FLUID POWER ROUNDUP FROM IFPE 2017

SAFETY INNOVATIONS FOR MINING OPERATIONS REFRESH THE EMERGENCY RESPONSE PLAN

MRO QUIZ – TRACK FACILITY EFFECTIVENESS

FLUID POWER ROUNDUP FROM IFPE 2017

SAFETY INNOVATIONS FOR MINING OPERATIONS REFRESH THE EMERGENCY RESPONSE PLAN

MRO QUIZ – TRACK FACILITY EFFECTIVENESS

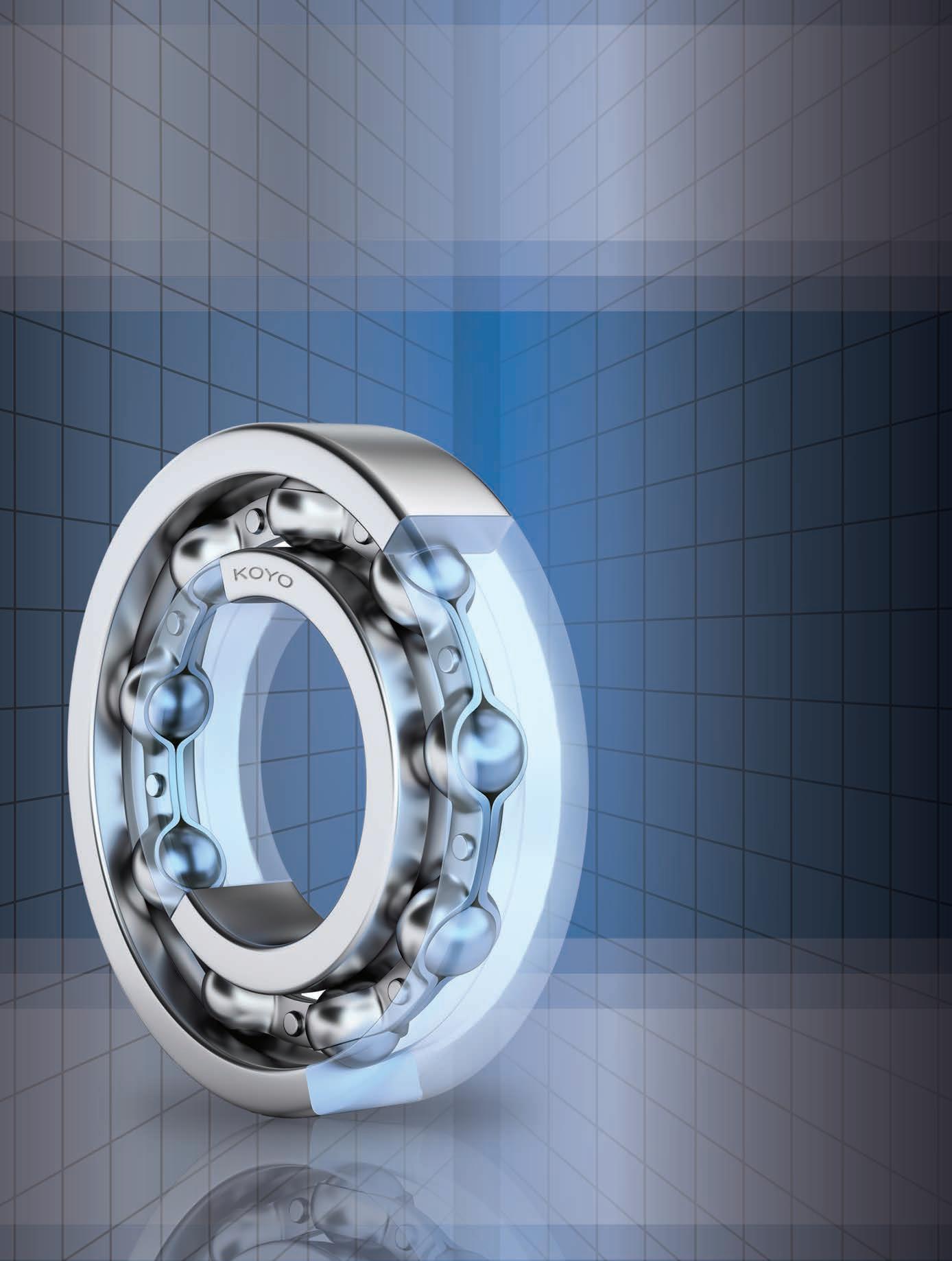

Nothing is more frustrating than shutting down a machine, even an entire production line because of a bearing failure. Baldor•Dodge® bearings represent the best quality and reliability industry has to offer. From punishing mining applications to corrosive washdown environments, and everything in between, there’s a Baldor•Dodge bearing perfectly suited for the task at hand.

Keep your machinery healthy, strong and efficiently rolling along with the widest choice of industrial bearings in the world…only from Baldor•Dodge.

baldor.com 479-646-4711

• Unmatched Quality

• Superior Reliability

• Energy Efficient

• Stock and Custom Orders

APRIL 2017

Volume 33, No. 2

Established 1985 www.mromagazine.com www.twitter.com/mromagazine

Rehana Begg, Editor 416-510-6851 rbegg@annexweb.com

Contributing Editors

David Berger, Carroll McCormick, Douglas Martin, Peter Phillips

Jim Petsis, Publisher 416-510-6842 jpetsis@mromagazine.com

Jay Armstrong, Sales Manager 416-510-6803 jarmstrong@mromagazine.com

Mark Ryan, Art Director

Tracey Hanson, Account Coordinator 416-510-6762

Beata Olechnowicz, Circulation Manager 416-442-5600 x3543 bolechnowicz@annexbizmedia.com

Tim Dimopoulos, Vice-President tdimopoulos@annexbizmedia.com

Ted Markle, COO, tmarkle@annexweb.com

Mike Fredericks, President & CEO

Machinery & Equipment MRO is published by Annex Business Media, 80 Valleybrook Dr., Toronto, ON Canada M3B 2S9; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

email: blao@annexbizmedia.com

Tel: 416.442.5600 ext 3552

Fax: 416.510.5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription rates.

Canada: 1 year $61.50, 2 years $97.95. United States: 1 year $105. Elsewhere: 1 year $120 Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbizmedia.com, 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2017 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

We acknowledge the (financial) support of the Government of Canada

Many organizational failures stem from the inherent uncertainty and dangers associated with the work environment. The resource sector, where safety is a complex issue, faces perpetual risk. Along with human hazards, it affects the assets – machinery, process and production.

Consider the recent case of a fire at the Mildred Lake oilsands upgrader. On the day of the incident (March 14), a fire broke out at the Syncrude oilsands site in northern Alberta. A press release was issued within hours of the incident, signalling that an emergency response was in progress. One employee was injured and non-essential staff and contractors were removed from the area to allow response crews to manage the situation.

Two days later, Syncrude posted an update stating that the fire had been extinguished, Syncrude Emergency Services and Operations personnel remained on the scene, and that the cause of the fire had been identified as a line failure and naphtha leak in the site’s hydrotreating area.

The work of dealing with the emergency was just beginning. The impacted area was to remain isolated to allow for damage assessment and the development of a repair strategy. Agencies such as Alberta Occupational Health and Safety and the Alberta Energy Regulator would need to conduct investigations to make sense of the event and to help prevent future incidents.

Among the questions raised are: What defects lurk in the processes, operating context and maintenance procedures? Can a plant ever be complacent in its responsibility to assess risks in its system? And, what will be the impact of the defect on operational reliability? (Syncrude posted record results last year and reported 2017 utilization guidance of 84 per cent, which includes downtime for planned maintenance.)

Failures must be exposed as early as possible to ensure the safety of employees, to allow plants to learn from intrinsic risks and to address it in cost-efficient ways. And it requires commitment.

So how can you foster a culture in which solutions are born from the rank and file?

It helps to reward problem detection. The Iron Ore Company provides a shining example for providing hope that organizational learning is possible across all levels. Their team has developed an integrated microphone for its graders so that operators can keep their hands on the controls while communicating. The solution allows grader operators to communicate with oncoming heavy mine equipment, such as their 320 haulage trucks. In the past, a grader operator would disrupt the flow of work by releasing the operating joystick in order to pick up and click a microphone. By integrating a radio button into the joystick, the crew found a way to alleviate the disruption.

The Iron Ore Company received the Rio Tinto CEO Ground Breaker Safety Award for its Thumb Activated Microphone on Graders initiative. Their innovation, emanating from employees, deserves a special nod. It addresses the risk of vehicle collision or rollover and further supports a safe and productive working environment.

