14 CAD and CAM still struggling with manufacturability problem

22 Canadian sanitizer disinfects cell phones in medical facilities

24 Robotic shot blaster relies on valve tech to boost efficiency

14 CAD and CAM still struggling with manufacturability problem

22 Canadian sanitizer disinfects cell phones in medical facilities

24 Robotic shot blaster relies on valve tech to boost efficiency

Bimba’s new PA Series is the perfect complement to our NFPA actuator line. It offers set bore sizes and rod diameters for a simple, straightforward counterpoint to the highly con gurable TA Series. Standard designs and features provide the versatility your pneumatic applications need, at a price that can’t be beat.

Find out more www.bimba.com

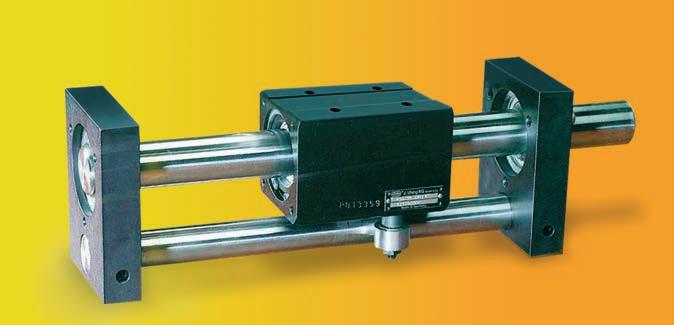

The developer of the original world-class linear motion systems, THK continues to redefine industry standards and to meet an ever-growing range of needs. From aerospace and machine tool to packaging and medical, THK products play a vital role in the advancement of technology and capability.

To learn more, call us at 1-800-763-5459 or visit www.thk.com. Exceptional designs deserve superior components.

SEE US AT: WMTS

JUNE 4-6, 2019 BOOTH #:515

ATX EAST 2019 JUNE 11-13, 2019 BOOTH #:2107

ROBOTICS SUMMIT & EXPO

JUNE 4-6, 2019 BOOTH #:115

Dr. Alain Aubertin

Vice President, Business Development and International Affairs, Canada Consortium for Aerospace Research and Innovation in Canada (CARIC)

Ajay Bajaj, P.Eng President, Rotator Products Limited; Past President and Board Member, Power Transmission Distributors Association (PTDA)

John Lamb Regional Sales Manager, Wainbee Limited; Chairman, Canadian Fluid Power Association (CFPA)

Dr. Ishwar Puri, P.Eng Dean of the Faculty of Engineering; Professor of Mechanical Engineering, McMaster University

Dr. Mary Wells, P.Eng

Dean of the College of Engineering and Physical Sciences, University of Guelph; Chair of the Ontario Network for Women in Engineering SUBSCRIBER SERVICES

8 Design News

Toyota reaffirms commitment to Canadian auto sector and other design news

14 CAD Report

CAD and CAM still don’t play well together, despite industry’s best attempts

24 Motion Control

Beckhoff’s TwinCAT 3 controls 18 synchronous NC axes to process die-cast automotive parts

30 Idea Generator

The latest in industrial products including automation, motion control and motors

18 Ahead of the Curve

Composite manufacturer relies on portable 3D scanning tools to dominate competitive industry

22 Releasing the Kraken

Kraken Robotic’s “over-night” success underpinned by years of next generation sonar and marine tech development

26 Canadian Innovator

CleanSlate UV Sanitizer disinfects grimy cell phones in medical and food processing facilities

29 Full Blast

Leading shot blasting provider, V+M Systems, relies on the AVENTICS valve system to save energy and assembly time

Followingdecades of slow burn effort, it looks as though Canada has finally become a major focus of international tech sector attention. More specifically, Toronto and Montreal received the most intense gaze recently as the two cities vie for the title of Canada’s Silicon Valley.

In fact, 2019 seems to represent a tipping point. In late May, for example, the Collision technology conference, billed as North America’s fastest growing, drew more than 25,000 attendees to Toronto from 125 countries. Among them were 1,100 startups from 60 different countries, 100 trade delegations, and 850 investors.

In addition to Canadian politicians, including Justin Trudeau, Toronto Mayor John Tory and Ontario Premier Doug Ford, the conference featured 700 speakers. Notable among them Joseph Gordon-Levitt, actor and co-founder of the online creative collaboration community HitRECord, and Canadian actor and filmmaker, Seth Rogen, who co-founded Canadian cannabis company, Houseplant. Other Canadian tech luminaries included Ryan Holmes, founder and CEO of Hootsuite, and Tobi Lütke, founder and CEO of Shopify.

In its fifth year, 2019 marked the first time Collision has been held outside the U.S. According to the organizers, the event moved to Toronto due, in part, to its vibrant tech and startup sectors and world-class AI hub headed by one of the “Godfathers of Deep Learning,” Geoffrey Hinton. The U of T researcher recently shared the Turing Award, considered the technology sector’s Nobel Prize.

Concurrent with Collision, Montreal got it’s own share of the spotlight in May, playing host to the world’s largest international robotics conference. Organized by the IEEE, the International Conference on Robotics and Automation (ICRA) pulls together top robotics experts from 71 countries. The five-day event attracted roughly 4,000 attendees with its 100 exhibits and 1,200 presentations on the latest in flying, self-driving, microscopic and bio-medical robots. This year also marks the first time the ICRA has been held in Canada.

To drive home the country’s growing leadership in robotics technology, four of Canada’s fastest growing robotics companies were featured prominently. Among them was Element AI, co-founded by one of the other “Godfathers of AI,” Yashua Bengio, University of Montreal professor and co-winner of the Turing Award. This year, his Montreal-based start-up launched its first product designed to apply deep learning AI techniques to the financial, insurance and logistics markets.

Similarly, Boisbriand, Quebec-based KINOVA displayed its innovative JACO assistive robotic arm and Gen3 Ultra lightweight cobot while Lévis, Quebec-based robotics veteran, Robotiq demoed its latest 2F-85 Adaptive Gripper, designed for industrial cobots. Of course, Canadian robotics leader, Clearpath Robotics, attended to demo its line of unmanned ground vehicles and OTTO material transporters, as well as the Waterloo company’s latest navigation software packages.

The only potential downer in May was the recent announcement that Ontario has cut a total of $24 million in funding to two AI research institutes. Even as the province attempts to whittle away at its $11.7-billion deficit, the cuts may seem misguided just as the country positions itself to evolve and adapt to a 21st century economy. However, considering that global spending on robotics is forecast to increase by 17.6 percent this year to a total $115.7 billion, its doubtful the cuts will have much impact, given Canada’s clear leadership in the field.

Mike McLeod

www.design-engineering.com

Publisher Alan Macpherson (416) 510-6756 amacpherson@design-engineering.com

Editor Michael McLeod (416) 442-5600 ext. 3231 mmcleod@design-engineering.com

Account Manager

Ron Salmon (416) (905) 713-4362 rsalmon@design-engineering.com

Media Designer - Team Lead Lisa Zambri

Account Coordinator

Cheryl Fisher (416) 510-5194 cfisher@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz (416) 442-5600 ext. 3543 bolechnowicz@annexbusinessmedia.com

Vice President/Executive Publisher Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

President & CEO Mike Fredericks

Design Engineering, established in 1955, is published by Annex Business Media, 6 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues. Printed in Canada

Publications Mail Agreement #40065710 ISSN: 0011-9342 (Print), 1929-6452 (Online)

Subscriber Services: Canada: $57.50 for 1 year; $92.50 for 2 years; $10 for single copy. Outside Canada: USA - $108 USD; Overseas - $116 USD $22 for single copy. Directory/buyer’s guide: Canada $28; Outside Canada $46. Add applicable taxes to Canadian rates.

Circulation email: blao@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3552 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer: privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing & Printing Inc. All rights reserved. DE receives unsolicited features and materials (including letters to the editor) from time to time. DE, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. DE accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. DE is indexed in the Canadian Business Index by Micromedia Ltd., Toronto, and is available on-line in the Canadian Business & Current Affairs Database.

I enjoy hearing from you so please contact me at MMcLeod@design-engineering.com and your letter could be published in an upcoming issue.

• 1/4 to 1.5 hp, 115V (single-phase input)

• 1/4 to 3 hp, 230V (single-phase input)

• 1/4 to 5 hp, 230V (three-phase input)

High Performance AC Drives

Starting at $138.00 (CFW300A01P6S2NB20)

The WEG CFW300 variable frequency drive is a high performance VFD for three-phase induction motors. The CFW300 series features a compact size and is ideal for applications on machines or equipment that require precise control with easy setup and operation. The CFW300 includes a built-in keypad and SoftPLC with free WEG Programming Suite (WPS) software for custom tailored control schemes.

A variety of plug-in option modules for additional I/O and communications protocols can be added to extend capabilities. A remote keypad and flash memory module are also available.

• V/Hz or sensorless vector control modes

• PLC (built in)

• PID control (built in)

• 5 digital I/O (built in)

• 4 digital & analog I/O option modules (supporting additional digital, relay, analog, temperature and encoder signals)

• Side-by-side mounting (no heat dissipation space required)

• Optional Remote keypad

• Optional RS-232 module (Modbus RTU)

• Optional RS-485 module (Modbus RTU)

• Optional USB module (for PC communications)

• Fire mode

• DIN rail or surface mount

• Flash memory module for project transfer

• One year replacement warranty

• UL/CE listed

Prime Minister of Canada Justin Trudeau was in attendance for Toyota Motor Manufacturing Canada’s announcement that it will produce the Lexus NX and NX Hybrid at its Cambridge, Ontario production plant beginning in 2022.

