MACHINERY AND EQUIPMENT

New gear drives extend life of Quebec gold mine

Caring for electric motors a multi-step process

How is it possible to have lube-free drive chain?

How Algoma Central reduces pollution from bearing oil

Ultrasonics solution finds hidden sludge blockage

What to do to stop wasting maintenance time

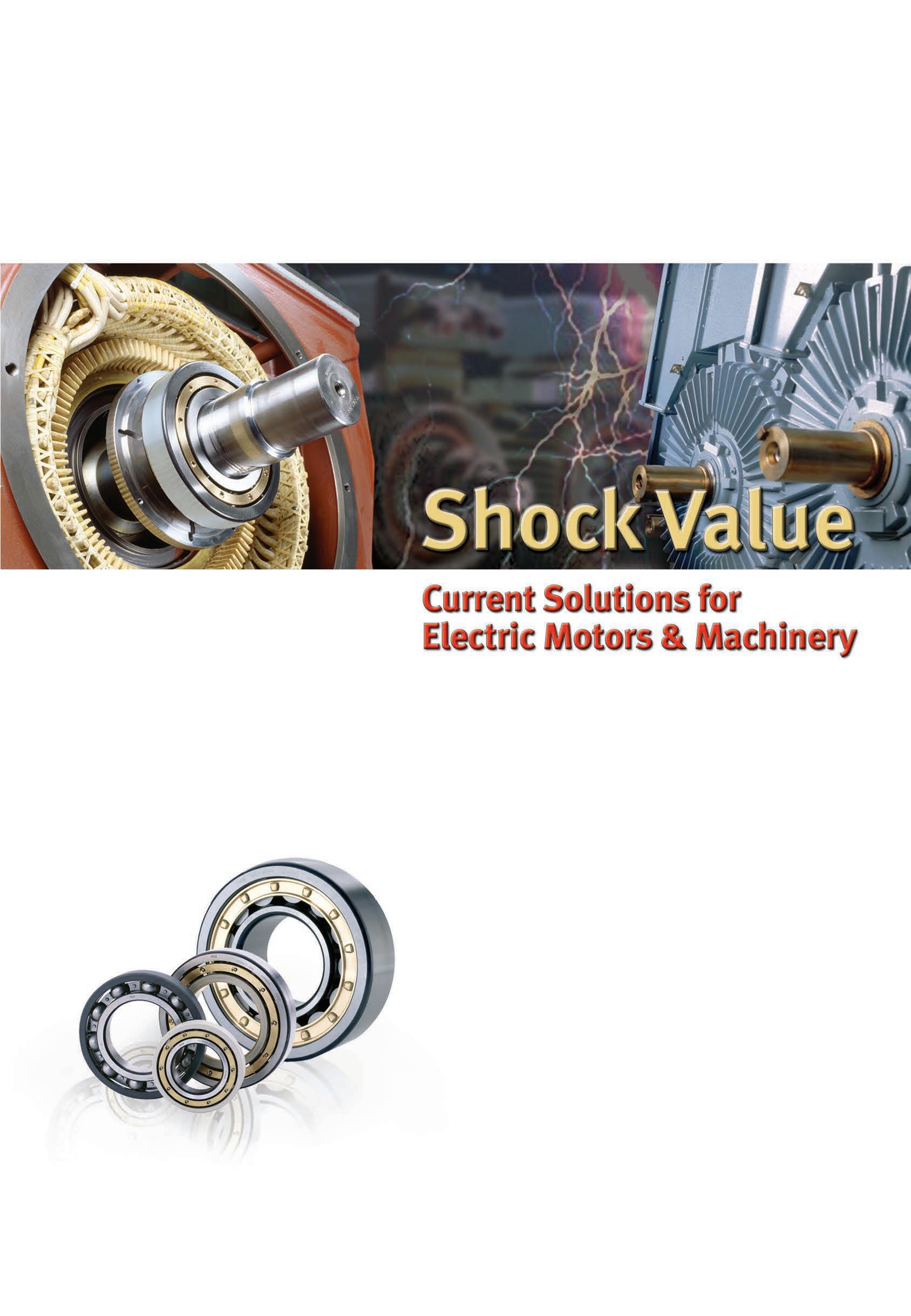

Sensor bearing protects against power surge damage SKF’s sensor bearing, equipped with an elec tromagnetic compatibility (EMC) filter, offers protection against potential damage to the bearing’s sensitive electronics from power surges or electric discharges, most notably in AC electric motor applications. The EMC filter is integrated in-line with the sensor bearing’s cable to protect the Hall sensor and other electronics in the bearing and can help improve bearing reliability and service life. All SKF sensor bearings serve as ready-to-mount, plug-andplay units incorporating a shielded sensor and versatile deep-groove ball bearing. The sensor body, impulse ring and bearing are mechanically attached to each other to form an integral unit retaining tight tolerances within the bearing. In ad-

dition to the standard product line, customized solutions can be developed for partic ular applications. SKF Canada www.skf.com/ca/en/

Hydraulic truck vibrator has aluminium housing for strength Martin has introduced the Cougar THD2500 hydraulic truck vibrator. The light weight, low-profile unit is easy to install, while the aluminum housing’s high strength assures a long working life. The vibrator requires no lubrication and maintenance is mini mal. Features include di rect bolt-on replacement, variable speed, and avail able continuous duty oper ation. Unloading speed and efficiency are im proved, safety is in creased and power con

Simple Reliable Performance

Plus, we’ve created a mobile app to make the job of matching the right ACB drive with the right Baldor motor easier than ever… wherever you are. Keep it simple with reliable, high performance Baldor motors and ACB drives.

baldor.com 479-646-4711

formance and production rate. The tool is designed to be used with the company’s Zip family of cutting wheels and is available for a limited-time in a starter kit in 4-1/2-in.-, 5-in. and 6-in. diameters. Walter Surface Technologies www.walter.com MRO

Tapered Roller Bearing

_Single and multi-row

_Metric and inch

_Broadest availability

Spherical Roller Bearing

_Cooler running temperature

_Efficient lubricant flow

_High load capacity

Cylindrical Roller Bearing

_Brass or steel cage

_Efficient lubricant flow

_High load capacity

Seal Solutions

_Premium large & small bore

_Variety of materials

_Bearing isolators

MINING SOLUTIONS

_Solid Cast-Steel Housed Unit with options for sealing and locking

_High capacity Spherical, Cylindrical and Tapered Roller Bearings

_Coupling with choice of Elastomeric Insert that can be replaced in minutes

Couplings

_Quick-Flex elastomeric

_No lubrication

_Replace in minutes

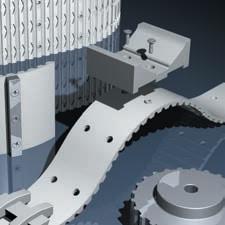

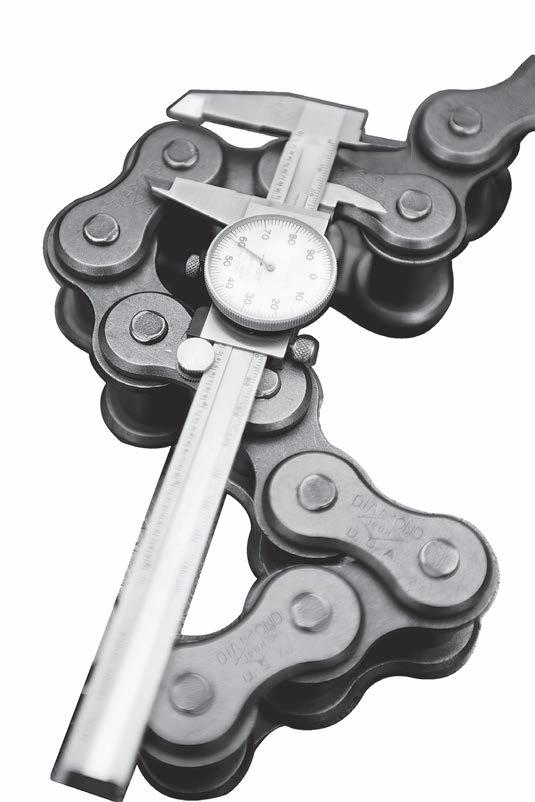

Chain

_Less stretch in operation

_Chrome hardened pin

_Pintle and attachment styles

_High performance sealing and lubrication solutions

_Chain that is less prone to stretching during use

_Bearing Repair, Gears and Geardrive services

Wireless wizardry / 12

Wireless test tools assist in high-voltage upgrades at Linamar plant in Ontario.

Ultrasonic tool finds the blockage / 15

The use of ultrasonics for measuring sludge and sediment levels helps locate the blockage in an oil pipeline that was being

New gear drives help extend mine life / 20

A new gear unit design for an underground conveyor adds to the life expectancy of the LaRonde gold mine in northern Quebec. How is it possible to have lube-free drive chain? / 21 Most lube-free chain is best described as chain which comes with its own supply of lubricant. Here’s how it’s done.

p12

columns

Mr. O, the Practical Problem Solver / 11

The trouble with being cheap when it comes to investigating the root cause of problems. How to stop wasting time / 26 Maintenance 101: Here’s how to get the best value from your assets.

departments

Editor’s Notebook / 6

Industry Newswatch / 8

Business Briefs / 10

Mr. O, The Problem Solver / 11 Maintenance 101 / 26

Product News

Product Spotlight / 2

Focus on Motors & Drives / 22

Focus on Parts Cleaning / 23

Focus on Test & Measurement / 24

Focus on MRO Products / 25

p22

editor’s selections

‘A seal had failed in an outdoor panel and rainwater dripped into the enclosure, gradually filling it up until the bus bar failed and blew apart. It was like there was a hand grenade inside the panel.’ Leigh Copp / 12

‘Ultrasonic inspection results showed that about 45 metres of pipeline was solidly impacted with sediment buildup and it had to be cut out and removed.’ Stephen Cox / 15

‘To ready the bearings for installation, LMI put them in a tub of liquid nitrogen. They shrank by 15%, plenty of room to slide into the stern tubes before warming up to a tight fit.’ Scott Groves / 18

‘Most lubrication-free chain is probably more accurately described as chain that does not need to be re-lubrucated.’