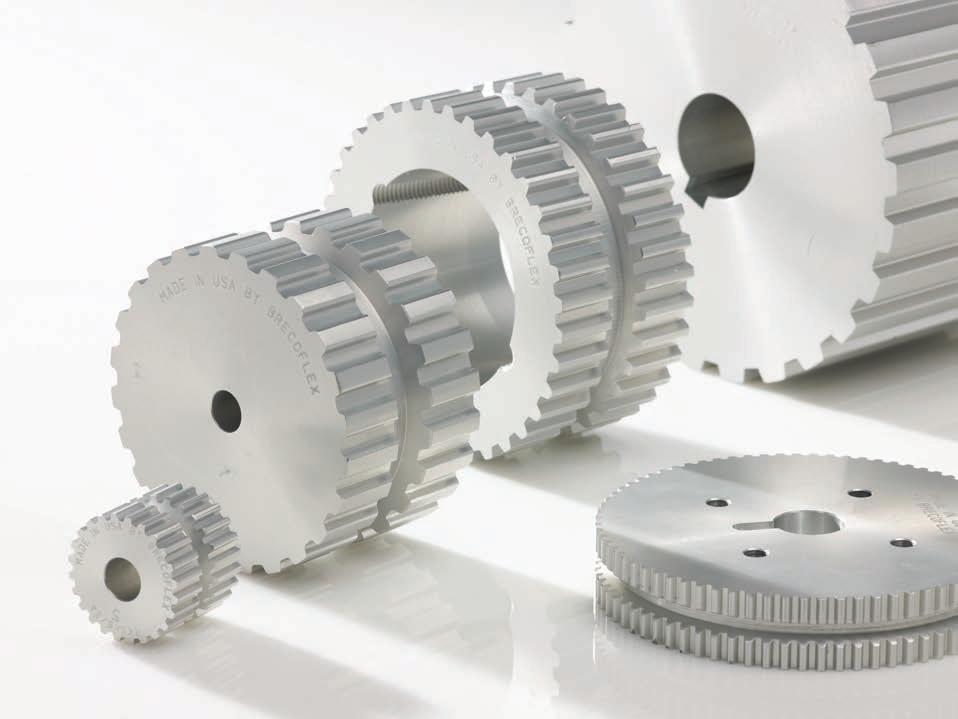

Sales and technical support responsibility for Kaydon and Cooper bearing brands are assumed by SKF Canada Limited. You can now turn to SKF for an even wider product range, supported by a larger geographical presence.

Kaydon - Thin section bearing Reali-Slim bearings produce larger ratios of diameter to radial section, which lead to space and weight savings of up to 85 percent.

goo.gl/73Adyk

Kaydon - Ultra Slim Bearing

At just 2.5 mm wide, Ultra-Slim ball bearings are available in bore sizes ranging from 35mm to 170mm. They are made of stainless steel for corrosion resistance. goo.gl/Gs4Q3Y

Cooper - Split bearing Cooper split bearings combine two crucial elements of running cost-effective machinery: flexibility and reliability.

Cooper - Split bearings Cooper split bearings combines two crucial elements of running cost-effective machinery:

goo.gl/RoXjya

Kaydon - Slewing ring bearing Kaydon slewing ring bearing solutions are ideal for heavyduty applications requiring significant load-carrying capacity and where precise positioning is critical. goo.gl/rj9QMy

A significant percentage of the bearing market is tainted with counterfeits. Use these pointers to side-step imposters.

Showstoppers / 12

A roundup of market trends, innovations and products from IFPE 2017.

Control your burrs / 20

A custom honing tool used to deburr piercing holes saves time and labour costs.

What maintenance professionals should know about tribology / 26

A friction, wear and lubrication expert shares insights into the industry’s prospects.

Safer mining / 16

Four ways innovation and technology are keeping mining operations safe.

Editor’s Notebook / 03

Newswatch / 06 Business Briefs / 09

101 / 34

Safety Quiz / 36 What’s Up Doug? / 38 Mr. O, the

/ 46

Spare Parts / 46

To the rescue / 22 The value of an emergency response plan is in the time it takes to resume operations. Fluid performance / 28

Calgary – Suncor provided a status update on the Syncrude Mildred Lake Oil Sands facility following the March 14 incident.

The incident involves an explosion and fire at the facility’s bitumen upgrader. One worker was subsequently sent to hospital in serious condition.

Preliminary investigation indicated that the cause of the incident was a loss of containment on a line near one of the naphtha hydrotreating units. Damage has largely been isolated to a piperack adjacent to the hydrotreater, containing piping, cables, and electrical circuits.

Syncrude has advanced the planned

Burlington, Ont. – Endress+Hauser, a global leader in process measurement and instrumentation, has concluded an agreement with Gerrie Electric that makes the independent electrical distributor its latest Authorized Channel Partner. The move, which leverages the strategic relationship between Rockwell Automation and Endress+Hauser Canada Ltd., is a major development in the process automation sector in Canada.

“The evolution to Industrie 4.0 and Industrial Internet of Things offers limitless opportunity for Canadian companies,” said Anthony Varga, G.M. at En-

Hannover – Deutsche Messe AG has finalized two partnerships that expand its portfolio of Hannover Messe events in North America. From September 25 - 28, 2017, Deutsche Messe will co-locate five trade fairs – Industrial Automation Canada, MDA–Motion, Drive & Automation Canada, ComVac Canada, parts2clean Canada, and CeMAT Canada – with the Canadian Manufacturing Technology Show (CMTS). From November 6-9, 2017, Deutsche Messe will stage Industrial Automation North America and MDA –Motion, Drive & Automation North America parallel to FABTECH at McCormick Place in Chicago.

“We have been very successful co-locating our Hannover Messe brands with IMTS

eight-week turnaround originally scheduled to begin in April in order to mitigate the impact of the unplanned outage. Suncor reported it planned to handle volumes of untreated Syncrude production to assist in managing inventory.

Pipeline shipments of treated product are expected to resume at up to 50 per cent capacity in April, gradually ramping up to full rates after the turnaround is completed.

For the first two months of the year, Syncrude operated reliably at utilization rates of approximately 95 per cent. Suncor has also seen strong production

dress+Hauser. “Thanks to the strength of our partnership with Rockwell Automation and Gerrie Electric’s expertise, we’ll be able to go to greater lengths to help modernize the Canadian manufacturing sector.”

Gerrie Electric can now provide its process automation customers with new cost-saving opportunities through the enhanced integration of Endress+Hauser’s measurement technology with the Rockwell Automation platform. The pretested and validated designs between Rockwell Automation and Endress+Hauser offerings help reduce the costs associated with bringing new measuring points or a new production line into the manufacturing facility.

in Chicago. Our partnership with CMTS gives us a good foothold in Canada and with FABTECH we now have a strong annual presence in the U.S.,” says Marc Siemering, senior vice president of Hannover Messe.

“Our topics broaden the appeal of these two fantastic events and will attract even more exhibitors and visitors to both.”

Organized by SME, CMTS showcases machine tools and tooling, metalworking and advanced manufacturing. The biennial event takes place in close proximity to Toronto at The International Centre in Mississauga, Ont., and hosts more than 700 exhibiting companies and 9,000 visitors. Hannover Fairs Canada, Deutsche Messe’s subsidiary in Canada, will organize the Hannover Messe events at CMTS.

For more information, visit www.industrialtechnology.ca.

A planned eight-week turnaround starts ahead of schedule to stem the impact of the incident.

from its other oil sands assets and offshore operations. As a result, the company does not expect this outage to result in a change to Suncor’s overall production guidance for 2017.

Suncor said it extends its best wishes for a speedy recovery to the Syncrude employee who was injured in the incident.

“Enabling big data analysis and the expansion of the Connected Enterprise is a boon for the Canadian manufacturing sector and is helping our customers compete on a global scale,” said Heather Gerrie, co-president & CEO at Gerrie Electric. “

For more information, visit www.gerrie.com.

Montreal – SNC-Lavalin is projecting higher profits from most of its operations and new contract wins this year despite a soft end to 2016.

The Montreal-based company anticipates that performances from all segments, aside from mining, will drive a 13 to 32 per cent improvement in adjusted earnings from its core engineering and construction operations.

Still, the $1.70 to $2 per share earnings guidance for the year missed analyst forecasts of $2.28 per share, according to Thomson Reuters.

SNC-Lavalin said it expects to benefit from higher infrastructure spending in North America, global nuclear opportunities and higher oil and gas activities in the Middle East and the U.S. However, it forecasts earnings from mining and metallurgy will remain flat because of softer commodity prices.

Its investment in Highway 407, a toll highway near Toronto, is also expected to generate higher returns, the company said.

“We expect 2017 to be another good year for SNC-Lavalin,” CEO Neil Bruce said during a conference call.

• High Performance, 100% Synthetic, Polyalphaolefin (PAO)-Based Fluids.

• Provides extended drain intervals and excellent compatibility with seals.

• Available in ISO Viscosity Grades 32, 46 and 68.

• Premium Quality, Petroleum-Based Hydraulic Oils (ISO Grades 32-100).

• Anti-wear fortified to protect hydraulic system components.

• High aniline points ensure long seal life with fewer leaks.

• NSF H1 Registered and NSF ISO 21469 Certified - Food Machinery Grade.

• High Performance, 100% Synthetic H1 Fluids.

• Available in ISO Viscosity Grades 7, 15, 22, 32, 46 and 68.

• Fortified with Lubriplate’s proprietary anti-wear additive .

• High Performance, FM Approved, Fire Resistant Hydraulic Fluid.

