FLUID POWER ROUNDTABLE

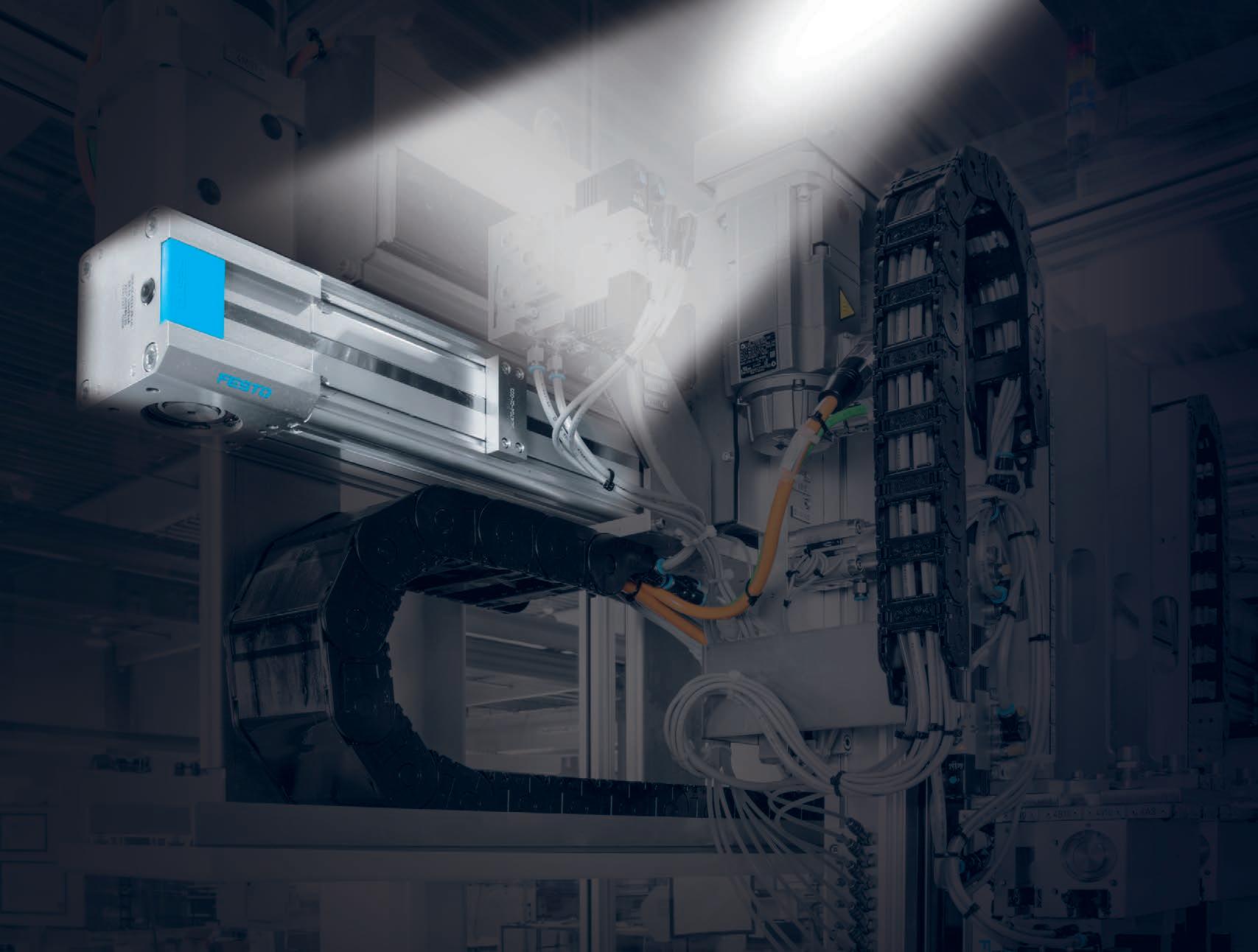

Whether you’re designing control systems or programming PLCs, you need to know the core products are going to perform like stars. Festo’s Stars of Automation offers you a one-stop solution, with over 4,000 durable, costeffective and high-quality components that enhance every factory system. For great value, look to the stars. Choose Festo.

