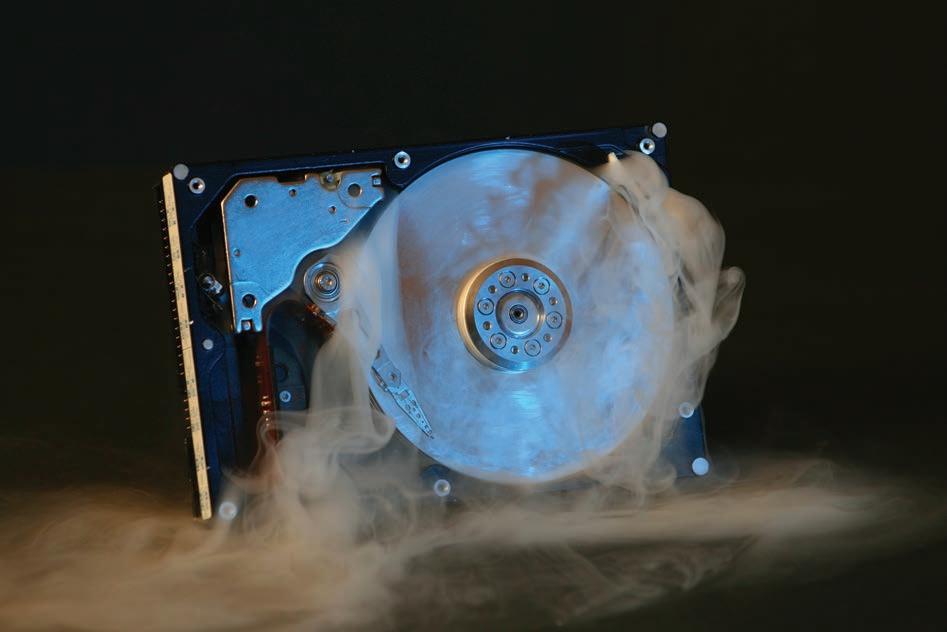

On the Cover: Backing up your CMMS data / 16

Maintenance 101: Are you facing a data disaster? You won’t know how much you’ll miss your data until it’s gone. Here are four examples that highlight the need for good backups of all your maintenance records.

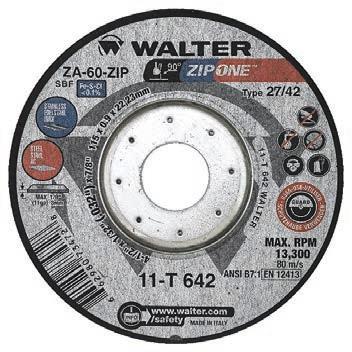

MRO on the Road / 25-26

Reports and photographs from the PTDA Canadian Conference, the IDI Industrial Distributors Inc. Summer Conference, and the opening of the international campus of Walter Surface Technologies.

Editor’s Notebook / 6

Industry Newswatch / 7

Business Briefs / 9

The Safety File / 15

Maintenance 101 / 16

MRO on the Road / 25-26

Product News

Product Spotlight / 2

Focus on Lubrication / 19

Focus on Seals & Gaskets / 20

Focus on Severe Service / 21

Focus on Tools / 22

Focus on MRO Components / 23

‘Pumps that are running will likely transmit vibration to the standby pump. This can cause fretting wear on its bearings.’

Marcus Wickert / 10

Increasing equipment reliability with proper lubricant selection / 17

The load, environment, temperature and speed of the application must be considered.

The impact of lubricants on machine performance / 18

How choosing the correct lubricant improves both machine performance and the bottom line, and extends service life.

‘If a pump simply won’t run, the culprit is likely the impeller or engine.’

Pam Meyer / 11

‘We accomplished what other rewind shops would not attempt.’

Cosimo Geracitano / 13

‘We don’t like buying products that are made by child labour or slave labour, or by people who earn $126 a month and have a very good chance of dying on the job.’

Simon Fridlyand / 15

‘When the server failed, the staff discovered there was no local support for a server of this type and that data recovery was not a simple process.’

Peter Phillips / 16

‘Each finished lube is a finely balanced blend of additives whose proportions must not be disturbed by adding aftermarket miracle additives.’

Mario Tammaro / 18

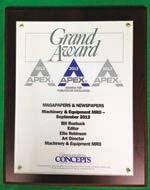

ome milestones were reached with our magazine over the summer.

First off, we have a new publisher in Jim Petsis. You can read a bit more about him in our Business Briefs column on page 9. We’re glad to welcome him on board and are already finding his enthusiasm and positive outlook to be a boost for all of us.

This issue also marks a couple of 15-year anniversaries on the magazine. Ellie Robinson, our stellar, award-winning art director, started doing design and layout for us back in 1998, and she has done a wonderful job of making our content look interesting, compelling and easy to read. That same year, Montreal-

based Carroll McCormick started writing for us. He originally was assigned a one-off article, but we were so impressed with his work, we wanted more. As it turns out, we soon made him our senior contributing editor, and he has provided case studies and feature stories – many of them award-winners – in almost every issue over the past 15 years.

Speaking of awards, we were very happy to receive a Grand Award this year in the international APEX Awards for Publication Excellence. We’ve won seven APEX awards in the past, but not at this level until now. I’d like to share with you the judges’ comments: “Makes excellent use

of the small newspaper format. A bold headline schedule, clear, legible type, imaginative use of captioned photo layouts, sidebars, subheads and bulleted and numbered text – all combine to create an appealing backdrop to the editorial well, where crisply written, interesting features keep readers involved and up-todate on current trends.”

There’s more. We also were nominated for a Canadian Business Press Kenneth R. Wilson Memorial Award for editorial excellence in the Best Industrial/Technical Article category, thanks to the excellent writing of Carroll McCormick. The fact is, his articles are nominated pretty much every year, and he has taken home several Gold and Silver awards on our behalf.

Another thing we’re truly pleased about is the great reader reaction we’re getting to our website. Not only do we

post digital editions of each of our issues online, we regularly update the site with exclusive feature articles as well as industry news, links to relevant industry events, and more. The latest analysis of visitors to our site showed more than 32,000 ‘unique’ visitors stopped by for a read last month. Also, more than 16,000 readers have subscribed to our weekly e-newsletter, which summarizes the new features, news items and events posted on our website in the previous week (if you want it too, it’s easy to sign up at mromagazine.com/subscribe).

You’ll be seeing some of our new ideas being implemented in the months ahead, and we’re also working on a new project we’ll sure many of you will find interesting and useful. We’ll have details on that soon. MRO

Bill Roebuck, Editor & Associate Publisher

SEPTEMBER 2013

Volume 29, No. 4

Established 1985 www.mromagazine.com www.twitter.com/mromagazine www.twitter.com/mroontheroad

EDITORIAL

Bill Roebuck, Editor & Associate Publisher 416-510-6749 broebuck@mromagazine.com

Ellie Robinson, Art Director Contributing Editors

Simon Fridlyand, Steve Gahbauer, Carroll McCormick, Peter Phillips, Robert Robertson, Angela Webb BUSINESS

Jim Petsis, Publisher 416-510-6842 jpetsis@mromagazine.com

Eric Achilles Cousineau, Adv. Sales Manager 416-510-6803 eachilles@mromagazine.com

Kimberly Collins, Advertising Production 416-510-6779

Melinda Marasigan, Subscription Enquiries 416-442-5600 x3548

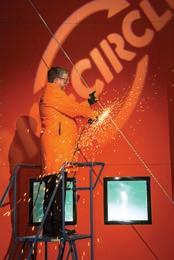

Schweinfurt, Germany – Shaeffler AG has destroyed 26 tons of counterfeit roller bearings marked with the INA and FAG brand. Their value was over $1.4 million.