• NSF H1 Registered and NSF ISO 21469 Certified - Food Machinery Grade.

• ECO-Friendly, Readily Biodegradable (OECD 301F).

• Fortified with Lubriplate’s proprietary anti-wear additive .

• Heavy-Duty, High-Performance, Extended Life, Hydraulic Fluids.

• ECO-Friendly - Free of zinc or silicone compounds.

• Provides long service life and extended fluid change intervals.

• Vegetable-Based Oils for use in environmentally sensitive applications.

• ECO-Friendly - Ultimately Biodegradable (Pw1).

• Zinc-free additives provide exceptional anti-wear and anti-rust protection.

• For equipment operating in environmentally sensitive locations.

• Zinc-free and non-toxic to aquatic life.

• Exceeds U.S. EPA LC50 and US Fish and Wildlife requirements.

• Meets or exceeds the requirements of most hydraulic equipment.

• Advanced Synthetic Polyalkylene Glycol (PAG)-based hydraulic fluids.

• Designed for environmentally sensitive industrial and marine applications.

• Meets U.S. EPA Vessel General Permit (VGP) Requirements. Readily biodegradable.

• Does not leave a sheen on the water.

Newark, NJ 07105 USA / Toledo, OH 43605 USA / Tel: +973-465-5700 www.lubriplate.com / LubeXpert@lubriplate.com

Southern Alberta, Saskatchewan & Manitoba: Robin Tetrault / Summit Agencies Ltd. / 403-236-8655 / robin@summitagencies.ca

Northern Alberta and Saskatchewan: Peter Liston / Summit Agencies Ltd. / 780-406-7462 / peter@summitagencies.ca

British Columbia: Brian Weihs / Summit Agencies Ltd. / 604-329-7848 / brian@summitagencies.ca

Southeastern Ontario: Mechanical Sales Co. / 2199 Dunwin Dr. / Mississauga, ON L5L 1X2 / 800-263-7226

Southwestern Ontario: RJ (Richard) Seguin / Mechanical Sales Co. / 800-263-7226 / rjs@mesaco.com

Northern Ontario: Gord Jopling / Mechanical Sales Co. / 800-263-7226 / gordj@mesaco.com Quebec and the Maritimes: Lydia Oosterbaan / Mechanical Sales Co. / 800-263-7226 / lydiao@mesaco.com - REPRESENTATIVES IN CANADA -

Chicago, Ill. – Registration is now open for the PTDA 2017 Canadian Conference, to be held June 7-9, 2017, at the Toronto Marriott Downtown Eaton Centre Hotel in Toronto.

For the sixteenth year, key decision makers of the Canadian power transmission/motion control (PT/MC) industry will gather for business networking and education, including several new events: a CEO/Senior Executive Roundtable, a Leadership Enhancement Seminar and DM-IDEX (Distributor-Manufacturer Idea Exchange), which is a distributor-driven fast-networking event. It will give Canadian distributor companies the opportunity to schedule meetings in advance with the manufacturers they wish to see during the conference.

Two education sessions will be offered. Jim Harris, an organizational change expert, will discuss how to thrive in an era of disruptive innovation. Sean Wise, a professor of entrepreneurship, will talk about big data and how participants can leverage it to help improve operations.

“[The PTDA Canadian Conference] is a great opportunity to not only reconnect with colleagues and friends, but it also allows our company to meet with many of our supplier partners. I am pleased that the revised format of the Canadian Conference will facilitate these meetings. In particular, the DM–IDEX will be a great tool to help accomplish our goals,” said Tom Dielschneider, vice president supply chain, Motion Industries Inc.

Ajay Bajaj, president, Rotator Products Inc., added, “This year PTDA is introducing something new called DM-IDEX. As a small distributor, it’s new territory for us. It gives us an opportunity to set appointments with manufacturers and that is very exciting. This was only previously available at the PTDA Industry Summit and now it’s available to Canadian distributors at the Canadian Conference also which gives us a new and unique member advantage.”

For more information, visit www.ptda. org/CanadianConference.

The EMEA Power Transmission Distributors Association (EPTDA) announced Rome as the host city of its 2017 Annual Convention in September 2017. The association is celebrating its 20th anniversary annual convention in 2017. EPTDA is the leading industry association across Europe, the Middle East and Africa. The association represents 252 leading companies from 34 countries worldwide.

For more information, visit www.eptda.org.

Montreal – Ground Breakers is Rio Tinto’s global group-wide recognition awards programme, with winners chosen by Rio Tinto chief executive Jean-Sebastien Jacques. Awards are given to teams who are doing great work around the business in support of our five priorities – safety, people, cash, partnerships and growth.

“The team put in a lot of hard work to develop an integrated microphone for our graders so that operators can keep their hands on the controls while communicating,” said IOC President and CEO Clayton Walker. “This is an important step to making IOC a safer workplace by addressing our critical risk of vehicle collision or rollover.”

Nominated by Bold Baatar, chief executive Energy & Minerals, the IOC team includes Rodney Farrell, Shane Greening, Colin Rideout and John Spurrell and are among more than 13,000 highly motivated and talented employees within the Energy and Minerals product group.

Brampton, ON – Martinrea International Inc., carrying on business as Hydroform Solutions, pleaded guilty and has been fined $75,000 after a worker suffered serious injuries when machinery fell while being lifted with an overhead crane.

Martinrea is an automotive parts manufacturer with a facility located at 1995 Williams Parkway in Brampton, Ont.

On June 21, 2015, a worker was operating a remote-controlled overhead crane to lift and move a stamping die. The die was resting on a large rectangular bolster plate that was enclosed on its long ends by two transfer bars.

As the die was being lifted, it swung and struck one of the transfer bars, causing the bar to fall and strike the worker. The worker suffered critical injuries.

The Ministry of Labour concluded that Martinrea committed the offence of failing, as an employer, to ensure that the measures and procedures prescribed by Ontario’s Industrial Establishments Regulation (Regulation 851) were carried out in a workplace.

For the safety violation, Justice of the Peace Richard Quon fined the company $75,000 in Brampton court on March 14, 2017. MRO

Source: Ontario Ministry of Labour

Industry Newswatch is edited by Rehana Begg. Visit www.mromagazine.com for the latest news and longer versions of items here.

“This initiative was a collaborative effort based on requests from operators and the radio crew developing a solution,” says Scott Melvin, manager, Mine Mobile Operations. “Working together to achieve a common goal has resulted in a very successful outcome that will keep our employees safer and we are very proud of the team for achieving recognition for their efforts.”

Source: Rio Tinto Alcan

News and views about companies, people, product lines and more.

• Ottawa – Canadian manufacturing sales in January were better than expected, the latest in a series of promising reports for the economy. Statistics Canada reports that manufacturing sales climbed 0.6 per cent to $53.8 billion, the third consecutive month of growth, helped by the petroleum and coal industry and the chemical industry. Economists had expected a decline of 0.2 per cent for January, according to Thomson Reuters. Statistics Canada said that manufacturing sales were up in 14 of 21 industries, representing 75.4 per cent of the manufacturing sector.

• Washington – U.S. factories cranked out more autos, steel and computers in February, the sixth straight monthly increase in manufacturing output. Factory production rose a seasonally adjusted 0.5 per cent last month from January, the Federal Reserve said. That followed another 0.5 per cent gain the previous month. Factories are benefiting from greater consumer and business optimism since last fall’s presidential election. Companies are spending more on big-ticket items such as industrial machinery, and Americans are buying cars at near-record levels. Overseas growth has spurred more exports.

• Calgary – A major oil pipeline spill last year in Saskatchewan cost $107 million to clean up, a $17-million increase from a September estimate of $90 million, according to pipeline operator Husky Energy of Calgary. The pipeline rupture last July allowed 225,000 litres of heavy oil mixed with diluent to spill onto the bank of the North Saskatchewan River, with about 40 per cent or 90,000 litres reaching the river.

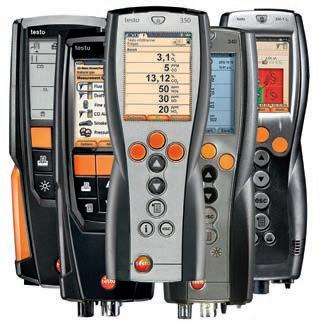

AGG and IFPE 2017 (March 7-11, 2017) got underway with a demonstration of the world’s first 3D-printed excavator, known as Project AME (Additive Manufactured Excavator). The show brings together fluid power, power transmission and motion control industries. One of the major draws of the show this year was the emphasis on technology

• Cleveland – Parker Hannifin Corporation, the global leader in motion and control technologies, is celebrating the 100th anniversary of its founding on March 13, 1917 and has launched a centennial website at www.parker.com/ centennial. The Parker Appliance Company, a manufacturer of pneumatic brake systems and leak-free fittings, was founded by visionary engineer Arthur L. Parker and developed in the early years with his business partner Carl Klamm in a small loft in Cleveland, Ohio.

