CAD REPORT

CYBERSECURITY

Cybersecurity

MOTION CONTROL

Case

Cybersecurity

Case

MISUMI components can cover up to 90% of your bill of materials with material certification available upon request.

Choose the material, surface treatment, dimensions and alterations of a component, and see instant pricing and lead time. Configured components have a unique globally-recognized part number, allowing easy re-ordering anywhere in the world.

Learn more about MISUMI’s offerings for Medical Industry.

14 Off-Road EV Scooter

Regina, SK-based LyteHorse Labs’ all-electric vehicle designed to tear up treacherous terrain

17 Power Up

DC for Industry promises to super-charge the benefits of green power

20 Five tips to secure OT systems against cyberattacks

Cybersecurity professionals provide their best practices for protecting industrial networks

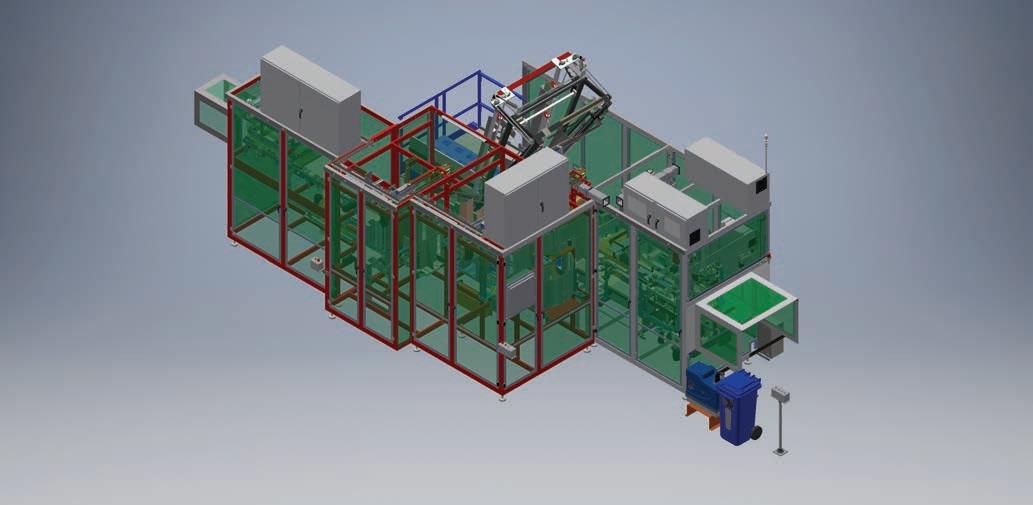

23 Pizza Packer

Brenton M2000 case packer does the work of three machines using Beckhoff XTS transport system

6 Design News

UBC researchers cook up cleaner, more powerful jet fuel and other engineering stories 10 CAD Report

2022 release of Siemens’ underappreciated Solid Edge software boasts 500 enhancements

26 Idea Generator

The latest in industrial products including fluid power, motion control and industrial networking

In November, Ontario premier Doug Ford announced the province would shoot for an ambitious target of producing 400,000 zero emission vehicles by 2030. The plan is an about-face for the premier, who nixed an EV rebate after taking office in 2018, as well as efforts to build charging stations.

In addition to automaker mandates to produce hybrid and battery electric vehicles, the initiative also pushes building a battery assembly plant and an increase Ontario-made auto part exports. However, charging infrastructure and/or rebates still aren’t on the table but may be warranted in the future, he said.

The supply-side nature of the plan isn’t surprising, considering that the initiative isn’t focused on selling those vehicles inside the country. Barring 2020, Canada locally produces 2 million vehicles per year on average; of those, approximately 75 percent are exported to the U.S.

It’s also no coincidence that Premier Ford’s announcement came one day before Prime Minister Trudeau, Mexican President Obrador and President Biden met for the first “Three Amigos” trade summit since 2016. At the top of Canada’s grievances is a multi-tiered EV tax rebate within Biden’s massive US$1.75 trillion social and climate spending bill. If the rebate portion is enacted unchanged, it would heavily favor EVs built with unionized labor by Detroit’s Big Three automakers.

While not an immediate blow, the EV rebate would effectively make any nonUS built EV up to US$12,500 more expensive, thereby progressively strangling Canada’s (and presumably Mexico’s) auto industry as the market transitions away from the internal combustion engine.

Expected to pass the House, the overall bill will face opposition in the U.S. Senate and it seems unlikely the EV incentive within it will remain in its present form. For one, U.S. auto makers would have to reneg on the sizable commitments made to labor unions to invest in EV production in Canada.There’s also the impact the rebate would have on their Mexican assembly plants that would become useless for EV production. To boot, Tesla’s plants aren’t unionized and all the foreign car makers will likely retaliate if they’re effectively priced out of the U.S. market.

All in all, this seem more like political theatre than trade policy. To offset its flagging poll numbers, the democratic party needs a big win out of Build Back Better as it heads into the 2022 mid-term election, especially with working class voters in purple states like Michigan. Until then, the democrats need to be seen backing the rebate as-is; altering it to align with trade realities will be left to others. |DE

MIKE MCLEOD Editor mmcleod@design-engineering.com

Editorial Board

DR. ALAIN AUBERTIN

Vice President, Business Development and International Affairs, Canada Consortium for Aerospace Research and Innovation in Canada (CARIC)

DR. MARY WELLS, P.ENG

Dean of the College of Engineering and Physical Sciences, University of Guelph; Chair of the Ontario Network for Women in Engineering

AJAY BAJAJ, P.ENG

President, Rotator Products Limited; Past President and Board Member, Power Transmission Distributors Association (PTDA)

JOHN LAMB

Regional Sales Manager, Wainbee Limited

DR. ISHWAR PURI, P.ENG

Dean of the Faculty of Engineering; Professor of Mechanical Engineering, McMaster University

NOVEMBER/DECEMBER 2021 Volume 66, No.6 design-engineering.com

READER SERVICE

Print and digital subsciption inquiries or changes, please contact Beata Olechnowicz, Audience Development Manager

Tel: (416) 510-5182

Fax: 416-510-6875

Email: bolechnowicz@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SENIOR PUBLISHER Paul Burton (416) 510-6756 • pburton@annexbusinessmedia.com

EDITOR Michael McLeod (416) 442-5600 ext. 3231 mmcleod@design-engineering.com

ACCOUNT MANAGER Wendy Serrao (647) 628-3610 • wserrao@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett (416) 829-1221 • ifawcett@annexbusinessmedia.com

ACCOUNT COORDINATOR Cheryl Fisher (416) 510-5194 • cfisher@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Design Engineering, established in 1955, is published by Annex Business Media, 6 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

Printed in Canada

Publications Mail Agreement #40065710 ISSN: 0011-9342 (Print), 1929-6452 (Online)

Subscriber Services: Canada: $57.50 for 1 year; $92.50 for 2 years; $10 for single copy.

Outside Canada: USA - $140.50; Overseas - $151.00; $10.00 for single copy.

All prices in CAD funds. Add applicable taxes to Canadian rates.

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Officer: privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

©2021 Annex Business Media. All rights reserved. DE receives unsolicited features and materials (including letters to the editor) from time to time. DE, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. DE accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. DE is indexed in the Canadian Business Index by Micromedia Ltd., Toronto, and is available on-line in the Canadian Business & Current Affairs Database.

No matter how many “ings” your process has, Productivity PLCs can handle them all while providing substantial cost savings. Whether you’d prefer a single controller for complete end-to-end control or a segmented control system with multiple controllers, the scalable Productivity PLC family has what you need for less.

This family offers three series of PLCs each with different I/O capacities but all using the same FREE advanced programming software, so you can easily scale your control hardware up or down depending on the application.

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

A team of researchers at UBC Okanagan say they’ve potentially created a cleaner yet more powerful aircraft fuel by doping it with graphene nanomaterials. Specifically, the project is studying the ignition delay, burn rate and speed at which microscopic graphene oxide particles and fuel separate into smaller particles.

“Most people have a general understanding of the composition of gasoline and jet fuel, and that it is a mixture of many hydrocarbons,” said lead author and UBCO doctoral student, Sepehr Mosadegh. “But they may not think about how combining these with nanomaterials and burning them can result in dramatically more powerful and cleaner engines.”

Based out of the UBCO School of Engineering’s Combustion for Propulsion and Power Laboratory (CPPL), the research project is collaborating with Ontario-based ZEN Graphene Solutions to study how the mixture could improve jet fuel’s combustion properties.

Using high-speed cameras and microscopy analysis, the researchers discovered that adding microscopic graphene oxide to ethanol improved the fuel’s burn rate by about eight percent. In addition, the researchers say the added nanomaterials alter the heat transfer and the fuel’s evaporation rate, impacting the overall burning rate.

To date, the team has published the results for doped ethanol, but expect to have promising results for other liquid fuels such as jet A and diesel. Their research is funded by the NSERC and appears in the journal, Combustion and Flame. ok.ubc.ca

According to the The Global E-waste Monitor 2020 report, more than 50 million tonnes of electronic waste is produced globally each year, but less than 20% of it is currently recycled world-wide, meaning that US$57 billion in precious metals (e.g. gold, silver, copper, palladium) are mostly discarded.

“This partnership represents a significant milestone for The Royal Mint as we reinvent for the future as the home of precious metals in the UK,” said The Royal Mint’s chief executive, Anne Jessopp. “The potential of this technology is huge – reducing the impact of electronic waste, preserving precious commodities and forging new skills which help drive a circular economy.”

Alberta-based Excir’s technology recovers 99% of gold from e-waste within in seconds.

To confront this problem, the UK’s Royal Mint announced it has contracted Alberta-based Excir to use the clean tech start -up’s patented process to extract and recycle gold and other precious metals from electronic waste. According to the Canadian firm, its technology can selectively recover 99%+ of gold from e-waste, such as circuit boards, within in seconds.

According to the mint, initial use of the technology has produced gold with a purity of 99.99% and engineers are currently working to scale up Excir’s material processing and chemical extraction process to mass production levels.