To destroy the bearings, they were lifted by the gripper arm of an excavator into a scrap press. The bearings came out of the press chopped and broken into pieces or so badly damaged that they were rendered unusable. Large-size bearings with an outside diameter of more than one metre, which were too big for the scrap press, were destroyed with a cutting torch.

In 2007, around 40 tons of counterfeit bearings were destroyed at the Schaeffler site in Schweinfurt. A large proportion of the counterfeit products originated from raids at bearing distributors in Europe, including Italy and Great Britain. But some of the counterfeit bearings were also from Germany.

“Brand and product piracy is not a phenomenon that is limited to Asia or South East Europe. It also takes place right on our doorstep,” says Ingrid Bichelmeir-Böhn, leader of the Global Brand Protection Team at Schaeffler. “The German and European markets are no longer only flooded with counterfeit luxury or consumer goods, there is also an increase in counterfeit industrial products that are relevant to safety, such as rolling bearings.”

Groups such as the World Bearing Association (stopfakebearings.com), the German Anti-Counterfeiting Association (markenpiraterie-apm.de) and the Quality Brands Protection Committee (qbpc.org.cn) ensure that the public is informed about the risks caused by the use of counterfeit industrial products. These organizations also work in conjunction with authorities, with the objective of creating the legal and organizational prerequisites to effectively fight counterfeit products.

Shaeffler recommends that, in general, it is always best to purchase goods from a source that is 100% reliable, i.e. from manufacturers and authorized distributors. In the case of any uncertainty that distributors and customers may experience during incoming goods inspections, Bichelmeir-Böhn and her team can be contacted at piraterie@schaeffler.com.

Brampton, ON – Sheridan College has become a member of the CDIO Initiative – a worldwide movement to restore the balance between teaching ‘practice’ skills and the fundamentals of math and science to engineering students.

What started as a partnership between the Massachusetts Institute of Technology (MIT) in Boston and a few Swedish universities in 2001 has gained significant international momentum, with 103 institutions adopting the model. Sheridan is the fifth Canadian institution and the first college in the world to be accepted.

As a new philosophy for engineering education, the framework educates students to Conceive, Design, Implement and Operate (CDIO) complex, valueadded engineering products, processes and systems in a modern, team-based, global environment. Rich in projectbased, hands-on learning, it aims to produce engineers who are ‘ready to

engineer’ when they graduate.

The CDIO syllabus codifies what engineers should know and be able to do when they graduate. Major competencies include disciplinary knowledge and reasoning, personal and professional skills (like experimentation, prioritization, resourcefulness, self-awareness, ethics and integrity), teamwork and communications, and understanding the societal and enterprise context.

as one in four in the industry worked fewer hours.

In utilities, 98,000 hours were added to workers’ schedules as a result of the flooding. In construction, 7.9% of workers put in 440,000 additional hours in the second half of June, the highest among all industries.

The proportion working fewer hours was similar for men and women, at 13.8% and 13.2% respectively. The average number of hours lost by men, however, at 26.2 hours, was more than the 23.5 hours lost by women.

Toronto – Ontario is losing out on as much as $24.3 billion in economic activity and $3.7 billion in provincial tax revenues annually because employers cannot find people with the skills they need to innovate and grow in today’s economy, according to a Conference Board of Canada report.

“Closing the skills gap could help the province reduce public debt or invest in much-needed infrastructure improvements,” said Michael Bloom, the Board’s vice-president of organizational effectiveness and learning.

Skills gaps currently affect much of Ontario’s economy, including sectors that account for almost 40% of employment: manufacturing; health care; professional, scientific and technical services; and financial industries. Skills gaps are projected to worsen if action is not taken.

“Ontario cannot afford to live with a skills gap of this magnitude. The need for action is urgent, since changes in educa

Ottawa – Extensive flooding affected Southern Alberta in the second half of June 2013. As a result, 300,000 employed Albertans, or 13.5% of the total employed population in the province, lost 7.5 million hours of work during that period, according to a review by Statistics Canada. At the same time, 134,000 people, or 6.0% of workers, put in 2.4 million additional hours. The net effect was a loss of 5.1 million hours of work.

There was a net loss in hours worked in all industries, except utilities and public administration. Workers in those industries experienced a small net gain in their hours as a result of the flooding. In some industries, however, the net losses were large.

Workers in natural resources, the majority of whom are in oil and gas extraction, totalled 1.4 million hours lost,

in sectors with few available jobs. In addition, employers sometimes fail to make the most of their employees’ skills and talents.

Calgary, AB – MainTrain 2013 will feature skill-building sessions, interactive workshops, technical sessions, case studies and supplier presentations covering a wide range of maintenance, reliability and asset management subject areas. The four-day conference takes place at the Sheraton Cavalier Hotel in Calgary, Nov. 18-21, 2013.

MainTrain is organized by the Plant Engineering and Maintenance Association of Canada (PEMAC).

Canadian astronaut Chris Hadfield is the keynote speaker for a gala dinner. Machinery & Equipment MRO contributing editor Tex Leugner will present a session on ‘Effective Data Collection for Thorough Failure Analysis’, while columnist Cliff Williams of ERCO Worldwide will hold a session called ‘Canada’s Got Talent’. As well, former contributor Len Middleton is a co-presenter of PEMAC’s MMP Module 1 course, which is being held during the conference.

For more information, call 1-877-5237255 or visit maintrain.ca.

Las Vegas, NV – IFPE 2014 will be held March 4-8, 2014, at the Las Vegas Convention Center in Las Vegas, NV, colocated with the Conexpo-Con/Agg exposition for the construction industries. The huge trade show also includes several conference sessions.

tion will take years to bear fruit in the labour force,” said Bloom.

Responses to the Board’s Ontario Employer Skills Survey show that employers most need post-secondary graduates in science, engineering and technology, and business and finance. The most widespread needs are for employees with two- or three-year college diplomas (57%), four-year degrees (44%), and trades (41%).

The negative impact on the Ontario economy goes beyond the issue of skills shortages. Another issue with economic consequences is skills mismatches in the labour force – individuals whose skills and training are not being fully utilized in the jobs they have.

The Conference Board estimates that these mismatches, by themselves, cost Ontario’s economy and workers up to $4.1 billion in foregone gross domestic product. Many post-secondary education graduates have skills and training

IFPE education provides critical information on new power transmission and motion control technologies to engineers and others involved in the design and manufacturing process. The IFPE Technical Conference is expected to reveal the latest industry research and developments. The Innovations Theater is applications-focused and for the first time will feature abstract-submitted presentations. Topic areas for IFPE 2014 education include fluids (including new and green); fluid power systems; fluid power in renewable energy applications; basic components; controls and control systems; auxiliary components related to fluid power; seals and sealing technology; analysis, modelling and simulation; noise and vibration (analysis, measurement, control); materials and manufacturing (including new and green); impact of Tier 4 and beyond; and standards (industry, national, international).

For more information, visit ifpe.com.

Ottawa – The Help-wanted index compiled by the Conference Board of Canada fell 9.5 percentage points in June 2013, bringing it to 128.7.

With domestic demand expected to slow this year due to a cooling housing market, soft consumer spending, and slower public and private investment, employers are likely to be cautious about their near-term hiring.

Including June’s drop, the recent trend in the index suggests that employment gains will be moderate in the coming months. MRO

• Congratulations go out to the EASA Ontario’s Warriors Against Cancer team that participated in the Enbridge Ride to Conquer Cancer in southern Ontario, June 8-9, 2013. The team comprised Anthony Lekkas, Peter Tedesco, Gerald O’Reilly and Denys Bolanos. The Ride started in Toronto and finished in Niagara Falls, a total of 220 km. The team raised a total of $11,792. The ride itself had 5,020 riders and raised over $19 million for cancer research.