“Today is a great day for Toyota, for Cambridge and for Canada,” said Trudeau. “Canadian auto workers are among the world’s best, and they have the skills and know-how to design and build cars that meet the needs of people today and tomorrow. Toyota’s new commitment to its Cambridge facility is a vote of confidence in our auto sector and will help Canada lead in the new high-tech economy of the future.”

Toyota Motor Manufacturing Canada (TMMC) has been producing Lexus vehicles since 2003, when it became the first facility to produce them outside of Japan. Since then, it has produced 1.3 million Lexus RX and RX Hybrid vehicles. TMMC’s history in Canada goes even farther as it has manufactured vehicles in Canada for over 30 years. In total, the carmaker has invested more than $8.5 billion since 1985.

“Building on our recent Toyota RAV4 announcement and our recent facility modernization investments, we are excited to announce that TMMC has been selected to

produce the popular Lexus NX and Lexus NX Hybrid models for the entire North American market,” said Fred Volf, President, TMMC.

Toyota currently employs over 8,500 people at its Cambridge and Woodstock plants and, since coming to Canada, has built more than eight million vehicles.

“Together with the company’s recent investments in our facilities, today’s announcement demonstrates the tremendous amount of trust that Toyota has in the team members here at TMMC,” said Volf. “It has been an honor to be producing a Lexus model, and now we’re being trusted to produce two of them.”

www.tmmc.ca

Siemens Gamesa Renewable Energy announced it has signed a contract to supply and commission 43 of its SG 4.5-145 wind turbines, with flexible rating up to 4.8 MW, for an undisclosed Canadian wind project. The order is for a nominal capacity of 194 MW.

The SG 4.5-145 will be the most powerful turbine with the largest rotor size to date in Canada. The 71-meter blade integrates aerodynamics and noise reduction features—including Siemens Gamesa DinoTails Next Generation technology— to guarantee a high

production of energy and reduced noise emission levels, the company says.

“We’re proud that our partners chose Siemens Gamesa and our SG 4.5-145 turbine for this project,” said David Hickey, head of the Siemens Gamesa business in Canada.

“The new SG 4.5-145 turbine will provide extremely cost competitive and clean energy to the consumers and communities of Canada.”

With more than 3,000 MW installed in Canada, Siemens Gamesa Renewable Energy is the market leader by cumulative installed capacity. Currently, Canada is 8th in the world for total onshore installed wind capacity with 12.8 GW as of December 2018.

www.siemensgamesa.com

Researchers at the University of Waterloo announced that they have developed a new fuel cell that lasts at least 10 times longer than current technology. According to the engineers, advancements in zero-emission fuel cells could make the technology cheap enough to replace traditional gasoline engines in vehicles,

“With our design approach, the cost could be comparable or even cheaper than gasoline engines,” said Xianguo Li, director of the Fuel Cell and Green Energy Lab at Waterloo. “The future is very bright. This is clean energy that could boom.”

Recognizing that fuel cells are presently too expensive to be practical, the Waterloo researchers designed a fuel cell that deliver a constant, rather than fluctuating, flow of electricity.

The team’s research paper about the technology, recently published in Applied Energy, details a stack of three fuel cells, each constrained to a fixed power output. By limiting the amount of time any one cell is operating, by way of a strategic power management system, the overall durability of the cell stack increases by between 4.8 and 11.8 times, the team’s

Novotechnik’s TEX Series has the mounting and connection configurations needed to be plug-in compatible with your existing or new application. The TEX Series is designed for use in tough environments like industrial, off-road automotive and others.

The TEX Series is available in stroke lengths of 10 to 300 mm. Repeatability is better than 0.01 mm and the TEX Series has outstanding linearity–to 0.05%. A wide range of standard configurations for mounting are featured including:

• return spring • pivot head mount • zero backlash ball coupling • bolt through flanges • snap clamps

flange mount • bushing mount

rod end bearing

cable and connector options

research found, depending on city or highway driving. This durability increase would then allow fuel cells to be less complex and therefore, less expensive.

“We have found a way to lower costs and still satisfy durability and performance expectations,” said Li, a professor of mechanical and mechatronics engineering. “We’re meeting economic targets while providing zero emissions for a transportation application.”

The researchers hope their work will lead to the introduction of fuel cells in hybrid vehicles, lowering unit costs by mass production and paving the way for the replacement of both batteries and gas engines entirely.

“This is a good first step, a transition to what could be the answer to the internal combustion engine and the enormous environmental harm it does,” said Li, who’s lab designs and builds green energy systems.

Li collaborated with lead researcher Hongtao Zhang, a former post-doctoral fellow; Waterloo mathematics professor Xinzhi Liu; and Jinyue Yan, an energy expert and professor in Sweden. https://uwaterloo.ca

We stock enough power to brew a 12 oz. cup of coffee for the entire population of New Orleans. Put that in your mug and drink it.

Engineers from UBC’s Okanagan campus announced the development of a surface coating that can shed ice from large areas using little effort. The coating is one of a class of surfaces called low interfacial toughness (LIT) materials, that is changing the way scientists understand ice adhesion, the UBC researchers say.

According to Kevin Golovin, assistant professor at the UBCO School of Engineering and study lead author of a paper published in the journal, Science, LIT materials work by causing cracks to form easily beneath the ice, allowing it to readily dislodge. He compares the effect to a string of dominos.

“If designed correctly, the force to knock down a single domino is enough to topple them all – adding more dominoes doesn’t require you to push any harder,” he says. “It’s the same with LIT materials. Once you form a crack, it can de-ice the

UBC engineer Kevin Golovin is helping change the way scientists understand ice adhesion through the development of LIT materials

(PHOTO CREDIT: SAM CHARLES, UBC OKANAGAN)

entire interface, whether it’s the length of a windshield, an airplane wing or a turbine blade.”

Golovin says LIT materials can be fabricated from commonplace paints and plastics and exhibit superior performance compared to state-of-the-art anti-icing materials.

“Ice buildup has adverse effects on a range of commercial and residential activities, from downed power lines to air travel delays to scraping one’s windshield,” he says. “This development is definitely a game-changer.”

https://ok.ubc.ca

Engineering researchers at the University of Toronto say they created a way to make magnetized micro-robotics, capable of traveling through the human body, using only a 3D printer.

In the lab of U of T Professor Eric Diller, each micro-robot is built by precisely arranging microscopic sections of magnetic needles atop a flat, flexible material. Once deployed, the researchers apply magnetic fields that induce the mini machines to worm through fluid channels, or close their tiny mechanical ‘jaws’.

(PHOTO CREDIT: LIZ DO / UNIVERSITY OF

“These robots are quite difficult and labor-intensive to fabricate because the process requires precision,” says graduate student, Tianqi Xu. “Also because of the need for manual assembly, it’s more difficult to make these robots smaller, which is a major goal of our research.”

According to the researchers, smaller and more complex micro-robots are needed for future medical applications, such as targeted drug delivery, assisted fertilization or biopsies. The researchers say their optimized approach opens the doors for developing even more complex micro-robots that are 10 times smaller than the current millimeter-size.

“As a robotics research community, there’s a need to explore this space of tiny medical robots,” Diller says. “Being able to optimize designs is a really critical aspect of what the field needs.” www.engineering.utoronto.ca