Exceptional designs deserve superior components.

The developer of the original world-class linear motion systems, THK continues to redefine industry standards and to meet an ever-growing range of needs. From aerospace and machine tool to packaging and medical, THK products play a vital role in the advancement of technology and capability.

To learn more, call us at 1-800-763-5459 or visit www.thk.com.

21 Fluid Power News

Wajax 2020 financial results and other fluid power news.

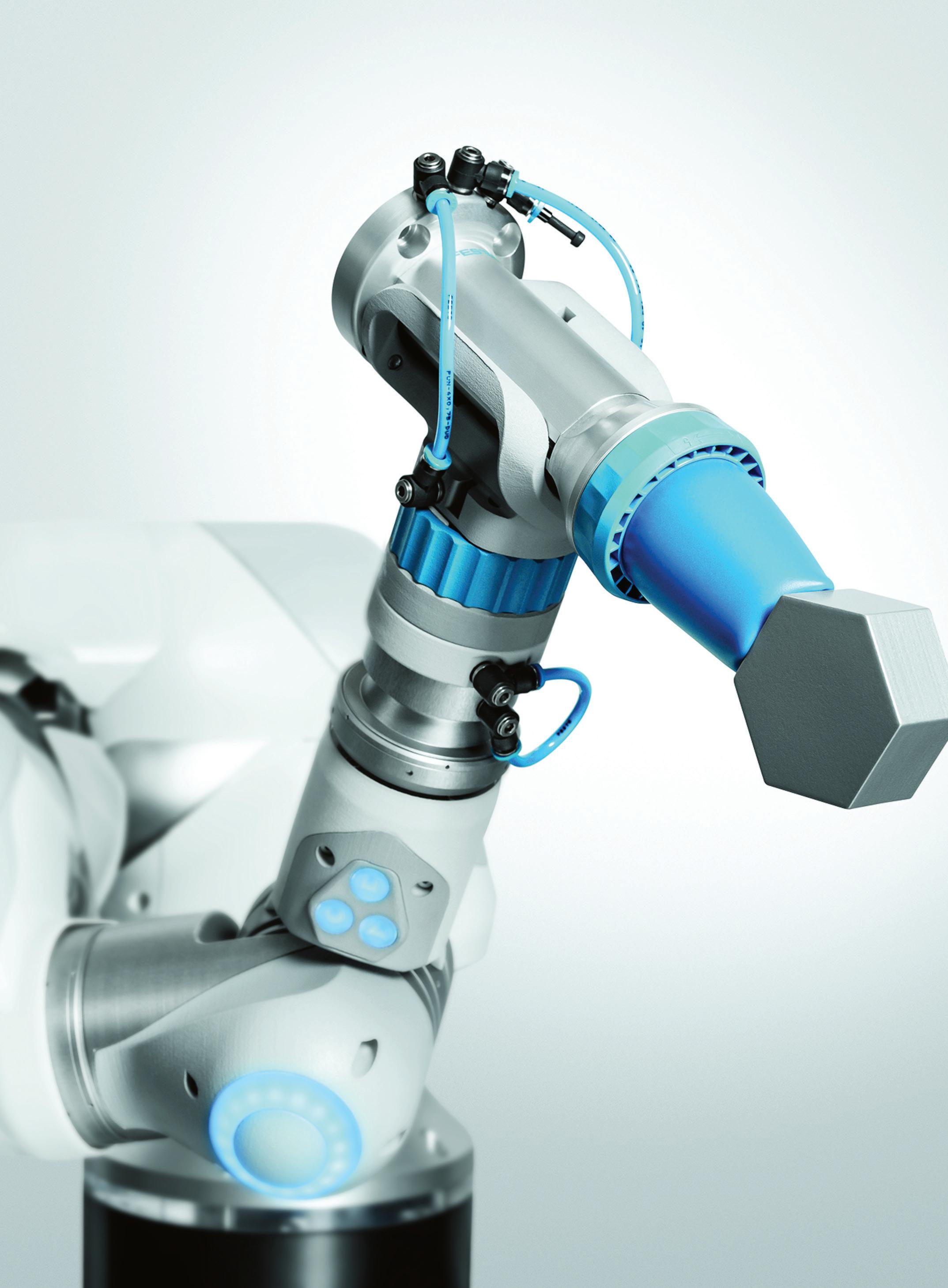

22 Getting a Handle on Grippers

Choose the right technology with these key facts and features behind several gripper types 25 Fluid Power Roundtable