When scaled up, the Royal Mint says it will be able to recover precious metals, including p otentially platinum, palladium, silver and copper, at room temperature at its site in South Wales, rather than exporting e-waste off-shore to high temperature smelters. www.royalmint.com

www.excir.com

ElectraMeccanica Vehicles Corp., the B.C.-based designer and manufacturer of the

single-seat SOLO electric vehicle, announced it has begun its fir st commercial deliveries, during an event at its Los Angeles service and pre-delivery inspection f acility.

Initial deliveries were provided to early consumer reservation holders and the first fleet customer s, including Skechers USA, Faction Technology, Cyber Yogurt and the Southern Califor nia Ruby’s Diner franchisee.

ElectraMeccanica says it will continue to ramp up production of the SOLO via manufacturing partner, Zongshen Industrial Group, while continuing work on the company’s U.S. Assembly and Engineering Technical Center in Mesa, Arizona. The production facility remains on track to finish construction by the summer 2022, at which time it be able to manufacture up to 20,000 vehicles per year, the EV maker said.

“As the first production SOLOs hit the road, I was reminded that bringing a revolutionary, production-ready EV to market is no small feat – par ticularly one as unique and differentiated as our three-wheeled, single-seat SOLO,” said Kevin Pavlov, CEO of ElectraMeccanica. “As we look ahead, we will

eMatrix Energy Systems’ modular battery pack system.

continue to ramp production to meet the ever-growing demands for right-sized EVs with a practical everyday use and helping to create sustainable value for our customers and shareholders alike.”

www.electrameccanica.com

Linamar announced it has entered into an exclusive manufacturing and licensing agreement with Michigan-based e Matrix Energy Systems, Inc. to gain access to the company’s modular battery pack technology. The auto parts maker says it has also taken a minority equity position in eMatrix ownership.

eMatrix’s modular battery pack system uses standard battery cells packed in a novel design that can easily be assembled to scale, the company says. The battery module is controlled by eMatrix’s battery management system that’s designed to optimize thermal performance.

“This partnership is the first major implementation by our eLIN Product Solutions Group and our first expansion into the highly opportunistic power storage segment,” said Linamar CEO, Linda Hasenfratz. “eMatrix are leaders in energy storage

systems for electr ified solutions and we are very excited for the value their products will bring to Linamar’s customers and stakeholders.”

www.linamar.com www.ematrixenergy.com

Porsche announced the sales launch of its 3D-printed bodyform bucket seats. Available in various Boxster, Cayman and 911 models, the seats feature 3D printed cushions and backrest surfaces available in three different rigidity grades, to allow drivers to customize them to suit their preferences.

“Seats adapted to individual drivers have been available for a long time in professional motorsport. Now Porsche also offers a road-approved customization with different rigidity grades as standard,” said Porsche test driver, Lars Kern. “During the initial test drives, I was impressed by the ergonomics; the slightly lower seat position and improved thigh support are similar to what you get from a seat in a racing car.”

According to the car maker, the seats feature a sandwich construction. The base support layer is made from expanded

polypropylene clipped to a mixture of polyurethane-based materials additive manufactured to produce the comfort layer. The seat’s outer skin is made of Race-Tex, a non-slip material that is perforated to provide passive ventilation.

Window panels in the seat expose full-color sections of the 3D-printed lattice structure, available in black, red and yellow. Eventually, Porsche says it plans to increase customization to allow customers to order seats that are 3D printed to their individual body contours. www.porsche.com

Detroit-based automotive robotics and automation startup, RoboTire, announced the close of its $7.5M Series A investment round. Led by The Reinalt-Thomas Corporation (aka, Discount Tire and America’s Tire), the round’s other investors include Automotive Ventures, Detroit Venture Partners, 640 Oxford Ventures and several angel investors.

Founded in 2018, RoboTire’s system introduces manuf acturing-level robots to traditional automotive repair shops, allowing them to change tires in under 15 minutes, the company says.

“This is a pivotal moment for RoboTire and sets us on a path to further transform vehicle maintenance,” said RoboTire founder and CEO, Victor Darolfi. “Our focus is to revolutionize the way tires are changed, and collaborating with Discount Tire—an iconic automotive and tire industry leader—will make our innovative technology more widely available to consumers who need both speed and service as part of their daily lives.” www.robotire.com

Researchers at the University of Victory announced the launch of a 9-foot tall wind data gathering buoy off the B.C. coastline near

Trial Island.

Over a six-month period, the 5,500 kg instrument will use a wind turbine and a 3D laser-scanning system, as well as meteorological and oceanographic sensors, to gather live data about wind speed and behavior.

The hope is the project will fill a knowledge gap that has prevented offshore floating turbines from being used more widely.

Constructed by Sidney, B.C.based AXYS Technologies, the bouy is the brainchild of the university’s Pacific Regional Institute for Marine Energy Discovery (PRIMED) lab, headed by UVic mechanical eng ineering professors, Brad Buckham and Cur ran Crawford.

According to Buckham, wind energy is gaining ground as a power source, but offshore turbines haven’t experienced the same rate of adoption as landbased turbines. This is mostly due, he says, to a lack of data needed by industry to develop accurate, certifiable and insurable technologies. |DE www.uvic.ca

Designing efficient systems involves much more than simply understanding a few basic principles. There is a true art to balancing the specific requirements of an application in order to achieve the desired goals in the best possible way. Help us understand the unique needs of your application and together, we’ll develop something that surpasses what any of us could have done alone.

Contact your distributor to learn more, or clippard.com to request a free catalog and capabilities brochure.

2022 release of

RALPH GRABOWSKI

In a Siemens CAD universe, NX sits at the center, while Solid Edge is an often overlooked satellite. It’s just as powerful as mid-level MCAD rivals Solidworks and Autodesk Inventor, yet lacks the mindshare of its competitors.

Part of the problem stems from its history of bouncing between homes. It was born at Intergraph, adopted by Unigraphics, passed along to EDS, sent back to UGS and now calls Siemens its home.

Another issue, as I see it, is that Solid Edge’s powerful hybrid Synchronous Technology is saddled by a perplexing (and initially over-hyped) combination of smart direct and parametric modeling. This feature may be its biggest differentiator from competitors, but the typical machine shop designer hasn’t shown much enthusiasm for this.

Yet, if it’s stability you want, then Solid Edge is the one for you. Autodesk and Dassault are bedazzled and distracted (and so far failing) in moving their mid-range MCAD offerings fully to the cloud. Siemens, however, repeatedly makes it clear MCAD belongs on the desktop, full stop.

Sure, ancillary functions, like co-designing and PLM, are suitable for running on the cloud. And so Siemens offers Solid Edge users cloud-based products like Xcelerator Share for collaboration and Teamcenter X for product lifecycle management.

Solid Edge 2022 shipped in October and when I saw what’s new in this latest iteration, I felt like I was back in the glory days of CAD. Here was a release claiming over 500 enhancements, a far cry from other CAD systems that, these days, might be satisfied by offering customers a third way to view symbols.

Let me walk you through some of the new and improved functions I found

most interesting.

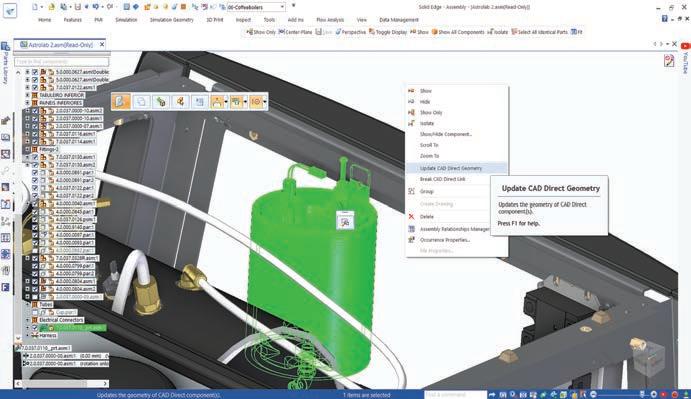

CAD Direct places parts and assemblies from NX, JT and Solidworks files into Solid Edge models. Copies of the foreign b-reps are stored in an intermediary format called “internal components” within a Solid Edge assembly file. There are no external files, which solves that particular data management problem.

To the user, the imported part/assembly looks and acts like a Solid Edge one, in that mates, constraints and so on work with the native assembly.

For example, image you’re designing a locomotive and you’ve sourced an electric generator from another supplier. You don’t need to edit it since it’s design is already done. You just need to place it so that you can connect its bolts and electrical connections to the rest of your locomotive. Should the supplier update the generator’s design,

the version in your locomotive design changes as well.

In the Pathfinder model tree, these foreign models are tagged as external. Nevertheless, a dynamic link is maintained if possible, so that when changes are made to the model in the originating CAD system, they are reflected in Solid Edge.

Dan Staples, Siemens VP of mainstream engineering, told me that more MCAD systems will be supported by CAD Direct in the future. For now, it works most reliably with Parasolid-based CAD programs, as they use the same geometr ic kernel as Solid Edge.

To catch up with its competitors, Solid Edge has gained added support for point clouds in the 2022 release. In the past, points were displayed as triangles or b-reps. Now, they remain points and an assembly in Solid Edge

can have multiple point clouds. In addition, components can be placed among them and measurements can be taken between solids and point clouds. A cloud of millions or billions of laser scanner-generated points also carry color and x-y-z data.

“Rendering them, as they are being rotated at high speed, is secret sauce stuff,” Staples explained.

Convergent Modeling is the technology through which Solid Edge lets you work with b-reps (solids) and meshes (facets) at the same time. Meshes are typically imported from scans and nonCAD sources, as they are in 3D gaming development software. In Solid Edge 2022, you can scan a handle in 3D, for example, bring it into Solid Edge and then cut a hole into it using Boolean subtraction of solids.

“The big nut to crack was Booleans between b-reps and facet meshes, but the result [in the past] was facets; now, everything stays in their form,” Staples told me. In other words, meshes stay

meshes, solids stay solids. (Dassault Systems has something similar that it calls Polyhedra.)