• Jim Petsis has been named to the position of publisher of Machinery & Equipment MRO With over a decade of publishing experience and more than 20 years of entrepreneurial success across various businesses in Canada, he brings a fresh energy and direction to MRO Magazine. Jim joins the MRO Magazine team of Bill Roebuck,

founding editor and associate publisher, and Eric Achilles Cousineau, advertising sales manager. You can reach Jim by e-mail at jpetsis@mromagazine.com or at 416-510-6842.

• Timken Canada LP, Mississauga, ON, has named engineering technologist Luigi Papais as regional manager for Central Canada. Papais has more than 11 years experience at Bonfiglioli Canada, most recently overseeing territories in Eastern Canada and the Eastern US.

• C&U Americas, Plymouth, MI, the North American subsidiary of The C&U Group, China’s largest bearing producer, has formed a new Aftermarket Team that will be responsible for expanding C&U America’s aftermarket bearing business in the US and Canada through distribu-

tion. Members of the Aftermarket Distribution Team include

Region),

(Southeast Region), Chris Haught (Midwest Region), Bill Childers (Western Region), David Strutt (Canada) and Rebecca Russell (Customer Service). MRO

BY CARROLL MCCORMICK

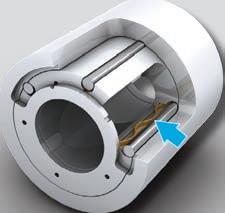

Problem: Your pump has failed. You disassemble it and lo and behold, you find broken, hollow bearing balls amongst the wreckage.

Solution: Don’t chew out your supplier for selling you faulty bearings. You are looking at something that occasionally happens when a pump, typically a process pump operating at high RPM, fails, according to Jennifer Moritz, training manager, SKF Canada.

• Automatic lubrication systems specialist FLO Components Ltd., Burlington, ON, has appointed Oliver Paiement as territory sales manager – GTA. Paiement is a chemicalenvironmental engineering technology graduate of Mohawk College of Applied Arts and Technology in Hamilton, ON, and holds several pertinent certifications, including Six Sigma certification and Certified Lubrication Specialist from the Society of Tribologists and Lubrication Engineers (STLE).

“This is not a quality control problem. Bearing steel has oxygen inclusions. For some unrelated reason, the bearing begins to fail. The temperature gets so high, as high as 350°C, that the oxygen [inside the bearing] expands and the ball diameter increases. The ball material laps on the raceway, the inclusion grows, the ball grows and laps some more, until the wall of the hollow ball becomes so thin that it bursts. Upon inspection, the ball is seen to be hollow,” Moritz explains.

In the absence of manufacturers’ steel specifications that might allow endusers to compare the number of oxygen inclusions and their maximum size, the best bet is to buy from one of the bearing companies that have high requirements for their bearing steel, Moritz advises. “We have really tight control on the allowable number of inclusions and their maximum size.”

Mr. O thanks Jennifer Moritz of SKF Canada for this tip!

Do you have a solution for a maintenance problem? Send it in and if it’s published, we’ll send you a Mr. O Problem Solver T-shirt. Include your address and telephone number, print complete details and, if possible, add a sketch to help explain your tip. Send your tips to Mr. O, Machinery & Equipment MRO, 12 Concorde Place, Suite 800, Toronto, ON M3C 4J2.

NSK supports its customers with a full range of rolling bearing and linear motion products engineered to perform better – and last longer. Our unrivalled technical knowledge allows us to understand their operational challenges and provide industry-specific solutions that improve bearing life and increase operating performance. For maximum productivity through advanced innovation, reliability and performance, Think NSK.

Here are eight tips for keeping costs down at the pumps.

Industrial pumps may seem fairly simple, but they can cause as much trouble as the most complex machinery. To help you avoid maintenance headaches with the pumps in your facility, we sought out a few experts, who are happy to share their observations and experiences. Here is what we learned.

TIP #1: Low oil levels and lubrication deflectors: “You have to really keep on top of your oil levels,” says Marcus Wickert, engineering division manager, NTN Canada. Here is just one good reason why, he explains. “A lot of pumps are oil bath and have lubrication deflectors. The deflector dips in the oil bath as the shaft rotates, picks up the oil and hopefully splashes it on the bearings. But if the oil level is not high enough, the oil will not hit the bearings, causing a bearing failure.

“Sometimes the deflector is not set up properly and will not adequately splash oil on the bearings. We frequently see issues with them. This is usually the first thing I look at if there is a bearing failure.”

And if you are checking oil levels through a sight glass, beware, Wickert advises. “The sight glass may show that there is enough oil in the pump, but is it set up correctly?” You should check that it is.

TIP #2: Beware changing pump mediums: Particularly in a borderline situation where pump bearings are getting barely enough lubrication to keep them cool, if the thickness of the medium being pumped changes, that could cause the bearings to fail, Wickert says.

“If the consistency of what you are pumping changes, the load on the bearings can change dramatically. If there is not quite enough oil being delivered to the bearings in the first place, the bearings will begin to overheat and lubricant will oxidize and deteriorate. The production people need to stay on top of these things.”

TIP #3: Cycle your standby pumps: It is clever to have a cluster of pumps doing a job, both to save energy during times of low loads, and to have a spare ready to take over in case a pump fails or needs maintenance. However, the spare pump should not sit there for months without being used.

“For example, there might be three pumps, with two operating and one on Air pumps need lubrication, filters, and air lines that are oriented so that water will drain away.

standby. You need a good cycling program,” Wickert advises.

But what could go wrong if you don’t? “Two things can happen: If it is a moist area, you can get corrosion in the pump bear ings as lubrication pools out. By cycling the pumps, you reintroduce lubrication to the bearings, preventing corrosion.

BY CARROLL MCCORMICK

Also, the pumps that are running will likely transmit vibration to the standby pump. This can cause a fretting mode of wear (cyclical rubbing between two surfaces), also called false brinelling. Brinelling follows from an impact load on a bearing. In false brinelling, the rolling element is just sitting there, vibrating. It wears an indent on the raceway.

Cycling pumps is a best practice that we always talk to people about,” Wickert says.

TIP #4: Beware of moisture in air pumps: Air pumps are driven with air delivered from compressors. The compressing of air warms it, however, and moisture will condense out in the air lines as it cools. This moisture must not be allowed to reach the pumps.

“Moisture will cause rust in the air pump piston and valving,” says Bruce Bergen, owner, Production Supply Co. Ltd., Richmond, BC. “Water, oil and rubber do not mix. It becomes an oily, gooey mess in the pump,” he says.

The solution? Where air is taken off the main air line, position the ‘t’ fitting so the secondary line goes upwards first, not straight down. This will help limit

Bearings in standby pumps that are not run periodically can lose their lubrication and corrode.

the amount of moisture that gets to the air pump. As well, Bergen counsels, “Run a drain line going down from the lowest point in the main line and install a ball valve to drain off moisture.”

TIP #5: Air pumps need filtering and lubricating: Air pumps need lubrication. “This is a specialty industry and lots of people just don’t know this,” Bergen says. Air lines leading to air pumps have a trio of gizmos on them, referred to as the FRL (filter, regulator and lubricator).

“The filter traps dirt and impurities that come off the inside of the steel air line piping. Most air filters are usually water separators too, through centrifugal action. Any water that accumulates needs to be drained off from time to time,” Bergen recommends.

The lubricator gradually drips oil into the air line, then the oil is atomized and whisked into the pump. “Checking the lubricant level is an easy visual check. If you check it on a monthly basis, you will soon find out how often it needs replenishing,” Bergen says.

