TURNING MANURE INTO HIGH QUALITY BEDDING

WASTE WATER TREATMENT

WASTE WATER TREATMENT

TURNING

FAN PRESS SCREW

SEPARATOR

•

•

Fan produces bedding material with a dry matter content of up to 38% in solids.

DONNA FLEURY

RONDA PAYNE

TURNING

SEPARATOR

•

•

Fan produces bedding material with a dry matter content of up to 38% in solids.

DONNA FLEURY

RONDA PAYNE

Live events – conventions, award shows, education opportunities –have been a hallmark of trade media for years. There’s no doubt we all miss traditional live events – for the excitement of finally “putting a face to the name” when networking, or the age-old tradition of catching up with your industry peers over a beer at the end of an event day.

But that doesn’t mean I don’t see the benefit of virtual events. While the experience is very different as both an attendee and an organizer, it feels as though many industries have started to embrace the differences, rather than try to replicate the exact experience of an in-person event.

For example: While we might not be able to physically have a pint together, with virtual events we have something we never really had before: the ability to multitask while taking in educational sessions.

up the educational aspect of the day with activities we might have never heard of before. Some have done trivia, social media challenges and more.

When I first came on as editor of Manure Manager, the status of this year’s North American Manure Expo was still up in the air – would it be in-person, online or a hybrid? We quickly realized the timing was not quite right for an in-person event, especially one that involved crossing the border. We’ve since been tirelessly planning this year’s online event to ensure the experience provides value to the communities we serve.

Features such as the ability to watch our sessions on-demand or time-shifted, a virtual trade show floor and well-timed breaks will allow attendees to enjoy a worldclass experience while also enjoying some of the unique privileges of a virtual event. Through the

“It’s time we look at virtual events as a learning experience.”

We can learn about new application techniques while we get our desk work done during the day. We can eat a snack while watching a showcase of the latest products. We can even save key sessions for later if we have to miss them live while we take our kids to school. Live events don’t come with replay.

And no, there’s no salad bar at lunch, but some virtual events have found innovative new ways to break

Pheedloop platform, one can meet new people and ask questions during education sessions, or, if they want a more lean-back experience, they can take notes and tending to their other business.

It’s time we look at virtual events not as a limiting experience, but as a learning experience. Let’s raise a glass at our desks this year, knowing next year, it is much more likely we will be raising a glass in person. •

A new study published by Bindu Paudel and Deepthi Kolady for SwineWeb explores consumers’ preferences and awareness of antibiotic use in meats, as well as what they’re willing to pay for pork that was raised without the use of antibiotics.

Antibiotics have always been a touchy subject for livestock producers; with use highly regulated, concerns about resistance high and public perception of antibiotic use sometimes fluctuating, the use of

antibiotics often depends on consumer demand. The study found consumers in the control group were willing to pay between 53 and 68 cents per pound more for pork chops labeled as being raised with conventional use of antibiotics (compared to the no-information option) and between $1.05 and $1.32 per pound more for pork chops labeled as being raised with minimal use of antibiotics (compared to no information).

The University of Saskatchewan is looking to utilize research to improve beef production’s efficiency and sustainability. Canada’s beef sector is currently valued at $18 billion; a multi-agency research team out of the university is looking to make advances in the field of genomics (and other “-omics”) into livestock production.

Led by veterinary reproductive biologist Dr. Gregg Adams, work

will take place at the university’s Livestock and Forage Centre of Excellence. Tools such as phonemics, microbiomics and proteomics involve the study of the appearance, structure and behaviour of animals, including their microbiomes and cell proteins. Thanks to notable progress in research over the last decade, these tools can be used to boost livestock production, according to Adams.

416

100

62

Number of U.S. farmers and farm workers who died of a work-related injury in 2017. [1]

Estimated number of U.S. ag workers who suffer a lost-work-time injury per day. [1]

Percentage of tractors, as of 2014, equipped with roll-over protective structure (ROPS) [1]

1. FIGURES ACCORDING TO CDC.

17

The project aims to integrate these advances and address some of the current challenges faced by Canada’s beef industry, which include disease management, fertility improvement and environmental impact mitigation. This will be accomplished by compiling previously unavailable behavioral data and other physical data on beef cattle, through placing multispectral cameras in their pastures and

Average percentage at which agriculture injuries over-indexed against all workplace injuries in British Columbia between 2014 and 2015. [2]

2. FIGURES ACCORDING TO WORKSAFEBC

33

Percentage of fatal occupational injuries in the agriculture industry that arise in animal production and aquaculture settings (2019). [3]

3. FIGURES ACCORDING TO THE BUREAU OF LABOR STATISTICS

close confinement areas. The teams will identify gene markers for desired traits. This will in turn help the team identify genomic characteristics that relate to performance. “Once we identify these markers… we can actually begin to collect the genetic material— the germplasm, embryos and semen from those individuals that have desirable characteristics,” said Adams in a statement.

$12.2

Amount (CAD) the Government of Canada allocated through the Emergency Processing Fund for safety adjustments and enhancements in meat processing settings. MILLION

1,638

Number of workers at Cargill’s High River, AB plant who received a COVID-19 vaccine at a company-run clinic over two days in April.

United Farmers of Alberta Co-Operative (UFA) has formed an exclusive Canadian partnership with livestock monitoring system HerdWhistle. The system will allow farms in the UFA to detect potential livestock health issues while they are still in early stages.

HerdWhistle is a cloud-based RFID system that monitors for potential livestock health issues and alerts feedlots. Owned by Calgary-based A4 Systems, it detects behavioral changes in herds through round-the-clock tracking and reporting, with an overall aim to reduce mortality and morbidity. By its own estimates, livestock health issues can be detected up to seven days before they are visible to most individuals. Vigilant monitoring and detection of issues can lead to a potential 25 percent minimum improvement in mortality rates.

Rob Giguere, VP of livestock services and market strategy at UFA, said in a statement one of the biggest benefits of this partnership is the contribution to farmers’ bottom lines.

“It provides traceability for real-time on lot activity, matching animal history from squeeze to sell. HerdWhistle tracks cattle activity on the lot and can help improve inventory issues,” said Giguere. “It assists with locating missing cattle in the wrong pens and head counts by pen or lot. It can also improve the efficiency of pen checkers, allowing experienced staff to focus on critical pens and animals.”

“We’re continuing to explore new opportunities particularly in the livestock sector and HerdWhistle is one that we’re very excited about,” he added. “HerdWhistle detects early health problems on the feedlot and can significantly reduce mortality. UFA is the exclusive partner of HerdWhistle for Canada, and we are excited to bring the offering to our feedlot customers.”

The first-ever Bayer range and pasture product has hit the Canadian market.

Bayer Environmental Science has launched TruRange, a herbicide formulated specifically for livestock ranges and pastures. The launch is supported by a new dedicated sales and technical team in Canada.

The product provides residual weed and brush

control for more than 70 different weed and brush species. This includes Canadian thistle, leafy spurge, tall buttercup and Western snowberry.