Some mesh elements can be converted outright to equivalent solids. When

it comes to exporting hybrid models, however, solids are still converted to meshes. “You’re never complete, but I’d say we’re very close to completion,” said Staples.

Related to this, Solid Edge Simulation gains hydrostatic pressure simulation. It now performs analyses on mesh models and is better at re-meshing frames prior to stress analysis.

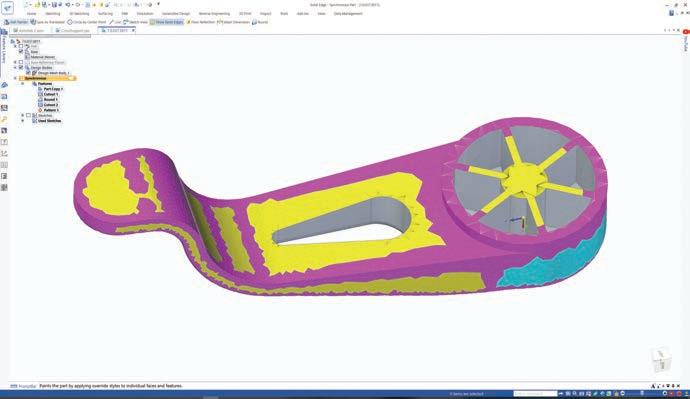

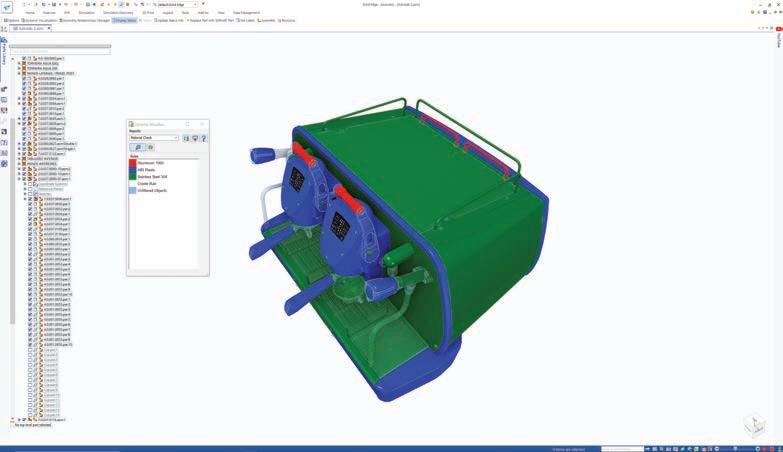

Dynamic Visualization creates visual reports by colorizing models according to user-defined rules. For example, you can color all components in red that are from a specific supplier, designed by a specific employee or made from a specific material, such as copper.

Parts are filtered, colored and hidden according to rules that you write and they can be shared with others.This lets you see if the assembly is made from the correct materials, or search more easily for suppliers already being tapped for components in the model.

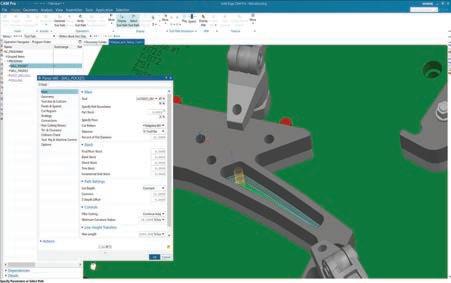

Free computer-aided manufacturing is now available to all Solid Edge 2022 users on subscription. The CAM Pro 2.5-axis milling software runs as an external program, but is associative with Solid Edge models. It automates tool path creation and generates machining visualizations. New in 2022 is adaptive tool paths.

Not free, but also new to Solid Edge 2022, is the addition of Simcenter Flomaster from Siemens. It extracts geometry from your model and then simulates 1D fluid flows through full and partial networks of pipes. In the demo I saw, it handled pressure pulses from compressors.

Other improvements include Solid Edge opening very large assemblies ten times faster than before. It does this by first showing just a 3D image of the assembly, which you can rotate and turn the visibility of parts off and on. To edit parts, you select just the ones to be loaded.

Synchronous Technology has gained the Radiate function.With it, you make changes to the diameter of shafts, with holes and slots changing automatically to accommodate the new size.

Rules-based configurators are used to design variations of products, based on a single model. Solid Edge 2022 embeds a new Design Configurator (not based on RuleStream or Driveworks) that stores configuration rules with the CAD model.

Xcelerator Share is much like using a CAD-oriented Dropbox for sharing files and commenting on them. It is similar to collaboration offerings from other CAD vendors, and it runs on any computer or tablet, including Chromebooks. And, similar to PTC’s Vuforia, it includes augmented reality for placing Solid Edge models visually in the real world.

Never mind the cloud. Solid Edge benefits from a company with deep pockets. It makes advances in its high-end NX software but then spins them off to Solid Edge. On top of that, Siemens uses its own CAD software in its engineering projects. No other CAD vendor can make that claim. As a result, Solid Edge offers functions that are otherwise tough to program and that many of its direct rivals dream of offering some day. |DE solidedge.siemens.com

Ralph Grabowski writes on the business of CAD on his WorldCAD Access blog (www. worldcadaccess.com) and weekly upFront.eZine newsletter.

We are spending more time indoors, at home and at work. Unfortunately, our homes and offices trap harmful pollutants and allergens like CO2, tobacco smoke, pet dander, pollen, volatile organic compounds (VOCs,) dust, dust mites, mold spores, viruses, bacteria, and other harmful contaminants.

The ebm-papst RadiCal © impeller with EC technology offers the perfect range of high performance to whisper quiet operation while consuming less energy in air purification products. For more information on RadiCal © or ebm-papst EC technology, please contact us at: sales@us.ebmpapst.com

Regina, SK-based LyteHorse Labs’ allelectric ATV designed to tear up treacherous terrain.

A new ride is quickly gaining traction in the growing electric vehicle market. Initially crafted as a potential alternative to golf carts, designers at LyteHorse took the concept and created an electric stand-up ATV that can be used in multiple work and recreation environments.

S askatchewan, Canada-based LyteHorse Labs designed the electric stand-up all-terrain vehicle, which has a maximum range of 129 kilometers (80 miles) and the ability to reach a top speed of 64 kph (40 mph).

In addition to its obvious recreational appeal, the company has developed the stand-up ATV to suit utilitarian applications, including law enforcement, militar y, fire and rescue, warehouses, airport and border security.

“The form factor of LyteHorse vastly re-imagines the power and utility of the ridden horse, with future-proof materials, technology and performance that will change the way electric mobility can be applied,’’ said Allen Bonk, CEO of LyteHorse Labs.

To create the original prototype for this vertical riding machine, Brad Bonk, Allen’s brother and co-founder of LyteHorse, used an electric motor from a washing machine, battery and controller attached to a chassis.The brothers tested it on the golf course.

“It was way more fun than golf carts,’’ Allen said. “It soon became obvious that there were significant utility applications for it, and there was a definite gap in the marketplace for an easy access, stand-up ATV.”

The Bonk brothers realized the utility vehicle could have broader applications when they discovered it could tow a two and a half-ton SUV.

BY THOMAS RENNER

“After taking it to the golf course, Brad and I decided to hook up the prototype to my SUV to see if it could pull the car,’’ Allen said. “And yes, that crazy little scooter ended up towing a 2.5 ton SUV across the car park.”

The production LyteHorse has towing capacity of 1,500 pounds, the company says. That extra capacity allows it to carry additional battery packs, which boost the vehicle’s travel range to 579 kilometers (360 miles), if needed.

The LyteHorse is another example of the expanding electric mobility market. According to a report from McKinsey, 2020 was a banner year for electric-vehicle sales. In the fourth quarter, sales of EVs grew 60 percent globally and 80 percent in China. In the United States, EV sales increased nearly 200 percent between the second quarter of 2020 and the second quarter of 2021.

LyteHorse Labs stands poised to tap into the emerging EV market, in large part due to the range of applications for which its product can be used. More than 20 mobility related industries can be made easier and better with LyteHorse, Allen said. In addition, units can also be customized with racks, lighting and other features, depending upon the application.

While it took several years and many iterations to develop the final product, Allen Bonk believes the LyteHorse will be a game-changing ride for the electric mobility market.

“It has definitely exceeded all expectations,” he said. “The machine is a beast and incredibly robust. The applications are endless.”

Brad Bonk has more than 40 years

The all-electric LyteHorse ATV boasts a top speed of 65kph and a range up to 129 kilometers.

experience building and repairing motorcycles, cars and hot rods. When the brothers realized the machine they were designing had such a wide range of applications, they developed different iterations of the LyteHorse.

“There was a lot of trial and error,’’ Allen said. “The steering for a stand-up vehicle is extremely complex. Making the suspension work in concert with the steering geometry proved to be very challenging.”

The engineering team designed different models for the various markets. The model called the “LH2” is a twowheel drive version that can be used for recreation, running errands or moving

about a resort community. The “LH4” is a four-wheel drive unit that provides maximum stability and traction in the most treacherous terrain. It can be used in more r ugged settings, such as hunting areas.

Each unit weighs about 317kg (700 pounds), and operates quietly. Unlike traditional all-terrain vehicles, there is also no scheduled maintenance. In the LH4 model, four independent electric motors power the vehicle, providing up to 24,000 watts of peak power.

To supply that power, the company even designed its own battery pack, the “LytePack,” a 2.4 kilowatt hour pack that provides 20-25 miles per pack. Each LyteHorse can hold up to four packs.

According to the company, its in-house built battery pacts last for up to 2,500 cycles before needing to be replaced; that’s nearly seven years if charged daily. The pack also allows the LyteHorse to operate in temperatures ranging from 40°C (110°F) down to -20°C (-4°F).

Beyond its obvious recreational uses, the LyteHorse is also highly configurable to suit a number of industry applications, including police, fire and search and rescue.