Fluid power leaders discuss the latest tech, the impact of COVID and the state of the industry 28 Fluid Power Product Showcase

Cutting edge pneumatic and hydraulic industrial technology

Columns

Design News

Annual ranking lists top engineering universities in Canada and other design news 13 CAD Report

3DExperience World 2021 wanders farther away from Solidworks roots

Industrial products including automation, motion control and sensors

Rise of the ZEV

Over the past four to five months, seemingly every major car maker has announced either a new or accelerated initiative to switch more of its future auto lineup to some form of zero-emission vehicle (ZEV). In January, GM even redesigned its iconic 57-year-old logo to resemble an electric socket with a light blue color scheme to suggest “the clear skies of a zero-emissions future.”

While it may seem sudden, the industry’s turn away from internal combustion started, in earnest, circa 2018, largely driven by a global shift in governmental policy. According to the International Council on Clean Transportation, roughly 22 countries, including China, Germany, the U.K, France, and Canada, issued some form of policy statement on the subject between 2017 and 2019.

Each proclamation either set goals to significantly reduce sales of internal combustion vehicles or asserted that ZEVs would make up a sizable percentage of new car sales by dates ranging from 2030 to 2050. Most of these measures lacked penalties for non-compliance, but they did make clear to the auto industry which way the road ahead was turning.

So, if the plans for an emission free vehicle future were already in place, what’s driving the most recent acceleration? Two events seem the most likely. First, Tesla had a phenomenal year. Its market capitalization hit $160 billion in February 2020 and then rose steadily to $847B nearly a year later, making it the most valuable automotive company in the world.

During that time, the company also started production of its Model Y SUV and, more importantly, announced a “tabless” battery technology. In September, CEO Elon Musk boasted its new cells would not only improve its vehicles’ range and power, but also reduce their sticker price to roughly that of gasoline-powered cars. Collectively, 2020 sent a strong signaled to legacy ICE car makers they might be in danger of becoming market has-beens, the Blackberry to Tesla’s iPhone.

The other major piece may well be the U.S. presidential election, when an administration that championed global warming measures like the influential California Air Resources Board (CARB) fuel efficiency standard replaced an administration that actively fought them. So far, 11 U.S. states have enacted regulation to steadily increase ZEV sales by 2035.

While it’s still uncertain how the electrical grids will handle millions of new ZEVs or how the extra power will get generated, it seems clear the world has 10 to 20 years to figure it out.

MIKE

MCLEOD

Editor mmcleod@design-engineering.com

Editorial Board

DR. ALAIN AUBERTIN

President & CEO, Consortium de recherche et d’innovation en aérospatiale au Québec (CRIAQ)

DR. MARY WELLS, P.ENG

Dean of the Faculty of Engineering and Professor, Mechanical and Mechatronics Engineering at the University of Waterloo

AJAY BAJAJ, P.ENG Owner and President of Rotator Products Limited; Past President, Power Transmission Distributors Association (PTDA)

DR. ISHWAR PURI, P.ENG

Dean of the Faculty of Engineering; Professor of Mechanical Engineering, McMaster University

MARCH/APRIL 2021 Volume 66, No. 2 design-engineering.com

READER SERVICE

Print and digital subsciption inquires or changes, please contact

Beata Olechnowicz, Audience Development Manager

Tel: (416) 510-5182

Fax: 416-510-6875

Email: bolechnowicz@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SENIOR PUBLISHER Paul Burton (416) 510-6756 • pburton@annexbusinessmedia.com

EDITOR Michael McLeod (416) 442-5600 ext. 3231 mmcleod@design-engineering.com

ACCOUNT MANAGER Wendy Serrao (647) 628-3610 • wserrao@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett (416) 829-1221 • ifawcett@annexbusinessmedia.com

ACCOUNT COORDINATOR Cheryl Fisher (416) 510-5194 • cfisher@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Design Engineering, established in 1955, is published by Annex Business Media, 6 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

Printed in Canada

Publications Mail Agreement #40065710 ISSN: 0011-9342 (Print), 1929-6452 (Online)

Subscriber Services: Canada: $57.50 for 1 year; $92.50 for 2 years; $10 for single copy.