2019-05-08 9:54 AM

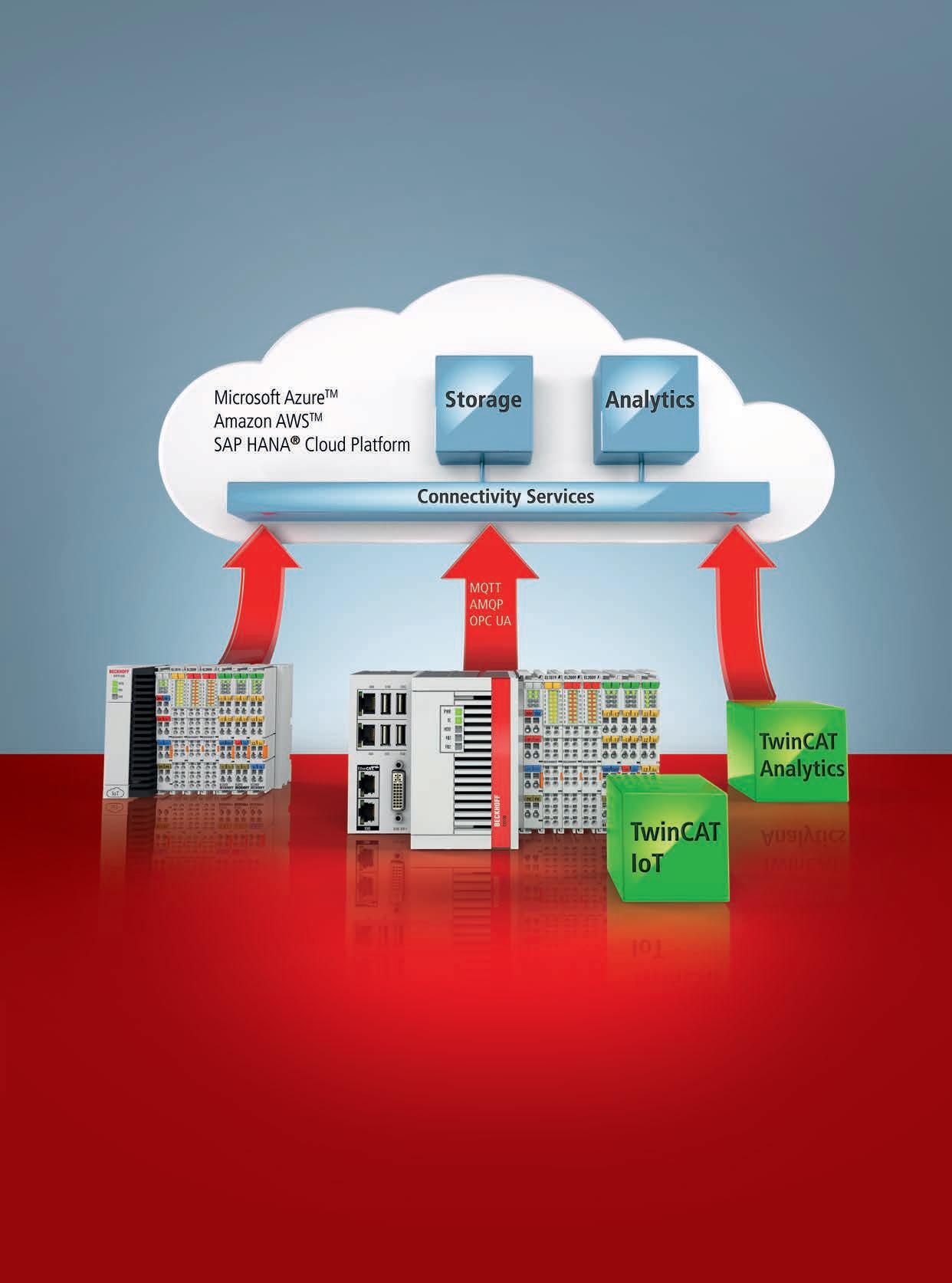

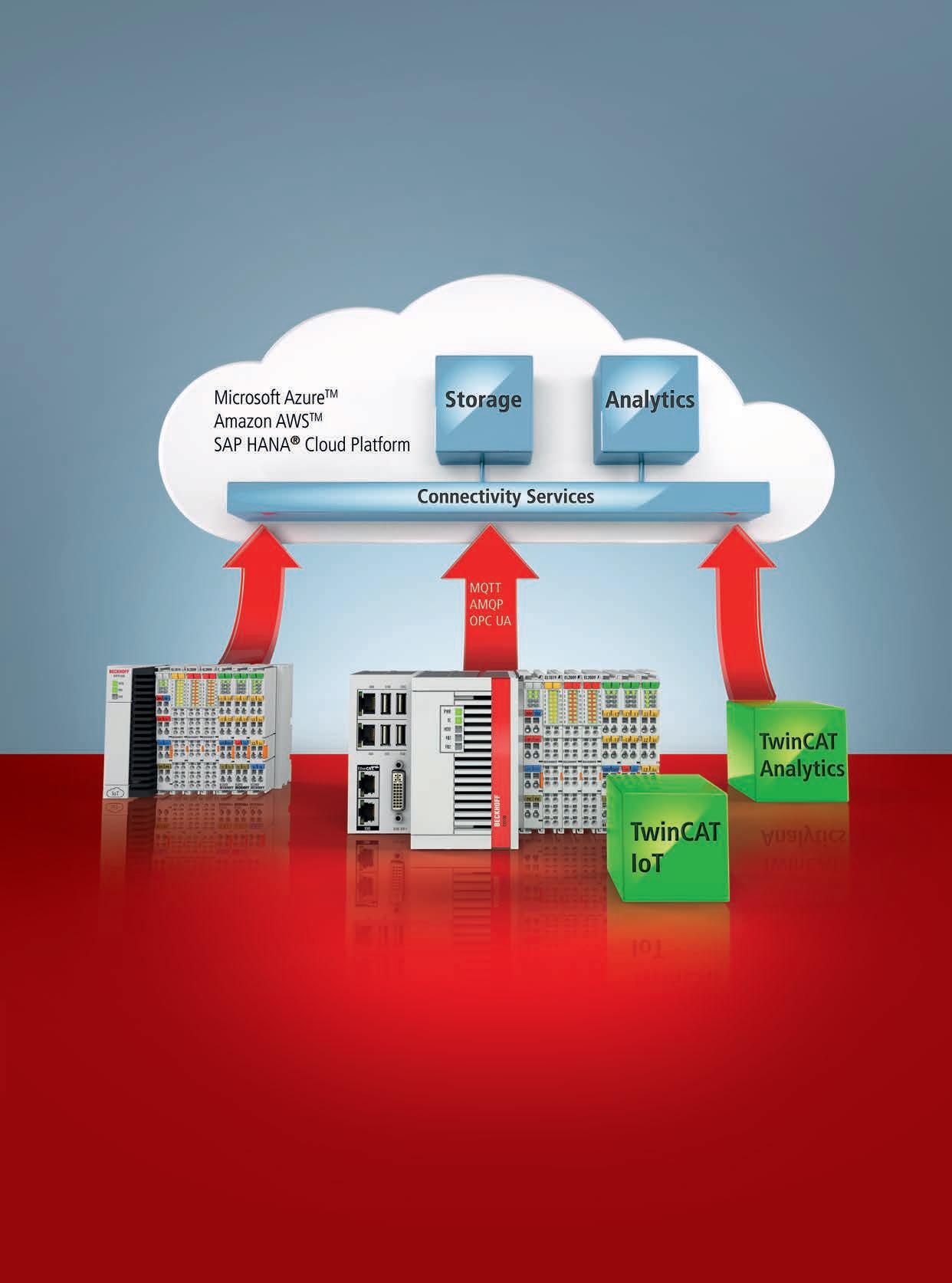

www.beckhoff.ca/Industrie40

Beckhoff provides the ideal foundational technologies for Industrie 4.0 and Internet of Things (IoT) applications via standard PC-based control. With the TwinCAT engineering and control software, machine control systems can be extended to support big data applications, cloud communication, predictive maintenance, as well as comprehensive analytical functions to increase production efficiency. As a system-integrated solution, TwinCAT IoT supports standardized protocols for cloud communication and enables the easy integration of cloud services right from the machine engineering stage. In addition to fault analysis and predictive maintenance, TwinCAT Analytics offers numerous opportunities to optimize machines and systems in terms of energy consumption and process sequences.

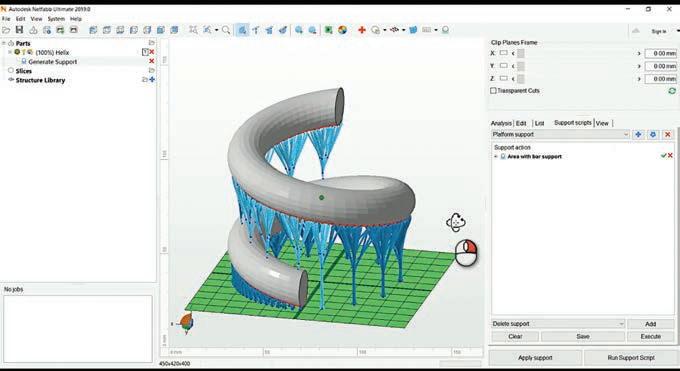

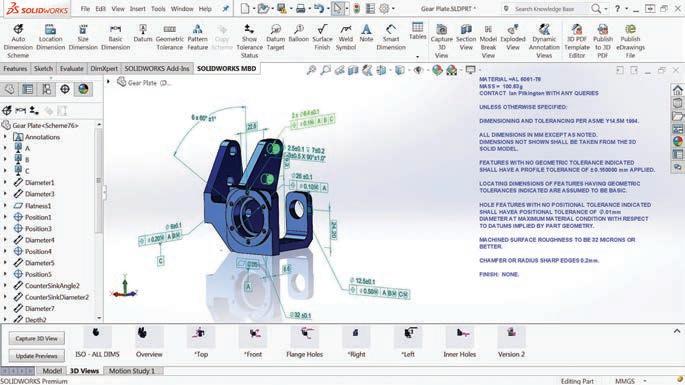

Although CAD and CAM grew up together, they still don’t play well, despite industry’s best attempts.

By Ralph Grabowski

Inan ideal world, CAD software would love CAM software. After all, the whole point of designing things is so they can be made. In the real world, though, CAD and CAM don’t get on that well. While today’s MCAD software usually recognizes that the output of its designs is for manufacturing, drawings produced for BIM and civil projects do not.

Prepping for manufacturing isn’t necessarily innate to the CAD software we use. We see our job as done when we send the drawing to a plotter or a PDF file. We can draw the entire solar system at 1:1 scale, right down to the lettering on a lunar lander’s plaque (as an early AutoCAD sample drawing showed), but most CAD programs can’t prepare the drawing to manufacture the plaque.

The gulf between CAD and CAM exists because CAD works with mathematical certainty. We designers take pride in our consistent use of tools that are precise, as CAD vendors reassuringly remind us. We place geometry using object snaps and parametric constraints, accurate to 14 decimals places.

CAD is so precise, in fact, that CAM

operators can’t work with the drawings we produce. That’s because CAM factors in the real-world problem of tolerance, a fancy word meaning “uncertainty”. It’s these plus-or-minus dimensions, on the order of 0.01mm or more, that come into play due to the imprecision inherent in lathes running in machine shops, or the gears and hydraulics of graders guided by GPS while smoothing freeway expansion projects.

As a result, CAM operators need to tweak CAD drawings. This is one of the major benefits of software like SpaceClaim and BricsCAD. The direct editing found in these programs allows machine shop operators to import models from “any” CAD system, and then adjust the drawings to suit CNC (computer numeric controlled) output, such as removing unneeded details (defeaturing) and extracting geometry for fixtures and tooling.