One of the critical differences between the LyteHorse and other ATV’s is the product’s stability. For one, it’s wheelbase is offset which helps make it far more stable than scooters and other electric off-road type vehicles, where riders can easily lose their balance and risk injury. In addition, the vehicle features a traction control system (Vari-Track) which enhances lateral stability, especially in off-road conditions.

“It’s very different from a traditional ATV,” Allen said. “It has no drivetrain, no scheduled maintenance and zero sound emissions. Also, it is safer as the LyteHorse tipping point is 67 degrees compared to a typical quad, which is about 37 degrees.”

Each LyteHorse includes multiple parts from igus, the Germany-based manufacturer of motion plastics. “We used igus anywhere bearings would normally have been used,’’ Allen said. “Suspension arms, steering

post, swing arms and suspension posts. The igus bushings have a strong track record of reliability and performance.”

The self-lubricating igus bushings are an important feature of the LyteHorse, as they can stand up in all types of challenging environmental conditions.

While designing the LyteHorse, the company’s engineers initially tested units with steel and nylon bushings, but ultimately selected igus bushings. Made with iglide J material, the bushings provide low wear against different shaft mater ials and low moisture absorption and good chemical resistance.

“We couldn’t achieve our requirements with conventional bearings because they are susceptible to dirt, salt water and extreme temperatures,’’ Allen said. “In the end, the flanged bushings we used convinced us that they were the best choice in terms of performance, durability, reliability and cost.”

He added other bearings proved to be too bulky and were prone to failure. “The durability and self-lubricating

properties were critical, but they also provided ease of integration,’’ Bonk said.

LyteHorse Labs is working with Detroit-based tier 1 automotive components supplier and engineering ser vices firm Mayco International as its production partner.

Currently taking reservations through its website, the company announced recently that it had passed 120 units pre-sold to customers in

30 U.S. states and in eight countries outside North America. It anticipates delivery of those units in the first quarter of 2022. They are also in discussion with distributors and expect dealers to engage early next year. |DE lytehorse.com www.igus.ca

Thomas Renner writes on machine design, engineering, construction and other industry topics.

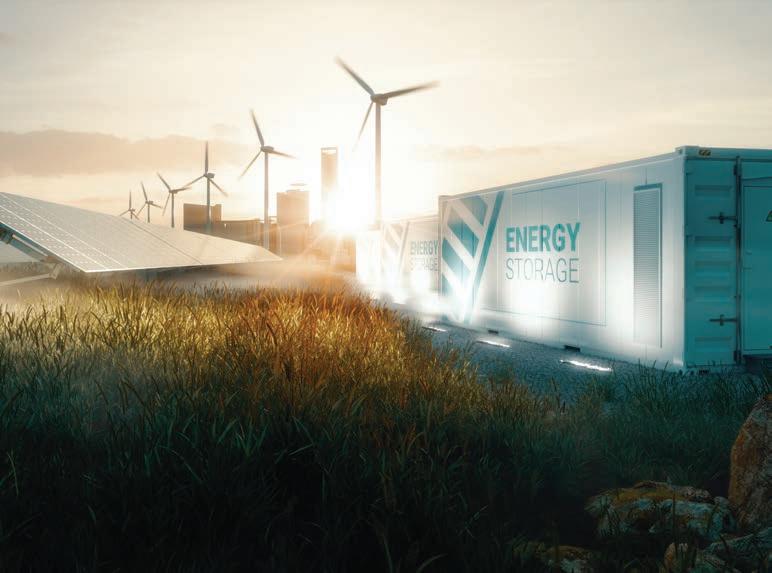

BY DAVID GERSOVITZ

For anyone passing the Whirlpool manuf acturing complex in central Ohio or the Honda Transmission plant downstate, the wind turbines dominating those properties make a powerful statement about industry generating g reen power for its operations.

Many more plants are generating solar power onsite. Globally, installation of photovoltaic (PV) panels by industry is outpacing solar uptake in the residential and commercial sectors. While some of that industrial solar output is sent to utilities to offset conventional power use, many other companies

are using it inside the plant.

That’s the case in manufacturing and processing, at breweries and candy factories, automakers, textile mills, distribution centres, and even cannabis grow-ops.

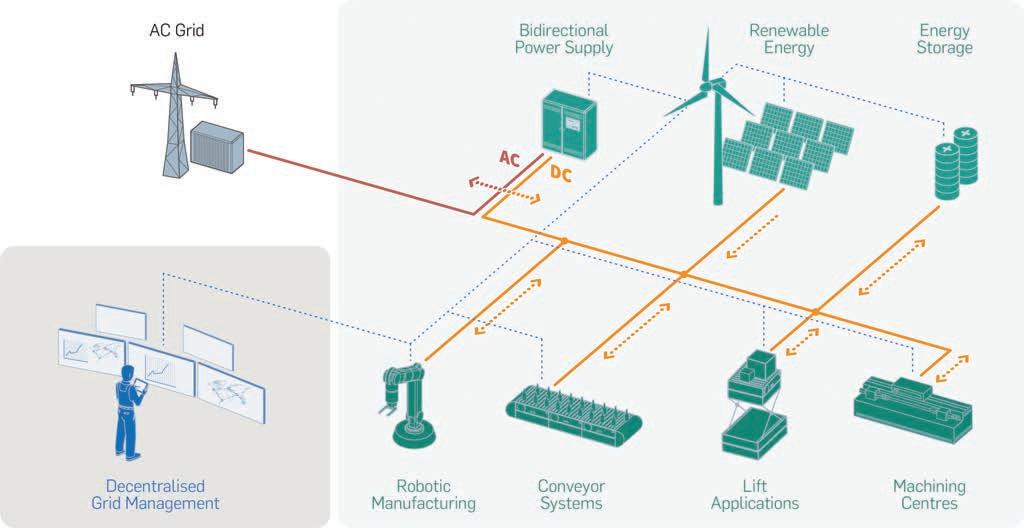

Wind turbines and PV panels generate direct current (DC). Companies integrating their own DC power into operations are functioning semi-autonomously or even fully independent from their local utility’s alternating current (AC) supply,

cutting the cord or, at most, keeping the latter as backup.

Soon, it will be possible to further autonomize by replacing a facility’s internal electricity infrastructure with a DC smart grid to power most production systems. The technology, often called DC for Industr y, is being developed globally.

The headline benefit of DC for Industry is significant in-house energy savings, ranging up to 15% or more.There will be potential

integration with high level plant control systems and, of course, carbon footprint reduction. There will also be opportunities for lower materials and maintenance costs, even improvements in machine and process design.

DC smart grid research projects are identifying and testing DC topologies and infrastructure in real world conditions. The development of global standards has begun. For some companies, implementation will upend a century-old relationship with the utility power grid.

Early 20th century utilities established dominance by leveraging AC’s comparable advantage. Unlike DC at the time, AC could be stepped up to very high voltages, transmitted over long distances from huge generating complexes with little energy loss. It’s then stepped down to voltages suitable for running machinery or household appliances.

Though banished from the utility network, direct current never disappeared. It powers smart phones, flat-screen TVs, LED light strips and most anything battery-powered. In industry, DC-powered servo, stepper and other br ushless motors are relied on for many functions. However, wherever AC is converted to DC on a per-device basis, there is an energy loss, usually 5-20 percent, that adds up throughout a factory.

When a plant’s AC power supply is centrally converted to DC just once, however,

The headline benefit of DC for Industry is significant in-house energy savings, ranging up to 15% or more.

those losses are reduced. In data centres, estimates of the aggregate AC to DC conversion loss range from 15-30%. Japanese telecom NTT, for example, claimed a 15% saving at one centre by replacing AC to DC converters at each server with more efficient centralized inverters.

With greater ambition, much more will be gained. For those switching to a DC smart grid, a logical follow-on will be reconfiguring

a plant or warehouse as a microgrid and taking complete control of its energy supply.

Electric utilities generally operate with a built-in inefficiency, in that they often generate or contract for more power than they require. By contrast, a factory microgrid would promote maximum efficiency. Whatever it generates, stores or purchases (both when, how much and from whom) would be for the facility’s sole benefit.

A locally-managed microgrid that integrates DC or

hybrid in-feeds (for example, grid AC converted to DC and combined with DC generated on site or nearby) with high-capacity battery storage and an internal DC smart grid would offer improved power supply stability and security. It would de-peak operatio ns and provide a steady, well-buffered current. Its relative autonomy would reduce or eliminate utility-caused fluctuations, blackouts, brownouts or rationing calls.

Potentially, DC feeds can be precisely matched to specific applications. DC-Industrie, a German multi-stakeholder research project, was able to reduce the feed-in power to an automotive robotic welding cell from 450kw to 50kw by the seamless integration of high-speed storage.

A DC smart grid can be bidirectional, recovering and re-using braking energy from production equipment

like variable-speed drives or cranes. Waste energy recovery operates on essentially the same principle as regenerative braking on a car: Excess kinetic energy is captured when decelerating and stored for use when accelerating.

Recovered power can be stored for backup or peaking purposes or turned into a revenue stream. Germany’s DC-Industrie researchers estimate a reduction in AC to DC/DC to AC converters with recovery of braking energy can yield plant-wide savings of 6-10% in manufacturing.

The mater ials required for a DC smart grid are potentially less expensive since DC cabling has less copper and insulation. In addition, a DC smart grid doesn’t require as many converters and other electronic devices connected to the plant’s DC mains. Having fewer on-board components–like rectifiers, converters, line reactors, filters or brake resistors–will enable designers

to shrink some production equipment. High power electronics could be mounted closer to a motor, or even integrated into it, shortening or dispensing with expensive shielded motor cables.

Many existing components in plant electricity distribution are DC-ready or readily adaptable. Where new technology is required, development is under way at companies like Harting, which has focused on heavy duty connectors over its 76-year history.

With DC mains, the voltage can be slightly higher – in a range of 650-800V – than the typical 400-600VAC network. Sparking and arcing can occur if any industrial connector is disconnected under load, regardless of current type.