The species are covered for up to 24 months. The product also includes a smaller amount of active ingredient than typical herbicides and is safe for use near cattle, with no grazing restrictions following application.

Canadian pork producers now have a new way to reduce problematic behavior in their pigs and produce healthier hogs.

Animal health and technology company Alltech has created a new solution-based product for pig pens that aims at curbing some of their bad habits.

The new AllBite product is a block that discourages pigs from chewing on their pen-mates and ultimately reducing vice behaviors such as tail-biting, ear-biting and general aggression. It is brand-new to the Canadian market and was first unveiled this spring.

The block is molasses-based, which encourages pigs to chew on it. It comes on a 23-pound, biodegradable container and hangs from a fence or ceiling from a chain. The ultimate

Ag manufacturing giant New Holland has inked a strategic partnership with the agricultural division of Texas-based Alamo Group.

Alamo Group specializes in providing attachments, all of which are compatible with New Holland’s lineup of both compact and mid-range tractors. The partnership will provide New Holland’s customers with the ability to finance their new tractor in the same transaction as their attachments from Alamo under

its Bush Hog, Rhino and Schulte brands, at the same rate. New Holland dealers can also expand their implement lineup and offer a variety of applications with complimentary New Holland tractors in one packaged deal.

Brett Davis, VP of New Holland Agriculture North America, said in a statement, “This partnership allows us to offer competitive packages to meet the demands of any farm, ranch or property maintenance application.”

goal is to discourage problematic behaviour in pigs that can ultimately lead to reduced ROI in the swine industry. According to Alltech, by giving the pigs something else to focus on besides them and their pen-mates, the block has a 93% success rate in reducing or stopping tail-biting.

There’s a new biogas plant in Finland in the livestockheavy southwestern region near Turku.

Weltec Biopower collaborated with its longstanding Finnish partner Doranova to construct the plant, a 250-kW plant that runs entirely from liquid manure from a group of three pig farmers. The plant was constructed as part of an effort in Finland to move toward more sustainable power created from nutrient recycling, aiming toward climate neutrality.

The country has a goal to process 50 percent of its annual animal waste – an estimated 17.3 million tonnes – by 2025. Currently, three fattening houses are being built, in addition to the current piglet production sites. This will allow 40,000 tonnes of pig manure as input material for the plant’s stainless steel digester, which has a capacity of 4,903 m3.

The heat generated will preheat the liquid manure. Heat loss in winter will be minimized through an extra-thick insulation layer. The digestate is then separated, allowing it to be transported to areas in need of nutrients.

With safety at the top of everyone’s mind, the governments of Canada and Ontario have made numerous investments in the advancement of farm safety – both physically and digitally.

In October, Ontario launched a new cost-share intake as part of a $25.5 million program to increase the adoption of technology to enhance health and safety in the agri-food sector.

The Agri-tech Innovation Program, valued at $22 million, is a cost-sharing program to help farm and processing operations adopt new technologies in the interest of worker health and safety.

Minister of Agriculture, Food and Rural Affairs Ernie Hardeman said in a statement the investment is “a significant step forward” to help the sector address pandemic challenges while also preparing the sector for

U.S. and Canadian swine farmers could soon have a trade solution for African swine fever in pigs, should the issue affect feral swine in either country.

The USDA’s Animal and Plant Health Inspection Service (APHIS) and the Canadian Food Inspection Agency (CFIA) have developed a protocol to ensure a bilateral trade agreement to ensure that trade will continue if ASF is detected in feral swine in either country, while still absent from domestic swine.

Upon first detection of ASF feral swine infection, trade between the two countries would initially stop, but would resume following three progressive phases with increasingly reduced restriction on live swine, swine germ plasm and untreated swine commodities. Transitions between first and second protocol will depend on how quickly the countries establish initial control areas and start surveillance in captive swine. The third and final phase will see trade restrictions reduced to the boundaries of the established control area.

USDA chief veterinarian Dr. Burke Healey called the effort “a science-based approach” that will aid both countries.

recovery and future growth.

The program is aimed at technologies that enhance protection of workers against COVID-19, lead to increased business efficiency and productivity and help build the sector’s resilience. Examples of advanced technologies include optical grading and sorting systems in vegetable processing or automated, robotic vineyard pruning robots.

Hardeman describes the investment as “an investment… for today and in our sector for tomorrow.”

Peggy Brekveld, president of the Ontario Federation of Agriculture, added, “Technology and modern equipment make today’s farms more efficient and safer – both for people and the environment… [The funding] will enable investments in new processes and state-of-the-art equipment.”

Meanwhile, a new initiative by the Canadian government will help create enhanced cybersecurity in ag.

Minister of Public Safety and Emergency Preparedness Bill Blair announced funding of $500,000 over four years to the Community Safety Knowledge Alliance for their Cyber Security Capacity in Canadian Agriculture project. The funding was made available through a broader

Cyber Security Cooperation Program. The program, launched in 2019, has $10.3 million available in funding over five years, with $4.2 million available between 2021 and 2024.

“Canadian agriculture is a critical and increasingly interconnected service, and it is a key part of our economy, trade, and food supply,” said Blair in a statement. “This funding to the Community Safety Knowledge Alliance for their Cyber Security Capacity in Canadian Agriculture project will help foster collaboration and protect cyber systems from compromise.”

The project aims to enhance the critical infrastructure within the agriculture industry in Canada. It will assess the current cybersecurity capacity of the sector, engaging with farmers, owners and operators along the way, as well as other stakeholders, to promote awareness and develop resources related to cybersecurity in the industry.

Cal Corley, CEO of the Community Safety Knowledge Alliance, added that there are “rapidly evolving” cyber threats within Canada’s ag sector, and those threats are “outpacing the abilities of many farms and other agricultural operations to adapt and respond.” The initiative, adds Corley, will help close some of those critical gaps.

New research suggests using liquid dairy manure with commercial fertilizer in sugarbeet can lower costs without reducing yields.

BY J.P. ANTONACCI

Sugarbeet growers in Minnesota and North Dakota hope new research into liquid manure application will net them a sweet return.

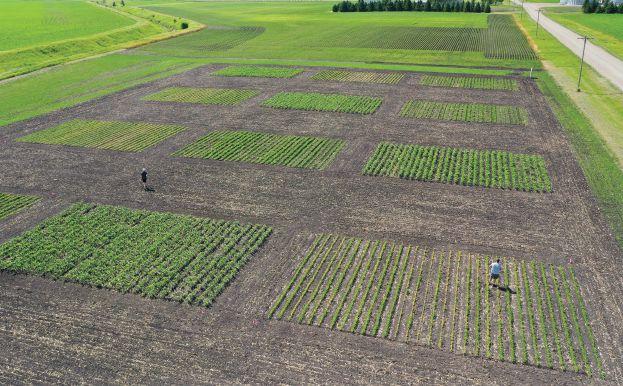

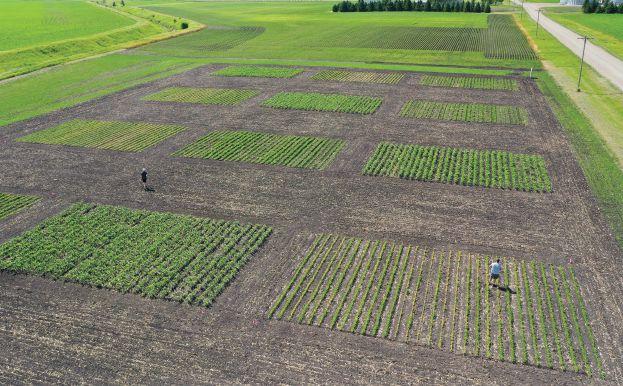

Professor Melissa Wilson, a manure management specialist at the University of Minnesota Extension, is leading a four-year project in which liquid dairy manure is applied to sugarbeet, corn and soybean crops at a pair of test sites in Minnesota.