Outside Canada: USA - $140.50; Overseas - $151.00; $10.00 for single copy.

All prices in CAD funds. Add applicable taxes to Canadian rates.

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer: privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

©2021 Annex Publishing & Printing Inc. All rights reserved. DE receives unsolicited features and materials (including letters to the editor) from time to time. DE, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. DE accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. DE is indexed in the Canadian Business Index by Micromedia Ltd., Toronto, and is available on-line in the Canadian Business & Current Affairs Database.

Need Pneumatic Components?

Everything you need at great prices, in stock and ready to ship same day

Pneumatic Air Preparation

All pneumatic motion requires clean and dry air with enough flow to provide the required pressure. The process of filtering, regulating and lubricating compressed air is known as air prep. The NITRA family of air preparation components include:

• Filters with 40 micron filter element (5 micron option) in sizes from 1/8” to 1” NPT port sizes

• Regulators with adjustment from 20-130 PSI and 4-57 PSI

• Combination filter/regulators available with same options in one unit

• Lubricators in 1/8” to 1” port sizes

• Total air prep units that combine all air preparation functions in one compact unit

Solenoid Valves

(A07005SN) Orders over $49 get FAST FREE SHIPPING Our shipping policies make it easier than ever to order direct from the U.S.!

Solenoid valves are electrically controlled to direct air flow to sequence operations in pneumatic systems. Solenoid valves are used to control cylinders, rotary actuators, grippers and other pneumatic devices. Use a manifold to simplify plumbing for a bank of valves. Modular systems even allow networked control of valve group.

• Available as stand-alone units or as part of a compact modular valve system

• Stand-alone units can be used with optional manifolds to make system configuration simpler

• Available in 3-port/3-way, and 5-port/4-way styles

• 4-way valves come in 2 or 3-position styles with center closed or center open

Pneumatic Cylinders

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

The most popular style of pneumatic actuator uses compressed air acting on a piston inside a cylinder to move a load along a linear path.

• Round body cylinders available in singleacting or double-acting styles, with up to an 18-inch stroke and 2-inch bore. Also available in stainless steel. Magnetic pistons are optional.

• NFPA tie rod air cylinders come in doubleacting style, with up to a 32-inch stroke and 4-inch bore. All include a magnetic piston. Adjustable air cushions are an option.

• ISO 15552 air cylinders are double-acting cylinders with up to a 600mm stroke and 100mm bore. All include magnetic pistons and adjustable air cushions.

• Metric and Inch compact air cylinders as well as dual rod guided air cylinders also available.

EDUCATION

ANNUAL RANKING LISTS TOP ENGINEERING UNIVERSITIES

Quacquarelli Symonds (QS), the London-based analytics firm known for its ranking of higher education institutions, unveiled its 2021 QS World University Rankings by Subject. An influential guide for post-secondary-bound students, the annual listing deter mines ranking based on four criteria: A university’s reputation among academics and global employers, plus the number of citations per research paper from that university, and QS’ own ‘H-index’, a measure of the impact a published scientist or scholar at a university has achieved.

In addition to an overall global score, each university is also ranked based on its strength in broad fields and sub-specialties (e.g. engineering and technology/mechanical engineering) and by geographic region and a specific country (e.g. North America/Canada).

Within Canada, University of Toronto held on to its top spot across each broad topic area, including arts and humanities; engineering and technology; life sciences and medicine; natural sciences; and social sciences and management. In fact, U of T ranked first in Canada in 30 out of the 48 specific subjects evaluated.

Globally, the ranking revealed U of T as the most well-rounded, ranking in the top 50 in 46 subjects, more than any other university. It also broke into the top 10 internationally in education; library and information m anagement; sports-related subjects; anatomy and physiology; pharmacy and pharmacology; geography and area studies; and anthropology.