With AC connectors, passive deterrents such as blocking plates or padlocks are usually sufficient to prevent disconnecting under load. The risk is greater with direct current, so DC connectors will require an embedded actuator to perform active locking, says Norbert Gemmeke, Managing Director of Harting Electric GmbH.

“This can be by an autonomous interlock in the connector,” he says, “or by the connector’s integration into the control system of the plant or system technology.”

Since the invention of the water wheel, each energy revolution has produced profound changes in manufacturing. Steam age factories rose vertically, to locate machinery close to the central boiler. Energy was distributed via metal shafts and wide leather belts.

With mass electrification in the 1920s, those shafts and belts gave way almost overnight to electric cables and motors. Production spread out linearly. New plants adopted more space-efficient, single-story layouts. Conveyor belts, pioneered for mining, moved indoors.

In a similar fashion, DC for Industry in conjunction with megatrends like digitalization (IIoT/Industry 4.0), artificial intelligence, 3D printing and field-to-cloud deterministic Ethernet will alter how things are made and processes controlled.

In the larger societal context, DC for Industry can help North American plants face energy uncertainty.

Questions abound, such as, where will the additional electricity for a net zero carbon economy come from? Can the continental grid system adapt to a post-carbon future?

Right now, the economics are bending towards renewables and locating them close to where the power is needed. Solar PV costs have plunged while panel efficiency keeps improving. The same is

happening to large-scale battery storage. DC for Industry, as a standalone solution for improving internal energy efficiency or as part a microgrid, will provide adopters with a tool to reduce or even eliminate supply concerns while improving their competitive position. |DE www.harting.com

This article was submitted by Harting.

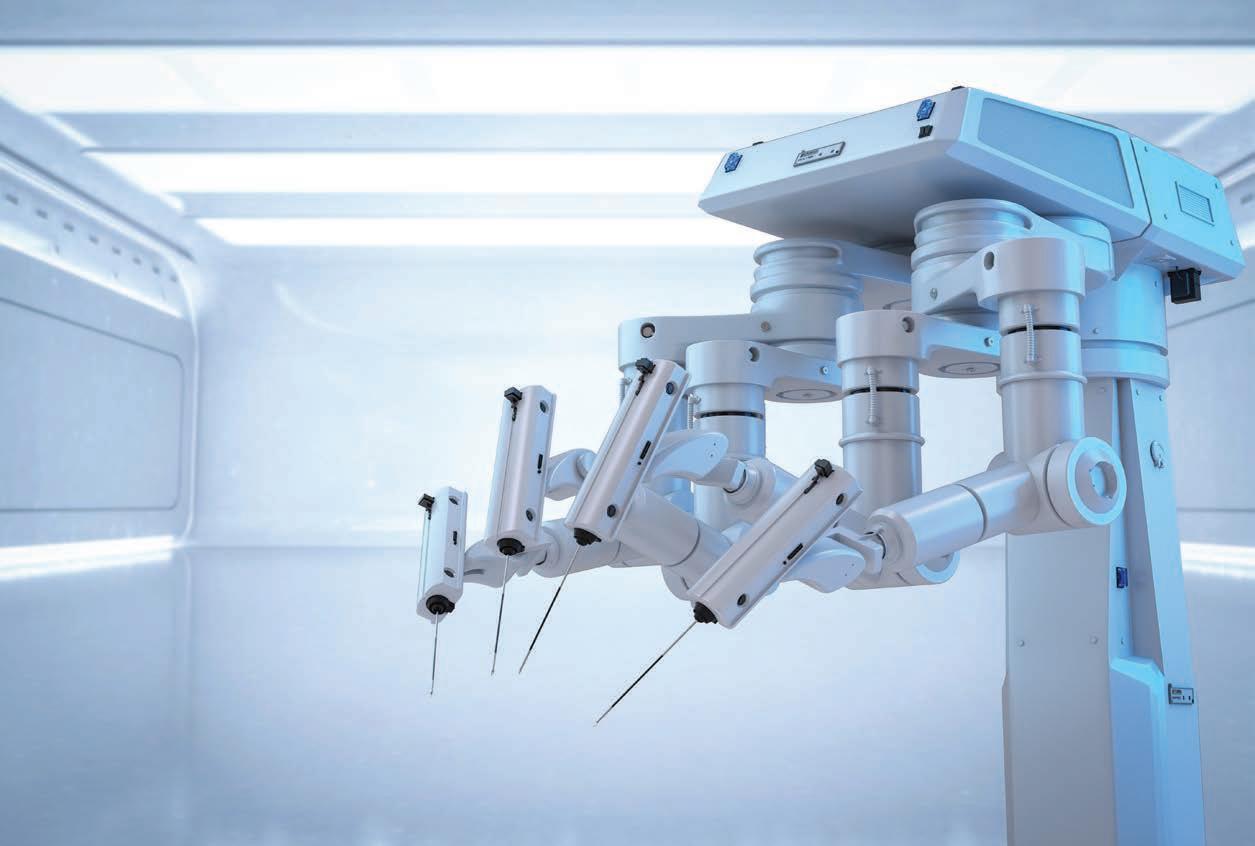

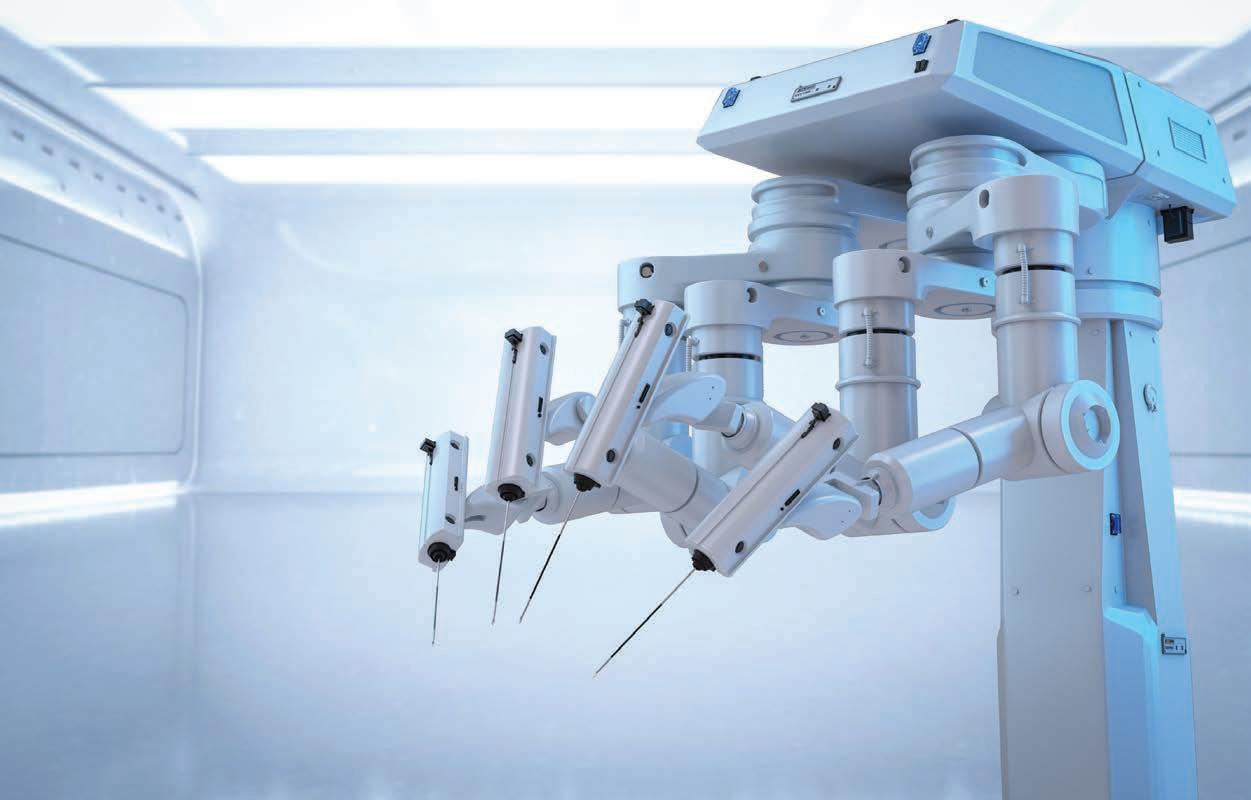

The Life Science industry draws on a wide range of technologies, services and products. While the objectives within each sector may differ, the need for innovation and rapid development is critical for companies industry-wide. Festo delivers on both fronts. With our team of highly specialized engineers and a vast array of customer resources, we produce tested and proven product solutions that help you meet your performance objectives while optimizing time-to-market.

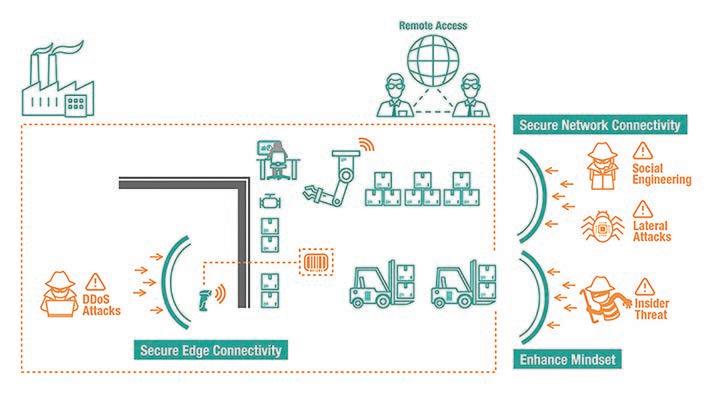

Looking back on 2021, it’s not surprising that cybersecurity-related keyword searches have increased in popularity.

A Deloitte and MAPI Smart Factory Study found that 4 out of 10 manufacturers surveyed reported having exper ienced security incidents in the past 12 months, with 86% of these stating that their industrial operations had been disrupted.