TIP #6: The dreaded 40/40 failure: Pumps built to API or ANSI standards dictate that manufacturers use 40-degree angular contact bearings for both the thrust and backup bearing. The backup

bearing often runs unloaded and the balls will skid along the outer race. “This generates a lot of unwanted heat, lowering the viscosity of the oil,” says Jennifer Moritz, training manager, SKF Canada. “The loaded bearing begins to overheat. This can lead to a catastrophic and sudden failure.

“It fails nastily. People hate it. A solution to improve bearing performance is to switch the backup bearing to a 15-degree angular bearing. Switch from 40/40 to a 40/15 pair.”

TIP #7: This pump is too big: Once upon a time, the Neucel pulp and paper mill in Port Alice, BC, had a 200-hp slurry pump that was too big for the job. It always operated at 900 rpm and the only way to control the pressure and flow was to throttle the valve and keep it 80% to 90% closed. Too, the huge pressure drop from 25 psi to 8 psi on the downstream side of the pump caused all sorts of maintenance problems.

Using funds from BC Hydro’s Power Smart program, the mill downsized to a 150-hp model and added a variablespeed drive. The new pump uses 75% less electricity (800 MWh/year) and is saving the mill about $28,000 a year in electricity costs.

The moral of this story is that rightsizing your motors for a better fit to the tasks they must perform can save loads of money and maintenance.

TIP #8: Assorted energy-saving tips: Here are some other ways to lower pump operating costs, with suggestions from the experts at pumphealth.com.

Two or more pumps can be better than one big one, because you can run fewer pumps during low-demand periods.

Variable-speed drives might be an economical alternative to throttling your pumps, which is like driving with one foot on the gas and the other on the brake.

Consider ways to lower your flow capacity and head requirements. Possibilities include reducing the water velocity in equipment and spray nozzles, minimizing the elevation difference between the discharge and suction tanks, and using larger pipes, which will generate less friction. MRO

Carroll McCormick, our senior contributing editor, is based in Montreal. He has been writing award-winning articles for us for the past 15 years.

BY PAM MEYER

You don’t know what you’ve got until it’s gone’ is a phrase that is often used. This concept can be all-too-familiar for anyone who has ever neglected an engine-powered dewatering pump. A dependable pump isn’t truly appreciated when it’s working properly, but that dependability is really missed if a pump’s performance declines, or worse, the unit stops working altogether.

To avoid pump downtime and subsequent headaches, a preventive maintenance program for both the engine and the pump must be followed. It should include daily inspections as well as lessfrequent checks.

Start each day with a pump inspection. Among the most important daily checks is the quality and level of the engine oil. Oil that’s contaminated can cause serious problems and decrease the life of an engine – likewise if there’s an insufficient amount of it. Change the oil or add more if necessary to reach the correct level, as per the manufacturer’s recommendation.

Check the gasoline level as well, making sure the tank is full, or at least full enough for the day’s usage. Also, look for any evidence of fuel or oil leaks. If a fluid is dripping, inspect the area for any parts that may need to be tightened or replaced.

Cleaning or possibly changing the air filter is another important practice that can prevent significant damage down the pipeline. A clogged, wet, dirty or damaged air filter can lead to a loss in power and shorten the life of an engine by allowing dirt or water into sensitive areas. A foam filter can be cleaned and reused, so it’s fine to check daily. A paper air filter, on the other hand, should always be replaced upon removal. It’s best to follow a recommended schedule to replace paper air filters in a timely fashion.

As well, inspect the condition of the hoses regularly. If they are worn, frayed or have any holes, the air gaps will likely cause the pump to lose suction. Patch any holes and seal leaking joints. A severely worn hose should be replaced. Finally, check the rest of the machine for broken bolts or nuts, or loose parts.

Of all the pre-operation checks, perhaps the most important thing to remember for daily maintenance is priming the pump before starting. Running a pump dry will damage the seals, causing a chain-reaction of further problems. If it’s a self-priming pump, simply add water. The term self-priming is somewhat of a misnomer, as water must

be added to the pump each time it is used. The pump will then take over, build pressure within the volute and begin discharging.

Once the pump has been prepped, it’s ready to go to work. In addition to daily checks, a pump requires other maintenance checks and services. While those don’t need to be done daily, they are crucial to the pump’s life and should be kept up with on a regular schedule. Generally, quality pump engines can operate up to 2,500 hours, and by following recommended maintenance schedules, you can only increase that time and the pump’s return on investment (ROI).

A few things need to be checked a couple of times a month, others even less frequently. For instance, a paper air filter should be changed monthly. Although a foam filter can be cleaned and re-used, it’s still a good idea to change it monthly as well.

Dirty spark plugs can cause a decrease in power and poor starting performance, so the spark plugs should be checked semi-monthly for dirt, damage or excessive carbon build-up. Clean spark plugs with a wire brush or spark plug cleaner. Immediately replace any spark plugs that have cracked porcelain.

Additionally, it is important to clean and inspect the fuel strainer and fuel filter every month. Fuel can become contaminated during operation, and if it’s not removed, can lead to trouble with engine starts. Replacing the fuel line and carburetor is expensive, so it is essential to prevent unnecessary damage caused by contaminated fuel.

On an annual basis, give the pump a thorough inspection for dirty, broken or misaligned parts. Such parts can cause problems with the engine or pump components. Inspecting the entire machine gives the most comprehensive view of what needs to be cleaned and repaired.

It’s also worth noting that dusty conditions typically require the shortening of the length of time between regular services, as extreme dust can clog filter elements or contaminate fuel and oil. Depending on the pump’s environment, maintenance schedules may need to be adjusted to accommodate for less-thanoptimal conditions.

Even with a regular, proper preventive maintenance program, pumps may still experience problems. This is unfortu nate, but common. Knowing what to look for and addressing it quickly will keep the problem from becoming a more expensive, time-intensive repair.

If a pump simply won’t run, the cul prit is likely the impeller or engine. If the impeller is sticking, simply disassemble it, clean it and reinstall it. As for the engine, several different things could affect it and prevent if from starting.

The first thing to check is the spark plug. If it’s dirty, clean it. If it’s damaged, replace it. If it’s clean and damage-free, connect it to the plug cap and ground the plug against the engine body. Pull the starter to see if the spark is weak or nonexistent. If a new plug doesn’t spark, the ignition system is faulty and will need repairs.

The engine also might not start if the spark plug is loose or if the plug is wet with fuel. If the spark plug is wet, check to see that the fuel cock is closed. If so, close the choke lever and pull the starter handle a half-dozen times to see if the electrode becomes wet. If so, the problem may be that the fuel is stale, in which case it should be drained and refilled with fresh fuel. If the electrode is dry, the problem may be with the fuel intake of the carburetor. Try to see where the fuel stops in the engine.

A number of other things could cause a pump to not self-prime. Start by checking the air on the suction side of the pump; tighten the suction hose or pipe, if needed. Check the drain plug as well, to ensure that it has been tightened completely. Insufficient water inside the pump casing also will prevent the pump from priming.

Engine speed also can affect pumping volume. If the pumping volume has dropped, check the wear on the impeller, see if the suction hose may be too thin or too long, or retighten any loose parts on the suction chamber. This also might be caused by a high suction lift that would need to be lowered, water leaking from the water passage, a broken mechanical seal, or a drop in engine output or speed.

Adopting a proactive preventive approach ensures that crucial maintenance services won’t be neglected, preventing a domino-effect of problems as the pump goes down, time is lost and

1. A clogged, wet, dirty or damaged air filter can lead to a loss in power and shorten the life of an engine by allowing dirt or water into sensitive areas.

2. Dirty spark plugs can cause a decrease in power and poor starting performance, so the spark plugs should be checked semi-monthly for dirt, damage or excessive carbon build-up.