Dr. Chris Lodge / 21

Three decades and counting

Way back in the fall of 1985, I was asked if I could help out with the launch and editing of a brand new magazine to serve an audience of readers who would be interested in the maintenance, repair and operation (MRO) of industrial machinery and equipment. Certainly, I replied, as the task sounded interesting. I honestly thought it would be something I’d do for a couple of years and then move on.

Well, here I am as we enter our third decade, still editing Machinery & Equipment MRO. I’m really not sure where the time went.

It turned out I loved this industry and the people in it. Our readers are an amaz-

EDITOR’S

ing bunch of creative problem solvers who often come up with uncanny ideas and methods to keep manufacturing plants, mines, mills, processing operations – and more – running effectively. As well, the MRO market is supported by hundreds of suppliers of continually improving products, services and solutions that make the jobs of our readers easier than ever. The same goes for the country’s industrial distributors, who supply and ship necessary parts – sometimes desperately needed – to all corners of Canada.

We’ve done our best to cover the information needs of this market. We’ve had great feedback from readers for our efforts, and won several editorial awards

from the publishing industry as well. Since our launch, our aim has been to present a consistent package of useful information with each edition. Each issue includes case studies, technical articles, management features, news of interest to end users and suppliers, and descriptions of new products and services. We’ve dispensed six issues a year to a changing mix of readers, from young apprentices to grizzled old-timers, yet we’ve faithfully covered what’s new in the same subject areas over the decades.

We’ve also added special sections as we saw the need. When there was a demand for it, we published Canadian Electrical Equipment News (CEEN) and Industrial Lubrication as stand-alone supplements. And this year, we’re developing a French-language version of our magazine. Quebec-based readers can watch for Maintenance, Réparation et Opération along with our regular April issue.

Over the years, the magazine has had a

few different owners. There was never any big upheavals – just a quiet transition from one parent to another. We started out as an independent magazine for the first few years, then were sold to the Southam publishing empire, joining many other trade and business-to-business publications. The magazine part of that business later came into the hands of Conrad Black’s Hollinger Corporation. After that, a Vancouver-based publisher, Glacier Media, acquired the whole magazine group (and later added another stable of trade magazines from Rogers Media — ones that were previously owned by the venerable Maclean Hunter publishing company).

But just when you think there won’t be any more changes, it turned out we were acquired once again, as of last month, this time by Annex Business Media.

Even so, it all promises to be business as usual for us, as it has since 1985. MRO

FEBRUARY 2015

Volume 31, No. 1

Established 1985 www.mromagazine.com www.twitter.com/mromagazine

EDITORIAL

Bill Roebuck, Editor & Associate Publisher 416-510-6749 broebuck@mromagazine.com

Hwee Kuan Choo, Art Director (on leave) Ellie Robinson, Acting Art Director Contributing Editors Carroll McCormick, Peter Phillips

BUSINESS Jim Petsis, Publisher 416-510-6842 jpetsis@mromagazine.com

Jay Armstrong, Sales Manager 416-510-6803 jarmstrong@mromagazine.com

Kimberly Collins, Advertising Production 416-510-6779

Melinda Marasigan, Subscription Enquiries 416-442-5600 x3548

Tim Dimopoulos, Vice-President Annex Business Media East 416-510-5100 tdimopoulos@canadianmanufacturing.com Mike Fredericks, President & CEO mfredericks@annexweb.com

World economy to expand 3% in 2015

Ottawa – The world economy will grow by 3% in 2015, even with the majority of regions in the global economy under-performing for the third consecutive year, according to The Conference Board of Canada’s latest World and US Outlooks. This will be due, in part, to the strong outlook for the US economy.

“The United States is a net importer of energy, so lower oil prices will help the US economy. In turn, a stronger US economy will boost the fortunes of export-dependent countries,” said Kip Beckman, principal economist, The Conference Board of Canada.

The sharp drop in gasoline prices to below $2 per gallon in many parts of the US is the equivalent of a massive tax cut for US residents. This factor, combined with a dropping unemployment rate and rising wages, will help boost consumer spending in 2015, says the Board. Overall, the US economy is forecast to grow by 3.2% this year.

The Asia Pacific region, excluding Japan, is expected to expand by 6% this year. China and other Asian countries should benefit from the drop in oil prices in 2015 as most countries in the region are net energy importers. This is especially true for China, where lower oil prices could offset some of the drag on economic growth resulting from weaker housing activity and investment spending. Real GDP in China is forecast to expand by around 7% this year.

Meanwhile, EU countries will continue to struggle with minimal economic growth expected in 2015. The exception is the United Kingdom, which has a flexible labour market and, unlike its EU neighbours, is not burdened with double digit unemployment rates. Real GDP in the euro zone is expected to grow by only 1.1% this year.

The outlook for Latin America is mixed as oil-exporting countries such as Mexico and Venezuela will be negatively impacted. Venezuela will remain in recession over the near term and is also dealing with 60%-plus inflation.

World oil prices are expected to rebound at the end of the year and rise above $55 per barrel as production, especially in North America, starts to decline.

APPRENTICE LOANS RECOGNIZE CRITICAL ROLE OF TRADESPEOPLE, SAYS CAF EXECUTIVE

Ottawa – The recent launch of the Canada Apprentice Loan stands to help overcome one of the key barriers apprentices face to returning to technical training,

according to the Canadian Apprentice ship Forum (CAF-FCA).

“Apprentices across Canada identify fi nancial hardship as a barrier to progress ing in their trade. Targeted student loan assistance stands to ensure this challenge doesn’t prevent apprentices from return ing to school,” said Sarah Watts-Rynard, executive director at CAF-FCA.

Technical training, which in most cases is delivered in rotation with hours spent gaining on-the-job experience, re quires apprentices to forego their pay cheque for several weeks while they at tend training at a post-secondary insti tution or union training centre. The Canada Apprentice Loan gives Red Seal apprentices access to up to $4,000 per block of technical training as an interestfree loan, money that can be used to off set living and educational expenses.

“The federal government’s announce ment is a reflection of the critical role of the skilled trades to Canada’s economy,” noted Watts-Rynard. “Apprenticeship remains the best way to develop highly-skilled tradespeople with the expertise required by employers, but we need to address the very real barriers to completing technical education and achieving certification.”

The Canada Apprentice Loan also helps correct the misperception of appren ticeship as a second-tier option, sending a message to young people and their par ents that apprenticeship is a valued postsecondary pathway leading to a rewarding career in high-demand professions.

PUMP SYMPOSIUM COMING TO CALGARY IN NOVEMBER

Calgary, AB – The Calgary Pump Symposium, an independent, not-for-profit event that provides educational training for the pump industry, is being planned for Calgary in November 2015. The venue and specific dates are to be confirmed later. The Symposium will consist of technical presentations, short courses, discussion groups and vendor exhibits.

For details on the grants, visit www. esdc.gc.ca/en/support_apprentices/ grants.page.

BC CITY REPLACING AGEING FLOOD CONTROL PUMPS

Richmond, BC – Richmond, BC, faces serious challenges from flooding. Built on several low-lying islands in the Fraser Delta, the city has an average elevation of just one metre above sea level. In order to keep Lulu Island, the main population centre, from being inundated by high levels of ocean and river water, the city has constructed a system of dikes and pumping stations. This system is being extended through a combination of dike extensions and pump upgrades that feature KSB Amacan P axial-flow submersible motor pumps.

“When a station is upgraded, our preference is to retrofit with two or four KSB Amacan pumps, which are replacing ageing long-shaft pumps,” reports Derek Hunter, foreman, Pump Stations. “Usually we try to change out the ageing long-

shaft pumps first because of problems associated with parts and efficiencies.”

Richmond has found that by standardizing on a single type of submersible pump, it can save on training and maintenance costs, while reducing the variety of spare parts it needs to keep on hand. Thirty-one KSB pumps have already been delivered, and six new units were ordered in December 2014.

MAINTENANCE

CONFERENCE

IN VANCOUVER SEEKS PRESENTATIONS

Mississauga, ON – A Call for Papers is now open for this year’s MainTrain conference, which will be held September 2124, 2015, in Vancouver, BC, says Cindy Sneddon, executive director of the event’s organizer, the Plant Engineering & Maintenance Association of Canada (PEMAC)

Sneddon says MainTrain needs the best workshops, experience-based presentations and case studies for its conference. PEMAC is seeking presentations that will provide participants with the tools to inspire, innovate and improve through excellence in maintenance, reliability and asset management.

If you have a story of innovation, a case study of improvement successfully increasing productivity and reducing costs, or can teach skills that will help inspire delegates to find efficiencies, PEMAC wants to hear from you.

To be considered for a presentation or workshop at MainTrain 2015, submit an abstract outlining what you would like to share. The association is looking for 45-minute presentations and half- or full-day skill-building workshops. The submission deadline is March 15, 2015.

For more details, visit the website at www.maintrain.ca/call-for-papers or contact Nicolle Guillen at events@pemac.org or 905-823-7255, extension 4.

The two-day event takes place every other year in Calgary; the first day features a number of half-day and full-day training courses, for a fee; the second day is free to attend and features presentations in the topic areas of Projects, End-User, and Pump Design, and also features discussion groups on various topics. A buffetstyle lunch is provided and features tabletop displays from pump-related vendors.

Participants may choose to participate on either or both days. For details, visit www.calgarypumpsymposium.ca/.