As the OT/IT convergence trend continues to gather pace, there are several attack surfaces emerging in industrial control systems. Although some of these are known vulnerabilities, there are also some that are unknown.

Therefore, everyone from management to each individual user needs to join forces to enhance industrial cybersecurity from the edge to the cloud. This article will present practical tips recommended by industry exper ts to help organizations start their cybersecurity journey.

Typically, industrial operations include a variety of legacy devices that are becoming increasingly vulnerable, as field networks are no longer always air gapped. In an ideal world, legacy equipment would be replaced with advanced solutions that have security features embedded into them.

However, budget restraints and the requirement that industrial operations not experience downtime, frequently leads to a mixture of old and new equipment operating together.

When this scenario arises, it’s important to have a security-hardened n etworking device that can connect to legacy devices. To ensure that secure-by-design methodology, it is advisable to check that networking devices adhere to security standards such as those detailed in the IEC 62443 standard.

In addition, devices need to be set up securely. For instance, it’s advisable to disable any unused ports and ser vices to minimize available entry points for intruders.

Industrial Control Systems present novel cyberattack surfaces and require OT network specific measures to secure.

Once network nodes are configured securely, the next step is to segment the networks following a zone and conduit policy. Dividing the connected networks into segments reduces the risk of an entire network experiencing downtime due to a single network node being compromised. However, it’s also important to choose the right solutions to divide industrial networks into segments.

“Our customers understand it is not sufficient to protect an OT environment by simply placing an IT firewall in front of the OT network,” says Gary Kong, an OT security consultant with industrial automation consultancy, YNY Technology.

“However, this advice is frequently ignored, even though our customers are aware that an IT firewall does not have the capability to recognize industrial protocols, which allows cyberattacks to take place at the supervisory or process level,” he adds. “It is a very worrying and high-risk decision as it leaves the system open to vulnerabilities and intruders.”

Firewalls that are used as solutions in industrial control systems not only segment networks into separated network zones to achieve vertical protection, but should also include a deep packet inspection eng ine function to filter unauthorized packets without affecting operations performance.

The purpose of OT/IT network convergence is to collect data and transform it into valuable information. To simplify network convergence, one convenient option is to utilize cloud technologies, which have powerful data analysis capabilities.

The question then becomes how to best secure data access between OT and IT and from field sites to the cloud.

“OPC UA brings a huge amount of security principles along with it,” says Ninad Deshpande, Product Manager for Cybersecurity at B&R Industrial

Zero backlash. Jam-proof design.

• For applications in positioning & reciprocating motion

• Zero play –even during reversal

Uhing® Rolling Ring linear drives run on a smooth, threadless shaft that won't clog or jam. If the system is overloaded, the shaft simply slips instead of churning and grinding. The drive bearings are in constant contact with the shaft, even during reversal, thereby preventing backlash.

Example applications: metrology machines, material handling systems, spooling equipment, packaging & converting equipment. Many different sizes meet varying requirements for axial thrust & linear speed.

For more information call 1-800-252-2645

Email: amacoil@amacoil.com www.amacoil.com

Some models feature mechanical control over speed and travel direction. No programming or electronic controls are needed.

Automation. “This communication protocol not only features application and user authentication, but also offers a security mechanism that meets the three pillars of security: Confidentiality, integrity and availability.”

When using cloud technologies, remote access can pose a significant security concern. Increasingly, machine builders are leveraging cloud platforms to streamline machine maintenance. However, before you are able to reap the benefits, make sure your remote access is secure by using features such as data encr yption and a VPN, as this will help keep your critical assets secure.

Now that we have considered how to reduce potential attack surfaces from the edge to the cloud for connected industrial control systems, we will now focus on the people who operate these industrial systems and devices. Outsourced vendors, system integrators, and even remote service engineers are essential for daily operations, maintenance, and troubleshooting.

They also play an impor tant role to implement security policies. Any investment will become futile if these people lack cybersecurity awareness and don’t know how to leverage these technologies. To avoid this undesirable scenario, it’s important that everyone involved in industrial processes have the same mindset and attitude toward cybersecurity. Only when this has been achieved will the results become apparent.

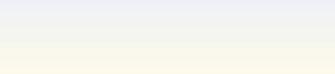

According to the security awareness pyramid, cybersecurity can be separated into a hierarchy of awareness stages. Commitment and suppor t from management form the foundation, which is followed by security programs and policies being implemented during the awareness building process. Taking security policies as an example, it is fundamental to define who has Read and Write access based on the security configurations.

However, when these policies are rolled out across an entire organization, it becomes a challenge to ensure everyone adheres to them properly. Facility managers often find implementing cybersecurity measures very

cumbersome, and subsequently they don’t ensure everyone follows the guidelines. Instead, they may end up doing things more akin to group level security, instead of ensuring each individual has their own unique login credentials, and this subsequently opens up new cybersecurity risks.

Thomas Burke, Global Director of Industry Standards for Mitsubishi Electric Automation, advocates increasing awareness and executing security policies.

“Make sure the end-user, make sure the suppliers and make sure employees really understand the different things that can happen and their important role in making sure that security is there,” Burke said during an episode of Moxa Security Talks.

Once awareness has been established and policies have been defined, employees will pay more attention to their system settings. It’s a complex task to examine all the systems at one time, but it’s never too late to get started. Performing a risk assessment helps define security priorities. From this position, it’s easier to identify and protect critical assets.

A good starting point is to examine configurations. If a large-scale network is being examined, it is recommended

The Security Awareness Pyramid separates cybersecurity into a hierarchy of awareness stages from management support at the base to the data security pinnacle.

to leverage visualization software to check the security settings and adjust the configurations where necessary.

The popularity of “cybersecurity” on Google Search will probably continue to increase in the coming year as more organizations tap into the benefits of digital transformation and OT/IT convergence. There is no way we will be rolling back to the days of the past.

Among the policies and practices cybersecurity professionals recommend, the first is to start with developing mindsets, formulating security policies, and systematically examining configurations. Once that groundwork has been set, the next step is to look at securing edge connectivity to protect the mixture of new and legacy systems.

It’s also important to remember to secure the network backbone that helps deliver the data that is required to achieve OT/IT convergence. It is also recommended to install industrial, OT-specific firewalls to consolidate vertical and horizontal protection. Last but not least, with the increasing demands on remote connections, hassle-free and secure remote access solutions save money and effort. |DE www.moxa.com

This article was contributed by Moxa

Among its varied and dire consequences, the COVID-19 pandemic has brought rapid change in the food and beverage industries. For example, millions prepared many more meals at home rather than dine out.

As a result, the industry experienced an exponential surge in demand for packaged foods, which threw supply chains into chaos. In turn, consumer packaged goods (CPG) manufacturers and contract packagers have had to dramatically increased their flexibility and agility.

This has also required

machine builder OEMs and automation suppliers to step up and deliver technologies that keep pace with constant disruption.

One such machine builder is Brenton, a packaging OEM that helps food manufacturers and packagers succeed in this challenging environment.

In addition to the general crush of demand for CPGs, experts at Brenton see a notable change happening in the contract packaging market.

“There has been a steady increase in new machine purchases from contract packagers recently,” said Brenton’s Vice President of

our main application area,” Grinager said. ProMach purchased Brenton in 1998 during one of the first waves of acquisitions by the conglomerate. As ProMach has g rown, so too has Brenton to become one of the biggest companies within the organization.

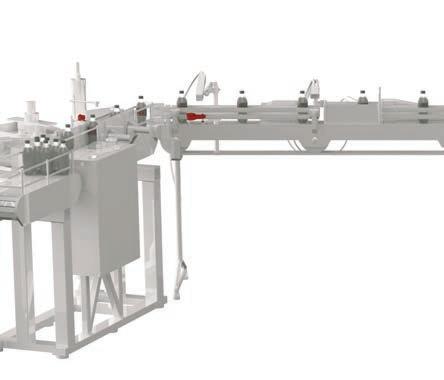

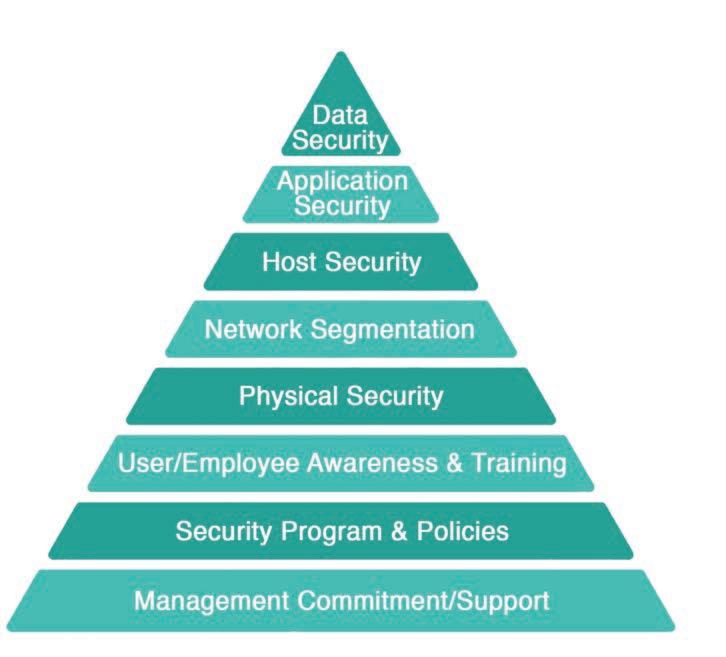

A major U.S. contract packager recently enlisted Brenton to take on a challenging case packing application for frozen pizzas. This fastpaced facility required machinery that could handle random timing infeeds and 26 different frozen pizza SKUs that were either boxed or simply shrink wrapped in plastic. This end user sought an OEM that could deliver high flexibility through more automated changeovers and a strong willingness to customize the equipment, especially on the infeeds.

Technology, Mike Grinager. “Now as much as 15% of our machine sales come from contract packaging applications.”

Brenton manufactures integrated end-of-line packaging systems and machines, specializing in case packing, cartoning, robotic palletizing and material handling for the food, beverage and pharmaceutical industries.