“We have all the crops within the rotation, we have manure in front of each one individually and we’ll get to see which rotation does the best,” Wilson says. “That way we can see where we get the best bang for our buck – economically, environmentally and agronomically as well.”

Each crop is planted on three plots: the first gets a low rate of manure (9,500 gallons per acre, supplying 85 pounds of first-year nitrogen); the second plot gets a high rate (14,000 gallons per acre, releasing 177 pounds of nitrogen); and the third only receives commercial fertilizer.

The manure, sourced from a local dairy farm, was applied before planting in fall of 2019 at

the first research site, followed by commercial fertilizer as needed to meet each crop’s nitrogen, phosphorus and potassium needs. Only fertilizer will be used for the remainder of the project at that site. The second site had manure applied at similar rates in fall 2020.

Since sugarbeet benefits from high nitrogen content in soil early in the growing season, but manure releases nutrients over time as soil warms, researchers were keen to see how the crop would respond to the various treatments.

“Sugarbeets are very sensitive to excess nitrogen in the soil late in the growing season. It actually will decrease the quality of the sugar if you have a lot of extra nitrogen hanging around in the soil,” Wilson explains.

One year into the project, sugarbeet crops which received liquid manure saw comparable – and in some cases better – yields and sugar content when compared to the fertilizer-only plot, suggesting a role for liquid manure in sugarbeet production.

“After this first year, things are looking pretty good,” Wilson says, noting more testing in different weather conditions is needed to get a more dependable picture.

“The good news is we’re learning so far that [liquid manure] didn’t reduce yields for the sugarbeet to a great extent, which is what we were hoping to see,” she says. “In fact, it seemed to increase the actual tonnage of the sugarbeet, but it did decrease the quality of the sugar a little bit. We have to see how that fits into each of the sugarbeet cooperatives’ economics, but overall it didn’t do as much damage as we were expecting.”

These early returns are promising, she says. If indeed farmers can replace some commercial fertilizer with cheaper liquid manure without sacrificing crop yields, which ultimately helps their bottom lines. Wilson says fields that haven’t had manure in recent years could also see a bump in soil health if manure is applied correctly and in the right volume.

Researchers seek to determine when in the rotation manure should be added to best ensure a productive soil nutrient balance.

“Sugarbeet farmers do have the opportunity to put this in front of sugarbeet. But we’d like to get a couple more years of experience under our belt to see where it will really be maximized – whether it’s in front of corn, soybean or the sugarbeet,” Wilson says.

So far, it’s looking like soybean isn’t the best contender to add manure into the rotation, since adding liquid manure at the start of the growing cycle left plants yellow and stunted. That compared to corn and sugarbeet plants that were larger in the plots that received manure in the fall, versus the fertilizer-only plots.

“We think we were seeing some issues with iron chlorosis deficiency in the soybean plots,” Wilson says. “Now that we know that’s an issue, we hope to change some management practices to reduce problems in the future.”

Researchers took soil samples in the middle of the growing season and again after harvest, but COVID restrictions at the lab mean they are still waiting to do the analysis.

Sugarbeets were topped and harvested in late September. Sugar extracted from the plot that only received fertilizer was 91.2 percent pure, while crops that received manure and fertilizer had 90.8 percent sugar purity.

In terms of volume, the sugar yield from the fertilizer-only plot was 9,710 pounds per acre, which jumped to 10,380 for the low-rate manure plot and 10,266 for the high-rate plot.

As for overall tonnage, the manure plots outperformed the fertilizer-only crop, with the low-rate plot yielding 35.8 tons per acre and the high-rate plot producing 35.6, compared to 32.7 from the fertilizer-only plot.

These figures are of great interest to the Sugarbeet Research and Education Board of Minnesota and North Dakota, which is funding the research because members are keen to learn how best to use dairy manure in their operations, and how the technology behind liquid-solid separation could be used by large-scale dairy farms coming into the region.

Beet sugar represents 55 to 60 percent of all sugar produced in the United States, while Minnesota alone accounted for roughly a third of the 34,751 tons of sugarbeets grown in 2019-20, according to the Department of Agriculture.

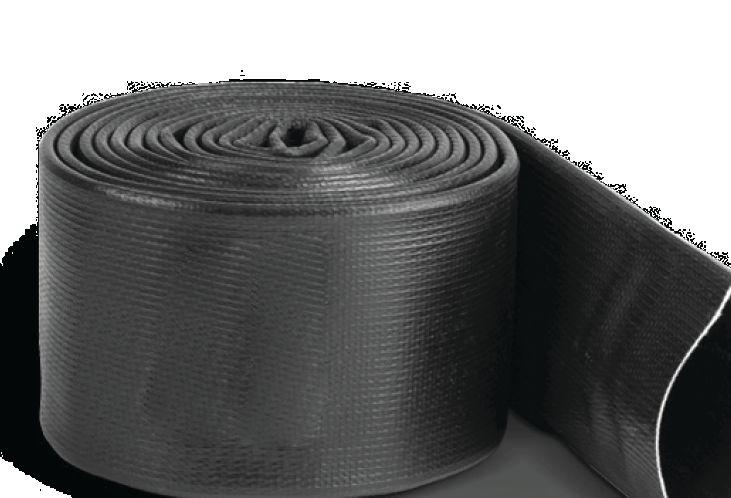

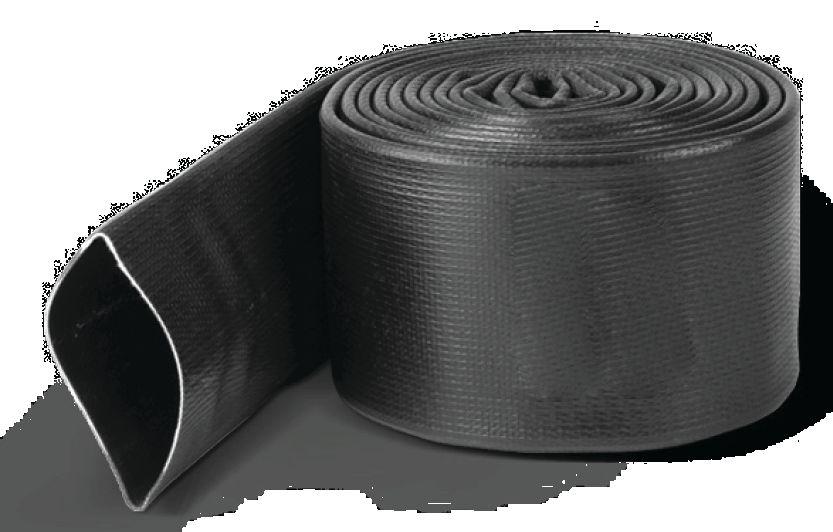

At that scale, lowering input costs by incorporating liquid manure into the fertilization mix can have a major impact on farmers’ return on investment. Liquidsolid separation technology can further help the bottom line by reducing the volume of manure needed to fertilize the crop.