• Cleveland – Parker Hannifin Corporation completed its acquisition of Clarcor Inc., a major manufacturer of filtration products, for approximately $4.3 billion in cash, including the assumption of net debt. The strategic transaction creates a combined organization with a comprehensive portfolio of filtration products and technologies.

• Ottawa – Canada’s Minister of Natural Resources, the Honourable Jim Carr, has announced the Government of Canada’s decision to approve NOVA Gas Transmission Ltd.’s (NGTL) Towerbirch Expansion Project subject to 24 binding conditions. The $439-million project will involve the construction of two new pipeline sections totalling approximately 87 kilometres along with associated facilities in northwest Alberta and northeast British Columbia.

• Las Vegas, Nevada – CONEXPO-CON/

• Sept-Îles, QC – Metal 7 Inc. has acquired Enduride (Enduride Canada-USA Inc. and Technologies Enduride Inc.), a specialized manufacturer of a wide range of rollers and idlers for power-driven or gravity conveyors located in Québec City. Enduride designs and manufactures a specialized range of conveyor rollers and idlers for the primary industry. Metal 7 specializes in the design and manufacture of high performance equipment for the iron ore and aluminum industries.

• Monroe WA –Brokk Inc., a manufacturer of remote-controlled demolition machines, recently acquired Aquajet Systems AB, a manufacturer of hydrodemolition robots. The acquisition expands the application solutions offered by Brokk in the construction and demolition industry.

Ten industry tips on how to avoid counterfeit bearings.

BY CARROLL MCCORMICK

Aquick internet search will yield plenty of hits about seizures of thousands and millions of counterfeit bearings.

“We’ve estimated in the past that 10 to 15 per cent of the global bearing market is counterfeit bearings. In Canada and the U.S. it is probably two to five per cent of the market,” says Antun Peakovic, Director of IP for The Americas, Schaeffler.

Flaws in counterfeit bearings include the wrong lubricant and missing lubricant ports, the wrong metals and incomplete hardening, contamination with iron filings, incorrect running tolerances and the wrong rolling element size. But because counterfeiters can be very good at their job, non-experts who think they can spot fakes have fools for lawyers, so to speak, and is setting themselves up for catastrophic equipment failures.

To take some of the fool out of fakes, here are 10 tips distilled from interviews with three (genuine) bearing manufacturers.

Tip 1: Buy only from authorized distributors: More than any other piece of advice, bearing manufacturers say to buy bearings only from their authorized distributors. If someone claiming to be an authorized dealer contacts you, take a moment to do a cross check: Go to the bearing manufacturer’s website and see if that authorized dealer is listed there. “But who does that,” laments Clayton Tharp, Brand Protection Manager, SKF Group Brand Protection.

“Fake bearings are not coming through authorized distribution channels. It is almost impossible to happen. The best place to look for an authorized channel is the manufacturer’s website. They list all their authorized distributors. If a distributor is not on the list, call the manufacturer and ask,” says Paul Meo, President and CEO of NTN Bearing Corp. of Canada Ltd.

As for so-called trusted sources, Peakovic comments, “The easiest advice is to go to a trusted source. We say trusted source, because a facility might have a trusted source they have gone to for years, but which may not be an authorized distributor. “Authorized distributors are the trusted source from the manufacturer’s standpoint, as they buy directly from us. You know the product is genuine and the related warranty is available. Otherwise, the warranty (or lack thereof) lies with the seller of the parts. [But] if your trusted source is from China or India, there is a decent chance there is a mix of counterfeit and genuine parts,” Peakovic says.

Tharp adds, “Half my work is going to companies and telling them to buy from our trusted sources.”

Tip 2: Believe it: fake bearings are everywhere. “Most customers are not aware that someone would counterfeit something like a bearing. They think usually of watches, handbags … They don’t realize how big it is and how much of the market in the world has counterfeit bearings,” Tharp says.

“Every type of bearing has been counterfeited, from minute needle bearings to two-foot diameter bearings,” Peakovic adds.

Don’t bother looking for a catalogue of what to look for in a fake bearing or package. Why? “We don’t want to train counterfeiters on how to improve their products. We did once issue a guide to key marking errors, and within two months we saw the same guide in a counterfeiters marketing product,” Peakovic says.

Tip 3: Beware emails bearing gifts. “I get questionable emails every day from people offering to sell me bearings from outside of the Americas,” Meo says. The likelihood that any of these emails are from legitimate distributors appears to be slim. As a first cut, Meo suggests, “If you get an email that is not from your trading region, ignore it.” If it is from

Lower Bombaria, say, be wary. But if it is from North America, it is more likely to be a legitimate channel.

Be sure your company is aware that counterfeiters use emails to suck people in. Peakovic advises, “Make sure you have guidelines in place for their purchase; for example, don’t buy from random email solicitors, and [ensure] that certificates of origin are reliable.”

Tip 4: The Internet is not your friend. While the Internet can quickly take you to bearing manufacturers’ websites and their list of authorized distributors, it can just as easily lead you to counterfeiters’ websites and a burn. “Counterfeit manufactures selling on the [Internet] regularly attempt to represent themselves as an authorized seller of the product,” Meo says.

“If you start looking around the web, and google SKF, you will get tens of thousands of hits of places to buy SKF,” Tharp says. Instead of randomly thrashing around on the internet, Tharp has this counsel: “You should have gone to <skf.com> if you are looking for a site to buy from. Go to the left side: “find a distributor,” for a list of authorized distributors. If people would buy from an authorized distributor, this is the way to avoid counterfeit bearings.”

Tip 5: Counterfeits will fool you. “People think that counterfeit products look shabby, that the box will be messed up and the bearing will look bad. But we always tell people that an untrained person cannot tell the difference between a genuine and a counterfeit bearing. I always warn people not to try and tell the difference. A guy with 30 years of experience – ‘I’ve been handling SKF all my life’ – they would not be able to tell the difference,” Tharp says.

A counterfeit brand, logo or bearing may not look right, but assume that they will be good enough to fool you. “Part of this issue is not just reproducing the bearings themselves, but [counterfeiters] getting more sophisticated

about [reproducing] a manufacturer’s packaging,” says Marcus Wickert, Director of Engineering, NTN Bearing Corp. of Canada Ltd.

Tip 6: Beware of hot deals and regular deals. A standard piece of advice trotted out as a sure-fire telltale is that if the price is too good to be true, it is likely to be a fake. But counterfeiters, crooked they may be, are not slow learners. “Counterfeiters figured out that if they sell bearings really cheap, people will wonder. So, they will sell bearings at near-regular prices to eliminate suspicion – a bit cheaper, but in the same price range,” Tharp counsels.

Tip 7: Certificates of authenticity aren’t worth the match to burn them. What could be more heartwarming than a lovely, official certificate wrapped around your new bearing? How about a genuine bearing. About certificates, Tharp says, “In some markets, Asian, for example, certificates are perceived as a measure of safety, a comfort sign. In their market a certificate is not necessarily a warning sign. In North America, it is a warning sign.

“Of course, paper documents like that are the easiest to forge. Part of our verification is we tell our customers to send us their verification certificates. I received two this week. One from Guatemala, one from Vietnam. You won’t find a certificate in a genuine SKF box.”

Tip 8: When in doubt, ask the manufacturer. Manufacturers are making more sophisticated packaging, with special markings, like currency, and even holograms. “Another initiative that NTN is taking, is that we are introducing hologram technology on our boxes that cannot be easily reproduced by counterfeiters. NTN is on the verge of launching technology where a distributor or end user can validate whether it is a fake bearing,” Meo says.

SKF has a smart phone app, called SKF Authenticate, that makes it easy

for buyers to get an expert assessment of their bearing purchase. Launch the app, shoot photos of the sales slip, box and bearing, supply some supporting information about you, and hit send. SKF will almost always reply within 24 hours, Tharp says. “We do thousands of verifications a year.”

Be sure to screw on your photographer’s hat, though: Shots must be in focus, and don’t be stingy. “The more pictures the better. If you can take pictures of all six sides of the box, good. Take overview picture of the bearing, and close ups of any markings,” Tharp stresses.

Peakovic says, “On our own bearings we have a data matrix code, an individual code for each bearing.” On the Schaeffler website is a downloadable app, called Precision Desk, which, according to Schaeffler, “… enables users to verify the authenticity of rolling bearings marked with a data matrix code. A check is made by simply scanning the data matrix code on the bearing or on the bearing packaging.”

Tip 9: Get personal with your distributors and manufacturers. “In our industry, there has been a departure of tacit knowledge at the end user with the

boomer retirement, [people] who have been interacting with manufacturers and authorized distributors – the old guy who has been dealing with a distributor for 30 years. The risk to buying from a questionable source increases exponentially, as Gen-X and millenniums today prefer Internet-based research to support their immediate needs, relying less on the knowledge and service relationship between manufacturer and distributor and end user,” Meo says.

Tip 10: Beware aftermarket assemblies. Complete aftermarket assembly components may be at risk. If they are knockoffs, they may have been built using counterfeit bearings or other assembly components. The risk is high enough that Wickert even made reference to a company that, when it buys gearboxes, they replace all the bearings because they are sure of their origin and make.