SHARP SLOWDOWN SEEN IN MANUFACTURING INDEX

Toronto – January 2015 data indicated a sharp slowdown in the Canadian manufacturing sector, with overall business conditions improving at the weakest pace since April 2013, according to the RBC Canadian Manufacturing Purchasing Managers’ Index (RBC PMI).

The latest survey signalled that output and new business volumes grew, but at much slower rates than in December 2014, while employment numbers dropped for the first time since the start of 2014. Manufacturers recorded softer input cost inflation during the latest survey period, while factory gate charges increased at the slowest pace for almost a year and a half.

At 51.0 in January, down from 53.9 in December, the seasonally adjusted RBC PMI signalled only a marginal improvement in overall business conditions at the start of 2015. Moreover, the headline index was at its lowest level for 21 months, largely driven by weaker rates of output and new business growth in January.

A monthly survey, conducted in association with Markit, a global financial information services company, and the Supply Chain Management Association (SCMA), the RBC PMI offers a comprehensive and early indicator of trends in the Canadian manufacturing sector.

WORLD DEMAND FOR PUMPS TO GROW 5.5% ANNUALLY

Cleveland, OH – Global demand for fluid handling pumps is projected to increase 5.5% annually to US$84 billion in 2018. In developed nations, an improved environment for fixed investment spending will enable pump-using manufacturers to invest in expansion and upgrade of facilities. In developing areas, increased investment in water infrastructure will spur gains as access to water supply and sanitation systems is expanded.

Continued growth in mining activity will boost pump demand in countries with large mining industries. Growth in oil production will also provide opportunities, especially in newly developed areas requiring infrastructure development. Centrifugal pumps will continue to be the most commonly used pump design due to their varied pressure- and load-handling capabilities.

These and other trends are presented in World Pumps, a new study from The Freedonia Group Inc., a Cleveland-based industry market research firm.

The Asia/Pacific region will generate

Richmond, BC, is replacing older flood control pumps with new models. KSB Pumps

44% of new pump demand through 2018. Pump sales in the region will rise 6.4% annually based on solid advances in fixed investment expenditures and construction spending.

“Several Asian countries are projected to record impressive gains, including China and India,” says analyst Mike Deneen. “China alone will account for 23% of all new global pump demand between 2013 and 2018.”

On a regional basis, Central and South America is expected to post the strongest annual gains, benefiting from ongoing industrialization. The US will remain the largest national market through 2018, due to its large process and manufacturing industries, water infrastructure, and oil and gas industries.

World Pumps (published 01/2015, 447 pages) is available for US$6,500 from www.freedoniagroup.com.

DEMAND FOR ELECTRIC MOTORS TO GROW MORE THAN 5% ANNUALLY

Cleveland, OH – The US market for electric motors is forecast to expand 5.4% per year through 2018 to $16.2 billion, accelerating from the 2008-2013 period (all figures in US dollars). Electric motors are key components in many durable goods and, as a result, suppliers will benefit from solid increases in motor vehicle, HVAC equipment and machinery output.

Rising demand for more efficient, more expensive motor products will also boost market value. However, pricing pressure from original equipment manufacturers (OEMs), as well as competition from lower cost imports, will limit value gains.

These and other trends are presented

dustry market research firm.

Demand for AC motors will grow faster than that for DC motors and remain the larger product category, with 2018 sales of $9.6 billion. According to analyst Lee Steinbock, “Motor vehicles are expected to make up approximately one-third of AC motor dollar gains, the result of a rise in hybrid and electric ve -

chinery, which are heavy users of AC motors, will provide additional support moving forward.

Demand for DC motors will approach $6.7 billion in 2018. DC motors are used extensively in transportation applications, and suppliers will benefit from increases in motor vehicle output and aerospace and other non-automotive trans-

sal motors, which can run on AC or DC power and are grouped with DC motors for the purpose of this study, are widely used in HVAC equipment and machinery, and higher output of these products will boost overall electric motor use.

Electric Motors (published 12/2014, 265 pages) is available for US$5,200 from The Freedonia Group Inc. at www.freedoniagroup.com. MRO

NSKHPS Spherical Roller Bearings

NSKHPS Spherical Roller Bearings offer higher speed and load capacities for a wide variety of industrial applications. Their innovative bearing design increases operating life, reduces maintenance costs and optimizes performance, resulting in high satisfaction. Learn more at thinknsk.ca

Machinery and HVAC equipment will be growing markets for electric motors.

Business Briefs

• Hanover, Germany – Two of the largest belt and hose makers in the world were joined together on January 30, 2015. Continental AG completed the acquisition of Veyance Technologies

Inc., Fairlawn, OH, from the Carlyle Group LP for about US$1.9 billion. Veyance Technologies sells Goodyear-branded industrial power transmission products; heavy-duty and lightweight conveyor belts; hydraulics; rubber track; and automotive and heavy-duty truck belts, hose, tensioners and air springs. Veyance was formerly known as Goodyear Engineered Products. Veyance had previously been acquired by Carlyle Group LP, a private equity firm, in 2007. The Continental ContiTech division, which also makes hoses and conveyor belts, was until now a competitor to Veyance. “Vey-

ance will complement ContiTech in markets in which we have been underrepresented up till now,” said Heinz-Gerhard Wente, CEO of the ContiTech division.

• Jyväskylä, Finland – The Santasalo Moventas Group has been divided in two, and operates now as wind energy company Moventas and the industrial gear manufacturer Santasalo Moventas Gears Oy, owned by the industrial group Clyde Blowers, has completed the corporate restructuring program that it entered in 2011. In connection with finalizing the restructuring program, the company’s restructuring debt has been paid, and the Santasalo busi ness has been established as its own company, headquartered in Wuppertal, Germany.

• Mississauga, ON – KSB Pumps Inc. became certified on December 15, 2014, under ISO 9001:2008 for development, production, marketing and service of pumps, valves, auxiliary equipment and systems. “It took considerable effort on the part of our ISO team to refine our quality assurance processes and develop the documentation needed to achieve ISO certification,” said Michael Blundell, president of KSB in Canada. KSB Pumps Inc. is the Canadian arm of the Germany-based KSB Group. It sells, services and

maintains a wide range of pumps and pump-related equipment for industrial and municipal applications.

• Toronto – Electric motors are among the highest in reliability incident reports, according to SKF Canada, Scarborough, ON. For many companies, electric motor failures lead to a continual cycle of costly repairs and unplanned downtime. As a result, the company recently launched the SKF Certified Rebuilder program for electric motor repair. Four repair shops have already achieved the certification: GMR Electric Motors, Saskatoon, SK; Les Entreprises LM, Montreal QC; Continental Electric, Edmonton, AB; and GPR Industries (1994) Ltd., Grande Prairie, AB. Several more companies are in the process of becoming SKF Certified Rebuilders and the Canadian network will grow significantly in 2015.

• Toronto – IDI Independent Distributors Inc., a Mississauga, ON-based national industrial buying group, held its annual shareholder conference in January 2015 at the Eaton Chelsea hotel in Toronto, where Vendors of the Year were named at the group’s annual Vendor Appreciation Dinner. They included: Safety Vertical – Superior Glove Works, Acton, ON; Hose, Rubber and Fittings Vertical – Veyance Technologies, Mississauga, ON; Bearings and Power Transmission Vertical – NTN Bearing Corp., Mississauga, ON; and Industrial Supply Vertical – Walter Surface Technologies, PointeClaire, QC. IDI’s membership now stands at 99 companies and 282 locations. The group recently added Ramsden Square, Kelowna, BC, and Christopherson Industrial Supplies, Prince Albert, SK, as new members.

• Cleveland, OH – Nook Industries, a manufacturer of linear

KSB Pumps sells, services and maintains a wide range of pumps and pump-related equipment

Walter Surface Technologies received IDI’s Industrial Supply Vertical Vendor of the Year award in January 2015.

The Veyance brand will in the future be known as Continental ContiTech.

motion components and systems, has achieved AS9100C certification. The ISO 9001:2008-registered company’s newest certification assures high-quality products for customers in the aircraft and aerospace industries as well as the other industries that it serves.

• Calgary, AB – Carlisle Power Transportation Products, Franklin, TN, and Transmission Supplies Ltd. (TSL), Calgary, AB, have formed a new partnership. Founded in 1905, Carlisle is a belt and belt drive solution provider that manufactures a full line of industrial belts and power transmission components in the US. TSL is a family-owned bearing and transmission supply specialist. The partnership makes TSL the largest ‘in-stock’ provider of Carlisle belts in Western Canada. Both TSL and Carlisle are ISO 9001 certified. Carlisle also operates offices in Waterloo, ON, and Winnipeg, MN.

• Plymouth, MI – C&U Americas LLC, the North American subsidiary of The C&U Group, China’s largest bearing producer, has named Thomas W. Rouse as its new president. He is responsible for managing all aspects of the C&U Americas’ operations, including new business, sales, marketing, engineering, customer service, warehousing operations and ad-

ministration. He succeeds William A. (Bill) Childers, who has retired from the company. Rouse previously was with Precision Gear Holdings LLC and Merit Gear LLC as president and CEO, and before that, he had a 20-year career at NSK Corp. C&U is represented in Canada by Global Bear Inc., Dorval, QC.

• Toronto – Harting Canada continues to experience double digit annual revenue growth, says Jon DeSouza, president and CEO. The company’s Canadian revenues increased by 40% to almost C$5 million in Harting’s fiscal 2014, which ended Sept. 30. The outlook for the com pany’s business in Canada and the US in fiscal 2015 is bright, he added. Key indicators suggest an acceleration of US GDP growth to the 3.0-3.5% range, he said. “Strong US demand and the Canadian weaker dollar benefits manufacturers in Quebec and Ontario – our largest markets,” says DeSouza. “We expect that to translate into increasing sales for our modular connectivity products in particular, as well as custom solutions like our North American-made backplanes and cable harnesses.” Harting expanded new product development with the opening of a new Quality and Technology Centre (HQT) at its headquarters in Espelkamp, Germany, in June 2014. For more information, visit www.harting.ca MRO

The trouble with being cheap

Problem: Mark Paradies was thinking about the ways that trying to be cheap when doing root cause analysis could cost companies millions of dollars. Here’s what he came up with: cheap investigations, cheap corrective actions and cheap training.