The concept of liquid-solid separation – or squeezing manure to yield two separate agricultural products – is decades old, but Wilson says the technology can now be scaled up for use on large-scale dairy farms with as many as 9,000 head of cattle. Liquid manure is applied to the fields to supply crop nutrients, while the dry solid manure becomes bedding for the cows – another cost savings for farmers.

“It’s an old technology that’s gotten a new life to it,” says Wilson. “People have been looking at liquid-solid separation for a while, but this is the first time I’ve been seeing it go into some large operations commercially.”

As an extension specialist, Wilson’s work doesn’t end in the field. But with the pandemic limiting opportunities for inperson education, she turned to a system called ArcGIS StoryMaps to share her research with farmers and other industry stakeholders.

“I was looking for opportunities to visually demonstrate what we’re doing” beyond the usual fact sheets and project

descriptions, she explains. “I think it’s really important to get the information out there to the people who need it.”

Her presentation for the soybean rotation project uses visuals to take viewers through the experiment and give them a sense of what the plots, processes and equipment look like.

“So far it’s been pretty successful,” Wilson says of the online presentation, which quickly amassed hundreds of views and prompted one sugarbeet farmer to contact her with questions.

StoryMaps gives Wilson – who has a PhD in water resources science and soil science, and has been at the University of Minnesota since 2017 – another way to share her enthusiasm for the ins and outs of manure management.

“I think it’s really exciting,” she says. “With fertilizers, you kind of know what you get. But with manure, it’s kind of a puzzle. Figuring out how to optimize it is interesting for me. I like doing research and I like trying to answer questions that farmers have.” •

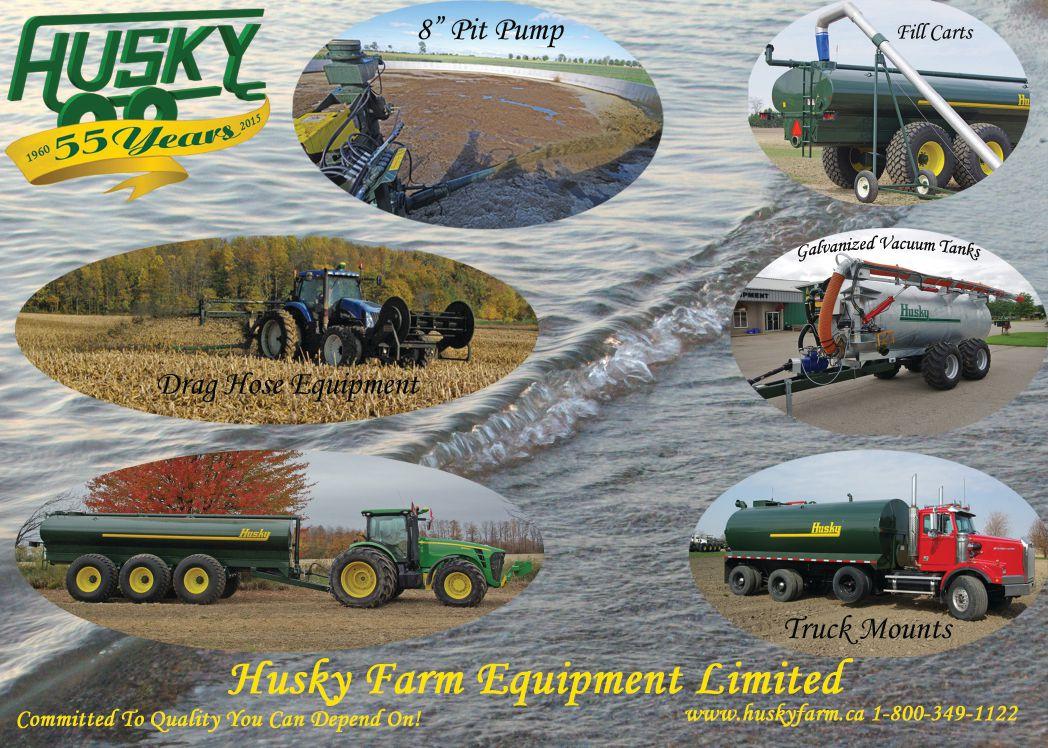

When the going gets tough, turn to the toughest pump on the planet. Since 1960, the unrivaled Vaughan Chopper Pump has been on the cutting edge. This original chopper pump was built first and made to last.

Choose the unmatched reliability of Vaughan. Ask about our free trial program and on-site demos.

• Barn Flush Pit

• Separator Feed

• Lagoons

• Digester Mixing

• Scraped Manure

• and More!

Al and Kathy Wulfekuhle of G&W Pork take a progressive approach to land management and biosecurity.

BY JULIENNE ISAACS

The story of G&W Pork, an operation in Quasqueton, IA, is in some ways the story of a marriage.

Al and Kathy Wulfekuhle began farming in 1979, with 90 sows on 180 acres.

“We were high school sweethearts –homecoming sophomore year is when we started seeing each other. I was 19 and Kathy was 20 when we got married,” Al says. “I was trying to be efficient, so we got married on a Saturday, had a three-day honeymoon in Chicago and moved to the farm on Tuesday, and I had everything prepared so we could start farrowing baby pigs on Friday. She thought it was the dumbest thing ever.”

“He’s been paying for it for 42 years,” adds Kathy, laughing.

Over those 42 years, the business – and the family – has grown. Al and Kathy have three children, Allison, Brian and Brett, and eight grandchildren aged one to 13 years.

ABOVE

And the farm, G&W Pork, is now an 1,800 sow farrow-to-finish operation with pigs on 18 sites; the family sells around 55,000 pigs per year to Tyson Foods.

Last year, the Wulfekuhles were awarded the Wergen Good Farm Neighbor Award, an initiative from the Coalition to Support Iowa’s Farmers which recognizes livestock farmers with exceptional animal stewardship and environmental practices.

Nominees for the award must be active in their community, produce livestock to the highest of animal care standards, and be dedicated to conservation and stewardship of their land.

The Wulfekuhles tick all of those boxes.

On the stewardship side, they partner with neighbors Curt and Cindy Gentz to grow 800 acres of corn and soybeans that cycle back to the farm as pig feed via their on-farm feed mill. Over the years, they created waterways, field

Kathy and Al Wulfekuhle have worked tirelessly for more than 40 years to promote pork – and healthy swine practices – in the area.