3. If it’s a self-priming pump, simply add water before starting it. Running a pump dry will damage the seals, causing a chain-reaction of further problems.

repair costs add up. It’s simple and straightforward; pump maintenance now will mean fewer issues later. Following a good maintenance program, such as the steps detailed above, is among the best and most inexpensive ways to keep an engine-driven dewatering pump flowing.

BY COSIMO GERACITANO

Earlier this year, representatives of one of the biggest and oldest companies involved in subsea cable repair and installation around the world contacted us from England. They asked if we could rewind and repair a large generator for a ship in their fleet. We were the sixth company they contacted; the previous five companies had said they could not do the repairs.

We eagerly took on the job of rewinding and rebuilding the 1,600 kW generator. It proved to be a challenging task, but we are driven by challenges. It was not an ordinary generator: it was an old unit manufactured in Europe – the nameplate was written in French.

The stator was rewound with formwound coils in groups of eight continuously wound units. Typically, form-wound coils are wound individually and then connected to each other, after installation, into groups as required. We could only guess that, originally, the coils had been wound continuously in groups of eight because space restrictions would not allow for the connections to be made after the installation of all the coils.

For the retrofit, single coils were installed and connected in a very restricted space.

To our surprise, we found out that North American coil manufacturers cannot make coils this way; the equipment required to do so would be very expensive, we were advised. If some place in the world were equipped to do so, the cost for one set of coils would be more than double the original cost, making the rewinding and repairing of this old generator unfeasible. However, the cable repair and installation company needed a solution, as it would be too expensive for it to retrofit the ship with a new generator.

Ultimately, we decided to have one set of single coils manufactured. We installed

and connected each coil as required in a very restricted space. Completing the job required perseverance, patience and skill. Thanks to our dedicated team, we accomplished what five other rewind shops would not attempt.

The ship is now on the Pacific Ocean,

and its crew is back to repairing under water cables.

Cosimo Geracitano is with Electro Motors Co. Ltd., Port Coquitlam, BC. For more information, visit www. electromotors.ca.

If safety standards like Canada’s were introduced worldwide, it would save thousands of lives each year.

BY SIMON FRIDLYAND

The collapse of a garment factory in Bangladesh in April, where more than 1,100 workers were killed, shocked the Canadian public. As a result, retail industry groups in North America, Europe and Japan promised an initiative to have all the factories from where they buy garments inspected within nine months to a year. Major factory upgrades are to follow.

Some major media outlets called it a smoke-and-mirrors exercise. It is designed to pacify the western public. The question is, why now? Only last November, 112 workers were killed in a Bangladesh factory fire. At that time, no one raised any desire for inspections of factories or upgrades. Only when the death of 1,129 people reached our TV screens and newspapers, did action become a priority.

We, as consumers, don’t like buying products that are made by child labour or slave labour, or by people who earn $126 a month and have a very good chance of dying on the job.

Two UN agencies have directed their attention to the prevention of child labour worldwide: the United Nations Children’s Fund (UNICEF) and the International Labour Organization (ILO). They have helped define the problem and develop international legal frameworks to help to correct the problem. As a result of their work, we now have several international treaties – or conventions – banning child labour and identifying concrete measures for governments to take. Once a country ratifies a convention, UN bodies monitor compliance and hold countries accountable for violations.

Goods produced with the involvement of slavery or trafficked labour meet the international definition for the proceeds of crime. The UN Convention defines ‘proceeds of crime’ as “any property derived from or obtained, directly or indirectly, through the commission of an offence.” By this definition, goods produced through the use of slavery and trafficked labour and any revenue generated from the sale of such goods are proceeds of crime.

I think it is time to establish internationally recognized minimum standards for worker safety. These standards would be ratified by participating counties and enforced similar to that for child or slave labour occurrences.

Occupational health and safety is not always visible to the untrained eye. For example, in order to understand the structural integrity of a building, an engineer examines it against the building code requirements, as well as the best engineering practice. The same applies to fire safety. Machine safety is examined against machine guarding standards, and so on.

Because safety is something that may not be readily visible, and is potentially very costly to comply with, in

jurisdictions where safety is not a real priority, unsafe conditions for workers prevail. In June, for example, 120 people died in a poultry plant in China, yet only three years ago, a Communist party official called it “an inspiring factory and a leading enterprise.”

In Canada, we pay a lot of attention to workers’ safety; of course there is room for improvement. Based on 2008 statis-

tics, there were 6.1 fatalities in Canada per 100,000 workers. During the same time, officially, there were 11.1 fatalities per 100,000 workers in China. There were 70,000 workers killed in China by workplace accidents last year – roughly 200 per day. That’s down from 75,572 in 2011 and 79,552 in 2010. I could not find any reliable statistics for Bangladesh.

If a system like Canada’s was introduced in those countries, it would definitely save thousands of lives each year.

It would also provide a more level playing field for Canadian manufacturers. The cost of only maintaining compliance with occupational health and safety regulations for small to medium size enterprises (SMEs) is about $1,000 per employee in the industrialized world. This does not take into consideration bringing facilities, machinery and management systems into compliance. However, these expenses are absolutely necessary to provide the minimum standard of worker's safety. In my opinion,

low-cost jurisdictions are cutting corners as far as worker's safety is concerned.

A common criticism is that a low-cost jurisdiction’s ability to maintain its competitive advantage stems from its weak enforcement of workers’ rights. The argument is simple: it is easy to keep costs down when you aren’t paying workers a minimum wage or investing in health and safety protection.

We cannot do anything about low wages; however, we can demand health and safety protection for workers, the way we demand protection against slave and child labour. Whether we are in Bangladesh or Canada, we still should have the right to be safe and alive after a day at work. MRO

Simon Fridlyand, P.Eng., of SAFE Engineering Inc., specializes in industrial health and safety concerns and PSR compliance. For more information, visit www.safeengineering.ca.

BY PETER PHILLIPS

Although I have mentioned in this column before how important it is to back up your CMMS database, recent events have brought me to discussing it again.

In the past six months, I have seen some disastrous failures of data backup systems. Companies that thought their CMMS data was secure faced some incredible setbacks when their database servers failed.

I am going to tell you four stories about some recent database losses. They will demonstrate why backups and technical support for your database are so important.

The first story comes from one of my company’s clients in North Carolina. This brand-new facility just started production in January 2013 and it has been populating its CMMS software with equipment, inventory and preventive maintenance tasks since construction started on the plant two years ago. Hours and hours of critical equipment information was gathered and entered into its CMMS program. Hundreds of work orders were created to record equipment, process failures and corrective actions during commissioning that could be used at new plants in the future.

servers. Although the turnaround period was three days after the server was received from New Brunswick, it carried an expensive price tag. All the data was recovered and steps were taken to run the backup on another system, separate from the database server.

Finally, a Nova Scotia organization learned that backing up its CMMS was critical to its operations. It has several facilities, with each site using a stand-alone computer to host its CMMS program and database. The sites are not connected to the organization’s network, nor do they have backup systems in place.

On July 22, the CMMS server failed. The facility IT person was confident that the server was successfully backed up every evening to a tape drive. When the staff checked the tape drive for the back-

You won’t know how much you’ll miss your data until it’s gone. Here are four examples that highlight the need for good backups.

up to retrieve the CMMS database, they found that there was none. Upon investigation, it was discovered the server backup log showed an exception error for the CMMS database.

What they found was the database was continually active 24 hours a day, every day. The technology they use for backups would only back up databases that were inactive during the backup process; therefore no backups of the CMMS were being successfully initiated.

After checking with a number of their other plants, they discovered several of them had the same problem. As I write this article, four days have passed since

this incident at the plant. One backup has been found that is over a year old. Efforts by the plant’s IT person and the CMMS support team have not been able to recover any more recent data from the server.