“[Genuine] aftermarket assemblies will come through authorized channels. If you stray outside these channels [you are at risk],” Meo says. MRO

Montreal-based Carroll McCormick is the award-winning senior contributing editor for Machinery and Equipment MRO.

Fluid power innovations at IFPE 2017 confirmed that keeping pace with technology is critical for the industry’s success.

BY REHANA BEGG

When the barrage of press materials hailing from fluid power component and system companies gearing up for IFPE 2017 flowed into our inboxes as early as November 2016, we knew this year’s show would be another blockbuster.

The International Fluid Power Exposition, co-located with CONEXPO-CON/AGG 2017, runs every three years and is a haven for power transmission and motion control enthusiasts.

This year’s show didn’t disappoint. Gradall Industries president and 2017 Association of Equipment Manufacturers (AEM) chair, Michael Haberman, described the general sentiment to be one where exhibitors were writing sales and attendees were ready to buy. “I think there is a noticeable difference in the attendees at this show, and the difference is their optimism,” said Haberman.

Dave Foster, vice president for Marketing & Corporate Communications at Volvo CE, agreed with Haberman: “These are not tire-kickers. These are people who are willing to buy multiple machines for work they have now and anticipated growth based on a renewed confidence in the market.”

More than 128,000 attendees descended upon Las Vegas, Nevada for the week of March 7 – 11, 2017. Attendees from 150 countries saw more than 2,800 exhibitors that took up the show’s record 2.8 million-plus net square feet of exhibit space. Exhibitors from leading U.S. and global manufacturers cemented the international scope of the show.

Attendees purchased a record-breaking 52,000 tickets for 143 education sessions, grouped into 10 tracks, including a new

Technology track. The show featured a comprehensive educational program, which included the industry-wide Energy Efficient Hydraulics and Pneumatics Conference and handson courses on effective use of hydraulics in mobile equipment. On the show floor, IFPE 2017 hosted the Power Transmission Distributors Association (PTDA) exhibit pavilion, while CONEXPO-CON/AGG 2017 showcased the Lift Safety Zone from the National Commission for Certification of Crane Operators and International Powered Access Federation.

The Association of Equipment Manufacturers (AEM), which owns and manages the show, commissioned IHS Markit to quantify the economics of the North American off-highway equipment and ancillary products industry (including product accessories, tooling and other supporting components) to the economies of the United States and Canada. Key findings of the report, “The Market Size and Economic Contributions of the Off-Highway Equipment Industry,” were delivered at a press conference by AEM president Dennis Slater. Joining Slater on a panel was Scott Hazelton, managing director, IHS, and AEM chair Michael Haberman, president, Gradall Indus-

tries Inc., New Philadelphia, Ohio.

The report highlights the fact that the off-highway equipment and ancillary products industry generated US$158.8 billion in economic value, which represented 0.9 per cent of 2016 total nominal GDP in the United States.

The report states that the Canadian equipment manufacturing industry supports 149,000 jobs and that in total, “nearly US$34 billion in sales activity is generated directly or supported by the industry, which adds nearly $15 billion to Canada’s GDP.”

Many OEMs and distributors are forecasting growth in infrastructure spending, bulk materials handling and construction, according to one exhibitor, Wisconsin-based Regal Beloit director of Marketing, Bearings, Ian Rubin.

“So far this year we’ve seen a good order rate. As more people start moving rock and stone in the quarries, we expect to see more orders for our components. Everybody is trying to get as much uptime as possible.”

Regal Beloit’s growth is also partially attributable to the company’s integration of brands such as Browning, Jaure, Kop-Flex, Rollway, SealMaster, McGill and System Plast into the Regal Beloit family after the acquisition from Emerson Electric Co in 2015. “We can now offer a broader range of products,” said Rubin. “We are now one-stop shopping. It helps us be able to solve problems. Instead of being one-size fits all, we can better customize to the user’s needs.”

MRO-PickupDelivery-MannuInbox.pdf 1 22/03/2017 10:55:49 AM

Ian Rubin, director of Marketing, Bearings, Regal Beloit, says orders are on track for 2017.

A major draw of this year’s trade show was the emphasis on technology and the future visions for infrastructure and construction. The demonstration of the world’s first 3D-printed excavator, known as Project AME (Additive Manufactured Excavator), was also in keeping with the show’s theme, “Imagine What’s Next.” The excavator was part of a larger tech exhibit (Tech Experience), which was housed in 75,000-square feet of interactive experience showcases and explored future innovations that shape manufacturing, including forward-looking jobsites, infrastructure development and workforce development. Here, attendees learned how to extract the benefits of autonomous machines and augmented reality in order to achieve precision in operations, cost certainty, specialization and productivity.

Many companies showcased new and innovative products, as well as best practices for the integration of fluid power with other technologies for power transmission and motion control applications. Following is a look at some of the products that were showcased at IFPE 2017.

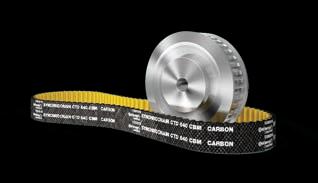

Among Schaeffler’s booth offerings were its X-life products an an innovative PWG differential roller screw, and an array of hydraulic components, including Schaeffler’s needle and cradle bearings, tripod rollers, piston rings, Triondur tribological coating systems, as well as its FAG SmartCheck, a breakthrough plugand-play condition-monitoring device. The modular online measuring system is touted for its timeous ability to detect rolling bearing damage, imbalances and misalignments on electric and geared motors, gearboxes, compressors, pumps, spindles and machine tools.

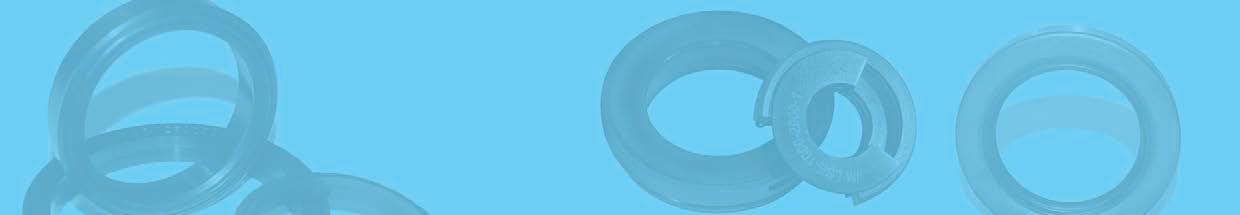

Regal Beloit Corporation has launched the Time Saving Axial Groove in Bore feature to the SealMaster Large Bore Performance Gold Line Mounted Ball Bearing. The new feature is available in both a medium 2 7/16” and up and standard 2 11/16” and up shaft sizes, and the Time Saving axial groove in the inner ring bore allows for easier bearing removal. This design provides clearance from the burr created by the setscrew used to lock the bearing to the shaft, which makes removal difficult and can cause damage to the shaft during removal. This feature has no impact to ball path roundness, load and speed rating, strength or bearing performance.

art robotics, precision vision systems and automated leak and end-of-line testing. The P1M product family includes seven standard displacement (cc) options: 28, 45, 54, 65, 75, 90 and 105, and features 280 bar continuous pressure rating for 28 through 75 and 310 continuous bar pressure for 90 and 105.

A new generation of low-friction transmission seals designed to save fuel, lower emissions and extend the operating life of industrial powertrains was the order of the day at the Freudenberg Sealing Technologies booth. On display was Freudenberg’s Levitas and Levitorq components, which are part of a Low Emission Sealing Solutions (LESS) product portfolio. The company reports that seals are responsible for “nearly one quarter of all lost mechanical energy in today’s automatic transmissions.” Levitas seals and Levitorq thrust washers both rely on hydrodynamic oil film technology to reduce transmission friction by as much as 70 per cent over conventional components, depending on application conditions.

Parker Hannifin Corp. featured its C Series Variable Displacement Piston Pumps, which are designed for use in closed-circuit hydrostatic applications. Featuring a rugged swash plate and bearing design, the pump offers a full range of controls, such as a manual le ver with feedback, hydraulic proportional and electric proportional. The pumps are available with a variety of accessories, including hydraulic pressure override, electric cut-off valve and cross-port relief valves to protect from pressure overloads. C Series hydrostatic pumps are rated to 420 bar (6090 psi) continuous pressure and 3800 input rpm.

Another notable is Parker Hannifin’s open-circuit piston pump for the mobile market. The P1M product family was developed specifically with the mobile equipment manufacturer in mind. The motion control technolo gies company reports that power densi ty, space claim and versatility were all taken into consideration in this product’s design. The P1M family of products will be assembled on a “no fault forward assembly and testing process” that includes state-of-the-

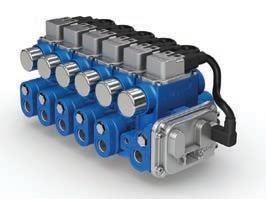

The main demonstration at the Eaton booth was the application of augmented reality technology in hydraulic equipment. “Instead of manually checking equipment or sorting through data, we believe the future of hydraulic monitoring will include a combination of telematics and advanced visualization technologies like augmented reality, which will help simplify condition monitoring and identifying service needs,” said Paul Brenner, global marketing manager, Eaton’s Hydraulics Group. Demonstrating this reality, Eaton featured its CMA Advanced Mobile Valve in 3-D via a Microsoft HoloLens experience. Viewers were given an overview of the valve’s mobile control capabilities, including Independent Metering, on-board electronics and more immediate communication.