ABOVE

boundaries, terraces and wetlands on those acres, and implemented cover cropping no-till and for strip-till practices.

On the animal health side, they’ve invested in strict biosecurity measures to keep the pigs as safe as possible.

Al, who sits on state and national pork boards and is chair of the national swine disease council, says swine health is the biggest challenge facing the industry.

“Iowa has 25 million pigs and three million people,” he says. “The challenge is that whenever you have a disease, it can spread quickly and easily from site to site. A lot of my work on the state and national boards has been to keep animals healthy

“We want consumers to know we’re trying to do the right thing.” – Al Wulfekuhle

and keep foreign animal disease out of the U.S., and if it does get here, to stamp it out when it spreads.

“We’ve seen the need for epi-tracing for pork. We want to be able to do it better and quicker than we do it on the human side,” he adds.

Al remembers a time when they would bring baby pigs to their kids’ classrooms and welcome busloads of visitors to the farm who would walk from barn to barn without changing their shoes.

These days, anyone going into a barn is required to shower and change clothes. The herd itself is “closed,” which means the Wulfekuhles raise their own F1 females using semen rather than bringing live pigs--who could potentially carry diseases--onto the farm.

Pork producers have an obvious responsibility to their animals and land, but Al Wulfekuhle believes neighborliness starts with the farm’s relationship with its employees.

“You have to want to help them get ahead in life and be successful,” he says.

All of G&W Pork’s employees are shareholders, and most own buildings they lease to the company.

“We made the decision a long time ago to give shares of our pig operation to employees and I think that pride of ownership and loyalty is key. We’ve tried to help all our employees to get into ownership. It’s been rewarding, because I’ve seen some of our employees start from nothing and do really well.”

The Wulfekuhles’ progressive approach to farming is not unique in their neighborhood. When Al and Kathy first started out, Al’s father helped him find a farm 32 miles from his own. Originally, the intention was to return to their home neighborhood, but before long the Winthrop area became home, and they never looked back.

These days, the Wulfekuhles’ neighbors, who are also independent producers, “follow each other a little bit,” says Al. “When one neighbor starts doing something, we all watch.

“For example, some neighbors have been strip tilling for five to seven years, but in the last couple of years, most everyone in the neighborhood has changed from tilling to strip tilling and using cover crops. It’s been an interesting transformation.”

When you’re a pig farmer, neighborliness means making a concerted effort to build hog barns away from homes; in Iowa, setback regulations require it.

But there’s a lot that farmers can do voluntarily. Al’s father was very conservation-minded, he says, and influenced Al and Kathy’s decision to add sustainable infrastructure – like the terraces and wetlands – early.

“The land is gently rolling here, so we have some long slopes and you need to have waterways and field borders to make

The strength and reliability of Nitro Spreaders set the standard for nutrient management.

The hydraulically driven variable speed apron chains feed fastmoving beaters that ‘bite’ the load and throw it into the field with remarkable consistency.

AtheneVariableRateControlSystem

ISOBUSUTdisplaysspreadercontrolsand variablerate&overlap(ifavailableonterminal).

The addition of a variable rate control system, further reduces overhead, increases yields, and verifies field application rates.

When you’re ready to spread, we’re ready for duty.

ABOVE

sure you control erosion and runoff,” he says.

The Wulfekuhles have made an effort to ensure their farm operates as a closed loop system: the pigs eat the crops that grow on-site, and the pigs’ manure gets recycled back to the land as fertilizer.

G&W Pork has worked with the same custom manure applicator, Hoefer Pumping, for 25 years.

“They do an excellent job for us, getting manure applied accurately and cleaning up around the sites when they’re done,” says Al. Everything gets knifed in with a minimal disturbance applicator.

The manure is tested before being applied at rates that comply with site specific management plans. In the past, the Wulfekuhles have used Corteva’s nitrogen calculator “Encirca” to attempt to monitor losses and only sidedress deficient areas. These days, they mostly rely on late spring N tests, says Al.

Iowa’s ongoing water quality problems have added to the pressure on the pork industry to prove to a listening public that their practices are sustainable.

Al’s advocacy and industry involvement often brings him face to face with anti-pork activists, but he believes the general public also wants to know how their meat is produced. This kind

of scrutiny presents an opportunity for farmers to get creative with how they talk about their farms, but it isn’t always easy to be transparent when biosecurity measures limit farm access.

The Wulfekuhles have approached this problem by allowing visitors (as long as they’re willing to shower and change clothes before entering a barn) and offering video tours.

“We’ve always tried to be open with our farm and show people if they want to see it, as long as they follow our protocols,” he says.

The Wulfekuhle’s longtime veterinarian, Josh Bowden, has worked in the Winthrop area for 10 years, and he says disease control is particularly challenging in the area due to the density of pig barns. Even in closed herds, diseases like Porcine Reproductive and Respiratory Syndrome (PRRS) can still spread via aerosol transmission from neighboring operations.

“You can only control what you can control, and that comes down to how people move and the biosecurity steps they take,” says Bowden.

Bowden says the Wulfekuhels and their employees do a great job of animal husbandry. “They are very good managers and they have great people that are

engaged in the process of raising pigs. We keep in very close contact with each other. We probably talk two or three times a week to hear about any issues they’re having in the sow or finishing barns,” he says.

For Al, watching pigs die of preventable diseases is one of the hardest parts of pig farming, and that’s why G&W places such an emphasis on pig health and welfare. Vaccinations help, he says, but the best approach is to keep animals as healthy as possible so they are better able to fight off infections.

“As producers we want to do everything we can to keep the animals comfortable, because the happier and healthier they are the better they produce for us. It’s in our best interests to take care of the animals,” he says.

Animal welfare and environmental stewardship are crucial elements of a healthy approach to pig farming. When it all works, Al Wulfekuhle says pig production is about as sustainable as it gets.

“When you grow corn and beans and feed them to the pigs, it’s the cycle of life. That’s part of what the consumer is asking for, and they’re asking for animal welfare as well. We want consumers to know we’re trying to do the right thing,” he says. •