Most of us CAD users were never trained in manufacturability and so we have no idea about it. Manufacturability is the extra information that ought to be included in CAD drawings so that parts can be manufactured without CAM oper-

ators needing to massage our output. For example, steel molds require mild draft angles so that plastic parts pop out easily. Sometimes molds also need extra pipes to deliver additional molten plastic to fill the mold properly. When the flanges of sheet metal are bent, allowance must be made for the bend radius, known as the k-factor (or y-factor in PTC software).

For instance, AutoCAD, Microstation and nearly all other CAD programs are ignorant that wood cut for kitchen cupboards needs to account for the width of the cutting blade or to nest the parts to minimize waste. Nesting places parts optimally on plywood or sheet metal to minimize waste. Regular CAD doesn’t do this.

The disconnect between CAD and CAM didn’t always exist. The first CAD systems, developed by McDonnell Douglas (Unigraphics, now NX from Siemens) and Dassault Aviation (now Dassault Systemes), purposely output to CAM.

However, most of the systems that followed were developed differently. CAD

software was programmed by PhDs comfortable with multi-dimensional matrix transformations, but CAM software was written by practical users, who typically read a plain DXF file output from CAD, added tooling and path information and output it as g-code (the DXF of CAM). Their concern is for roughing strategies, 2- through 6-axis milling and turning-drilling.

Another split: CAM has its own language that takes into account things like swarfing, flow cuts, toolpaths, cutters, multi-axes, point control, grooving and inside roughing. Mold design, by itself, is sufficiently complex that it’s sold separately from CAM software.

Added to that, g-code isn’t universal. Nearly every CNC machine offers a unique set of capabilities. As a result, most g-code needs to be tweaked for each machine through post-processors. CAM software vendors like post-processors, as they make significant revenues selling machine-specific code. CAD vendor, on the other hand, find them annoying, considering they didn’t particularly want to be in the business in the first place.

The split manifests itself in other ways. Nearly all MCAD software is owned by just a few corporations, while there are roughly more than 200 CAM packages. They have names like Alphacam, BobCad-Cam, CamWorks, Dolphin CADCAM, Esprit, FeatureCAM, GibbsCAM, Hypermill, Mastercam OneCNC, PowerMILL, SolidCAM, TurboCAD/CAM, Visual Mill, and ZW3D CAM. Many are

home-grown, but others are repackaged from OEM providers, such as that made by MachineWorks of England.

Nobody knows why the CAM software industry hasn’t coalesced. Some attempts were made, the biggest by Vero Software. The company raised more than $10 million to acquire a dozen CAM packages but in 2014, Vero was taken over by Hexagon. MCAD vendors that didn’t develop their

own CAM internally, purchased one or more CAM vendors instead, such as Autodesk acquiring HSM and 3D Systems buying GibbsCAM, among others. If they don’t own one, then they embed CAM software from third parties, as Solidworks and OnShape do.

So, what’s changing? CAD is a mature market, as the CEO of PTC is fond of pointing out. There are no new customers, only customers to be enticed from competitors with functions competitors don’t offer, such as better output to manufacturing devices. Once one MCAD system does it, competition ensures all the others quickly become congenial to the idea. We’ve seen the same rush in other areas, such as direct modeling, generative design and lattice generation.

The most basic manufacturability tools finding their way into CAD are GD&T (geometric dimensioning and tolerancing) and PMI (product manufacturing infor-

mation), additional dimensions that tell manufacturers how much inaccuracy can be tolerated and the surface finish to use. Only in the past two years have translation packages boasted about translating PMI. Regular CAD packages now offer to save to STL (stereolithography), the universal format for 3D printers. These are baby steps, given that CAD and CAM have both been around since the late 1960s.

Of course, machining or the subtractive manufacturing process, guided by CAM software, isn’t the only way to make things. Additive manufacturing, or 3D printing, has gained significantly in recent years as a viable manufacturing process. Like machining, AM has its own uncertainties and complexities that require specialized software to successfully output models.

Despite its manufacturing orientation, MCAD lags in interfacing with additive

manufacturing, even though the technology is more than twenty years old. One problem is that common modeling commands, like extrude, shell and chamfer, mirror those of the subtractive rather than the additive processes. Fortunately, a new crop of independent programmers are filling the gap with software that designs and outputs models explicitly for 3D printing.

Firms in this space include nTopology (Element software) and ParaMaters (Meso-Structural software). Their ideas are being integrated into MCAD slowly; last fall, PTC bought Frustum for its Generate software, which is also used in NX from Siemens PLM, and Autodesk acquired Netfabb. AM-specific software creates internal lattice structures to minimize the weight and the amount of material needed, optimize the topology to further reduce weight (less material, faster printing), and add supports to keep the part from falling over during printing.

Awareness of 3D printing exploded with the promise of cheap 3D printers for homes, which ended as a bust. In contrast, the industrial version of 3D printing is booming, although here we are talking about machines that cost $50,000 and up, take up significant floor space and require proper venting. I am fascinated by the new variations on materials announced every few weeks to output parts made of multi-colored plastics or sintered metals.

And so we have an industry balancing between promise and frustration. The promises of AM include the ability to:

• Output intricate parts that are impossible to make with subtractive manufacturing

• Produce spare parts on demand and eliminate dedicated warehouses

• Generate prototypes more quickly, to avoid overnighting to outside manufacturers

• Minimize material cost and weight, to the benefit of surgical and aviation applications

Sure, mistakes are made with subtractive manufacturing, but mistakes seem more precarious in additive manufacturing. While SM works from g-code, AM works with STL files exported from CAD. STL is a simplistic format that consists purely of 3D coordinates for the myriad of triangles defining the surfaces of models; the format doesn’t even include units. It’s these surfaces and the triangles that then create problems for 3D printers:

• Too thin walls that lead to collapsed 3D prints.

• Non-watertight designs due to one or more holes in surfaces and/or edges that don’t match

• Too many triangles used to define surfaces or ones that overlap unnecessarily

• Triangles with inverted normals or ones that cut into each other.

Software firm Materialize reports that one in five parts fail during 3D printing, because walls were too thin. As a result, an entire sub-industry has sprung up to write software that fixes these problems and optimizes the 3D printing process, such as by “shrink wrapping” the CAD model to make a shell copy of the 3D solid. All this capability ought to be in MCAD.

We see market inefficiencies in the disconnect between CAD and CAM that has gone on for 50 years. The linkage between CAD and final product is pretty tight for some MCAD, but completely lacking in other major disciplines, such as architectural and civil engineering. Small firms are successful in filling in the niches ignored by big CAD, especially in the areas of kitchen cabinets and 3D printing. DE

Ralph Grabowski writes on the business of CAD on his WorldCAD Access blog (www.worldcadaccess.com) and weekly upFront.eZine newsletter. He has authored many articles and books on AutoCAD, BricsCAD, Visio and other design software.

Composite manufacturer, ACE Technology, relies on portable metrology tools to dominate competitive industry.

Founded in 2004 in the UK, ACE Technology’s mission is to offer best-inclass composite material manufacturing services. The first industry it served was motorsports, a demanding sector that requires both a quick time-to-market as well as unprecedented flexibility in handling several design changes during the entire manufacturing process.

Right from the beginning, the company understood the importance of being distinctive to maintain its leadership position in a very competitive market. Its approach was to offer its customers complete solutions, by better extending its capabilities.

Today, ACE Technology is a full-service supplier that offers a breadth of expertise—from the design process to the manufacturing of products (including pattern and mold tools, jigs, fixtures, etc.) as well as quality control. The company additionally operates four autoclaves and prides itself in developing high-end com-

posite components.

Over the years, the company had to adapt to variations in customer demand, which is a reality for many engineering companies. Thanks to its diversified service portfolio, Ace Technology was soon able to obtain contracts in new industries, such as aerospace, defense and communications.

In 2009, for example, the company won a major contract that involved manufacturing technology for satellite reflectors. This contract, which required high-accuracy measurements as well as specific RMS value measurements, drove the company to purchase its first piece of advanced metrology equipment: A portable measuring arm. As ACE’s Director, Paul Skinner, explained: “At the time, it was the only portable solution available as an alternative to a fixed and expensive CMM.”

ACE integrated advanced metrology as part of their core business across vari-

Portable CMM tools, like this Creaform MetraSCAN 3D, allow ACE Technology to scan parts, even those made of carbon composites or with mirror-like surfaces, directly to CAD for modification.

ous industries it served. The company also added 3D laser scanning, since it was looking to expand its services to the early stages of the design process.

Not so Portable

For a specific project, ACE Technology was mandated to entirely ‘composite engineer’ a Le Mans Prototype racing car. The company had to build its expertise in geometric optimization of composite material as well as address both stringent mass targets and crash testing requirements.

Performing that geometry optimization first involved digitizing the existing part and then improving its design by working on the 3D copy. However, the company was often required to travel across the UK, to visit customer facilities, as part of the scope of the project.

“It was during such applications that we realized the portable arm [we bought] was really not so portable,” Skinner said. “Immediately, a large heavy tripod became both a logistical and health and safety concern. In addition, mounting an arm inside a vehicle presented two different problems: Access and movement. While the vehicle moved as we entered it, any datum sets were immediately lost, unfortunately making all subsequent data useless.”

The Optical Option

Director Skinner put ACE engineering intern, Edward Smith, in charge of researching 3D scanning and other new

0.01 mm

repeat accuracy LDN Linear Axis

90% faster gripper change

SWS Quick-change System

NEW: Up to 50% higher gripping force

PGN-plus-P Universal Gripper

Everything for your Handling System

More than 4,000 components for handling and assembly.

portable technologies. The company needs were clear: An intuitive and truly portable device that could scan various surfaces (such as carbon fiber, epoxy, virtual mirrors, polished aluminum) with simple-touse software.