Regarding cheap investigations, he has seen many companies assign supervisors to investigate accidents ‘in their spare time.’ This is definitely a cheap investigation. But the problem that results could cost the company millions of dollars.

For example, let’s say that a near-miss doesn’t cost anything and no one is seriously injured. Therefore, a supervisor does a quick investigation without looking into the problem in too much detail. He recommends retraining those involved and the training is conducted days later. Case closed.

However, the root causes and failed safeguards are never fixed. Nearly a year later, a major accident occurs that could have been prevented if the root causes of the previous near-miss had been found and fixed. An major incident can cause injuries or deaths, and lead to expensive fines and legal costs. If this is the case, was the savings of a cheap investigation worthwhile?

Solution: One key to a world-class incident investigation and root cause analysis program is to spend time identifying which ‘small incidents’ are worthy of a good investigation, because they have the potential to prevent major accidents.

These near-misses (of a big accident) should be treated as seriously as the big accident itself, with a thorough investigation, management review and implementation of effective corrective actions to prevent recurrence of the causes (and, thus, the big accident that’s waiting to happen).

Mark Paradies writes at www.taproot.com, where you can find his additional thoughts on the trouble with cheap corrective actions and cheap training.

Do you have a solution for a maintenance problem? Send it in and if it’s published, we’ll send you a Mr. O Problem Solver T-shirt. Include your address, telephone number, print complete details and, if possible, add a sketch to help explain your tip. Send your tips to Mr. O, Machinery & Equipment MRO, 80 Valleybrook Drive, Toronto, ON M3B 2S9.

German engineers wrote the book on dependability.

Around the globe discriminating designers and end-users know there is no substitute for NORD when it comes to dependability. Wherever our products are deployed in demanding applications, industry places its trust in our precise German engineering. They know we will never compromise on the reliability of our products. And that they won’t have to compromise either. Choosing NORD is your guarantee of lasting performance. You know our name and you’ve got our word on it.

Thomas Rouse is the new president of C&U Americas.

Harting Canada’s Jon DeSouza.

Wireless Wizardry

BY JEFF BLACK

Wireless test tools assist in high-voltage upgrades at Linamar plant, helping keep maintenance workers safe.

5,000-kVA transformer outside and a 5,000-kVA busway coming in to a 5,000amp switchboard.”

The problem was that there was standard switch gear and vented panels that weren’t arc resistant and thus posed a significant risk to safety.

“That’s five times the old Category 4 boundaries so there is no PPE available,” Copp said. “So we were pretty concerned and we started looking at alternatives on how we can improve the situation.” Certainly, the right personal protective equipment (PPE) was going to be essential for the maintenance workers.

Like a grenade going off

In one event signalling the problem, a seal had failed in an outdoor panel and rainwater dripped into the enclosure, gradually filling it up until the bus bar failed and blew apart.

“It was outdoors and nobody was around, but it literally was no different than if I’d put a hand grenade inside the panel,” Copp said.

His team did a complete analysis of the system and learned that the high-incident energy potential was well above what was considered high risk. Indeed it was between 190 and 212 calories per square centimetre – four to five times above the acceptable safety threshold for the heaviest class of PPE typically available.

That led Copp and his team to design and install a high-voltage protection system around the feeder lines coming into the plant. Those 13,800-kV feeders from the local utility now go through a standard high-voltage 15-kV fuse before going into the transformer. Current-limiting fuses respond in one quarter of a cycle – before fault current can build to a dangerous level. These high-voltage fuses, however, won’t respond quickly enough. “It goes upstream of our fused isolation switch and becomes an additional point of lockout,” Copp said.

In addition, the fuses have been augmented with a high-speed multiline cir-

to safety and continuous evaluation of all

“Our warranty is never ending,” Copp joked about his group’s work. “But we also have to compete with outside guys

A recent job awarded to Copp’s team was a project to reduce the risk of arc flash from incident energy at one of Lina-

ON.

cuit breaker – high technology switch gear in a sealed vault.

“We monitor the current on the primary side of the transformer and the secondary side, and we set up a differential protection scheme where we look at the ratio of those two currents, as well as their individual absolute values,” Copp said. “With that I can say, ‘OK I need to make sure I don’t exceed the transformer ratings and this ratio must always be what the transformer turns ratio is, and if it isn’t, that’s indicative of a fault and we can trip open that breaker’.”

The new equipment brings the cur-

“Like probably every other manufacturer of our size and station in our market, we’ve got between, 3,000- and 5,000kVA distribution boards in our plants,” said Copp. “In Canada, we’re predominantly 600 volts. So [there’s a] 3,000- to continued on page 14

Linamar Inc.

Leigh Copp.

Linamar headquarters are located in Guelph,

rent levels down to a Category 2 or 3 using the old category ratings, or to a level where there is practical PPE available to protect the maintenance workers.

Wireless tools ‘a game changer’

When working among electrical panels in high-energy incident areas or working on proactive maintenance like Linamar’s arc flash risk mitigation project, Copp and his team deploy the latest wireless test tools. He calls the connected tools “a game changer” when it comes to high-voltage work, because they remove technicians from dangerous energized areas and provide real-time data.

For example, three-phase motors used throughout the facility can be monitored while in use after hooking up wireless clamp meters. Copp uses the Fluke AC and DC clamps equipped with iFlex devices with the Fluke Connect app on his Android phone.

“So I would put the instruments on, close the door, start the machine up, link them to my phone and then go around to the front of the machine and actually monitor the voltage and current while the machine is operating with the doors closed, completely safely.”

Indeed, deploying such an approach to maintenance – trou-

Beyond wireless

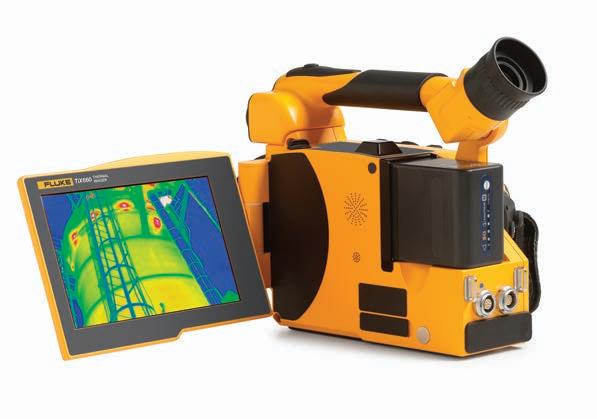

Beyond the valuable safety features of remote monitoring, implementing a preventive maintenance program is easier when you capture data and log it nearby the equipment under test. The Fluke Connect system, which includes a smart phone app and connected tools such as clamps, multimeters and infrared cameras, also features equipment logging.

Developed to help customers work faster and smarter, Fluke Connect EquipmentLog can help reduce equipment downtime and costs. Users create a folder for each asset with a description of the asset and the location.

It also stores all the measurement data captured for this asset over time, allowing maintenance technicians to do a side-by-side comparison from previous inspections, so any accelerated trends can be easily identified to help determine when maintenance needs to happen. This keeps equipment running longer, saving time and money, and reduces the risk of unplanned downtime.

Another feature of Fluke Connect, called ShareLive video call, allows a technician to communicate critical data, get answers and additional work approvals instantly, without leaving the inspection site.

The ShareLive video call feature allows a technician to communicate critical data and get answers without leaving the inspection site.

Visit biocircle.com for more information

NO MORE Toxic Solvents!

THE NEXT GENERATION OF CLEANING TECHNOLOGY

Powered by Nature Boost, CB 100, CB 100 ALU, GS 200 and BIO-CIRCLE ULTRA effortlessly clean & degrease any and all types of metal!

Easily break down greases, ink, rubber marks, tar and nearly all other hard-to-remove industrial contaminants.

Incredible cleaning power – at ROOM TEMPERATURE

Stays cleaner, longer! Will NOT GET SATURATED with oil & other contaminants

Nature Boost is 100% VOC-FREE, NON-FLAMMABLE, NON-TOXIC & BIO-RENEWABLE

bleshooting while the equipment is operating – is an ideal scenario to keep industrial processes running, according to Ken Bannister, an engineer, author and consultant who works with commercial, industrial and government clients in Canada on maintenance programs.

Keeping up throughput

“The more you can do from the perimeter of the equipment without going into lockout and shutting the equipment down and losing throughput in a manufacturing state, the better it is,” Bannister said.

The Fluke Connect system is a growing number of wirelessly connected test and measurement tools that leverage Bluetooth Low Energy (BLE) technology, industrial networking and cloud computing in an integrated test and measurement platform. The platform aims to improve efficiency and productivity – and data accuracy – by collecting data.

Another advantage of an app such as Fluke Connect is that you can collect all of the data from multiple tools in one place. The data is logged by date and equipment and easily can be shared.

“I was looking at a vacuum tube oscillator. I was monitoring the filament voltage and current at the same time. And inside this cabinet, it’s 15,000 volts at radio frequency and it’s very dangerous. You need to be a metre-and-a-half away from that,” Copp said.

“When I’m monitoring more than a couple of devices at a time, it’s kind of tricky to look at them with your eyeball and actually catch the correlation. I love to graph the data and see the correlations with the Connect App running on my tablet. I can link to those devices and store the data as well for subsequent analysis.”

Linamar continues to build its troubleshooting and technical maintenance workforce through a strong apprenticeship program that including seven young women – a conscious effort to increase female technicians in the industrial trades arena.