They now realize that much of their data is missing and a plan will be needed to re-enter the data. This will take a substantial amount of time and effort by the maintenance department, time they don’t have available. Steps have been taken to correct the backup issue with scripts that will back up the database to the server even when the CMMS is active, and the solution has been sent to other plants with the same issue.

Next up is another large corporation. It manufactures bread products in Quebec. A young engineering student, although warned not to, attempted to manipulate some of the database tables in the company’s CMMS software. In the process of doing so, he crashed its CMMS program.

Even if you are sure your CMMS is being backed up, ask your IT department to double check the backup files.

The database was corrupted and inoperable. The staff went to restore its database from a tape backup, only to discover that the backup tape system had not been operating for several months.

With mountains of equipment PMs, repairs and sanitation records, there was no option but to try to recover the data from the corrupted files. It took over three weeks for its CMMS tech support team to recover and reconstruct the database. During this time, the CMMS was out of service, which caused a great deal of hardship for the maintenance and purchasing departments.

This incident prompted the company to regularly check its plant and other locations to make sure its backup systems were actually working.

Another case comes from a building materials manufacturer in New Brunswick. Late last fall, its CMMS suddenly stopped working. The main server that housed both the CMMS database and the daily backup had failed. This particular server used a multiple drive technology that split the database over several hard drives, which was supposed to be more reliable and safer for data storage.

When the server failed, the staff discovered there was no local support for a server of this type and that data recovery was not a simple process. The server had to be sent to a Toronto data recovery company that specialized in these types of

Because its software and databases are all located on one computer at each site, the chances of losing the complete database is very probable and in fact has happened at three of the organization’s facilities in the past six months.

You might say they haven’t learned very much from their recent losses; however two of the facilities wanted to start their CMMS over again because their first ones were never properly formatted with correct naming conventions and nomenclatures. As a result, the software was hard to navigate and rarely used. Reloading the CMMS program was not a big issue, however it did point out to the staff that they must back up their data.

The corporate IT at this point does not have a common network where the facility databases can be stored and backed up properly to a common server. For now, each facility has purchased an external hard drive and has scheduled daily backups of its database in case there are any future failures of the stand-alone workstations.

There are alternatives to maintaining your own database and backup systems. Most CMMS companies offer web-based applications where the CMMS program is accessed over the web. The hosting company maintains the data and backup systems at secure data storage sites. However, the cost of ownership is often much more than owning and maintaining your own software and hardware. Also, some organizations have security protocols that do not allow web-based software applications; due to security risks, they must maintain their own server systems.

So let’s see what we have learned from other people’s CMMS data failures.

1. Even if you are sure your CMMS is being backed up, ask your IT department to double check the backup files.

2. If you are running a stand-alone computer, find a way to back up your data. The external drive solution works well.

3. Maintain your annual tech support service from your CMMS provider. In two of the cases mentioned here, that support helped to retrieve lost data. Without this help, the data would not have been recovered.

Building a CMMS database takes a lot of time. The information it holds is critical to your maintenance operations. Treat it with care, protect its integrity and back it up regularly.

Like most things in life, you don’t know how much you will miss it until it is gone.

MRO

Peter Phillips of Trailwalk Holdings, a Nova Scotia-based CMMS consulting and training company, can be reached at 902-798-3601 or by sending an e-mail to peter@trailwalk.ca.

The load, environment, temperature and speed of the application must be considered. BY GENE

M. FINNER

Modern lubrication technology can provide MRO specialists with proven, effective problem-solvers for today’s demanding applications. Different friction regimes require different lubricant forms, and proper lubricant selection must consider the application load, environment, temperature and speed.

Inadequate lubrication or an incorrect lubricant choice can lead to equipment failure. When conventional or OEM-recommended lubricants fail, MRO specialists need to identify the proper lubricant to get the job done right. Knowing the friction regime involved,

both. In startup and shutdown periods or with transient shock loads, conditions can occur in which the relative motion and/or the distance between surfaces converge toward zero.

Different lubricant forms

Any machine, component or surface requiring lubrication will have a primary lubrication regime based on its steady-state operation. Fluid-based lubricants are used for hydrodynamic and elastohydrodynamic lubrication. Solid lubricants are used for effective boundary-regime lubrication. A combination of lubricant forms often is needed for mixed regimes.

understanding the capabilities and advantages of different lubricant forms, and analyzing the specific application conditions are important considerations.

Lubrication friction regimes

Effective lubricating films must meet the requirements of one or more friction regimes or conditions. They are formed as a function of application speeds, loads, component geometries, substrate material properties and lubricant material properties.

Hydrodynamic regimes involve fluid lubricants forced between opposing surfaces by speed and load. The fluid keeps the surfaces apart with pressure. As pressure increases, the fluid may act like a solid, deform the surfaces, and create an elastohydrodynamic (EHD) regime.

Boundary regimes are not created by fluid under pressure, but rather by surface-active materials that form boundary films on and between the substrate surfaces. Anti-wear and extreme-pressure (EP) additives and solid lubricants can adhere to surfaces and provide boundary layers.

Mixed regimes combine hydrodynamic and boundary regimes; some applications have

Silicone compounds are sticky, non-hardening, thermally and chemically stable materials made with silicone fluid, inert fume silica and other additives. They are useful as light-load lubricants, non-curing sealants, electrical moisture barriers and electronic damping media.

Application conditions

Selecting an effective lubricant must consider critical application variables. These are summarized by the acronym LETS – Load, Environment, Temperature and Speed.

Load involves the amount of force or stress placed on the component. Heavy loads may require boundary lubrication with specialty greases, anti-seize pastes or anti-friction coatings with solid lubricants.

Moderate loads may require greases or pastes with lower amounts of solids. Light loads can usually be handled by greases, oils or silicone compounds.

specialty lubricants to help prevent or solve challenging lubrication problems. They know proper lubricant selection can help them optimize friction and wear control to save energy, maintain efficiency and lower maintenance costs. Here are some examples of the lubricant choices available.

u Industrial greases

• To gain extended lubrication reliability and avoid potential service disruptions, an electric utility lubricates circuit breaker triplatch-and-close bearings with fluorosiliconebased Molykote 3451 Chemical-Resistant Bearing Grease.

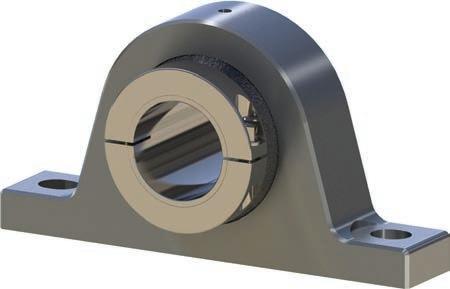

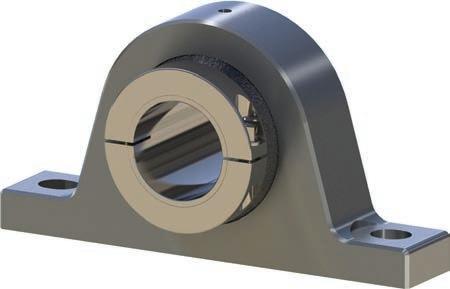

• When a recommended grease for rollingelement bearings in pillow blocks could not withstand frequent water washdown, a cheese plant switched to Molykote G-1502FM Grease and sharply reduced the number and costs of bearing failures.

• Replacing a lithium grease that required frequent service, a lime calcining plant chose Molykote Longterm 2 Plus Grease for severe-duty bearings in its fans, crushers and conveyors.

Greases are usually composed of 80% to 90% oil in a thickener and a few per cent of special additives, including solid lubricants. Greases work best when speeds are moderate to high, friction is rolling rather than sliding, and a regular lubrication service interval is possible.