MM_Bambauer_MayJune21_CSA.indd 1

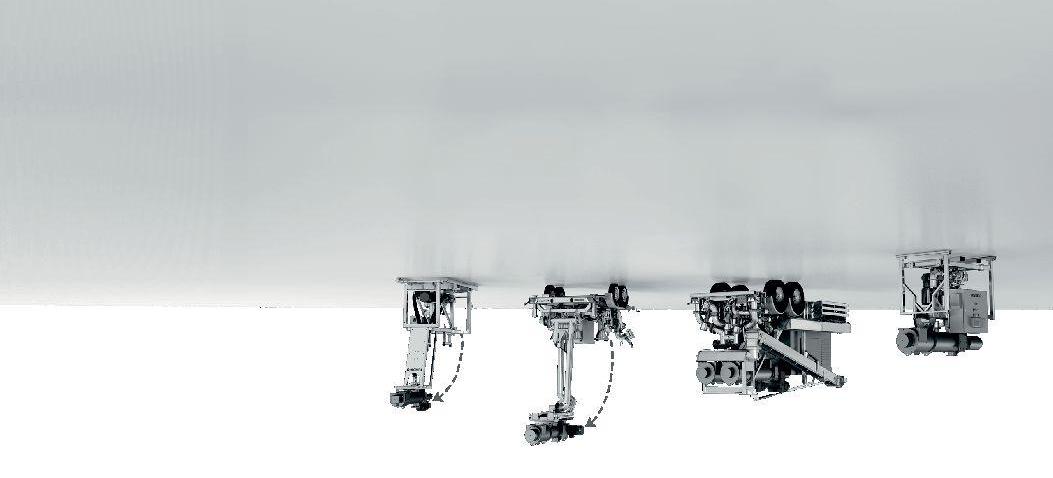

INNOVATIVE SCREW PRESS SEPARATION TECHNOLOGY

+ Largest Screw Press on the Market

+ Turnkey Systems: Separator Pump(s) Control Unit

Stationary or Mobile Skids

+ Patented Auger with Counter Bearing

+ No Auger Screen Contact

+ Multi Disc Technology

Texas-based research digs deep into the value of microbes in soil.

BY RONDA PAYNE

In farming, there are many examples of practices that have been used for centuries without much science-based understanding of why or how they are beneficial. In the realm of forage crops, composted manure has been applied to fields to deliver stronger, healthier and more vigorous plants, but there has been minimal mainstream awareness of the biological or chemical interactions that make it so.

It’s similar to the household microwave people use on a daily basis; most use it to heat their food without a clue as to how it works – they just know that it gets the job done. More importantly, the average person can’t take what the appliance does and adjust it to fit various situations.

Over the past century, science has begun to reveal some of the ways applying composted organic matter like manure is beneficial. For example, a recently published study from Texas Tech University explored manure application to better understand whether or not it increased soil

microbial biomass and soil carbon to improve soil health relatively quickly. If so, this would allow farmers to apply the science to increase productivity in numerous field applications.

Lindsey Slaughter, soil microbial ecology/ biochemistry assistant professor with the department of plant and soil science with the university, oversaw the thesis research of graduate student Rael Otuya, who wanted to explore the interaction between manure application and increased soil health. Samples of soil were taken from two semi-arid Texas forage fields in the summer of 2017 after the grasses on the site were into their growing season. The sampling, done twice a year, continued into the fall of 2018 to measure microbial abundance and the soil’s organic carbon and nitrogen after a single composted manure application.

“We have been interested in how permanent grasslands can increase soil microbial biomass and soil carbon in these soils that are usually pretty

ABOVE The soils in parts of Texas are semi-arid, so patience is key when dealing with compromised soils.

low in both due to the semi-arid climate and intense farming in this region,” she says. “We need a way to add more organic residues to the soil than would normally be there from growing plants to help build up microbes and soil carbon quickly.”

She adds that because the southern High Plains of Texas is a high cattle production region, there is an abundant volume of manure to supply the necessary extra carbon and organic residues. The study tested the one-time, low-rate application of composted manure to the established forage fields of either warmseason grass (a relatively new Old World Bluestem cultivar known as WW-B. Dahl) which was occasionally fertilized, or to a mix of the grass and alfalfa.

“The grass-only pastures needed nitrogen fertilizer every year, but the grass-legume mix did not,” she says. “We added composted cattle manure donated by a local operation to each pasture in March 2017.”

The only exclusion to the application of compost was a control patch of land 20 meters square covered with tarps.

Not surprisingly, the farming practices of the past were proven to improve soil health. Farmers of bygone times would have waited to see plant vigor to know the manure application was working, but here and now, science told the story beneath the soil. The composted manure applied during the study led to the desired benefits of increased levels of microbes and soil carbon, which are factors in soil health.

“Even if a farmer has no formal background in agricultural science, plant/soil science or ecology, they have understood for centuries that giving plant or animal waste back to the land is a rich source of nutrients that shouldn’t be wasted,” she says. “[They] have seen that it improves the quality of their soil and of the plants that grow then and in the future.”

However, what might not have been expected was that the desired results take time, at least in semi-arid Texas soils, so patience is key when dealing with compromised or challenging soils. It took about 18 months to see the positive outcomes. The field that received fertilizer made better use of the composted manure because the added nitrogen is believed to help microbes break the manure down.

This reveals the value of microbes. As they break down organic matter, the

nutrients created become more readily available to plants while decomposed residues build up overall organic matter in the soil. This ensures a healthier, more robust soil over time that supports the ecosystem.

“Increased microbial biomass and soil carbon are important in pastures, both as a reservoir for nutrients and for having the biological tools to help make more organic matter/soil carbon and also make nutrients from the organic matter available to plants,” she says.

Upon learning these results, a farmer may think it’s time to develop a new composted manure plan for their forage field. However, there are numerous details to assess prior to doing so. The first, and perhaps most obvious, is to test the soil to determine nutrient needs. Returning to the microwave analogy, the food must be tested to see if it’s hot before heating it up.

Soil testing ensures current nutrient levels are reviewed prior to manure application which allows farmers to select the right compost for the growing needs of the land based on the intended crop. This baseline then leads to the need to know the nutrient levels within the types of manure available. Analyzing both the soil and the manure will allow for calculating application rates to meet the needs of the plants without over-applying.

“If someone is using their own manure or locally-provide manure from another farmer, they should definitely get the manure analyzed for nutrient levels including nitrogen if possible, phosphorus, potassium and other nutrients that we commonly test for in fertilizers and soils before use,” she says. “Farmers should treat manure like a fertilizer, where the carbon and benefits to soils and microbes is a bonus.”

Finally, understanding the relationship between composted manure and a field’s particular soil also makes a difference to volume and timing of application. Soils that are wetter than the Texas study fields need to be assessed for run-off risks.

“Over-application might cause excess or unused nutrients to runoff into nearby water and cause potential pollution problems,” she notes.

Knowing runoff can be a concern was one of the reasons the study looked at low application rates.

“The composting process for the cattle manure helped reduce the chance of excess leaching or run-off of nitrogen,”

she says. “Try not to apply manure before it rains or on a very windy day that could wash or blow the manure towards other areas or water bodies.”

Regardless of climate, Slaughter and her team are aware of the benefits of correctly applied manure, in the right format (type of manure and treatment) in improving soil health.

“There are a ton of studies across North America that also test the effect of various types of manure in different cropping systems,” she says. “There are some general results from our study and others that hold true across North America, namely adding manure increases soil carbon and microbes.”

Appreciation of benefits must be balanced with the science of soil and plant nutrient needs as well as the speed at which the amendment is likely to degrade and make nutrients available in the soil. Over-application may not deliver the desired microbes and carbon immediately, but may lead to an overabundance of nutrients in the future. It’s like understanding the wattage of that household microwave before setting the time or power level.

“Farmers could plan to apply compost annually or every few years depending on their nutrient management needs and the supply,” she says. “There are likely to be continued benefits of applying compost over several years, although we only tested a one-time application for two years.”