Using phone apps and high-tech tools is a snap for these younger workers. “They pick it up instantly,” Copp said. Indeed, the younger technicians have been brought up around technology, so they are very comfortable with it. And with the connected systems and the improved interfaces, you don’t need to be an expert to set it up.

MRO

This article was written exclusively for MRO Magazine. Jeff Black is the managing editor at Fluke Corporation. www.flukecanada.ca

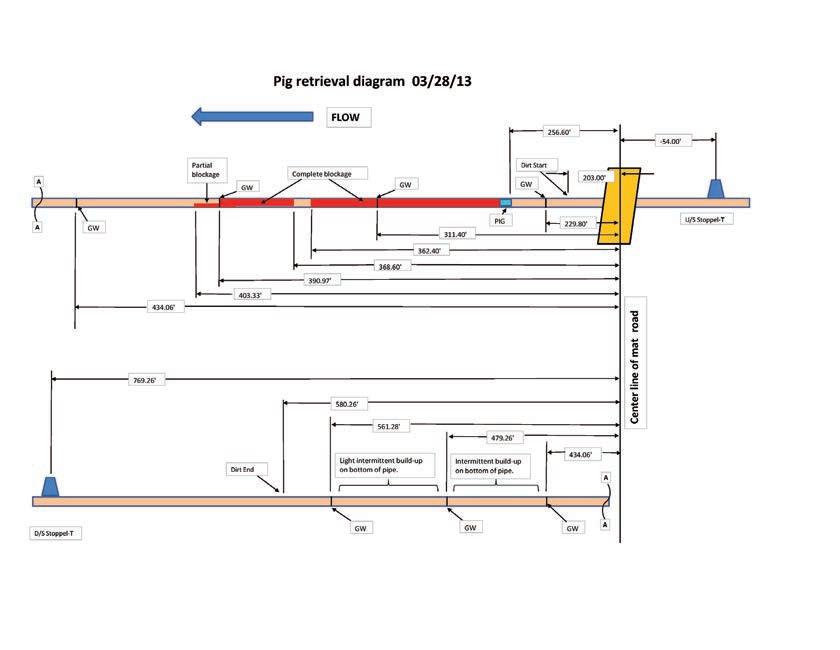

During routine cleaning operations with a pigging tool in early 2013, a pipeline company encountered a blockage in one of its pipelines. Because the pipeline transported a sediment-containing light hydrocarbon product, the company wanted to ensure that the blockage was removed in a timely, economical and environmentally safe manner.

The problem area was in a 240-km section of pipeline in Minnesota. The company encountered a challenge when, after cleaning the first 32-km section of the pipeline, the cleaning tool became blocked by what was determined to be the excessive build-up of sediment in front of the cleaning tool. Due to the large amount of sediment in this particular line, the tool had gathered enough sludge to completely stop any further progress of the cleaning pig.

Although the company knew the approximate location of the pigging tool used to clean the pipeline, the engineers faced three challenges. First, they need ed to know the amount and characteris tics of the sediment blockage. Second, they needed to know the location of the blockage in relation to the stopple tees (valves for stopping flow in the pipeline). Third, they needed to isolate and contain the sediment, determine the sludge level, and ensure that not only could the tool be removed, but that when the line was put back in service, the company would have no further issues with flow.

Initially, the use of X-ray technology to solve the issues was discussed. How ever, because of the diameter of the pipe, and due to the fact that it was full of sed iment and product, the parties agreed that the use of X-ray technology would not only prevent them from meeting their timeline goals, they would also not re ceive all of the information needed to solve their problem.

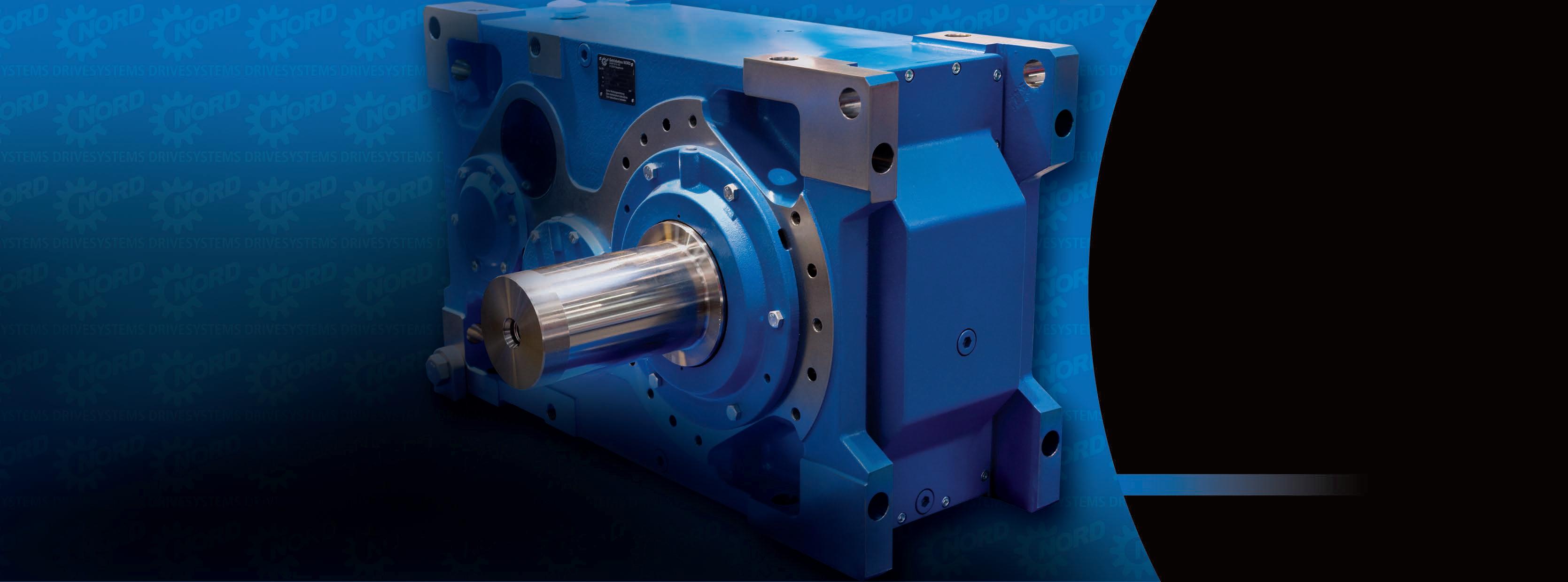

After further discussions, and re view of available technologies, it was determined that a technique could be developed using ultrasonic inspection technologies to determine not only the location of the blockage, but the amount of sediment in the line, its true length, and other characteristics necessary to facilitate an expedited repair and return to service. As a result, the pipeline company approached SGS PfiNDE, a supplier of ultrasonic inspection technology, for a solution.

BY STEPHEN R. COX AND DAVID A. HARMAN

FINDING THE BLOCKAGE

The use of ultrasonics to measure sludge and sediment levels helps locate a blockage in an oil pipeline that was being cleaned internally.

Ultrasonic inspection technologies require only a single technician with minimal equipment, results are displayed in microseconds and readily available for interpretation, and do not pose a safety hazard. On the other hand, radiographic imaging requires multiple personnel with extensive equipment requirements, takes several minutes for each shot along multiple sections of the pipeline, additional time for film development prior to interpretation of the results, and poses a safety hazard to all nearby personnel.

An ultrasonic transducer can transmit and receive sound through the entire volume of materials. With an ultrasonic inspection system, a single transducer is connected to the ultrasonic instrument and is used to take measurements from any location with access to the outside surface on the circumference of the pipe.

SGS staff travelled to a rural area of Minnesota and, using pipeline rights-ofway, arrived at the approximate location of the blockage. To begin the project, SGS inspection personnel first helped determine the exact location of the pigging tool. Once the tool was located, work was immediately started to deter-

mine the extent of the blockage and the -

mined the use of an ultrasonic scope — which allowed the user to manually set the material velocity as opposed to using data logger equipment with pre-set velocity values — was required due to the

unique problems encountered by varying velocities of the steel pipe, sludge and fluid. The equipment selected allowed the inspectors to drop the velocity down to that of water, which is considerably lower than carbon steel. The inspection technicians also used a low-frequency, 2.25-MHz transducer, which allowed significant penetration through the pipe, the fluid and the blockage.

The inspection technicians knew the velocity of the steel used in the pipeline

continued on page 16

tomorrow has already been tested. Say goodbye to hardwiring with HARTING connectors.

Figure 1: About 45 metres of the pipeline was solidly impacted with sediment build-up.

Figure 2: Ultrasonic signals could be transmitted through the entire volume of the pipeline.

Figure 3: Cutaway of pipe shows the sediment blockage.

Fig. 2

Fig. 1

Fig. 3

was 0.230 in./μs (0.230 x 105). In addition, technicians knew that the velocity of water (as opposed to oil) is approximately one-fourth that of steel, or 0.053 in./μs (0.053 x 105). As a result, inspection technicians initially set the velocity on the ultrasonic scope to water.

Once the ultrasonic system was coupled to the pipe, and the pipeline diameter of 24 in. was taken into account, the inspection technician made the necessary adjustments in velocity settings to match the known distance from the top outside surface to the known distance of the inside bottom surface. This adjustment brought the velocity setting closer to the true velocity of the petroleum product in the pipe -

FOCUS ON TEST & MEASUREMENT

sediment, the technician was able to transmit ultrasonic signals through the wall thickness of the pipe and the entire volume of product in the line, and receive a return signal from the bottom (180 degrees) of the inside pipe wall. Additionally, the technician was able to transmit ultrasonic signals through the entire volume of the bottom wall thickness.

Using the ultrasonic inspection technology, the inspection technicians were able to obtain a full-volume reading. Ultrasonic readings were taken along the entire section of pipeline containing the sediment around the circumference, enabling them to plot out the exact location of the sediment and determine its volume.

accurately develop a strategy to effectively and efficiently cut and remove the specific section of the impacted pipeline.