While Brenton pushes the envelope in packaging technology today, the company has been in existence for over 30 years.

“We started in the retort and retort packaging business and quickly got into case packing , which is now

“This application presented a challenge as we had to eliminate change-out flights for different sized products. Switching from 10-inch to 15-inch pizzas required time-consuming mechanical adjustments,” Grinager said. “We also had to deliver a high throughput of 15 cases per minute without product damage. This is complicated by the fact that pizzas on the line are stacked as many as 15 high in variable orientations while they speed down the packaging line.”

Brenton eventually decided that these demands necessitated a mechatronic linear transport system for the company’s popular M2000 – an intermittent motion, side-load case packer. “This led Brenton to the eXtended Transport System (XTS) from Beckhoff, which we found could adapt

to these product changes on the fly,” Grinager said. “Using XTS, we developed a pitch-less M2000 machine that expertly handles a completely random infeed timing of all pizza shapes, orientations and SKUs, including display-ready and bulk packaging.”

A true mechatronic solution, XTS offers linear motor characteristics with constantly cycling movers on an endless path. Movers can accelerate, brake, position and synchronize themselves on the fly with automatic collision avoidance provided in TwinCAT 3 automation software.

They can also take up absolute and relative positions, g roup and accumulate and create clamping forces in motion. In addition, movers can drive through curves and along straights, recover energy through regenerative braking and use return and outward paths for transport purposes.

Simple XTS motor

modules form a complete unit with the movers and guide rails. The desired geometries, lengths and radii are deter mined by the number and type of the components selected. As well as straight segments, module options include 22.5-, 45and 180-degree segments to enable circle, clothoid and S-curve designs.

The XTS movers contain magnetic plates that, together with the coils in the m otor modules, generate propulsive forces. Movers can move at high speeds with acceleration greater than 100 m/s2.

Mechanically robust encoder flags on the wireless movers communicate their position to the motor modules via the EtherCAT industrial Ethernet protocol.

The upgraded M2000 machine now features 5.5 meters of XTS track with 12 movers to control the frozen pizza infeed. “With the XTS, the M2000 can easily handle pizza stacks,

regardless of their weight, shape and orientation,” Grinager said. “That’s the beauty of this machine – it takes a stack of 15 shrinkwrapped circular pizzas and can quickly adapt to an infeed of pizzas already in square packaging – all with minimal changeovers.”

A series of buckets on the M2000 holds the pizzas as XTS takes them around a 180-degree corner to grip and stabilize stacks until they are loaded spine-first, spine-last or mixed. Using two movers in tandem, the XTS grips the buckets for fast and secure transport to case packaging steps.

The XTS can also relax and straighten the pack pattern when pushing in or out, and buffer product in front of the load station to give other production processes extra time if needed. “XTS g reatly reduces jams and downtime as it moves perfectly stacked pizzas into cartons,” Grinager said. “None of this was possible with other systems we evaluated.”

Brenton’s first XTS application had to handle a heavy payload for this application type considering the tall stacks of pizzas. In addition to their efforts with Beckhoff, Brenton worked with Bishop-Wisecarver in the U.S. to integrate a HepcoMotion GFX guidance system, which can accommodate high payloads.

Later iterations of the Brenton M2000 also include high-speed EtherCAT I/O systems with a variety of EL series I/O, including 8-channel high-density (HD) terminals.

“Interoperability between the EtherCAT I/O system from Beckhoff and other fieldbuses is very helpful,” Grinager said. “Establishing connectivity with EtherNet/ IP devices was easy for the Brenton Engineering team,” said Patrick Triemert, Application Engineer at Beckhoff USA. “However, with its extremely high-speed and synchronization, EtherCAT is the perfect bus for mechatronic applications like XTS.”

Brenton has experienced impressive throughput from the XTS-equipped M2000 machine. It’s now able to carton as many as 41 different SKUs and up to 27 cases per minute, or 140 frozen pizzas per minute.

The machine can also implement up to 26 different pack patterns, including more complex spine-tospine, display ready and commercial patterns at 12.5 cases a minute.

“One XTS-equipped M2000 can actually do the work of three conventional case packing machines,” Grinager said.

After eliminating many of the change-out steps, Brenton reduced the typical downtime required for remaining infeed changeovers

from around 30 minutes down to just five minutes with XTS. It also saved at least 200 hours of engineering time for the M2000’s infeed section and removed about 100 infeed parts, including chains, pushers and rotation mechanisms.

“These types of components add no value to the machine, so getting rid of them frees up the Brenton machine shop and assembly team to focus on other work,” Grinager said.

In addition to packaging markets, XTS is opening up new project types, Brenton says, particularly in pharmaceutical applications where they have even more potential to expand market share.

“XTS supports many new machine designs for projects that we might have passed on previously,” Grinager

According to Brenton’s packaging specialists, XTS greatly reduces jams and downtime as it moves perfectly stacked pizzas into cartons.

said. “We now have in our reach new concepts that are faster, more flexible and can reduce machine footprint by as much as 50%. Following our initial successes, Brenton is also researching XTS Hygienic for washdown applications in food manufacturing

and the XPlanar flying motion system for the most challenging material handling requirements in the industry.” |DE brentonengineering.com beckhoff.com

This article originally appeared in Beckhoff’s PC Control magazine.

Clippard introduced its Cordis flow controller, which uses a fast-reacting mems technology sensor upstream from a

proportional valve. The controller is capable of a 50:1 turndown ratio, 50 ms response time and ≤25 mV resolution. It also offers the option of a DR-2 regulator for accurate and precise pressure control. Unlike other mass flow controllers that require a

30-minute warm-up time, large differential pressures, and limited flow ranges, Clippard says the Cordis requires less than one minute warm-up, its pressure drop is ≤14-inch H2O, and its flow ranges from 0 to 30 sccm. Standard control options include 0.2 to 10 VDC, 4.32 to 20 mA, and 3.3 VDC serial. www.clippard.com

NPT port sizes. It also includes air filters (particulate, coalescing oil removal, and vapor removal), air regulators, air filter regulators, air micro-fog lubricators, manual shut-off relief valves, soft start/dump valves, solenoid-activated control valves, and pre-assembled combination filter-regulator-lubricator units. www.automationdirect.com

Emerson introduced its ASCO Series 062 series of rocker isolation valves, designed for clinical laboratory applications. The 16mm valve offers two-way and three-way functionality and control neutral and highly aggressive liquids.

It also features an easy-toflush rocker mechanism, combined with a separating diaphragm, that prevents clogging and heat transfer to in-vitro diagnostic reagents. The Series 062 valves have a smaller internal volume, reducing contamination risk, maintenance requirements and potential reagent waste. The valve also offers padmount and barb-fitting mounting options, as well as a lifetime of 10 million cycles. www.emerson.com

AutomationDirect has added Norgren Excelon Plus air prep components to its existing lineup of pneumatic air prep products. Norgren Excelon Plus 82 series air prep products come with 1/4- and 3/8-inch female NPT port sizes; the 84 series comes with 3/8-, 1/2- and 3/4-inch female

Teledyne FLIR released the Tau 2+, a longwave infrared (LWIR) Tau 2 camera with a noise equivalent differential temperature (NEDT) of less than 25 mK (milliKelvin). With its existing lens options and optical interface, the camera’s improved DRI allows multiple fields-of-view (FOV).

The Tau 2+ image processing algorithm can provide clear thermal details in challenging environments, the company says. It also features a new level of minimum resolvable temperature differences (MRTD), improved scene contrast with blacker blacks and whiter whites, and a low image noise. Commercial off-the-shelf connectors include USB, CMOS, Camera Link or Ethernet. www.flir.com

Basler announced it has added two sensor models (GMAX2505 and GMAX2509) to its ace 2 camera line that feature Gpixel CMOS sensors. With resolutions of 5 and 9 megapixels, respectively, the cameras also feature Basler lenses, coordinated accessories and the company’s pylon Camera Software Suite.

All of the line’s 16 models are equipped with USB 3.0 or GigE interface and global shutter sensor and deliver frame rates from 12 to 64 frames per second. This latest addition expands the portfolio of Basler’s ace 2 camera series with its two product lines ace 2 Basic and ace 2 Pro to a total of about 90 models, with sensors from Gpixel and Sony providing resolutions from 2.3 to 24 megapixels and frame rates up to 160 frames per second. www.baslerweb.com

Teledyne FLIR introduced the FLIR Bridge, an IIoT edge gateway that aggregates sensor data from fixed sensors, visible cameras and thermal cameras. Compatible with OPC UA, Pi Historian and other monitoring platforms, the bridge provides insight into a range of key assets. The FLIR Bridge Pro version provides support for an unlimited number of FLIR

cameras and sensors along with most third-party sensors. The device includes the ability to apply filters to the incoming data, including custom alarm and alert settings, such as those based on standard deviations or Fourier Transforms. FLIR Bridge Standard offers connection to up to five FLIR devices or third-party fixed sensors along with the same data filtering capabilities as the Pro version. www.flir.com

Westermo launched its Viper-8 series, an Ethernet switch line, optimized to meet the demands of onboard rail applications. The series supports services such as public address systems, passenger information systems, onboard Wi-Fi, video surveillance and train control and management systems. It offers full-speed routing through its eight 1 gigabit ports.