The next steps for the research team will include exploring whether higher volumes of manure, or more applications per season, would achieve the desired results of increased microbial biomass and soil carbon more quickly. She will also be studying the role of moisture in the process of breaking manure down to promote the integration of its nutrients into the soil.

Slaughter’s latest project is a collaboration with fellow researchers from Texas Tech and the USDA Agricultural Research Services (ARC) to help develop new management strategies for agricultural grasslands that improve production and soil health, conserve natural resources and reduce greenhouse gas emissions. The project was recently awarded a $500,000 grant from the USDA’s National Institute of Food and Agriculture Cooperative State Research Education and Extension Service. •

BKT provides you tires that are reliable and safe, sturdy and durable, capable of combining traction and reduced soil compaction, comfort and high performance.

BKT: always with you, to get the most out of your agricultural equipment.

Don’t take shortcuts, plan ahead and put steps in place to reduce risks and improve safety.

BY DONNA FLEURY

Reducing risk and ensuring manure pit operation safety is very important for livestock producers. Although on some operations, this task only happens once or twice a year, planning ahead, developing Standard Operating Procedures (SOPs), ensuring everyone is trained and good communication helps reduce risk and keep everyone in the operation safe.

Of all the hazards, manure pit gases are considered the biggest concern for health and safety around manure handling and storage. Manure pit gases from any storage pit, whether closed or open or under barn storage, can be toxic to both humans and livestock. “Manure gases are the biggest risk for pit safety, with hydrogen sulfide (H2S) of top concern, and is extremely dangerous and highly unpredictable,” explains Dan Andersen, associate professor and extension specialist with Iowa State University. “When agitating and pumping manure, H2S is released,

ABOVE

and the question is where does it end up?”

“Depending on the year, there are a few manure gas fatalities, usually related to H2S exposure,” says Josie Rudolphi, assistant professor and extension specialist with the University of Illinois. “H2S is tricky as it is colorless, flammable and extremely hazardous with a rotten egg smell. It is also heavier than air, which means it collects in lower lying and poorly ventilated areas. If it collects in low lying areas without good air movement, it is in the breathing zone for people and animals and can be immediately dangerous to life and health.”

Manure applicators and any individuals working around the barn and confined spaces are recommended to be equipped with H2S monitors or four-gas or multi-gas detectors that provide alerts when levels are increasing. This alert system gives workers time to move away from higher concentrations of H2S, or other gases such as methane, carbon monoxide and ammonia. At H2S

While some pit-related tasks only take place once or twice per year, safety is crucial at all times.

levels of two to 20 ppm, symptoms can include nausea, headache and dizziness. At H2S levels greater than 100 ppm, the gas causes altered breathing, collapse and death. These monitors must be kept charged and more importantly calibrated frequently to ensure the gases are detected at the levels they need to be detected.

“Monitoring is very useful as gases like H2S can get extremely toxic in a hurry and at high levels can paralyze olfactory senses in the nose so you can no longer smell it,” explains Tracey Erickson, extension dairy field specialist with the South Dakota State University. “Methane is odorless and difficult to detect by smell, as is carbon dioxide. Exposure to ammonia results in immediate symptoms, with a burning sensation and redness in the eyes as the gas rises. At a minimum, all workers should have H2S or multi-gas monitors and understand the protocols for dealing with manure and manure gases. For larger operations, commercial manure handlers and producers dealing with manure on a regular basis, having a self-contained breathing apparatus or supplied air respirator is recommended. It is important

Risks are not limited to the manure pit itself – they are present in all aspects of handling and removal, mening ventilation is of the utmost importance.

to understand the different types of personal protective equipment [PPE] available and the differences in levels of protection each provides. And note that the masks we have been wearing recently for COVID-19 won’t provide adequate protection for manure handling.”

A buddy system is important in the

CONSISTENT NUTRIENT VALUE - AGITATION MAKES THE DIFFERENCE

Center agitation system evenly blends nutrients

Better utilization of “waste” translates into less purchased fertilizer

ENVIRONMENTALLY SOUND

Designed and constructed using bolted glass-fused-to-steel panels for secure storage and high corrosion resistance

Aboveground - minimizes the danger of run-o , leaching and groundwater contamination

Environment-friendly odor control - releases odors above ground level into higher air currents

event something happens and someone collapses. Any worker who enters the manure pit should wear a safety belt or harness as a lifeline in case of exposure and collapse. That allows people in the peripheral area to keep a safe distance away and pull them to safety. Anyone else trying to enter the exposed area to save the first victim face the same exposure, risking the lives of both victim and rescuer. The second person should be able to call for emergency help if needed, providing adequate directions and a description of the emergency hazard so emergency personnel are adequately prepared.

CONSIDERATIONS FOR MANURE HANDLING AND REMOVAL

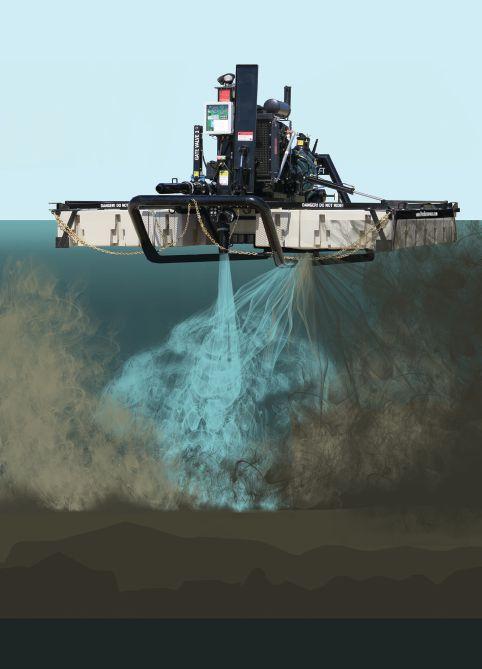

The risks are not only limited to the manure pit itself, but also to all aspects of handling and removal. “Ventilation systems are really important, especially for enclosed barns, such as swine barns where the manure is stored in the barns,” says Andersen. “The goal of the ventilation system is to exhaust the gases out of the barn, and SOPs should ensure the ventilation system is set right to provide high ventilation rates while agitating and stirring up the manure. Also, check and make sure all of the fans are actually working and functioning properly. If it is a curtain-sided barn, check and make sure the curtains and inlets are operating properly. A word of caution to manure haulers who sometimes like to get out of the tractor to stretch their legs and walk around the barn. If they end up walking in front of the fans blowing out the H2S, they can be

exposed to the gases.”

“The ventilation system must be properly functioning, both for people working in the area as well as animals,” adds Rudolphi. For example, in some Midwest hog facilities with underground manure pits, keeping the area well ventilated when agitating and removing the manure and moving out animals if possible during the process helps to keep them from being fatally exposed to gases. Andersen notes, “Think ahead to the process, make sure you are working with partners for any maintenance. If you are going into a confined space, make sure to ventilate the area for a period of time before entering. We highly recommend using a gas meter to test the space before entry, a bit like the canary in the coalmine without the canary. Lots of people do maintenance on the area around manure storage every year and it turns out fine, but every once in a while there is a case or two where it doesn’t, so caution is a good idea.”