Oils typically consist of 95% to 99% lubricating oil and a few per cent of additives to enhance pour point, viscosity index and resistance to oxidation or corrosion, and to aid wear prevention. Some oils are mixed with solid lubricants to provide an easily applied dispersion.

Anti-seize pastes consist of roughly equal amounts of oil and solid lubricants, along with small amounts of special additives. Pastes often are used where components are static for long periods of time and where loads are high, speeds are slower and friction is sliding rather than rolling.

Dry-film lubricants or anti-friction coatings (AFCs) consist of solvent, resin binder and solid lubricants plus other additives. Once dry, the lubricating film is tack-free and will not attract dust or dirt. Dry-film lubricants work best in applications where speeds are slow and loads are high.

Environment affects the lubricant durability in the application. High humidity may require solid lubricants. Waterrich environments need lubricants with waterwashout resistance. Exposure to chemicals and fuels may call for fluorosilicone grease. Dusty, dirty conditions may need a dry-film lubricant. Inaccessible components may require an oxidation-resistant grease, paste or AFCs.

Temperature includes the actual operating temperature, soak temperature at standstill and the ambient temperature. Synthetic lubricants generally have a wider service-temperature range than conventional greases and oils. Silicone-based lubricants are proven in cold temperatures. Some high-temperature greases and oils stiffen in extreme cold and oxidize or dry out in extreme heat.

Speed can run from high to low and involve rotational and reciprocating speeds as well as frequency of motion. Static conditions are harsh on liquid-based lubricants. Slower speeds can require use of higher-viscosity oils or, with heavier loads, anti-seize pastes or AFCs. Higher speeds can be best served with lower-viscosity lubricants to prevent problems with shear.

Effective MRO problem-solvers MRO specialists in various industries can use

u Lubricating oils

• To eliminate harmful degradation byproducts of PAG-based compressor oils, a pet-food manuf acturer selected Molykote L-4646 High-Temperature Compressor Oil for extended-life lubrication, cooling and corrosion protection.

• Oils failed under high contact pressures on a cement plant’s ball-mill support bearings; Molykote M-55 Dispersion provided a solid lubricant film to prevent bearing wear, noise and failure.

u Anti-seize pastes

• An aluminum-casting operation replaced an industrial grease with Molykote P-74 Paste for more effective, reliable lubrication of mixer-component roller bearings used in melting ovens.

• Applied to threaded pipe connections used in rock-drilling machines, Molykote G-N Metal Assembly Paste helps prevent micro-welding, seizures and difficult assembly/ disassembly.

u Anti-friction coatings

• With corrosion protection, dry-film lubrication and high-pressure wear resistance, Molykote 3402-C Anti-Friction Coating is helping extend the service life of yaw brakes for wind turbines.

Everything works better with lubrication. But with the huge variety of lubricants available, it can become a challenge to select the right lubricant for the application. Making a good decision requires knowledge of the application and its requirements – load, speed, temperature, environment, etc. It also requires knowledge of lubricants – types and their functions.

In a recent maintenance conference organized by the Plant Engineering & Maintenance Association of Canada (PEMAC), Mario Tammaro, a senior advisor at Petro-Canada Lubricants, Mississauga, ON, provided some useful information on lubrication fundamentals, rules, and key fluids for manufacturing and processing applications.

Tammaro prefaced his remarks by pointing out that in today's manufacturing and processing plants, equipment must work harder, at higher temperatures and extreme pressures, and at higher speeds, often in harsh environments. Under these circumstances, proper lubrication and correct choice of lubricants have become even more paramount.

The fundamental purpose of a lubricant is to reduce friction and heat by preventing metal-to-metal contact. All lubricants will do this, but at widely varying degrees of efficiency.

BY STEVE GAHBAUER

Finished lubricants consist of base flu ids plus specially chosen additives.

The performance characteristics and applications of a lubricant depend upon the type, quality and proportions of base fluids and additives.

While mineral lubricants are still in use, synthetic lubricants are becoming more prevalent. These include alkyl benzenes, organic esters, phosphate esters, polyalkene glycols, polyalphaolefins, silicones, silicate esters, and others.

Additives enhance the properties that the oil already has and enable it to do things that it could not accomplish by itself. But keep in mind that additives can sometimes counteract each other. Each finished lube is a finely balanced blend of additives whose porportions must not be disturbed by adding aftermarket ‘miracle’ additiives.

Of vital importance is the lubricant's viscosity, the measure of ‘thickness’ or resistance to flow. Viscosity varies with temperature – oils gets thicker when colder and thinner when hotter. That is why viscosity of industrial lubricants is always measured at a fixed temperature: 40°C.

ISO standards list viscosity grades from 10

to 1500. The viscosity index (VI) is an inherent property of the base oil, used to blend a lubricant. The higher the VI, the less the viscosity changes with temperature.

Oxidation is a chemical deterioration that affects all hydrocarbons. The further it progresses, the faster it will go. As a rule of thumb, every 10°C rise in temperature over 80°C decreases oil life by about half. Oxidation alters the composition of the oil, produces acids, sludge and gums, and is accelerated by contaminants – metals, dust, water. It can be greatly reduced with the right base oils and additives.

Anti-wear additives minimize wear caused by metal-to-metal contact, but they only function when load, pressure and/or temperature are high enough to activate them.

Heat generated at points of metal-to-metal contact causes additives to chemically react with metal surfaces. In this case, extreme pressure (EP) additives can be used. They prevent welding and excessive wear of contacting parts under high load conditions by producing a

compound that forms a slick layer between metal surfaces and reduces friction and heat.

The cardinal rule for maximum lubrication efficiency is the right lubricant, at the right time, in the right amount, at the right place.

Key lubricating fluids for manufacturing and processing plants comprise hydraulic fluids, gear oils, heat transfer fluids and greases. Choosing the correct one for the application is a bit of an art.

Hydraulic fluids must resist oxidation and have a long service life. They require excellent anti-wear properties to protect moving parts (pumps, valves, etc.) and should not emulsify water, but have good rust-protection properties.

Gear oils must have adequate film strength and are recommended for industrial gears. They, too, must resist oxidation and have a long service life.

Heat transfer fluids are unique lubricants that transmit heat to operations. They must be absolutely resistant to oxidation, because if they do oxidize, they become more viscous, which results in a significant reduction in the fluid's thermal efficiency and in costly premature fluid change-outs.

Greases are used to reduce loss in open-system equipment, to seal against corrosion and entry of abrasive fluids, and to protect bearings and gears against the effect of shock loads at low speeds.

Greases are solid or semi-solid lubricants produced by the dispersion of a thickening agent in a liquid lubricant. They are commonly classified according to their stiffness, or lack of it, and are referred to by their NLGI number –6 to 1, 0, 00 and 000.

When looking for a high-temperature grease, determine the temperature range, whether the equipment performs continuously or intermittently, what the relubrication intervals should be, and whether the grease can drip onto and contaminate products.

The proper selection of lubricants will enhance equipment performance, extend machine and component life, reduce downtime and costly repairs, and improve the overall bottom line. IL

Steve Gahbauer is an engineer, a freelance writer, and a contributor of technical articles to MRO Magazine. You can reach him at gahbauer@rogers.com.

CONTINUED FROM PAGE 17

• In reducing wear and preventing sticking of rods in metal-forging dies, Molykote 321 Dry Film Lubricant is helping to reduce energy costs, extend die life, save replacement costs and increase productivity to meet ship schedules.

u Silicone compounds

• To eliminate production stoppage, mater ial leakage, costly repairs and frequent valve replacement, a mining operator is using Molykote 111 Silicone Compound to lubricate and seal its knife valves, which were failing with a mineral-oil grease.