Remote-controlled demolition robots manufacturer Brokk introduced the Brokk 500, which features 40 per cent more demolition power than its predecessor, the Brokk 400. A key part of the machine’s enhanced performance is the Brokk SmartPower electrical system, a more powerful breaker, extended reach and industry-leading serviceability. The machine delivers 1,086 footpounds (1,472 joules) with each blow of the 1,510-pound (685-kilogram) Atlas Copco SB 702 hydraulic breaker. The Brokk 500 will be available beginning May 2017.

Rehana Begg is the editor of Machinery and Equipmnet MRO. Reach her at rbegg@annexweb.com. The next

Vegas.

Innovative companies are helping to make mining safer.

BY CARROLL MCCORMICK

Canadian companies are helping make mining safer. Here are four ways they are contributing to the cause:

Deep in Glencore’s Kidd Mine in Timmins, Ont., 160 vehicles operate with proximity warning devices that let each other know they are there. Called MineProx, these devices, installed last year and developed by Montreal-based Newtrax Technologies Inc., are designed to reduce collisions and near-misses. The company offers safety and operations management systems for underground hard rock mines.

Newtrax divided the vehicles into two groups: big ones, called predators, and smaller ones, called victims. “Predators are usually large vehicles (scoops or hauling trucks) that have lower visibility due to large blind spots while operating,” says Cynthia Younes, Marketing Manager, Newtrax.

Each vehicle is equipped with a MineProx Proximity Warning System Vehicle Transceiver. In addition, Newtrax installed an ultra-rugged user interface (URUI) in the operator cab of each predator. The URUI lets operators be aware of other vehicles and miners in its proximity.

With MineProx, the predators detect victims, making their operators aware that victims are nearby. MineProx also lets small and large trucks signal for right of way. “Say you [are in a victim vehicle and] are going up a ramp and you see that a big vehicle is coming. You can communicate with the large vehicle, so the large vehicle would know and get out of the way,” Younes says.

To better protect miners, Glencore purchased 735 special headlamps that are visible to the predator vehicles through the URUI. If a miner feels he is at risk near one of these vehicles, he can trigger an emergency alarm on his cap lamp. “Once the alarm button is pressed, the operator in predator vehicles in range

will see an emergency stop request on their URUI. The screen beeps loudly and flashes very visibly. Most accidents happen because vehicle drivers can’t see miners in their blind spots,” Younes says.

The lamp does more, Younes adds. “It is used as a personal safety device. It notifies miners if there is an evacuation. The light also enables the manager on the surface to detect if a miner is knocked down or unconscious – 30 seconds without moving.”

The traditional approach to mine ventilation has been to install a ventilation system, based on mine modelling, by pumping in fresh air and hoping for the best. The shortcomings of this method include over-ventilating some areas while under-ventilating others, inadequate air monitoring, and additional fresh air not being directed to blast zones, where fumes reach particularly high concentrations.

In the latter case, according to the

United States Department of Labour Mine Safety and Health Administration, between 1978 and 2003, 8.5 per cent of 1,131 blast-related injuries were caused by blast fumes.

“The detonation of explosives generates potentially harmful gases such as carbon dioxide, carbon monoxide, oxides of nitrogen, ammonia and sulfur dioxide. Blasting also reduces the oxygen concentration in the air. Breathing contaminated air after a blast may kill a miner in a few minutes. Carbon monoxide levels can approach 500-800 parts per million. The current Ontario guideline for carbon monoxide gas is 25 parts per million,” says Michael Gribbons, Vice-President, Sales and Marketing, with Sudbury, Ontario-based Maestro Mine Ventilation.

Maestro has developed a suite of solutions to solve ventilation problems. They range from air quality stations, airflow meters, mine airflow regulators and fan monitors, to ventilation control systems that balance out an entire mine’s venti-

A Hard-Line remote operator station keeps the miner out of the mine. (Hard-Line)

lation system – delivering more fresh air to where it is needed, and less to where it is not.

While ventilation control systems, such as the one Maestro installed in 2016 in in Glencore’s Kidd Mine in Timmins, Ont., are hailed most loudly for their huge energy savings, they also have a big safety component. They can dilute atmospheric contaminants to acceptable levels, maintain temperature and humidity within acceptable limits, and monitor for fires and gas concentrations. Automated underground ventilation systems only started showing up in Canadian mines in 2012, according to Gribbons. “Most mines in Canada are just starting the process. They will typically start with the measurement portion before taking the next steps.”

Remote machine operating

Operating at a distance from operating equipment and dangerous conditions is what Alliston, Ontario-based Provix Inc. makes possible with its wired and wire -

less video camera systems, and remote control platforms it designs and manufactures.

They work for any type of surface or underground equipment. In 2013, for example, Provix deployed a remote video multi camera system at Rio Tinto’s Diavik diamond mine in the Northwest Territories for a bolter. Later, Rio Tinto installed Provix camera systems on its entire fleet of remotely operated jumbos, bolters and simbas at Diavik.

“While Provix remote mucking control and video systems have been a mainstay for many years, it is only recently that more attention has been focused on remote drilling and bolting. With stricter regulations around working at the face becoming prevalent in many jurisdictions, the ability to provide close-up viewing and operation from 75plus metres away has become a requirement,” says Karly Winfield, Technical Sales Consultant, Provix.

“Remote bolting itself is still in its infancy in Canada. Many operations have not yet started remote bolting and are still manually operating the bolters/ jumbos at site,” Winfield adds.

While some Provix installations, such as at Goldcorp’s Red Lake, Ont. mine, allow bolting to be done at a distance, their cameras, called PTZ cameras, so-named for their pan, tilt and zoom functions, are also used to help miners working right on the equipment see better.

This is the case at Vale Canada’s Creighton nickel mine in Sudbury. “At Vale’s Creighton mine … two jumbos have now been equipped with Provix dual PTZ cameras ...,” Winfield explains. Remote control viewing stations had been previously set up in sea-cans, but they were not always easy to move. Provix recently developed a fully portable remote control viewing station that fits

in the back of a utility task vehicle; Goldcorp has recently implemented the latter set-up at Red Lake. “This extra-large pelican case houses all of the controls and monitoring equipment to allow the operator to easily deploy the equipment...,” Winfield says.

Provix cameras also let operators see, from a safe distance, what is going on in places such as loading chutes and pockets, conveyors, grizzlies, crushers and rock breakers. “At a loading chute, for instance, the operator is able to view the fill level in the dump box without having to exit the vehicle,” Winfield says.

The Holy Grail of making mining safer is surely the ability for operators to work from outside the mine. Established in 1996, Dowling, Ontario-based HLS Hard-Line Solutions Inc., a technology developer and manufacturer of remote control and automation systems, offers such a solution with its Teleop Control System.

Working from an operator station and communicating through a network backbone, an operator can run heavy equipment from anywhere. “Teleop allows the operation of heavy machinery from a distant and safe location, and does not require operator line of sight. Teleop can be used on any type, make, model, or year of machine. Teleop allows for continued operation during shift changes and after blast cycles, saving hours of lost operation time every day,” says Avryl Evans, Manager of Sales & Marketing, Hard-Line.

Hard-Line offers several versions of its solution: Teleop is a one-to-one system for manually operating a single machine. Teleop Auto, officially launched last September at MINExpo in Las Vegas, enables auto speed, steering and

braking. “We demonstrated the technology by operating Teleop Auto live from the trade show floor. Our Teleop Operator Station was located in the booth and communicated with our LHD located in our test drift at the NORCAT Underground Training Centre in Levack, Ont., through a Wi-Fi network,” Evans says.

An operator using Teleop Multi can run several machines, even at opposite ends of the mine, albeit one at a time.

The most sophisticated version is Teleop Auto X. An upgrade in the process of being released, it allows an operator to run several machines simultaneously, and with auto speed, steering and braking.

“Teleop Auto is currently being implemented at several Goldcorp mine sites, with one already using Teleop Multi. Teleop AutoX will also be implemented,” Evans says. “The operator can select from a pool of multiple machines from each operator’s station, give the machine the command to autonomously drive and simultaneously switch to another machine and operate it while the first machine is driving.”

Kent Cook, who works at Goldcorp’s Red Lake Mine, says, “Tele-operations provide us with the ability to continue operations without the risk of exposure to environmental hazards associated with underground mining activities. One routine example: Once a blast is initiated, the subsequent gases and ground seismicity typically make it hazardous to re-enter for a period of time. Tele-operations allows us to re-enter these zones almost instantly after the blast is initiated, eliminating any risk to personnel.”

MRO

Montreal-based Carroll McCormick is the award-winning senior contributing editor for Machinery and Equipment MRO

An operation uses a custom honing tool to deburr piercing holes in house, instead of sending parts out.