In the Canadian Engineering and Technology category, U of

T (ranked 18th globally) was joined, in order, by University of British Columbia, University of Waterloo, McGill University, Université de Montréal.

University of Alberta, Queen’s University, University of Calgary, McMaster University and Western University round out the top 10.

The number of subjects the University of Toronto ranked in the top 50, more than any other unversity globally.

Drilling down to the mechanical engineering specialty, the ranking flips slightly with McGill University taking the top spot, followed by U of T, UBC, University of Waterloo and Université de Montréal.

Inter nationally, QS ranked MIT, Stanford, Cambridge, Harvard and Singapore’s Nanyang Technological University as the top five mechanical eng ineering programs in the world for 2021. www.topuniversities.com

CANADA, QUEBEC MAKE $100M INVESTMENT IN EV BATTERY ASSEMBLY

The Quebec-based company designs and manufactures all-electr ic school buses and class 6 and 8 commercial trucks and currently employs more than 465 people. When the new assembly plant is completed in 2023, the company says it will have the capacity to produce 2,500 vehicles per year and add 135 jobs in the near term, plus another 150 jobs over the long term.

The Canadian government and Quebec have announced an equal investment totalling nearly $100 million in Lion Electric, for the establishment of an automated battery-pack assembly plant. The company says construction is projected to break ground at an as-yet-to-beconfirmed location in the near future.

Lion Electric says the investment will also allow for cost str ucture improvements, better control of the design and shape of its batteries, and ultimately increase production volume. The company will also be the first Canadian manufacturer of medium and heavy-duty vehicles to have state-of-the-art, automated batter y-pack manufacturing facility.

“Lion is an important player in the Quebec and Canadian transportation electrification ecosystem,” said Lion Electric President and Founder, Marc Bédard. “This plant will allow Lion to consolidate a key element of our electric vehicles

Precision Control Solutions

Designing efficient systems involves much more than simply understanding a few basic principles. There is a true art to balancing the specific requirements of an application in order to achieve the desired goals in the best possible way. Help us understand the unique needs of your application and together, we’ll develop something that surpasses what any of us could have done alone.

Contact your distributor to learn more, or clippard.com to request a free catalog and capabilities brochure.

supply chain. Thanks to loans from the federal and provincial governments, we will now be able to manufacture in Canada what we previously imported.”

In addition to production, the company said it will also establish an R&D innovation centre within its plant to improve energy storage capacity and performance of its batteries, as well as refine products for future use, including batteries for emergency vehicles.

https://thelionelectric.com

AUTOMOTIVE

CANADIAN TIRE, NUPORT ROBOTICS TO COMMERCIALIZE AUTOMATED SEMI TRUCKS

Canadian Tire and Toronto-based startup NuPort Robotics Inc. announced a partnership with the Ontario government to invest $3 million to develop automated semi trucks. The goal is to test short-haul shuttle runs, referred to as the middle mile, that semi-tractor trailers make daily between distribution centres, warehouses and terminals.

Backed by $1 million from Ontario’s Autonomous Vehicle Innovation Network (AVIN), plus $1 million from Canadian Tire and NuPort Robotics, respectively, the two-year project is applying NuPort Robotics’ AI technology to retrofit two conventional semi-tractor trailers.

“The trucks are currently transporting goods between a Canadian Tire distribution centre in the Greater Toronto Area and nearby rail terminals within a 12.5 mile radius, and

early results are promising” said Raghavender Sahdev, CEO of NuPort Robotics. “The aim of the project is to develop a system that incorporates an autopilot feature for conventional tr ucks with a driver, leading to the most efficient way to drive and increase safety. The sensors work as a ‘safety cocoon’ to cover blind spots and prevent accidents and the end result is peak fuel efficiency, meaning lower carbon emissions, and peak driving performance for an overall more optimal transportation experience.”