After a few experiments, Smith realized that the two major portable arms on the market had the same limitations: They were still too difficult to move and oper-

ate around an object. He then considered an optical solution, the Creaform MetraSCAN 3D and HandyPROBE, which quickly proved to resolve all the issues previously experienced with measuring arms.

Smith had already used a MetraSCAN 3D version at a previous company, which made him familiar with the benefits of Creaform products. “These solutions had superior scan speed, maneuverability and consistent accuracy,” he noted, adding that the latest developments of the device resulted in exceptional scan quality even with mirror-like surfaces and carbon parts.

ACE Technology purchased a 3D scanning system comprising a MetraSCAN 3D, a HandyPROBE as well as the VXelements software. According to Smith, the ease-of-use of this system quickly became a major selling point for the company.

“Our core business is product design and manufacturing,” he said. “We didn’t want to dedicate a specialist to this equipment. Therefore, we were seeking a product with a relatively friendly learning

curve so that several technicians could pick up and use it intermittently, sometimes weeks apart.”

VXelements was also perfectly suited for this type of workflow and greatly simplified the team’s tasks. Previously, during a reverse engineering process, data was exported into a Solidworks plug-in or other complex third-party software. Now, live transfers make it possible to directly view the surface-ready data and section cuts in SolidWorks.

In the past, designing and manufacturing mold tools and fixtures typically required tactile measurements of datum tooling holes and key critical feature measurements. However, the Creaform solution replaced this cumbersome equipment seamlessly. Just like a measuring arm, the handheld and wireless HandyPROBE enables sophisticated probing.

Both the HandyPROBE and MetraSCAN 3D work in synergy with the C-Track, an optical camera system

that provides 6 degrees of freedom over a volume of 16m3. The HandyPROBE dynamically reports a Cartesian co-ordinate of a component or tool datum, which can then be used to build tools and set nominal positions or report surface deviations to a CAD file.

In both the aerospace industry and with F1 tooling, it’s common practice to have either a portable arm and a laser tracker or a laser tracker featuring a handheld probing and scanning solution. However, both these situations significantly prevent possible movements around the measurement area. The process is both complex and error-prone. In contrast, the C-Track solution simplifies the procedure by automatically and dynamically realigning the area with its optical cameras, thereby drastically reducing measuring time.

Today, ACE Technology operates two factories in Cambridgeshire, England and employs a workforce of about 50 skilled professionals. The company is now

Our custom motors allow you to match your ideal specifications, minimize your machine size, and control your supply chain risk. Aerotech can design, test, and manufacture your custom motor in one facility and provide you with a single point of contact throughout the process.

• Size and geometry

• Any feedback sensor

• Windings customized for bus voltage, current, resistance, inductance, BEMF constant

• Stack motors to increase force

• Vacuum or cleanroom compatible

looking to further grow its presence in the aerospace industry, currently finalizing a new supplier accreditation and compliance. Moreover, ACE purchased a high-end Markforged 3D printer, making it possible to offer fiber-reinforced nylon tooling and components.

According to Skinner, the MetraSCAN 3D plays a vital role in the adoption of 3D printing by capturing data from patterns, tooling or final parts that can be quickly converted into files suitable for 3D printing. 3D scanning technology can further be used to develop 3D-printed jigs, templates and fixtures, making it possible to shorten the time required when developing various composite production processes.

“The MetraSCAN 3D is a key investment to support our scan to CAD initiative,” Skinner added. “We are confident that it will play a vital role in our future expansion.” DE www.ace-technology.co.uk

This article was contributed by Lévis, Quebec-based Creaform.

Kraken Robotics “over-night” success underpinned by years of next-generation sonar and marine tech development.

by Mike McLeod

Toanyone who casually follows the Canadian technology scene, Newfoundland’s Kraken Robotics, like its namesake, seems to have suddenly burst to the surface, relentlessly moving from conquest to conquest.

In 2019 alone, the St. John’s-based marine technology company has acquired a new business unit, secured nearly $7 million in contracts and been named to the TSX Venture 50, placing first in the annual listing’s technology category. Further, the company says it’s on track to double revenue growth again this year, to approximately $15 million.

In reality, Kraken has been literally and figuratively lurking in the depths, slowly building its strength since 2012 when the firm’s founders spun off from commercial fishing technology company, Marport Deep Sea Technologies, to better focus outside the fishing sector. The team, including Marport’s then-CEO Karl Kenny, bought the intellectual property rights to the Synthetic Aperture Sonar (SAS) and

related marine technologies they’d developed while at Marport. The new company immediately set about leveraging its high-resolution sonar toward military, oil and gas, exploration and related markets.

“Synthetic aperture sonar, like our AquaPix sonar, is a next-generation system,” explains David Shea, Kraken’s VP of engineering. “It’s designed for very highend imaging of targets on the seabed. Presently, most applications for our sonar are in mine countermeasure-hunting. The U.S. Navy has determined that to acoustically classify a target as a mine accurately, you need a resolution of at least 5cm.”

According to Kraken, its SAS systems can capture detail down to 3cm by 3cm out to approximately 300 meters. When paired, one array on either side of a torpedo-shaped towfish or an autonomous underwater vehicle (UAV), the range extends out 600 meters. Shea says that kind of performance is an order of magnitude better than most commercially sonar technology available.

“Many of our competitors use real aperture, side-scan sonar systems,” he adds. “One of the challenges with those systems is that their resolution is fairly good close to the array but degrades very rapidly the further the target is away.”

The reason behind that performance discrepancy is related to the effective length of these systems’ sonar arrays, better known as aperture. As with radar dishes, and telescopes, the bigger the better. A longer array allows for a narrower beamwidth, or the expanding cone formed as an acoustical signal travels out. Eventually, that signal reflects off a target and returns to the sonar’s receivers. The bigger the aperture, the tighter the beam, meaning it can travel farther and return higher detailed data.

Traditional side-scan sonar employs a long, thin array, that sends and receives sequential pings as it moves through the water on a set course. The resulting data is then compiled into a single set, similar to making one panoramic image from multiple, overlapping photos.However, each piece of the overall image is limited by the resolution of the fixed-length array.

Synthetic aperture sonar, as its name suggests, isn’t constrained to a fixed physical aperture size. In addition, through sophisticated beamshaping and multi-aspect receivers, a SAS system can scan objects from multiple angles, to form acoustic images that are at a higher resolution than an image captured from a single flat aspect.

“With SAS, we take a smaller array, sliced up into many very small elements, and move it on a path through the water, constantly sending and detecting pings to and from the seabed,” Shea explains. “Our system then combines those multiple pings, using very sophisticated signal processing software, to make the system act like one very long array. To put some numbers

behind that, our physical array is one meter long but, in software, we can make it act as if it was 25 meters long.”

While the concept of SAS sonar has existed for more than 40 years, its actual use is relatively recent due to the system’s computationally heavy data processing requirements. Even so, the technology largely remains the domain of tier-one defense contractors.

In contrast, Kraken developed its SAS technology, from the beginning, with an eye toward both military and commercial customers. In addition, Kraken’s Interferometric SAS can also conduct detailed bathymetric studies that overlaps this depth data with detailed sonar images.

“Our original AquaPix INSAS product is tuned for mine-hunting in shallow water,” Shea says. “Our newer product, MINSAS, or Mini Interferometric Synthetic Aperture Sonar, is compact and fits in smaller vehicles but is also depth rated up to 6000 meters. The gross majority of commercial work is at less than 3000 meters but we are seeing some countries pushing their exploration into deeper water, especially for seabed mining.”

To assist customers with those projects, Kraken has also engineered related marine technologies to make the complex process of sonar data collection as straight forward as possible. The most notable are the company’s two sonar platforms: The Katfish, an actively controlled towbody, and the Thunderfish autonomous underwater vehicle (AUV). Designed for shallow water, high-speed surveys, the Katfish depends on a surface vehicle for locomotion, but has drone-like capabilities including navigation control, depth maneuvering and obstacle avoidance. Its tether cable supplies power and transmits data on board for processing.

“The Thunderfish is fully autonomous, meaning it’s free swimming with two

propellers on the back,” Shea says. “The interesting thing about both systems is that they use the same SAS systems, as well as our navigation solution, processing software and actuators, as well as our underwater laser scanner. So they are both fully integrated survey packages. The difference is that the Thunderfish performs all the data storage and processing on board and uses our pressure tolerate batteries to descend down to 6000 meters.”

Kraken’s pressure-tolerant batteries are one of the company’s latest innovations, produced by its recently acquired subsidiary Kraken Power. Conventional cells employ an oil compensation system that encapsulates lithium ion cells in a pressure vessel. A mechanical system feeds or removes oil as pressures and temperatures change. Kraken’s batteries immerse the cells in a jello-like polymer, eliminating the weight, fragility and leaks associated with oil-based systems.

“Once that silicon-like gel cures, we put a box around it that gives the battery some sturdiness,” Shea explains. “The unit is then shock tolerant and self-healing; repair only requires scooping out the silicon, putting in a new part and repouring the silicon. We can also make the battery any shape as applications require or new battery technologies become available.”

Although Kraken has built its business to date on engineering and developing superior hardware, it has begun offering robotics-as-a-service, as many customers are ultimately after acquiring data rather than hardware.