For metal stamping operations, the very nature of the shearing process used to create intricate, tight tolerance piercings inevitably creates burrs requiring a secondary finishing step to remove them. This is particularly true for parts with wall thicknesses in excess of 0.005 inches, which often results in heavier burrs.

As a result, stamping operations must decide how to most efficiently remove the burrs.

For many, this means manually deburring each part in house. However, finishing, smoothing, and removing burrs by hand not only significantly increases the manufacturing time but is also prohibitive in terms of labour and employee ergonomics. For large production runs, this option is even less viable.

Another alternative is to send parts out for a secondary finishing step, such as thermal deburring or tumbling. While these techniques effectively remove excess material, this increases the time to ship and return the parts as well as the added cost. Both techniques are also known to mar the surface of the part.

However, the production of hundreds of thousands of stamped parts with tight tolerances and intricate piercings –of as low as 0.078 on one recent job – still creates challenges when it comes to deburring.

For Jesse Parke of Precision Stamping Co. of Howell, Michigan, a company that specializes in deep drawn parts, this left him with only one alternative: finding a more efficient and inexpensive method to complete the deburring work in house.

Founded in 1946, Precision Stamping specializes in deepdrawn metal parts for automotive, industrial and military parts providers worldwide. The company primarily produces products such as oil-cooler lines and quick disconnects for the automotive industry.

According to Parke, a third-generation stamping engineer, Precision Stamping can pierce holes in sheet metal blanks and formed shells using complex machinery and setups that are “flirting on the edge of what’s possible and what’s wishful thinking.”

Parke points to one particular recent part, a spring cup that required a unique solution. Like many deep drawn parts, the part was flared at the top with a narrower diameter for the body. The part specification included piercing a hole in each of the “stepped” sections, leaving a heavy burr.

To resolve the problem, Precision Stamping initially opted to send the parts for thermal deburring, a process that removes the excess material by vapourizing and burning it off. However, this step takes additional time, vendor expense, shipping expense, and often required cleaning off black carbon residue once the parts were returned to the shop.

Eager to discover a more efficient alternative, Parke began to explore and research options to keep the parts in house. Although he was initially unable to find a viable option, in 2015 at a trade show, a colleague recommended the Flex-Hone from Los Angeles-based Brush Research Manufacturing.

The self-centering, self-aligning, and self-compensating Flex-Hone features abrasive globules attached to flexible filaments along a central shaft and can be used in any rotating spindle.

Commonly known throughout industry as the ball hone, the Flex-Hone is used prominently in CNC machining operations for deburring and surface finishing of metal parts with cylindrical bores or through-holes. Although it is often used with automated equipment, the abrasive tool can also be used with a drill.

The product is sold through a worldwide network of distributors and is available in a broad range of sizes, abrasives and grits. However, for this particular application, none of the standard options would work for the spring cup, due to its two-stepped design.

Parke decided to contact Brush Research and explain to the company’s engineering solutions department that this job required a “stepped” hone that would work with the specific dimensions of the part.

“With the part being stepped, I was not sure if we would need a custom brush or what the ideal choice would be,” says Parke.

As the inventor and manufacturer of the Flex-Hone, the company has the knowledge and capability to create custom hones to meet the needs of unique applications. This can include custom sizes – from extremely large diameter to miniature – as well as unique configurations, such as tapered or stepped.

According the Parke, the company responded quickly with a tool that met their needs.

Now, after the parts are stamped and cleaned, they are transferred to a nest for piercing. When that is completed, they are moved to another nest, where a stepped Flex-Hone is inserted and rotated using an automated pneumatic drill. The same oper ation is repeated in the opposite direction to ensure maximum deburring as well as maximize brush life. The part then drops through an escapement in the machine as finished goods.

Since Precision Stamping started using the custom FlexHone, Parke said they have ex perienced a steady increase in production output. In one sixhour period, operators were able to run 8,000 pieces and not one needed additional deburring.

“The Flex-Hone is definitely helping us keep costs down by not having to send parts out for thermal deburring,” he said. “If you don’t have to do that, you’ve saved all the part-handling time and saved all that money.”

Parke said that all told, the improvements have been sig nificant. “Now we can deburr in house and they look ten times better than what we were get ting before after the thermal de burring.”

Since the jobs that make it to Precision Stamping are the more complex, technical ones, with the simpler open-tolerance jobs going overseas, Parke said he ex pects to use custom Flex-Hones for future customer jobs as well. “I see that only increasing as we match the correct Flex-Hones with the correct tooling.” MRO

PRUFTECHNIK is a leading single-source solution provider for machine laser alignment, condition monitoring and nondestructive testing.

PRUFTECHNIK’s technical innovations optimize the availability of your production assets—and stop small amounts weighing heavily on your bottom line.

www.pruftechnik.com/ca

This article was submitted by Brush Research Manufacturing. For more information, contact info@brushre search.com or visit www.brushre search.com.

A supplier of MRO safety solutions has proof that an emergency response plan can speed up resumption of normal operations.

BY REHANA BEGG

As the new wildfire season began on March 1, Fort McMurray residents were still reeling about the wildfire that razed the northern Alberta community last year. After sweeping through the city, the wildfire – dubbed “the beast” –would destroy about 2,400 homes and buildings and force the evacuation of its 80,000 citizens. The estimated recovery damage was above $4.5 billion, making the disaster the most expensive in Canadian history.

Extended fire seasons, along with other factors conducive to extreme weather events, can easily become catastrophic by placing the lives of people, their homes and their livelihoods at risk. The Fort McMurray disaster set back oilsands production output by 1.2 million barrels per day for two weeks, resulting in losses of more than $985 million, according to the Insurance Bureau of Canada and Catastrophe Indices and Quantification Inc. Other businesses in the vicinity experienced an estimated net revenue loss of $54.7 million. The amount of lost labour income during the evacuation was estimated at $458.4 million, and physical infrastructure losses was estimated at $4.54 billion.

While the human and environmental cost remains difficult to monetize, we can be grateful for the timeliness, skill and tireless commitment of first

responders. Their ability to take action, along with the community’s assistance, underscores the importance of being prepared when plants are flung into unfamiliar terrain.

Emergencies cannot always be anticipated but they can and should be planned for. A plant’s emergency response plan can help stabilize a company’s operations during a turbulent period.

Anticipating the response measures that need to be taken once emergency evacuation orders are given is a unique experience that Acklands-Grainger’s Fort McMurray, Alta. employees could never truly have been prepared for. Employees who were ordered to go home and evacuate the city describe the drive out of the city as “apocalyptic.”

How well plants or facilities respond to an emergency situation of this magnitude comes down to how well defined their emergency response plan is, says Jeremy Slater, regional sales manager, Acklands-Grainger.

“During the wildfire 80,000 residents were evacuated,” says Slater. It meant the displacement of 82 Acklands-Grainger team members, so the priority was to look after them and make sure they were safe. Once the evacuation order was issued, “you had to leave with just

your clothes on your back,” says Slater. ”Within 24 hours of the evacuation we had confirmed that all of our team members were safe and accounted for and began providing critical information, resources and support.”

Less than a week after the evacuation order, a team of designated employees was called back to the Fort McMurray branch to help get first responders the supplies that were needed to save the town. “Acklands-Grainger is the largest supplier in the country of MRO safety solutions and first responders would require a lot of what we have when there’s a fire… It’s what we’re good at.”

The industrial distributor’s emergency preparedness effort centered around three guiding principles, namely, team, community and customers, says Slater, as he recalls how his teammates stepped in to help. “It was our team first because you can’t help the community if you don’t take care of your team members. That’s how we shaped all of our meetings when we were planning how to support the community.”

With roots in the Fort McMurray since 1974, Acklands-Grainger already had a reputation for its customized equipment maintenance and repair programs to ensure the safety and full productivity of the businesses they serve. Well

before the Fort McMurray wildfires, the industrial distributor had participated in a number of emergency situations (including H1N1 and SARS), giving it the upper hand when it comes to mobilizing communities when disaster strikes. To boot, Acklands-Grainger has been a national founding sponsor of the Red Cross “Ready When the Time Comes” workplace disaster volunteer program since 2009. The program trains and prepares employees of Canadian businesses for large-scale disasters, such as floods, fires, tornadoes and major storms.

Since there was no power in the Fort McMurray area, Acklands-Grainger’s head office instructed an IT team to set up computers and generators to get the

building up and running. “Our systems had to work. We had logistics, product management, marketing – everyone had a role to play,” says Slater.

A hallmark of an effective preparedness process is that it must balance planning and improvisation, says Slater. “Every head from every department in our company was assigned a task –whether it was making sure we had the right product in the right place to support rescue efforts or keeping track of our employees.”