For security, the series also offers features, such as routing capacity for network segmentation, secure boot, firewalls, VPN, intrusion detection and access control. The Viper-8 runs Westermo’s WeOS operating system, is compliant with the EN 50155 rail standard and features a GORE-TEX membrane that prevents internal condensation. It also offers triple isolation between all interfaces to protect against overvoltage and flashover. www.westermo.com

Moxa Inc. introduced the new EDR-G9010 Series, an all-in-one firewall/NAT/VPN/ switch/router line designed for industrial networks. The series

offers 8-port TX GbE and 2-port SFP GbE along with deep packet inspection (DPI) for Modbus TCP/ UDP and DNP3 traffic and an embedded IPsec VPN. The routers are certified for IEC 61850-3/IEEE 1613, NEMA TS2, ATEX Zone 2, and Class I Division 2. It also offers redundancy mechanisms, including Turbo Ring and VRRP. The -T model in the line offers an operating temperature range from -40 to 75°C. The Series is also compatible with Moxa’s MXview network management software, with which users can view the unit’s security parameters and the network’s performance as well as perform regular configurations backups. www.moxa.com

Antaira Technologies released the LMP-1802G-M12-10G-SFP67-24-T Gigabit Ethernet Managed Switch that features M12 shock- and vibration-proof connectors, two 1G/10G SFP slots and 16 10/100/1000BaseT(X) ports. Each PoE/PoE+ port also delivers 30W for up to 240W total power with data. The switch employs DHCP option 82 and static routes in its Light Layer 3 network management that supports the ITU-T G.8032 ERPS v2 (Ethernet Ring Protection Switch) protocol, providing <50ms recovery time to the network. Operating at

temperatures from -40°C to 70°F and housed in an IP-67-rated metal chassis, the switch has 16 M12 ports that offer 148,800pps for fast packet switching with store and forward technology. The 8-pin M12 CAT6A sockets with X-coding female connectors feature auto-negotiation speeds, full/half-duplex mode and auto MDI/MDI-X connections.

www.antaira.com

Siemens introduced the SIMOTICS S-1FS2 line of servomotors, designed for the clean condition applications. The motors are offered in power ratings from 0.45–2kW (0.60–2.68 hp) with torque

from 3.1–14 Nm (2.28–10.32 ft-lbs.).

Crafted with housings of 1.4404 (AISI 316/316L) stainless steel, EPDM seals and bearing grease with NSF H1 approval, the motors are corrosion resistant and offer IP69k (30-bar) protection on the motor housing and IP66/67 on the entire motor. The S-1FS2 is designed for the 3-A (U.S.) and EHEDG (Euro) requirements of the food and beverage industries. Options include a holding brake, stainless steel shaft with or without feather key, cable tail for direct drive

connection and a MOTION CONNECT coupling. www.siemens.com

Moticont unveiled its DDLM Linear Actuator Series, which includes the DDLM-038-051-01, a non-commutated electric cylinder that is 1.500 in. (38.1mm) in diameter with a housing length of 2.00 in. (50.4mm). Developing 3.1 lbs (14.0 N) of continuous force and 9.9 lbs (44.1 N) of peak force at 10% duty cycle, it has a stroke of 0.375 in. (9.5mm).

dance with ISO Class 1 as a single-layer and three-layered e-chain system. In fact, the e-skin flat was the only energy chain to receive ISO Class 1 according to ISO 14644-1 with a bend radius of 70 millimeters. The e-chain uses a high-performance plastic that is resistant to wear and abrasion and can consist up to six chambers per layer. Three-layered structure supports chains in the lowest layer. igus has also developed the CFCLEAN series for use in the e-skin flat. The cable cores can transmit energy and signals for motor control, bus and Ethernet. www.igus.com

Zero cogging and direct coupling of the actuator to the load results in zero backlash, the company says. The 0.250 in. (6.4mm) diameter shaft has an internal thread on each end, a total length of 3.8.75 in (98.4mm), and extends 1.375 in. (34.9mm) past the mounting ends of the actuator. The shaft extends through the 9/16-18 UNF x 0.250 (6.4mm) long threaded stud at each end of the housing. www.moticont.com

WAGO has expanded its line of IP67-rated I/O fieldbus modules to include components that support EtherNet/IP and EtherCAT protocols and offer configurable I/O as well as IO-Link master ports. With a built-in Bluetooth interface, users can configure these modules for commissioning and maintenance procedures while in the line of site of their plant floor equipment.

igus unveiled the e-skin flat, a particle-free energy chain designed for cleanrooms. In a Fraunhofer cleanroom test, the e-chain demonstrated cleanroom performance in accor-

For IIoT and SCADA applications, users can leverage OPC UA for data monitoring and control. Non-encapsulated modules are IO-Link hubs for connection to an IO-Link Master. These hubs come in either 8 or 16 configurable DIO ports and each channel is configurable for a 24 VDC digital input or output rated at 2 amps per channel. www.wago.com

Rockwell has added the PowerFlex 755TS to its PowerFlex AC variable frequency drive portfolio. The 755TS is the first six-pulse drive to incorporate the company’s TotalFORCE technology. The drive features Adaptive Control, which monitors machine characteristics and compensates for changes over time automatically. The 755TS is available with optional corrosive gas protection (XT). CIP Security capable, the drive is also a drop-in replacement for other PowerFlex 755 drives, with the same dimensions, mounting-hole and wiring locations. It also uses the same slot-based architecture that allows users to continue using I/O and safety cards from their existing 750 drives.

rockwellautomation.com

Delta Computer Systems launched its LC8 Load Cell module for its RMC200 motion controller. The module connects directly to eight load cells without the need for external signal conditioners. The LC8 provides eight load cell inputs, divided between two detachable terminal blocks. The maximum sensitivity is 5mV/V in full Wheatstone bridge configurations. Quarter and half bridge configurations are supported with a user-supplied bridge completion circuit. Both four and six wire load cells are supported. Each of the eight inputs includes a sense input for wire voltage drop compensation. Excitation voltage is 6.75V, designed for 350-ohm load cells; lower resistance load cells are supported as long as current limits are not exceeded. Externally supplied excitation voltage is also supported within input range and maximum differential limits. deltamotion.com

WAGO’s introduced its 750-366, a fieldbus coupler that supports Device Level Ring (DLR) in conjunction with an EtherNet/IP network. A DLR topology network ensures that I/O communications remain online in case of a single point of failure. The coupler can be combined with any of WAGO’s 500+ I/O modules. Its dual DLR Ethernet ports are used as an integrated switch, eliminating the need for additional devices. Onboard web-based management allows for parameterization of the device along with firmware updates. The 750-366

also supports a variety of additional protocols including HTTP(S), DHCP, DNS, SNMP, and FTP(S). www.wago.com

POSITAL has added models to its IXARC rotary encoder line that feature housings that are 27mm long and 36mm diameter. The encoders’ radial cable entry and shaft seal have protection ratings of IP65. They also features a variety of flange and shaft configurations. The added encoders are based on POSITAL’s magnetic

measurement technology in both incremental and single-turn absolute versions. Absolute versions have resolutions of up to 16-bit and are available with analog, CANopen or SSI interfaces. Incremental variants are programmable; resolution can be set anywhere from one to 16,384 pulses-per-turn in software without requiring changes to the mechanical properties of the devices. Similarly, pulse direction and the output driver – either Push-Pull (HTL) or RS422 (TTL) – can be reset through software updates. www.posital.com

Red Lion introduces the next generation of its PM-50 panel meters. Available as a 3.5-inch or 4.3-inch graphical touchscreen display, the line allows users swipe between relevant screens. Visual alerts notify the user either on the unit itself or via the PM-50 app. The PM-50 offers built-in Wi-Fi as well as wired connectivity via Ethernet and Modbus. The PM-50 can replace a meter with a 1/8 or 1/16 DIN panel cut out and is set up via an on-device programming wizard, mobile app, or web browser. Additional capability is available with field-installable modules to provide outputs, communications and AC power functionality when needed. www.redlion.net

AW-Lake Company introduced its Water Inline (WIN) Ultrasonic Flow Meter designed for process cooling applications. With no moving parts, the meter

incorporates two wetted ultrasonic transducers that face each other directly in the flow tube. It has an accuracy of +1.0% of reading over 25:1 turndown, 100:1 total turndown with minimal pressure drop. Holding an IP67 (NEMA 6) rating, the meter operates safely when temporarily submerged in water. A detachable LCD display version comes standard with Modbus RTU communications. A built-in data logger enables data access via Modbus. Units without a display come standard with analog and pulse outputs, 24V AC/DC power, one pulse, and one analog output. aw-lake.com

WAGO has expanded their TOPJOB S Mini terminal block series to include a version for 12 AWG that is 60 percent smaller than the line’s standard terminal blocks. The 12 AWG variant operates at up to 600V and 20A and has UL 1059 approval as well as AEx, ATEX, and IECEx for hazardous locations.

Featuring the line’s Push-in CAGE CLAMP connection technology, the Mini terminal block is available with open tool slot or orange push buttons. It can also be mounted in various ways: miniature rail, snap-in mounting foot for chassis mount or direct mount with fixing flange. |DE www.wago.com

ManufacturingJobsite.ca is Canada’s premier online job portal for the growing manufacturing sector. A laser focus on the right people across the country’s largest manufacturing media audience means you get the right applicants the first time. No more massive piles of unqualified applicants, just professional employers reaching qualified professionals.

Powered by the top manufacturing media brands in Canada, the reach to over 500,000 industry professionals on ManufacturingJobsite.ca is amplified by:

Website advertising to 185,000 qualified monthly site visitors

A comprehensive and magnifying reach across multiple associated job boards

Email promotion and job alerts to 131,000 industry emails using Canada’s largest CASL-compliant direct access to manufacturing professionals

Social media promotion to all brand networks on Facebook, Instagram, Twitter and LinkedIn

Extreme measurement accuracy: down to 25 ppm

Wide measuring range: 10 mΩ to 10 MΩ

Highly precise vibration analysis: up to 50 kHz

High resolution: 24-bit precision

High sampling rate: 100,000 samples/s

Channels synchronized at < 1 μs

Through a wide range of EtherCAT Terminals with advanced functionality, Beckhoff integrates measurement technology in a standard I/O system. This delivers high speed, high bandwidth and precise synchronization capabilities in a DIN rail-mounted form factor. Modular measurement terminals empower applications ranging from temperature, power, current and voltage measurement up to complex mains monitoring or Condition Monitoring. The signals are acquired via electrically isolated channels and sent to the controller for further processing. To promote more efficient engineering in these applications, Beckhoff offers numerous time-saving TwinCAT software libraries.