“The inspection, repair and maintenance market is huge,” Shea explains. “Oil and gas is certainly a big consumer, but the off-shore wind market growing massively. It’s very shallow where the turbines are based, so there’s concern about what’s happening on the seabed.” DE www.krakenrobotics.com

Color-coordinated operating elements

n Enhance operator safety

Use colors to clearly designate which elements to handle

n Identify machine functions or sections – Simplify operation

n Create strong aesthetics Colors tie to equipment elements or branding, reinforcing design quality and product value

Now in seven colors: orange, grey, yellow, blue, red, black, green. Colors are controlled in production to maintain consistency.

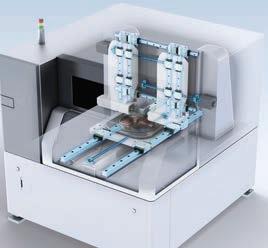

TwinCAT 3 controls machine with 18 synchronous NC axes to process die-cast automotive parts.

In the Ecmec SPM machine, the synchronized spindles move along 18 axes to cut the metal parts with exceptional precision, while the synchronized cutting spindles process the metal simultaneously.

Founded in 1983 and located in the Swedish city of Växjö, Ecmec AB produces hydraulic and mechanical fixtures, accessories for robot grippers and customized machines for assembly, part handling and machining operations. The latest example is the newly developed Ecmec SPM (Special Purpose Machine) machining center, which integrates and simultaneously executes all steps for processing up to 200,000 pressure die castings per year for the automotive industry.

Developed for an auto parts supplier, the SPM can complete several process steps simultaneously without having to remount the part being worked on. The machining center is designed for high-volume production of up to 200,000 parts per year and performs its functions and processing steps simultaneously within the same cycle.

The machine also reduces the previous processing and conversion times by more than one third, while requiring less shop floor space with its reduced footprint. Beckhoff supplies TwinCAT 3 automation software for the Ecmec machine’s PLC and NC operations as well as the main spindle and forward-feed drives.

When equipment manufacturers design a customer-specific machine, they must keep an eye not only on component costs but also on development expenses. For this reason, the time from first draft to delivery should be as short as possible.

“Since we don’t build a machine of this magnitude every day, we looked for a partner who could supply control and drive components designed to meet customer requirements,” says Daniel Eklund, managing director of Ecmec.

Those requirements were considerable, Eklund says. Parts that were previously made on two machine tools with three to five axes had to be processed by a single machine operating 18 NC axes simultaneously. Two main spindles are designed as four-axis units, meaning they can move freely along the X, Y and Z axes as well as rotate and tilt.

Another three main spindles move as three-axis units supplemented by an additional one-axis main spindle. With this configuration, workpieces can be machined on all sides without having to be remounted. A tool changer with four different tools makes the design even more flexible.

“The Ecmec SPM employs a totally different set of processing methods compared to traditional machines and does everything much faster,” explains Eklund. “It processes the workpieces roughly 33 percent faster than conventional machines and requires less machine footprint.”

“Addressing all 18 axes simultaneously requires a fast and powerful control system, which is where Beckhoff came into play,” says Eklund. “To avoid interface problems, we looked for a solution from a single source, and Beckhoff was able to

meet all the customer specifications.”

The flexible hardware design was another reason for the decision to select Beckhoff technology, because it made a big difference for the project group.

“We ran through various alternatives, but the NC I software modules from Beckhoff represented the best option,” says Eklund. “The Beckhoff system is very powerful and easy to operate, which is something we truly appreciate. It is a prime example of German engineering.”

At the core of the machine is TwinCAT 3 NC I software, which controls the six mechanical spindles simultaneously. The numbers of axes and channels were adjusted to satisfy the application’s requirements with respective option packages. As a highly scalable system, PC-based control also provides the best possible hardware platform for this application. The TwinCAT real-time kernel and the ultra-fast system communication over EtherCAT offer ideal conditions for high-precision motion control, Eklund explains.

“This platform provided very fast control properties and a much faster response time than the conventional PLCs we used in the past, which was one of the main reasons why we selected PC-based control technology from Beckhoff,” he says.

In addition, the TwinCAT development environment provides numerous features that make the designer’s work easier. For example, Ecmec’s programmers developed their own control and machine software on the basis of TwinCAT 3. They also opted to use the syntax with G- and M-codes as defined in the DIN 66025 standard, which makes it easier for the machine operators to change setups for new workpieces. These and other features enabled Ecmec to develop this high-performance machine in a very short timeframe.

The Ecmec SPM is controlled and operated via a C6930 control cabinet Industrial PC with a custom-designed CP3921 multitouch control panel featuring push-button extensions. The user interface is TwinCAT HMI for NC processing, which is programmed based on standards such as .NET. The axes and I/O channels are configured via TwinCAT Engineering with NC I functions.

The two main spindles are equipped with AM8000-series servomotors with speeds of up to 11,000 rpm. The other four spindles ensure a high degree of processing efficiency for downstream processing steps as well. The maximum feed rate is 30 m/min, and the maximum acceleration rate is 0.2 g. The six main spindles and 12 servomotors are controlled by Beckhoff AX5000 servo drives for fast and dynamic positioning. In addition, One Cable Technology (OCT) saves a significant amount of installation space.

To protect the operators and avoid equipment collisions, all servo drives are equipped with AX5805 TwinSAFE cards. The machine also uses TwinSAFE terminals and the EL6900 TwinSAFE Logic terminal with certified safety function modules and Safety over EtherCAT (FSoE). DE http://ecmec.se www.beckhoff.com

Integrating our accumulated expertise with precision machine components into highly customized pre-built motion systems, NSK automation solutions augment machine function and accuracy, and streamline the process from design concept to clear competitive edge.

Driving accuracy and automation. Delivering expertise and reliability.

PRECISION MACHINE COMPONENTS

www.nskautomation.com

CleanSlate UV Sanitizer disinfects grimy cell phones in medical and food processing facilities.

By Matt Mowry

Whilecell phones are our near constant companions, many in the infection research community referred to them as bacteria cocktails. One study, for instance, found that 94 percent of cell phones used by hospital staff bore infectious contaminants. Another study reported that 89 participants in one medical workplace were aware that mobile phones could be a source of contamination – but only 13 of them disinfected their phones regularly.

A device developed by infection-control startup, CleanSlate UV, can eradicate 99.9998 percent of drug-resistant MRSA bacteria in 20 seconds as well as other dangerous bugs like E.coli, Listeria and Salmonella. The device works on smartphones, tablets, badges and other portable items, does not require any training to use and disinfects without harsh

chemicals that can damage electronics. The CleanSlate UV Sanitizer can be used in healthcare facilities, biotech manufacturing sites and even food processing plants.

“The growth in mobile technologies is presenting a major infection control challenge in hospitals, food processors and other sensitive environments,’’ said Manju Anand, CTO of CleanSlate UV, which has offices in Toronto and Buffalo. He said 25 percent of hospital devices are contaminated with pathogenic bacteria.

“Yet, staff and visitors wash their hands and then immediately touch these dirty devices. This puts patients and staff at risk and existing chemical solutions have not been an effective tool to solve this challenge.”

The CleanSlate UV team knew the hazards presented by cell phones and

mobile devices in healthcare environments. One co-founders contracted a hospital-acquired infection (HAI), while another is a “germaphobe,” said Anand.

According to statistics from The Centers for Disease Control and Prevention, HAIs are a growing concern in the medical community. On any given day, according to the CDC, about 1 in 31 hospital patients has at least one healthcare-associated infection. Another study of healthcare workers found three or more bacteria species grew on nearly 21 percent of the cell phones tested.

The data was clear and CleanSlate UV engineers and product designers took on the task of developing a solution. They worked for nearly 10 months to develop the first generation of the sanitizer. Subsequent generations have taken nearly a year to complete.

“Designing the device is one thing,’’ Anand said. “Getting it into case study trials, peer-reviewed studies and mass manufacturing is another. We’ve learned some good lessons along the way.”

CleanSlate UV also received feedback from healthcare providers as it sought to refine the design and application for the technology.

“Their feedback led to meaningful product design and user interface improvements,’’ Anand said. “They helped prove how valuable the technology can be to patents and visitors, not just to clinicians.”

Given the often hectic and rushed environment of their target market, the CleanSlate UV team knew their Sanitizer had to be quick and simple to operate. Users deposit the mobile device into the machine, close a lid and wait 20 seconds for the device to be cleaned. Once com-

pleted, the lid opens automatically and the mobile device can then be removed with clean hands.

The device utilizes short-wavelength ultraviolet light (UV-C), which destroys nucleic acids and breaks apart germ DNA, preventing them from being able to function or reproduce. While deadly to germs, UV light won’t harm touchscreens, cameras or IR sensors, and is optimal for hard, non-porous surfaces.

The device can also sanitize multiple items at once and includes RFID-enabled tracking and compliance auditing. The UV-C light does not dry out or degrade materials, which occur with chemical wipes, and can be safely used on a variety of devices with no risk of damage.

Mobile devices are placed on a movable chamber that transports the device into a UV compartment, where the sanitization occurs. After 20 seconds, the device slides out, ready for use.

Anand said the CleanSlate UV team faced several significant challenges in design-

ing the device. “One of our biggest challenges in designing the product was the lack of a uniform standard by which countertop UV solutions would be judged,’’ Anand said. “This was in large part due to the infancy of the market. We found that a lot of other solutions had cut corners or taken the ‘easy route’ because people may just not have known better. Trying to determine where it was important to improve – versus what was ‘good enough’ for most customers – was sometimes difficult given the number of stakeholders in healthcare.”

The sliding chamber was a critical component, and engineers found a lubrication-free and maintenance-free solution from igus, the Germany-based manufacturer of motion plastics. The sanitizer includes igus’ DryLin W linear guides, which slide, instead of roll, and aren’t dependent of external lubrication.