Setting the standard

Renold Syno sets new standards for a complete range of maintenance-free roller chains.

Experience maximum performance without additional lubrication.

Renold Synergy is the only true high-performance roller chain in the market.

Lasting up to six times longer than comparable chains, Synergy reduces downtime and operating cost.

Call today to put Renold innovations to work for you.

We have the solutions you need – ready for quick delivery

The repair plan developed as a result of the ultrasonic inspection data collected, and permitted the removal of the pipeline section containing the blockage and the impacted pigging tool well within the stopple tees, thereby stopping the flow of the liquid product before the operation.

As well, the pipeline company was able to remove the entire sediment blockage and build-up, thereby reducing any further issues that might have resulted from partial removal, while at the same time preventing any product leakage, which would have posed serious environmental issues.

Finally, the removed section was replaced and after the successful completion of testing, normal pipeline operations resumed.

Typically, pipeline companies consider the use of ultrasonic inspection technologies such as shear wave, phased array, FAST and TOFD only for use in high-end weld investigations, and while looking for cracks, dents and internal defects. Used properly, by a well-trained, skilled technician, ultrasonic testing is appropriate for finding discontinuities below the surface of the material, such as internal corrosion, manufacturing flaws in pipeline materials and flaws in welds.

However, with today’s generation of ultrasonic technology, inspection techniques can be developed to provide safe and virtually instantaneous results that can be used quickly, efficiently and economically to obtain additional information, such as determining fluid levels and checking for the presence of sludge. It also is suitable in many other instances where, traditionally, a more costly and time-consuming technique like radiographic inspections would have to be used.

Events such as a pipeline blockage show that each situation or issue provides a unique set of challenges for ultrasonic inspection to overcome and when properly used, the technology can often be a viable alternative to X-ray or destructive testing.

MRO

Stephen R. Cox is key account manager and David A. Harman is ASNT Level III with SGS PfiNDE Inc., Broken Arrow, OK, a division of SGS SA, Geneva, Switzerland. SGS Canada’s offices are based in, Mississauga, ON. For more information, visit www.sgs.ca.

Diagram of worksite shows overall measurements.

Keeping your motor running

How to keep electric motors running longer by preventing bearing failures through proper selection, care, lubrication and condition monitoring.

Avital piece of equipment in today’s modern manufacturing processes, the electric motor is found in practically every type of application. Its simple and reliable operation makes it rather easy to overlook during everyday maintenance practices. Unfortunately, it’s often too late to employ minor repairs when an electric motor begins to show signs of neglect.

However, there are several standard maintenance tools and practices that are easy to implement to help keep electric motor rebuilds and replacements at a minimum.

First, it’s important to ensure new and rebuilt motors are in prime condition. Here are some critical steps. Perform vibration checks. Make sure to perform vibration checks for defects. The recommended limit is no more than 0.05 in.-per-second overall (0-120,000 cpm).

When purchasing, request mechanically balanced motors. Always ask for mechanically balanced rotors, especially on applications using high-efficiency/high speed models. Acceptable limits can be found in the International Standards Organization (ISO) specifications. Specifications are provided in G-6.3 for lower horsepower (under 100 hp) or less severe motors, and G-2.5 for highhorsepower, vertical or critical motors.

Store motors properly. The best way to prevent moisture from entering the bearing cavity and causing corrosion before installation is to store motors with the bearings fully packed with grease. If your motors are lubricated

with oil, make sure you discuss proper storage with your motor supplier.

Rotate stored motor shafts. sure new and rebuilt motors are in prime condition by rotating the rotor by hand every month. This will prevent fretting corrosion, a wear process that produces false brinelling — evenly spaced depres sions in the bearing races that may ap pear to have been formed by indenta tions due to shock loading.

ring. If a bearing is dropped, it is best not to install it. If using a vise to assist mounting, protect the shaft with a sheet of soft metal. Inspect bearings carefully. Inspect the shafts and housings for size and damage. Remove any nicks and burrs with emery paper. If shafts or housings show obvious signs of wear or damage, then replace or repair them.

Avoid overheating. Never bring a flame in direct contact with a bearing and never heat one beyond 446ºC (230ºF). During heat-mounted operations, place the bearing against the shaft shoulder until it cools and locks in place to ensure the bearing does not creep away from the proper position.

Pay attention to the bearing press fit. Ensure the bearing’s proper fit by applying even pressure to the outer race with a press. A bearing that has an outer diameter of less than 100 mm (4 in.)

the recommendation that’s right for your operation, especially for those motors that require oil instead of grease. Use the correct lubrication practices. Over 90% of electric motor bearing failures are due to overgreasing. Overgreasing also causes seals to burst, thus allowing grease to bypass the bearing and go straight into the motor windings. Adopt stringent alignment limits. Another cause of electric motor failure is misalignment. There are many methods to use to align the driver and the component it is driving, but what is most important is to align to tight tolerances. Remember, the bigger and faster the motor, the tighter the tolerances need to be.

Follow good housekeeping practices. Don’t let dirt or process materials build up on the motor, as it can act as insulation and generate unnecessary heat that has a negative impact on bearing life.

When you need to repair a motor that has bearing problems, it’s important to handle replacement bearings with care.

Store bearings in their original packaging. The best way to store bear ings is horizontally in a dry place and in their original, unopened packages. Never place bearings on a dirty surface.

Rotate bearings while in storage. For greased bearings, periodically turn over sealed and shielded bearings to pre vent the grease from settling on one side. Replace with identical bearings. Use identical bearings for replacements. If needed, contact your authorized bear ing distributor or manufacturer for inter change information.

Never wash new bearings. wash new bearings before installation. Bearing manufacturers take great care to package and ship bearings that are dirt-free and ready for lubrication. There’s really no need to wash them or remove the protective slushing compound.

If you need to replace electric motor bearings, ensure you use proper installa tion and repair practices.

Be sure to handle bearings with care. Never pound directly on a bearing or

atmospheric contaminants. Be sure to talk with a lubrication engineer about

Bearings and lubrication are critical components of electric motors.

©Murmakova/iStock/Thinkstock

Water World

BY CARROLL MCCORMICK

High above the bottom of a drydock on a late March afternoon in Thunder Bay, ON, the aft end of the enormous bulk carrier, the Tim S. Dool, looms over Lakehead Marine & Industrial Inc. (LMI) workers as they slide a 17.24-

tonne (19-ton) propeller shaft into the ship’s stern tube. The 222.5-metre-long (730-ft) gearless ship, nearly two months out of the water, is almost ready to be released back into Lake Superior with its new water-lubricated propeller shaft bearings.

Marine-friendly bearings convert an Algoma Central ship’s propeller shaft bearings to water lubrication from oil, reducing pollution in the Great Lakes.

Dupont ™ Krytox® Lubricants

Krytox® lubricants will:

• Ensure bearings run quieter and wear less

• Reduce rusting as well as extend bearing and component life

• Protect bearings under high loads

• Prevent metal-to-metal contact and thereby reduce wear

They are chemically inert; safe for use with acids, bases or other harsh chemicals and reactive gases. Nontoxic, nonflammable, oxygen compatible, thermally stable, operates at temperatures up to 800°F, low vapor pressure, low outgassing. Offers extreme pressure, anticorrosion and antiwear properties.

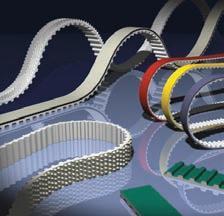

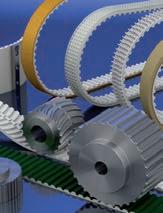

BRECOflex CO., L.L.C. is the pioneer and world leader in the polyurethane timing belt industry. We offer our customers the widest range of timing belts, drive components, metal pulleys and accessories designed and manufactured with the highest priority given to quality and precision.

Whether you are looking for a standard product from our inventory or a custom design tailored to your requirements, your application will benefit from our perfectly matched timing belts and pulleys. We take pride in our rapid customer response time and industryleading product delivery and quality.

additional information regarding our products and technical support services, visit our website at: www.brecoflex.com or call 732-460-9500.

Above left: The Thordon bearings are frozen in liquid nitrogen to shrink them before installation in the stern tube. Top right: Algoma Central’s Tim S. Dool bulk carrier plies the Great Lakes. Above right; For corrosion protection, LMI applied a 2-mm (0.08-in.) coating of epoxy, prepared by Thordon, on the stretch of shaft between the forward and aft bearings.

Photo: Thordon Bearings

Photo: Algoma Central Corp.

Photo: Wajax

This is the first of two back-to-back conversions from white metal, oil-lubricated sleeve bearings that LMI in Thunder Bay was doing for St. Catharines, ON-based Algoma Central Corporation in 2013. The proprietary polymer alloy sleeve bearings, manufactured by Burlington, ON-based Thordon Bearings, ride on a film of water pumped continually through the ship’s stern tube. The over 2,000 ships already using these bearings no longer risk polluting the lakes and oceans they ply with shaft bearing oil.

These conversions are team projects. Thordon does the feasibility study, technical and commercial proposals and some of the machining work. LMI is the constructor responsible for some fabrication tasks and the installation of the components to Thordon's specifications. The other key partner is the local branch of Lachine, QC-based Wajax Industrial Components, an authorized distributor for Thordon Bearings.

Raymond Parent, branch manager, Thunder Bay, is the Wajax middleman who, in addition to having buying and selling tasks, keeps an eye on everyone to make sure the projects proceed according to specifications, and on time. “I watch the logistics of the whole conversion to ensure there are no delays or complications. I help with communications between LMI and Thordon to sort out any technical difficulties in a timely manner. In a job this size, unknowns come up. We are here to ensure that the small technical questions and logistics are dealt with.”