• For high-performance downhole electrical connectors and cables, an oil and gas supp lier uses silicone-based Dow Corning 4 Electrical Insulating Compound to ease installation and fill gaps and voids for protection against moisture, chemicals and high pressures. IL

Gene M. Finner is product steward, Industrial Assembly and Maintenance, Dow Corning Corp. Dow’s application-driven and performance-matched Molykote brand Smart Lubrication solutions can help improve equipment reliability, extend maintenance intervals and reduce total cost of ownership. For more information, visit www.dowcorning.com.

Adhesive white lubricant helps keep costs down

Klüber Lubrication has developed Klüberplex AG 11-461 and 11-462, an adhesive white lubricant with high load resistance that not only copes with demanding requirements, but also ensures a clean look due to its light colour. Developed as an operating and priming lubricant for open gear drives, the anti-corrosive lubricant offers good adhesion, even at high temperatures. Its use extends re-lubrication intervals, which helps to reduce lubricant consumption and costs. It is suited to applications for the lubrication of wire ropes, shackles, pulleys, open gears and plain bearings.

Klüber Lubrication

Online Reader Inquiry No. 484

Lubricant/cleaner line keeps rust and contaminants at bay

Rust-Oleum has introduced a line of industrial lubricants and cleaners formulated to provide long-lasting lubrication and asset protection. The line includes products most commonly used for everyday equipment and machinery maintenance: Multi-Purpose, Penetrating, Silicone, Dry PTFE, White Lithium Grease, Moly Chain and Graphite. They are designed for applications ranging from rusted parts, stuck threads and fittings, to conveyors, chains, cables, gears and bearings. Each product is designed for a specific set of uses, which are described by the product name and packaging graphics. The cleaning products include a heavy-duty cleaner, degreaser and brake cleaner and are effective at remov ing contaminants such as soil, grime, grease, diesel, adhesive gum and more.

Rust-Oleum

Online Reader Inquiry No. 479

Eco-friendly absorbent pads made from renewable resources

Lubrication system extends chain life

The Rotalube chain lubrication system from Interlube is designed to extend chain life and reduce maintenance costs. It delivers the right amount of lubricant to the exact point of the chain that enables lubricant to penetrate into the bearing areas. Its porting system meters lubricant through precision ejectors incorporated within the sprocket assembly, and it maintains accurate lubrication whatever the condition of chain. The modular system is available in four sizes: 1/2 in., 5/8 in., 3/4 in. and 1 in. The system can be used throughout the food, automobile, steel, glass-fibre and cement industries in food processing machines, industrial dryers, tissue converting factories, waste paper conveyors, truck manufacturing plants, escalators and elevators.

Timken Canada/Interlube

Online Reader Inquiry No. 477

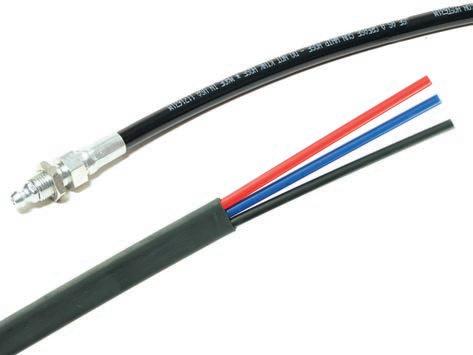

hose and tubing from Parker Hannifin makes it easy to properly perform quick and effective preventive maintenance on all types of equipment. These products are compact and can eliminate gallons of unnecessary in-line grease. Tubing bundles reduce the installation time and material cost and require less grease to fill a lube system. The hose operates in temperatures from minus 40°F up to 212°F and bundle tubing assemblies operate from minus 65°F up to 200°F. Sizes range from 1/8-in. I.D. up to 1/2-in. I.D.

Parker Hannifin, Parflex Division

Online Reader Inquiry No. 487

Oil Eater Naturals is a line from Kafko International of ecofriendly absorbent pads, rolls and socks made of natural plant byproducts, featuring woven construction. They are designed to provide a safe and clean workplace while helping users meet OSHA and EPA requirements. The line includes Oil-Only pads and rolls, universal pads and rolls and absorbent socks. Oil-Only pads and rolls soak up oil yet repel water; universal pads and rolls absorb oil, water and other liquids; while absorbent socks control larger spills and protect drains. Product sizes range from 16 in. by 18 in. to 28 in. by 150-ft. rolls in a variety of weights and finishes. Applications include production lines, industrial and maintenance facility floors, loading docks, paint shop floors and more.

Kafko International

Online Reader Inquiry No. 485

Lubrication system distributes oil to hundreds of lube points

Oil-Rite’s Hydracision distributes oil to as few as 12 separate points and as many as hundreds. The self-contained unit combines efficient hydraulic movement of fluid with the precision of positive displacement injection. It supplies the user with options but does not require extensive calculations, complex components or pages of schematics to operate. Promoting an environmentally sensitive approach to lubrication, it provides frequent, small doses of lubricant rather than large applications of oil at infrequent intervals. Oil reaches critical areas when needed with little or no run-off or waste. Less oil is used and the machinery benefits from more consistent lubrication.

Oil-Rite

Online Reader Inquiry No. 478

Addition of accessories enhances standard modular lube skid

The Hydac lube skid model LSN/LSW/LSA has been designed to be a modular system to fit most lubrication and fluid transfer applications. It is available as a stand-alone pump/motor/ filter configuration, or with AC air cooling or plate heat exchanger water cooling. While system lubrication, filtration and cooling are part of the standard platform, these systems can be outfitted with a wide variety of accessories, such as pressure switches, temperature switches, flow meters, ball valves and control logic solenoid valves.

Hydac

Online Reader Inquiry No. 480 IL

can be your

LPS® provides world-class MRO solutions that bring value to our customers. This includes solutions outside of our high-performing lubricants, cleaners, and specialty MRO chemicals.

Just because it is white does not make PTFE right for your application.

BY BILL SEARLE

There are a wide range of polytetrafluorethylene (PTFE) products to choose from in the industrial gasket market. The product has evolved dramatically since the late 1960s, from just virgin and commercial-grade PTFE to the present day offerings, including what is described as calendared or restructured filled PTFE sheet.

PTFE has many benefits. The two most notable are it has exceptional chemical resistance; there are only a

few chemicals that will attack the polymer. Also, it can withstand temperatures up to 260°C (500°F).

However, the product has one significant weakness, as it exhibits creep and cold flow characteristics under compressive loads, thus affecting the gasket’s performance, since frequent retightening is required.

Most users of PTFE are unaware of the fact that several different materials can be used successfully for the same application. The ques-

tion to ask is what product is right for your application.

There are varied processes in how PTFE sheet is manufactured, involving sintering the PTFE into a billet form and then skiving it into a sheet, or having sintered PTFE sheet manufactured from a moulding process. Fillers or fibres can be added in both processes to reduce the creep behaviour.

In another process of calendaring (where the sheet is made from a Tef-

These gaskets were tested at 1500 psi at 500°F for one hour. The restructured Teflon (left) lost only 6% of its initial pressure, while the skived Teflon (right) lost 60% of its initial pressure.

lon cake, as it were), the sheet is sintered, creating a sheet with a very even homogenous structure throughout the entire manufactured sheet, thus dramatically creep.

With any different processes, there are different costs associated with the various manufacturing techniques and these affect the cost to the end user. For example, prices in Canada can range anywhere from $750 for a 1/8x60x60-in. glass-filled, sintered PTFE product, up to $3,000 for the same size sheet manufactured from the calendared process – also known as the restructured process. Pulp and paper mills in Canada use a wide range of PTFE gaskets in their facilities. As an example, for an application using sodium hydroxideor or sodium borohydride in the bleachery portion of the mill, the specifications call for a gasket manufactured from a restructured sheet process. This gasket is four times the price of a glass-filled, sintered process gasket.