NuPort Robotic says its approach to autonomous trucking is unique in that it focuses on the middle mile, using a known set of predetermined trucking routes instead of general highway driving.When implemented on fixed routes, the company says Canadian Tire will benefit from faster commercial deployments and improvements in supply chain sustainability.

www.nuport.ai

Corp.CanadianTire.ca

UWATERLOO ROBOTIC EXOSKELETON WALKS ON ITS OWN

Researchers at the University of Waterloo have developed exoskeleton legs, called ExoNet, that can independently make control decisions, by combining computer vision and deep-learning AI. The system mimics how able-bodied people walk by sensing its surroundings and adjusting its movements.

While other such motorized systems have been developed before, they are typically manually controlled by joysticks or s martphone applications. ExoNet improves on this basic design by fitting the exoskeleton with wearable cameras paired with optimized AI computer software to process the video feed to accurately recognize stairs, doors and other features.

The next phase of the ExoNet

research project will involve sending instructions to motors so that robotic exoskeletons can climb stairs, avoid obstacles or take other appropriate actions based on analysis of the user’s current movement and the upcoming terrain. The researchers are also working to improve the energy efficiency of the exoskeletons’ motors by using human motion to self-charge the batteries.

“Our control approach wouldn’t necessarily require human thought,” said PhD candidate in systems design engineering and ExoNet research lead, Brokoslaw Laschowski. “Similar to autonomous cars that drive themselves, we’re designing autonomous exoskeletons that walk for themselves.” Waterloo.ai

ADDITIVE MANUFACTURING

BURLOAK FIRST ADDITIVE MANUFACTURER APPROVED TO SUPPLY BOEING

Burloak Technologies, a division of Ontario-based Samuel, Son & Co., announced it is the first additive manufacturer to