“During the initial R&D stage, we discovered that the UV lights must be on and warm for effective sanitization in 20 seconds,’’ said Kevin Wright, the Canadian sales manager for igus. “Since the

Plastic DryLin W linear guides, by igus, allow the CleanSlate UV Sanitizer's sliding chamber to quietly move devices to be cleaned to the unit's disinfection chamber, without potential contamination from lubricants.

Point-and-shoot, reliable results

User-friendly, no experience required

High level of details and color data acquisition

creaform3d.com

UV light is dangerous to human skin and eye, we had to design a moving chamber that transports the device into the UV chamber when the sanitization was initiated by the user. It was important to have a bearing system that was extremely quiet, especially in the evening shifts where any noise from the devices can be disturbing to the patients and staff.”

Drylin W guides are resistant to dirt and dust due to dry operation, and are typically used in agricultural machinery, vehicle construction, packaging, furniture and robotics.

“We used roller stainless steel bearings, but due to the metal contact between the ball bearings and guide, the carriage made noise that was beyond the acceptable limits in the hospital settings,’’ Anand said. “Furthermore, the friction caused by non-rolling motions would result in more work for the motor, adding to stress to the system.”

In life cycle tests, Anand said, the steel bearings also failed upon reaching 10-20 percent of the expected life of the product. The system could not include lubricants

since the product is sold in hospital and food processing facilities.

“Reliability was utmost, as any downtime due to CleanSlate device breakdown would result in ineffective sanitization of mobile devices using chemical wipes, which could damage or degrade the electronic devices used in hospitals,’’ Anand said.

With the CleanSlate UV Sanitizer, more than 40 hospital systems, biotech companies and food processors in the United States, Canada, Australia and Hong Kong are making significant strides in reducing the number of pathogens found on mobile devices.

As more mobile devices are introduced and become increasingly commonplace, healthcare facilities, especially, will need to take steps to keep facilities free from germs and bacteria that flourish on them.

“So many people come to a hospital every day; having this type of machine available for them to use reinforces the

message that hygiene is important,” said Josée Shymanski, Manager of Infection Control at Montfort Hospital in Ottawa. “Combining cleaning your phone with cleaning your hands in one hygiene moment that takes just over 30 seconds is a good practice for your health. In addition, it shows that as an organization, we value clean care, and hopefully that translates to our patients feeling safe.”

“Many hospitals have ignored this problem for a while,’’ Anand added. “They’ve tried to ban devices outright or pretend the staff doesn’t use personal devices while on shift. But now that hospitals are issuing touch screen devices to patients and staff members, they can’t ignore it any longer. We frequently have hospital staff reach out telling us they’ve been looking for a solution to this problem for a while and are so glad they found us.” DE https://cleanslateuv.com www.igus.ca

Matt Mowry is the DryLin Product Manager for igus North America.

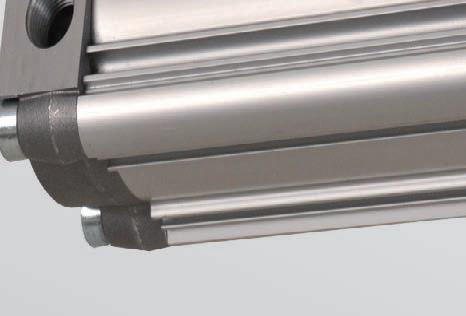

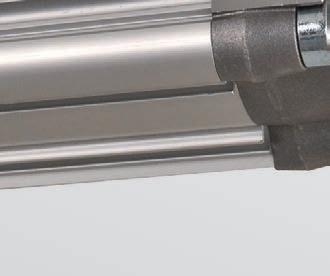

Leading shot blasting provider, V+M Systems, relies on the AVENTICS valve system to save energy and assembly time.

During the shot blasting process, small abrasive blasting objects are projected against the surface to be treated at high speeds using compressed air. This generates a residual compressive stress, increasing the permanent strength of the material by up to 60 percent.

At the same time, the treatment enhances the material’s bending strength and corrosion resistance while expanding its surface, which is important primarily for bonding components. Automobile manufacturers use shot blasting for metallic components, such as engine, chassis, and transmission parts that are subjected to high levels of stress in later use.

“Perfect movement and positioning are the most important requirements for industrial robots used for shot blasting,” says Martin Stolte, CTO at V+M Systems GmbH, a medium-sized enterprise specializing in shot blasting systems. “We wanted to mount the valve directly on the robot arm to optimize both the performance and the energy efficiency of our new systems.”

When an automotive manufacturer added the Aventics AV05 series to its list of approved components, V+M Systems immediately settled on the product.

For V+M Systems, modularity and the AV05 system’s light weight were the most important criteria. This allowed the engineers to integrate pneumatic control of the robot arm directly at the load.

“We have achieved improved system performance that also saves energy thanks to much shorter air lines,” Stolte said.

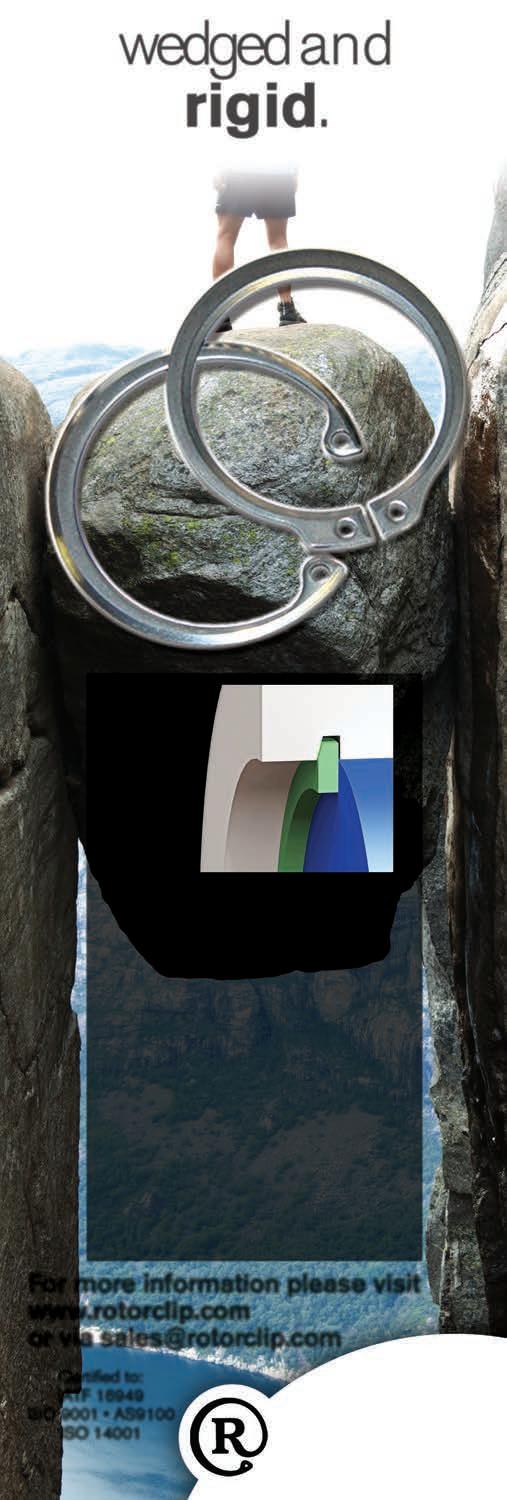

Unlike standard valves with a rectangular base plate and mounted valve, the spool in the AVENTICS Advanced Valve (AV) family is arranged diagonally in the valve housing. This reduces the volume of the valve on the base plate by approximately 45 percent.

“Beside the compact design, weight also played an essential role,” Stolte underscores. “The AV system is so lightweight that we can mount it directly on the moving robot arm.”

It has no effect on the robot dimensioning at all. Thanks to high-performance polymers and a specially developed injection molding method, the valves in the AV series are nearly 40 percent lighter. This light, compact design allows the valve to be positioned near the load, shortening the paths between the load and the valve.

“We save assembly time and costs when piping, and users record a lower compressed air consumption thanks to a reduction in dead volumes,” Stolte says. “This matches the philosophy of our customers in the automotive industry – to significantly increase the energy efficiency of this type of system.”

The integrated fieldbus connection and the input and output modules from the Aventics Advanced Electronic System (AES) also play a role here. They process analog and digital signals, allowing for both fast assembly and flexible application. As a result, V+M Systems can incorporate machine diagnostics via the valve system by reading in pressure switches. DE http://vm-systems.de www.aventics.com

V+M Systems’ shot blasting systems, which use air and abrasive particles to strengthen metallic automotive components, incorporates Aventics’ AV05 valves, mounted directly on the robot arm, saving energy and assembly time.