“Lock out and tag out to make sure people can’t get into a confined space or through the fence without others knowing they are there,” explains Rudolphi. “For example, don’t start the pit agitating process if other co-workers or someone else is in the maintenance area or fixing the equipment. Keep people a safe distance away from the pit for 20 or 40 minutes until the pit has been adequately agitated. Fencing and signage are other important considerations around manure pits to ensure that children, visitors and animals are kept out. Placing signage that indicates hazardous gases are present provides a visual warning and helps people understand the risks and that it is an area of caution. Some jurisdictions require fencing around manure storage areas.”

Other safety considerations include access ramps to outside pits. Some pits were designed with good access ramps, while others were not. Because of these differences, it is important to develop SOPs that work for each individual site and do the best you can. Make sure to understand how to work around the access ramp, how to keep equipment out of the pit. Check to make sure parking brakes are working properly. General equipment maintenance, handling and basic safety are important.

“Road safety is another consideration when moving manure,” adds Andersen. “Manure equipment on the road is often moving slower than other drivers tend

•

•

to think it is, increasing the risk of rear ending. If possible, try to pick routes where there is less traffic and try to avoid times of day when the roads are busier. Not everyone traveling in the country understands farm equipment very well and aren’t aware of the proper distance and space requirements.”

“There are different hazards for producers working in the environment, and manure gases don’t always come to mind,” says Rudolphi. “In many operations, producers are rarely working with manure throughout the year, compared to equipment such as tractors or livestock that they are working with every single day. Similar to electricity, producers don’t often see the susceptibility or severity of manure gas hazards. Manure gases can be sort of out of sight out of mind, so building awareness and communication for everyone in the operation is key. There are various tools and resources that can assist producers, including a checklist for addressing the hazards around pit safety, including considerations before, during

and after manure handling and disposal, to keep everyone in the environment safe.”

When developing SOPs and training around manure pits and other safety hazards, consider a safety hierarchy for controlling exposure. The first step is to try to eliminate or remove the hazard. With livestock operations, manure will always be produced and can’t be eliminated, so the next step is to prevent exposure to the hazard through engineering controls, warnings and training. And lastly, if exposure can’t be prevented such as working in and around manure pits, then consider the tools and PPE safety equipment required to manage and control exposure.

“Along with having SOPs and training plans in place, making safety a mindset and part of a thought process as you go through daily tasks, whether that is operating machinery, driving a car or handling manure is really important,” explains Erickson. “Often people get in too big of a hurry to do the next job and forget to slow down and take the time to evaluate the risks at hand. One way to evaluate risks and plan ahead before taking on any task is to use the SIPDE process, which is

women who are making a difference to Canada’s agriculture industry will be highlighted through podcast interviews on AgAnnex Talks. Stay updated by visiting AgWomen.ca or subscribing to the podcast at AgAnnex.com

short for scan, identify, predict, decide and execute. This useful process helps identify and evaluate potential risks, predict possible outcomes, decide what actions to take and execute your decision.”

Erickson emphasizes that communication is very important for improving safety. “All of the people working around livestock operations and manure systems, whether family or employees or commercial applicators, must be made aware of and understand the dangers. They need to know how to operate all of the equipment and proper manure handling safety protocols. They need to know what they are doing when they go out there to do a task, and be confident and able to perform the task they are asked to do safely. Never assume people know how to do the things they are asked to do. And sometimes people on farming operations take risks that maybe they shouldn’t. Don’t wait until some unfortunate experience on the farm or with family or coworkers happens before making changes. Short cuts are not worth it, plan ahead and put steps in place to reduce risks and keep people and animals safe.” •

One of the biggest complicating factors when it comes to using manure as a nutrient source is manure’s lack of uniformity. When you buy a bag of urea, you know you’re getting 46 percent nitrogen all throughout. But when it comes to manure, you just can’t guarantee the same level of certainty.

But that doesn’t mean it has to be a great manure mystery.

Manure nutrient content can change and vary spatially and over time. Here are a few examples: a stockpile or pit that is open to the air will lose nitrogen to the atmosphere as a gas making the outer layers less nitrogen-rich; liquid manure will separate into solids that have a higher phosphorus content and liquid which will be more nitrogen-rich; and changes in livestock management (such as feed type) may create inconsistencies in manure stored earlier versus later.

This lack of uniformity with a product can make it difficult for you to know the exact nutrient rate being applied. Though there will always be some level of uncertainty, there are some measures that can be taken to improve uniformity, account for changes and add some predictability to your practice.

Now, if composting is outside your comfort zone, simply turning the stockpile with a front loader will help spread the nutrient content much more evenly.

For large operations, we recommend sampling manure at application right off the spreader or during pumping to get the best estimate of what is actually being applied.

The main drawback with this approach is you unfortunately won’t get your results back until after the application. But the good news is, once you’ve sampled a few times, the nutrient content should remain similar as long as no management practices have changed.

Essentially, keeping good records remains incredibly important at all times with all aspects of manure – including, but not limited to, sampling.

For smaller farms with solid manure, sampling from the stockpile before application is acceptable, since the amount of manure is low and less likely to be highly variable compared to large volumes of manure.

“Calculating application rates hinges on accurate measrement.”

Calculating correct application rates hinges on having an accurate measure of nutrient content. To do this, you not only need to sample your manure, but you also need to take a good sample that is representative of the manure applied.

Before you sample, you might want to consider these ways to improve the uniformity of the manure. For liquid systems, agitate the manure well before pumping, and use a tank mixer afterward to keep the solids and liquids sufficiently mixed throughout application.

When dealing with solid manure, composting is an excellent way to reduce bulk and improve the overall nutrient uniformity within the manure.

As a minimum, we recommend sampling annually for the first three years of operation, and then every three to four years or whenever manure management changes. Though sampling more often, every year or at each time of application, will give you the best opportunity for accurate application.

Whether you are sampling liquid or solid manure, the key to getting a representative sample is to take many samples from the beginning, middle, and end of application or loading/pumping. Taking 20 small samples and mixing them together is better than taking three larger samples. You might even want to consider collecting separate samples by load or manure storage site.

Proper manure sampling will help you reduce nutrient uncertainty and make the best and most accurate application possible. Lack of uniformity does certainly present a challenge, but it doesn’t have to become a great manure mystery.

And, with the right tools, hopefully it won’t become one. •

OPTIONS TO FIT YOUR ALLEY OR CROSS GUTTER

Works around the clock year after year, just like it did on day 1.

I WANT AN EFFICIENT DRIVE UNIT WITH EASY OPERATION, THAT REQUIRES MINIMAL MAINTENANCE. Don’t get stuck in the same old, same old. Place your drive unit where you want it. Our unique design also moves the drive unit laterally which reduces wear to a minimum. Elevating the drive unit over the cross gutter allows easy access for maintenance and keeps the working area clean.

• Irrigation & Drought Prevention Equipment • Municipality Equipment • Zimmatic Pivot Dealer • Water Transfer