Scott Groves, marine business development manager for Thordon, notes, “This is a big job. A lot of technical expertise goes into it and it has to go right.”

Preparations began in 2012 with discussions between Thordon and Algoma on possible conversions. Following that, Algoma sent drawing packages to Thordon and requests for proposals to LMI and other shipyards.

Once everyone’s ducks were lined up, with contracts signed and marching orders delivered, work began on the Dool conversion. Based on its engineering survey of the metals inside the Dool aft shaft, Thordon specified two cast bronze sleeve liners for the propeller shaft. They will turn inside the Thordon bearings. The lead time for this special order, from a European foundry, was about three months.

Before sending the 76.2-cm (30-in.) internal diameter (ID) by 101.6-cm-long (30 in. x 48 in.) bronze liners to Girotti Machine in St. Catharines for machining, Parent and Jim Richards, an outside sales representative with Wajax, stepped in. “We ensured that LMI’s measurements were current, correct, clear and concise so that Thordon could finalize the dimensions for the bronze liners and the Thordon bearings,” Parent explains.

Thordon’s machinists turned down the 1,384 mm-long (54.49-in.) aft bearing to 610 mm (24.02 in.) ID and 695 mm (27.36 in.) outside diameter (OD). Its finished weight was 195.04 kg (430 lb). The final dimensions of the 552 mm-long (21.73-in.) forward bearing were 608 mm (23.94 in.) ID, 652 mm (25.67 in.) OD and 53.98 kg (119 lb).

On February 8, 2013, LMI workers flooded the dry dock, winched in the ship, positioned huge wooden blocks alongside the hull to keep it upright and pumped out the water. “We built a scaffolding around the aft end, then removed the propeller, hub, shaft and old bearings,” says Roy Summers, general manager, LMI.

LMI’s tasks included fabricating an adapter plate where the former oil seal was and an outboard retaining ring that holds the Thordon bearing in place. The

main action in the shop, though, re volved around that huge shaft.

“We polished the shaft and heated the bronze liners to obtain a 2.54-mm (0.100in.) clearance for installation. Once cooled to a shrink fit on the shaft, we machined them to their final OD,” Summers explains.

To ready the bearings for installation, LMI put them in a tub of liquid nitrogen. Frozen to about -196°C (-320.8°F) they shrank by 15% — plenty of room to slide into the stern tubes before they warmed up to a tight fit.

After a final check of some key dimensions, LMI reinserted the 7-m (23-ft) shaft, bolted on the hub and replaced the variable-pitch propeller.

To deliver lubrication to its bearings, Thordon designs and manufactures waterquality packages, which pump measured amounts of lake or sea water through propeller shafts at continuous rates. LMI installed one in the Dool, along with the necessary plumbing and electrical systems.

Groves explains what the water quality packages do. “Water is pumped into a cyclone separator. It takes out abrasive solids down to 80 microns in diameter and having a specific gravity of 1.2 or greater. The water then goes through a flow meter,

which maintains the correct flow rate.

“We want to pump water through the bearings at a rate of 1.5 litres/minute (0.40 gal/min.) per mm of shaft diameter. That’s 91.5 litres (24.17 gal.) a minute for the Dool. When the shaft starts to turn, it drags the water around it until it is riding on a hydrodynamic film of water. This takes only about 10 revolutions.”

The Dool left the dry dock less than two months after it arrived, on March 28, 2013. Waiting its turn for a bearing conversion was Algoma’s self-unloading bulk carrier, the John D. Leitch. LMI pulled it into the drydock on April 1 and the team of LMI, Thordon and Wajax, which had been preparing for months for this conversion too, continued their work. (Editor’s note: LMI filed for bankruptcy in July 2014 and the business was closed in November.) MRO

Carroll McCormick is the senior contributing editor for Machinery & Equipment MRO.

OUTWORK THE DAY

OUTLASTS + OUTPERFORMS. The dense fiber structure of Material4X ® provides consistent quality, higher abrasion resistance and greater tear resistance than standard synthetic gloves. DURABILITY REDEFINED

Above: One of the Thordon bearings has been inserted in the Dool’s stern tube.

Photo: Wajax

Gold Rises

BY BILL ROEBUCK

conveyor adds to Quebec gold mine’s life expectancy.

Agnico Eagle’s LaRonde gold mine, located in the Abitibi region of northwestern Quebec, is working to increase production with various projects, including using an upgraded gear unit for an underground conveyor application.

The mine awarded a contract to Santasalo, a manufacturer of industrial gear units for process industries, which will supply a design upgrade of its D-Series gear unit. The order, which was placed by the Canadian Bearings branch in Vald’Or, QC, is the first order placed of this design specification that establishes a new power range for Santasalo’s three-stage bevel-helical conveyor series gear drive.

LaRonde is Agnico Eagle’s flagship mine; the 7,200-tonne-per-day mine and plant has produced 4.4 million ounces of gold since it opened in 1988. The mine still has 3.9 million ounces of gold in proven and probable reserves.

A recent expansion and upgrade project

has taken place in order to increase the mine’s life expectancy to 2025. This includes a new underground conveyor system to convey mined ore to the 2.2-km-deep mine lift hoist that will bring the ore to the surface for further processing at the plant.

LaRonde is expected to increase gold production rates, anticipated to exceed 300,000 ounces per year by mid-2016 and continuing over the life of mine, reflecting the higher gold grades expected at depth.

Ore is processed at the LaRonde mineral processing complex, which includes copper and zinc flotation, as well as precious metals recovery and refining. The processing plant produces doré bars containing gold and silver, as well as zinc and copper concentrates that also carry valuable gold and silver credits.

For the LaRonde upgrade work, Santasalo’s gear unit was selected as the most reliable technology for the tough conditions surrounding this application. The D-Series helical gear unit is mounted on a swing base and directly connected to the conveyor pulley shaft via the company’s Zapalex ridged flange coupling.

Quick facts about gold

Gold is recyclable. Almost all the gold ever mined still exists and could be up to 6,000 years old. Gold is the most malleable metal in the world. It’s strong but yielding. One ounce of gold can be stretched to a length of 80 km; the resulting wire would be just five microns wide.

A total of 171,300 tonnes of gold have been mined since the beginning of civilization.

100 million people worldwide depend on gold mining for their livelihood.

Even at only 10 parts of gold per quadrillion, the world’s oceans are estimated to hold up to 15,000 tonnes of gold.

“This project has helped us build a strong relationship with our partner, Canadian Bearings, and also assisted in promoting our brand image with a key mining/producing company like Agnico Eagle,” said Joe Sitta, Santasalo’s director of capital sales Americas.

Production was expected to return to more normal levels (about 55,000 to 60,000 ounces) in the fourth quarter of 2014, following the completion of the hoist drive upgrade. Production was also expected to benefit from the mining of higher-grade ore.

Installation of a coarse ore conveyor system remains on schedule and is budgeted for start-up in the second half of 2015. The new conveyor is expected to minimize the impact on trucking capacity and reduce congestion in the deeper portions of the mine. Studies are also underway to investigate the potential to define reserves and carry out mining activities below a depth of 3.1 km (the current lower limit of the LaRonde reserve base). MRO

Bill Roebuck is the editor of MRO Magazine.

Above: Santasalo’s bevel-helical conveyor series gear drive has been upgraded.

LaRonde’s underground ventilation cooling system is extensive.

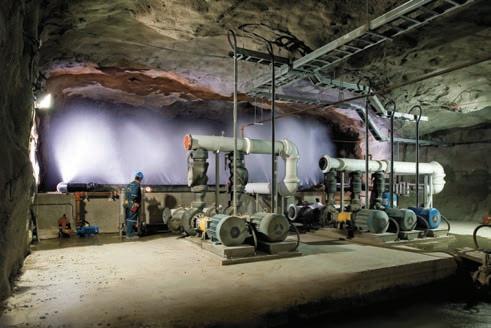

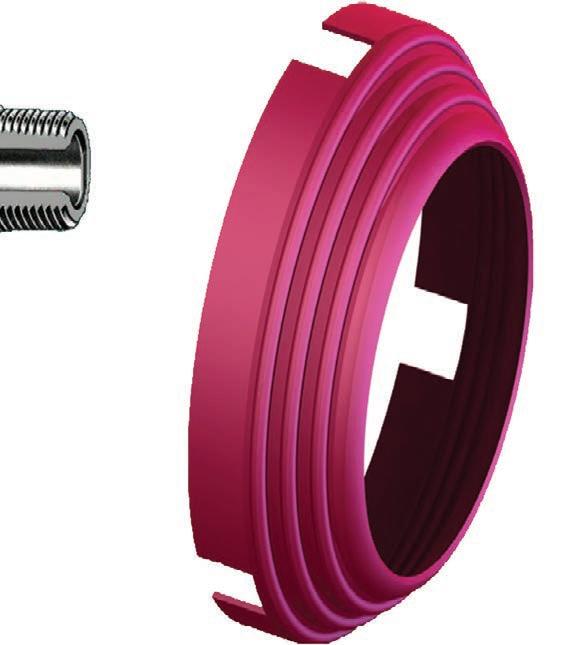

Can drive chain really be lube-free?

BY BILL ROEBUCK

is like a standard unlubricated chain. Other types of solid lubricant include wax-like coatings applied by immersing the chain in vats of hot, melted lubricant, which permeates the components.

When lubricants are not practical, lube-free chain can deliver performance through the use of a polymer bush or with an oil-impregnated bush that has no obvious lubrication.

The idea of lubrication-free drive chain might seem to be a misnomer to many. After all, drive chain needs to be lubricated to prevent wear of the surfaces between the pin and the bush and the bush and the roller.

Without proper lubrication, the wear on these components will cause chain to elongate, leading to problems such as jumping in the sprocket teeth, fluctuating drive loads and possible failure of the chain itself.