Festo released its DHEF adaptive shape gripper that can pick and move different shapes without the need for manual adjustment. The result of research performed by Festo’s Bionic Learning network, the DHEF mimics the action of a chameleon’s tongue – wrapping its elastic silicon cap around objects. It works in conjunction with the gripper’s pneumatic drive to grip components with variable or free-form shapes. It also has no sharp edges, making it suited for gripping sensitive objects or several parts in one movement. Additional features include a standard sensor slot for position sensing as well as a bayonet lock for easy replacement of the cap. www.festo.com

Rockwell Automation released its FactoryTalk Analytics LogixAI, (AKA Project Sherlock), an add-on module for ControlLogix controllers that uses AI to detect production anomalies and alert workers so they can investigate or intervene. The add-on fits directly into a control chassis and streams controller data over the backplane to build predictive models. It can continuously monitor a production operation, detecting anomalies against its derived understanding. Workers can then be notified of problems by configuring alarms on an HMI or dashboard. The LogixAI module is the newest addition to the FactoryTalk Analytics portfolio that includes FactoryTalk Analytics for Devices, which learns about an automation system’s structure to tell workers about problems with individual devices.

www.rockwellautomation.com

B&R released its Power Panel C50 that combines a controller with a projected capacitive touch screen in a single HMI device. The panel features a dedicated processor for the HMI application, making it well suited for mapp View HMI applications. The fanless unit can be used at temperatures ranging from -20°C to +60°C and features clear or anti-reflective glass. It can be operated with leather gloves and supports gestures like zoom or swipe provide an intuitive user experience. The widescreen C50 is available in four different sizes from 7 inches to 15.6 inches with IP65 protection. The C50 also features a range of integrated interfaces, including POWERLINK, Ethernet and USB. I/O modules, axes and safety components can also be connected directly to the panel.

www.br-automation.com

AutomationDirect introduced its IDEM high precision, snap-action 15A-rated micro limit switches in plunger and lever actuator styles. Plunger Series types include pin plunger, spring plunger and roller plunger actuator. Lever Series types include lever, hinge lever and roller lever. The limit switches’ snap action assures reliable, repeatable contact closure regardless of actuation speed and provides long service life, the company says. Panel mount options are available and screw terminals provide easy connection. A terminal enclosure with cable strain relief is available to cover and protect the terminals. Available individually or in packets of five, the switches are cULus and CE approved and are backed by a 1-year warranty. www.automationdirect.com

Balluff latest family of IO-Link masters provide more flexibility in designing controls architectures with Smart IO-Link devices. The Device Integration IO-Link masters — BNI00E1 (Ethernet/IP) and BNI00AZ (Profinet) — feature 4x Type A IO-Link ports and 4x Type B IO-Link ports, each with up to 2A of output per channel to meet a wider range of requirements. The units also feature M12 T-coded power connections capable of up to 12A of power. These IO-Link masters feature 9A of galvanically isolated output power with up to 2A per port on Type B ports to drive high amperage devices such as pneumatic or hydraulic valves. The master’s webserver capabilities allow for remote configuring, parameterizing and monitoring IO-Link devices with IODD files without the need for additional software. www.balluff.com

Miki Pulley introduced its BXR-LE, a line of spring-applied electro-magnetic brakes that hold a static position, without the need for external power. When the stator is energized, the brake is disengaged allowing free rotation. When no current is applied, compression springs halt the brake rotor thereby stopping the input shaft rotation. The series comes in six size configurations, designed for smaller machine and robotic applications, where cantilevered loads can negatively impact operation. With accompanying voltage controller, power

consumption is stepped down to 7VDC after a split second of 24VDC for brake actuation. The series allows a maximum of 6000 RPM with a static friction torque range from 0.06Nm to 3.20Nm (0.044ft-lbs to 2.36ft-lbs).

www.mikipulley-us.com

HMS Networks released four Ixxat CAN FD repeaters that enable CAN FD and CAN

components to be networked using tree and star topologies, as well as allowing implementation of drop lines. No configuration is required in the process. The repeat-

ers are available with two and four channels for copper-wired networking (versions CAN-CR100 and CAN-CR300) and for copper and fiber-optic connectivity (CAN-CR110/FO). All repeaters have a galvanic isolation of 1kV, except for the CAN-CR120/HV version, which withstands up to 3kV. With the fiber optic version, it is possible to bridge distances with high electromagnetic interferences or to design applications with very high demands on galvanic isolation. The repeaters come with slim plastic housings for DIN rail mounting, and the CAN connection is done via screw terminals.

www.ixxat.com

• For applications in positioning & reciprocating motion

• Zero play –even during reversal

Uhing® Rolling Ring linear drives run on a smooth, threadless shaft that won't clog or jam. If the system is overloaded, the shaft simply slips instead of churning and grinding. The drive bearings are in constant contact with the shaft, even during reversal, thereby preventing backlash.

Example applications: metrology machines, material handling systems, spooling equipment, packaging & converting equipment.

Many different sizes meet varying requirements for axial thrust & linear speed.

For more information call 1-800-252-2645

Email: amacoil@amacoil.com www.amacoil.com

Some models feature mechanical control over speed and travel direction. No programming or electronic controls are needed.

Brushless Servo Motor

Haydon Kerk Pittman has added its EC042B IDEA motor series to its line of brushless DC motors. This drive and servo motor line enables distributed control without the use of a PLC or external motion controller. With a diameter of 42mm, the line is offered in three motor lengths with continuous torque up to 0.15Nm with integrated inputs, outputs, encoder and RS-485 communication. The GUI integrates a trapezoidal and S-curve trajectory generator with a movement profile plotter. The IDEA Motor can store and execute multiple programs with I/O driven nested, prioritized and vectored interrupts as well as polled I/O for autonomous real time control.

www.haydonkerkpittman.com

Bison Gear and Engineering has launched its VFsync, a permanent magnet AC motor. The synchronous motors sport an IP66/ IP54 platform that range in power from .25 to 1.5 hp and are supplied with swivel connectors and shielded cables. Popular frame sizes include IEC B14, sizes 71, 80 and 90 along with NEMA 56C mounting. The product line includes the motors, quick connect cables and a market leading, programmable and networked VFD available

in an IP 20 panel style or enclosed IP66 models. VFsync motors are designed to work with Bison Gear & Engineering’s line of integral horsepower gear reducers. Each frame size is available in either 230 or 460V construction, and either TENV, TENV w/encoder or TEFC styles.

www.bisongear.com

Step Motors

Applied Motion Products released step motors for applications with limited space. The line includes NEMA size 8 at 1.24 or 1.85 inches long (holding torque up to 4.53 oz-in); NEMA size 11 at 1.22 or 2.05 inches long (torque up to 14.16 oz-in); and NEMA size 14 1.02 or 1.57 inches long (torques up to 25.53 oz-in). These hybrid-type,

RoHS-compliant motors are available in both single and double-shaft versions and feature a 1.8 degree step angle. To address customers requirements for specific connectors and couplings, Applied Motion Products provides its motors with customized cable and connector assemblies and a variety of options including flats, thruholes and custom lengths.

www.applied-motion.com

Mitsubishi Electric Automation, Inc. released its TM-RG2M / TM-RU2M line of low-profile direct drive motors, which feature direct control of a load without traditional transmission components. According to the company, it provides direct control with the accuracy of a servo motor. The direct drive motor features two installation meth -

Backings,

Drive Components and Accessories

ods - flange type with pilot and table type with positioning pinholes. It is designed for use in industries such as semiconductor / LCD manufacturing, machine tool, material handling and inspection. Suitable applications include coating and vapor deposition systems, index tables, tool changers, rotary material handling robots and rotary axis on XY theta inspection positioning systems. https://us.mitsubishielectric.com

Leine Linde has released ADS Uptime, its next generation of condition monitoring system for encoders. The Advanced Diagnostic System (ADS) retains the core features of its previous generation but introduces a wireless service check-up through Bluetooth and single cable support for diagnostic and control loop feedback information. ADS

Uptime allows performing service checkups on the go via the ADS Uptime app so technicians can detect unusual trends or recognize warning signs. ADS Uptime also allows users to store recorded and access information over the encoder’s lifetime. Detailed data and parameters on things like scanning quality, time in motion, temperature, frequency and vibration are accessible. The vibration parameter has been enhanced to allow measurement in both the radial and axial directions. www.heidenhain.com

Pepperl+Fuchs introduced the UCC*-50GK series ultrasonic sensor, which uses ultrasonic pulses to measure the distance to the target and reports information through one of three sensor outputs. The sensor doesn’t require a PLC and is incorporated into an existing project via UART, LIN-Bus or PWM. It is also equipped with a power save mode and features pre-stored sound profiles and a choice of beam widths. The sensor also has three beam patterns and a sensing range of up to 4m. With an IP66/67 rating, the sensor has a PTFE protective film, operates in a temperature range of -25°C to +70°C and features integrated temperature compensation. www.pepperl-fuchs.com

OmniVision Technologies announced its OV2778, an 2MP RGB-IR automotive image sensor for cabin- and occupant-monitoring. The OV2778 comes in a 6.5 x 5.7mm automotive CSP package and offers advanced ASIL functional safety. The OV2778 is built on OmniVision’s 2.8-micron OmniBSI-2 Deep Well pixel technology, which delivers a 16-bit linear output from a single exposure with low-light sensitivity. With the second exposure, the dynamic range increases to 120dB. The image sensor is AEC-Q100 Grade 2 certified for automotive applications. www.ovt.com

• Industrial Ethernet cable connectivity solutions

• Engineered to withstand impact, flexing, torsion, and temperature extremes

• Enables real-time factory communication to optimize productivity

• Full range of CAT.5 to CAT.7 options works across multiple protocols -- flexible, scalable

Amphenol RF has added ruggedized fixed-length cable to its ARC line of coaxial connectors and RF cable assemblies. The assemblies include N-Type and TNC configurations and feature adhesive lined, multi-layer heat shrink tubing. This construction offers shock resistance and reinforces connector retention and cable rigidity. All ARC products are IP67 rated in both the mated and unmated condition.

www.amphenolrf.com

The problem: Damage caused by electrical current passing through bearings in electric motors.

The solution: Current-insulated bearings from Schaeffler — including hybrid ceramic or ceramic-coated versions featuring our proprietary Insutect™ coating — that have been engineered to stop stray electric current in its tracks.

Now that’s electrifying! www.schaeffler.ca