Since roles and responsibilities assigned during disruptive events tend to be outside of the scope of normal business operations, having an effective means for communication was essential. Acklands-Granger employees held conference briefings twice daily and

If your company does not have a comprehensive emergency response plan, it is time for an upgrade. Get started by accessing the Canadian Centre for Occupational Health and Safety’s practical workplace training and reference tool, Emergency Response Planning Guide. Written in plain language, the 155-page pocket guide offers guidance for conducting a risk assessment, evaluating potential losses, identifying potential emergencies, conducting drills, following up after incidents and continuously improving response capability. For courses and more information, visit ccohs.ca.

used a variety of communication tools, including text, email, and a webpage that team members could access for updates and in-person meetings. Communications were configured in a way that ensured anyone with limited access to cell phones would have the option of dialling in from anywhere so they could not only access updates from any location but also to ensure that the information originated from a verified source.

At the branch, a small team mobilized, camping out at the office so they were available around the clock to provide emergency responders and infrastructure companies what they needed –gloves, masks, respirators, generators…

Emergencies and disasters can occur at any time and without warning and no plant or facility is ever immune. If Acklands-Grainger’s experience serves as a best-in-class example of emergency response preparedness, its best defense is arguably preparedness and its proactive stance on establishing frameworks and rigorously adhering to its comprehensive EH&S management system.

Mining, as well as oil & gas operators

typically employ highly qualified staff who also have the requisite expertise to handle foreseeable emergencies. But sometimes, due to the severity of the hazard, the geographic area or number of workers involved, crisis situations may overwhelm the health and safety capabilities of the response team.

For Slater, a well-defined supply chain infrastructure, knowledge to support the operation and a working partnership to be able to execute on the plan are among a list of criteria that set his team apart. Slater is especially proud of the skill displayed by Acklands-Grainger’s leadership in helping mobilize the community in getting back on its feet. “During a crisis it really boils down to the training that you’ve provided your team. Because they have prepared, they can respond quickly and with confidence when they’re in these situations.”

Rehana Begg is the editor of Machinery and Equipment MRO magazine. Reach her at rbegg@annexweb.com.

A lesson learned from the Fort McMurray wildfire is that businesses should regularly review and update their PPE program as hazards change. There may be limited PPE and safety supplies available for purchase during an emergency. Employers should plan in advance of an emergency for the PPE needs of employees and have it on hand. Be sure to train workers in the proper use of PPE, including how to put it on and take it off correctly and how to clean, maintain and dispose of it after or between uses. Different types and levels of PPE may be used depending on the specific hazard. The following sampling of workplace safety products were culled from the Acklands-Grainger (acklandsgrainger.com) to spur a review of what you have on hand and to nudge you to seek out the most effective gear.

Power generator. A backup generator can continue operations when the power is out. The industrial gas-driven portable from Dayton is powered by a Honda engine, 20.8 HP, 12,000 rated watts, fuel tank capacity of 13.5 gallons (51 L) and 11.7 hours runtime – half load. GFCI protected.

Breathe easy. Select the appropriate respirator to protect against the hazards they are exposed to. This 3M reusable half facemask respirator is compatible with a broad range of twin-design, lightweight 3M filters to protect against gases, vapours and particulate hazards.

Face off. Face shields are used in conjunction with other PPE. Ensure that the interaction among PPE is seamless. Honeywell’s Uvex Bionic face shield provides all-day comfort for workers exposed to impact, chemical splash and airborne debris.

IN CONVERSATION WITH DR. NICHOLAS RANDALL

The study of friction, wear, and lubrication – otherwise known as tribology – is of enormous practical importance to industrial maintenance professionals because it can not only optimize functionality but also help prolong the life of mechanical equipment. However, there are few professionals in this field who invest in furthering their knowledge of recent advances, whether lowering friction or reducing wear of mating components.

As an expert in the field of surface mechanical properties testing and instructor of an upcoming MIT Professional Education course, “Tribology, Friction, Wear and Lubrication” (June 26 - 30), Dr. Nicholas Randall has a clear understanding of what it takes to succeed in today’s market. Here he shares insights on the future of tribology and how it could impact industry.

What are some of the biggest challenges for tribology?

Misperceptions about the field, by far. Many people still view tribology as traditional and old, when that simply isn’t the case. Because of this, there is still little funding focused on providing specialized tribology training. We need to dedicate more resources to continuing education and provide better training for our engineers. I believe it’s critical that essential elements of tribological understanding lie at the core of every engineering program.

Another area that still challenges many people in the field of tribology is that of scale-dependence. Will the friction between two surfaces at one-dimensional scale be the same as that at a different scale? For example, we know that water is a good natural lubricant and that wet surfaces slide better. But that is at the macroscale! In contrast, at the nanoscale, we see that water molecules on a surface may actually increase friction due to their viscous effect, which becomes the dominant mechanism.

I would expect transportation to be one key area. Apart from automotive, there is a lot of current development in magnetic levitation, high-speed trains, aero engines, space travel, etc. But automotive is probably the biggest one as governments push to lower emissions and increase efficiency. The only way that we can still improve the efficiency of the internal combustion engine is to lower friction and wear. One way is to coat many of the mating components with low friction coatings, another is to develop better lubricants. Texturing surfaces is an additional way of optimizing engine performance.

How do you think Tribology will evolve in the future?

I think that tribology will evolve the most in fields where it is still not fully understood, including

• Functionalized surfaces, including biomimetic surfaces

• Better surface coatings to lower friction and wear, particularly in engines

• Nanoscale tribology and the effects of scale dependence

• Biotribology as we continually strive to increase the lifetime of materials in the body

Until we truly recognize the importance of tribology in our lives, we won’t attribute the required resources to solve tribological problems. MRO

Dr. Nicholas X. Randall, co-instructor of the MIT Professional Education course, Tribology, Friction, Wear and Lubrication, currently serves as the vice-president of Business Development at CSM Instruments in Needham, Massachusetts. For information about his course, visit http://professional.mit.edu/programs/short-programs/tribology.

Detection techniques for varnish precursors.

BY NEIL BUCHANAN

More than ever, operators need to choose the right turbine fluid that will combat varnish accumulation. To do that, the industry needs to update its fluid test methods because relying on the rotating pressure vessel oxidation test (RPVOT) alone has proven ineffective for comparing turbine fluids. As a result, misinformation could lead operators to choose a less-effective fluid for their gas turbines.

The problem lies not only in the decision-making approach itself, but in what the industry still accepts as the baseline test for measuring how the fluid will perform.

One particular method (RPVOT, or rotating pressure vessel oxidation test) for measuring fluid performance – while still extremely valuable as a benchmarking tool – is not as useful for predicting the actual, in-use performance of today’s gas turbine fluid formulations, but it is a great resource to use when comparing particular system results over time.

RPVOT is an accelerated aging test designed to evaluate the oxidation stability of new and in-service lubricants having the same composition. This test was established as an ASTM standard in the 1960s and has now become the de facto measurement for helping end users determine the remaining useful life of turbine fluids.

The RPVOT is conducted by placing the lubricant, water and a copper catalyst in a pressure vessel fitted with a pressure gauge. The vessel is then pressurized with oxygen to 620 kPa (90 psi), placed in an oil bath at 150°C or dry block taken to 150°C, and rotated axially at 100 revolutions per minute (rpm). The result reported is the time taken for a pressure drop of 175 kPa (25.4 psi) below the maximum pressure. The drop in pressure indicates that oxygen has been consumed by reacting with the lubricant’s components. The number of minutes required to meet the required pressure drop is used to infer the oxidation stability of the lubricant.

For older technology, Group I based turbine fluids, this testing method proved useful in predicting oil performance.

New-generation turbine fluids, however, degrade at non-linear and unpredictable rates – which can be attributed to the specific antioxidant(s), as well as the natural oxidation-resistant characteristics of Group II base oils. As a result, the RPVOT provides little to no warning as to when the lubricant will start to degrade and generate system deposits.

Thus, various tests are performed over time and trending is used to show the bigger picture. This is evident for several reasons. Here are two:

Some of the antioxidants that generate very high RPVOT values could also produce high levels of insolubles upon depletion, showing a direct correlation to varnish formation within the lubricating system. Thus, in some cases, these chemistries that showcase very high RPVOT values have contributed to increasing varnish potential in gas turbines.

RPVOT values can be strongly influenced by the addition of some corrosion inhibitors and metal passivators. These additive species can negate the effects of the primary catalyst in the RPVOT test, a copper wire coil, improving the test results and giving a false indication of the fluid’s oxidation properties. This is why other oxidation tests are run as well. Corrosion inhibitors typically deplete out of turbine fluids fairly quickly, once put in

service, as they are polar and designed to provide a protective film to metal surfaces. It is not unusual in some turbine fluid formulations to see a sharp drop in RPVOT values during the first year of service as a result of corrosion inhibitor depletion. RPVOT retention is a much stronger indicator of turbine oil performance than initial RPVOT results.

To be clear, the RPVOT need not be discarded. Its results give a quality comparison of batches of the same composition. Operators can (and should) use this test to measure base-level fluid properties at the beginning of oil use and, over time, track oxidation effects on those properties.

Furthermore, if you have a reservoir with mixed brands or formulations of turbine fluids, performing RPVOT testing is recommended as part of a complete test slate to help evaluate

the condition of the fluid. RPVOT results can also be used as part of an overall analysis program for in-service oils of the same composition.