“A well-lubricated chain is still one of the most efficient and reliable methods of power transmission,” says Dr. Chris Lodge, vice-president of engineering at Renold Jeffrey. Dr. Lodge is likely the most educated and knowledgeable engineering executive in the chain business today.

However, he says, lubrication incurs additional costs and there are many applications where it is either impractical or undesirable. For example, chain lubrication is undesirable in the food industry because lubrication could contaminate the product. Also, it is impractical to use in applications where the chain is inaccessible or difficult to reach.

Until fairly recently, there were many applications where companies had to run with the chain unlubricated, thus facing frequent chain replacement and costly downtime, simply because a lubrication-free alternative was not available or was not cost-effective.

As a result, in recent years, there has been a significant increase in the number of lubrication-free chain products on the market – and manufacturers are continuing to develop more.

What exactly do manufacturers mean by ‘lubrication-free’? Dr. Lodge explains.

Most lubrication-free chain is probably more accurately described as chain that does not need to be re-lubricated. The chain effectively comes with its own supply of lubricant, which in most cases is so cleverly engineered within the chain, that to all intents and purposes, it appears not to be there at all. The lubricant is there but it is trapped inside the chain.

With such chain, there is no need for lubrication again over the life of the product. There also is no visible lubricant that can cause contamination.

Types of lubrication-free chain

There are two categories of lubrication-free chain – those containing a solid lubricant and those containing a liquid lubricant.

Solid lubricants include surface coatings applied to the chain’s components during the manufacturing process. However, once they have worn away, the chain

A great deal of research is done by manufacturers to find ways to trap lubricant inside a chain for longer periods. One resulting development is Renold’s Syno brand, which is made using a specially-manufactured, sintered, oil-impregnated bush. During operation, the oil is released on to the bearing surfaces. When the chain stops running, the oil returns to the bush through capillary action, like water being soaked up by a sponge.

This type of lube-free chain can be used virtually anywhere and lasts hundreds of times longer than standard chain running without lubrication. However, there are still applications where an alternative solution is required, such as where frequent washdowns are common, where the chain is being operated outside, where there are temperature extremes, or in

very heavy duty applications. For applications such as these, Renold has developed a special polymer bush chain, where there is no metal-to-metal contact at the bearing surfaces. This chain operates without any lubrication at all; it is truly lubrication-free technology. The design breakthrough was the result of the development of a special polymer material that delivered the necessary performance without the cost of using a high-performance engineering polymer. In this case, the cost of the polymer rollers is in line with those of steel rollers.

With the availability of the oil-impregnated bush and development of the polymer bush, there are now few applications for which there is not an off-the-shelf, lubrication-free chain solution. MRO

Bill Roebuck is editor of Machinery & Equipment MRO. For more information on these chain products, visit the website at www.renoldcanada.com.

SOLUTIONS.

With sales and services, support and training, we serve Canada‘s maintenance professionals with innovative technology for plant reliability.

• Laser shaft and geometric alignment

• Portable vibration analysis and balancing

• Continuous online monitoring

• Training and Machinery Services

Renold’s Syno chain is made using a specially-manufactured, sintered, oil-impregnated bush.

Renold Canada

What’s new in motors, controls and belt drives

Wireless digital tool aligns sheaves and pulleys

The Easy-Laser E180 allows accurate and efficient alignment of sheaves and pulleys on belt and chain drives. Its digital readings allow greater precision, and combined with a display unit, make it easier to follow the belt manufacturer’s tolerances. Results are documented directly as a PDF. The adjustment values are displayed live, which makes alignment easy. Using a separate display unit makes it even easier, as you can follow the machine’s adjustment continuously at the point where the adjustment is being carried out. The machine’s shim and adjustment values are automatically calculated. The work can be carried out by one person. The tool can be used on all types of sheaves and pulleys, such as V-belt, timing belt, flat belt and chain drives. With nonmagnetic aluminum sheaves and pulleys, the low weight of the tool means that it can be attached using strong double-sided tape.

Synthetic material improves performance of cog-belt Carlisle Power-Wedge cog-belts are now made of EPDM, a durable and static conductive synthetic rubber with a broad operating temperature range. The material resists hardening and glazing and is oil and heat resistant. These heavy-duty, smooth-running belts feature side walls that reduce vibration for extended component life, while a redesigned cog profile reduces bending stress for improved flexibility and performance on small-diameter pulleys.

CTP Transportation Products www.carlisletransportationproducts.com

Benchmark Maintenance Services Inc.

www.benchmarkpdm.com

Decentralized servo drive makes for more cabinet space Siemens has introduced the Sinamics S120M decentralized servo drive, a compact, ready-to-connect motor with integrated drive that offers users the option of mov-

ing the motor inverter outside the control cabinet and directly onto the motor, thereby reducing both cabinet space and required cooling. The decentralized axes are connected back to the central S120 components in the cabinet via a hybrid cable and the AM600 adapter module. The cable contains all encoder and power cables and serves multiple S120M axes through a daisychain connection. Features include a synchronous servomotor with multi-turn absolute encod er, optional holding brake and an integrated power unit available in three shaft heights covering the power range of 0.25 kW to 1.5 kW. Typical applica tions include packaging, printing, glass, textile and other processes where machinery and production lines require multiple servo axes in a space-restricted environment. Siemens Canada www.siemens.ca

Notched V-belt stands up to high temperatures in HVAC EPDM-formulated raw-edge, notched Vbelts from Browning have a temperature rating of minus 51ºC to plus 121ºC (minus 60°F to plus 250°F). They have a 43ºC (110ºF) higher heat tolerance than polychloroprene belts, making them suitable for rooftop blower units or industrial process exhaust systems. In addition, these notched V-belts can improve drive efficiency over wrapped-style V-belts. All

belts feature high fibre loading, multiple plies of a tubular-woven knit fabric in the overcords, and wide notch spacing to increase rigidity and stability. They meet RMA standards for matched tolerances right off the shelf and are static dissipating, as well as oil and heat resistant. Emerson Industrial Automation/ Browning http://bit.ly/mro_browning

Online program makes belt drive selection a breeze

TB Wood’s has introduced a belt drive selector program at beltdriveselector.tbwoods. com. The online tool allows users to quickly and easily select the right belt drive for a specific application, with minimum filter entries. The web-based tool works on PC, tablet or Mac platforms. As it always uses the latest software version, there is no need to download updates. Users can display relative, discount and quote pricing, and favourite belted solutions can easily be marked, shared and recalled. The program includes Classic, Narrow, Light-Duty and Premium V-Belt Drives and Synchronous Plus, QT Power Chain, Power Chain II and Timing Synchronous Drives.

TB Wood’s www.beltdriveselector.tbwoods.com

What’s new for cleaning parts

Weld cleaning system replaces hazardous pickling pastes

Walter Surface Technologies has introduced additional components for the Surfox weld electro-cleaning system that promote a cleaner, healthier and safer industrial work environment. These components include the Surfox H standard electrolyte cleaning solution for regular use,

cleaning up to 3 fpm to 6 fpm; the Surfox duty jobs, which has a higher pH than Surfox H; application pads with increased conductivity; passivation tester providing numeric values of state of passive layer; stainless steel grade ID tester; and marking kits, which use an electrochemical process to permanently mark stainless steel surfaces. The system cleans stainless steel without toxic pickling pastes, saves time for workers and is easy to use.

Walter Surface Technologies www.walter.com

Electric high-temperature oven cleans fuel nozzles

Grieve has introduced the No. 818 1,000°F high-temperature universal oven currently in use for cleaning and heat treating fuel nozzles at a customer’s facility. Internal measurement is 24 in. wide by 36 in. deep by 24 in. high, 24-kW power is installed in Incoloy-sheathed tubular heating elements, and a 1,000-cfm, 3/4hp recirculating blower provides a frontto-back horizontal universal airflow. The

oven features 8-in. thick insulated walls, an aluminized steel interior and exterior, plus inner and outer door gaskets, and accommodates up to seven shelves on 3-in. centres. Standard equipment includes a digital indicating temperature controller, manual reset excess temperature controller with separate heating element control contactors, a recirculating blower airflow safety switch and a UL Listed control panel, top-mounted to minimize floor space requirements.

el features. The modular, waterbased systems each include 6 gal. of eco-friendly Oil Eater Original cleaner/degreaser. The basic level unit includes a 440-lb-capacity working tray, flow-through brush with adjustable fluid control, adjustable goose neck spigot skimmer pads, stainless steel drain screen, 26gal. soaking capacity and a thermally protected 350-gph pump. The premium model adds a preset fluid heater, low-fluid-level protection switch and a secondary 50-micron fluid filtration. To this, the profession-

Aqueous parts washer designed for turbine blades

MecWash Systems’ BladeWash aqueous parts washers have been developed for cleaning the internal cooling channels in all types of turbine blades, as well as other parts with internal bores and complex geometries. Originally designed for turbine blades made of nickel-based super alloys, the system completely removes the casting media used in the manufacturing process so that the blades may be used in an engine assembly. The wash process features a high flow rate designed for flushing components. The components are held in a very confined wash chamber, while water is pumped through and around the components at 1,000 l/min to 1,800 l/min (265 gpm to 475 gpm). The system is built to a robust specification, yet occupies a small footprint.

MecWash Systems

www.mecwash.co.uk

al model adds a high-impact HDPE lid, pump protector drain magnet, 20-piece cleaning brush kit and 10-W moisture-resistant LED work light. Add-on options include a washable-reusable stainless steel filter, drain magnet and stainless steel

Multiple Functions

� All-purpose mat designed for general industrial applications

� Perfect for tool cribs, while adhesive rolls provide walkway protection

� Gray color masks drips and spills, encouraging longer use

Go to www.BradyCanada.ca to request a FREE Sample!

Grieve Corporation www.grievecorp.com