Photo credit: Nuport Robotics

Photo credit: University of Waterloo

Photo credit: Burloak Technologies

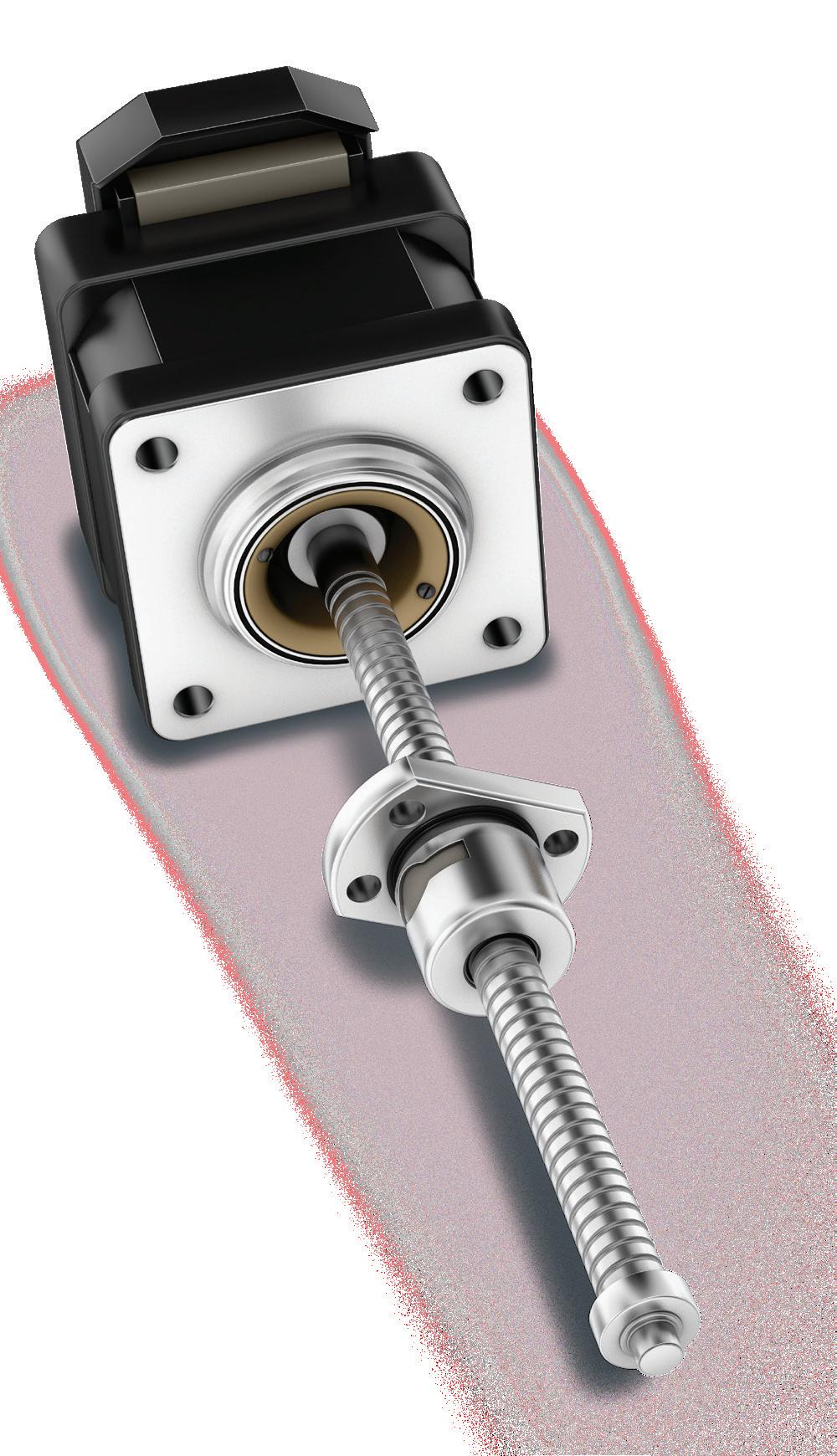

SOLUTIONS FOR MEDICAL

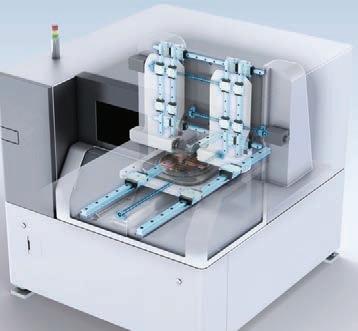

Compact, high-accuracy positioning through seamless mechatronic integration.

For life-critical medical, imaging and laboratory applications, NSK integrates a high-resolution motor with our precisionmachined ball screw to create the MBSA Motorized Ball Screw Actuator. The result: smooth, near-silent, extremely reliable and ultra-accurate motion, improving efficiency and throughput while lowering costs.

Stay in motion. Stay in control.

satisfy Boeing’s internally developed BAC 5673 specification governing additive manuf acture of aluminum AlSi10Mg aerospace components.

“This approval marks the completion of a qualification process that included a rigorous evaluation of Burloak’s capabilities by Boeing,” said Peter Adams, Burloak’s founder and CIO. “We would like to thank Boeing’s additive manufacturing team for its collaborative approach. Together, we developed a well-defined specification that has demonstrated robust, repeatable processes to produce flight components using additive manufacturing.”

Burloak Technologies and Boeing say they are currently working to apply the BAC 5673 specification to several programs for existing and future components.

“Achieving this qualification further validates Burloak’s position as a global leader in the additive manufacturing space, and clearly demonstrates our ability to commercialize this transformational technology,” said Colin Osbor ne, Samuel’s President and CEO. “This milestone also signals the increasing importance of additive manufacturing within aerospace and represents a step forward on the path to a greener future for aviation.” https://burloaktech.com

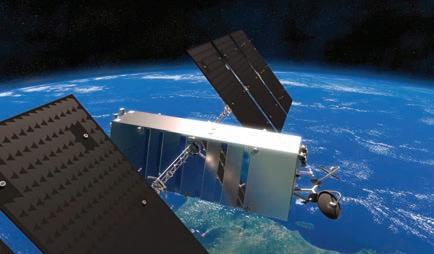

TELESAT LIGHTSPEED RECEIVES $400M FROM QUÉBEC

Canadian satellite communications company, Telesat, announced that the Québec government will invest $400 million into Telesat Lightspeed, the company’s

advanced Low Earth Orbit (LEO) satellite network. Under the terms of the MOU, the investment will consist of $200 million in preferred equity, as well as a $200 million loan.

For its part, Telesat said the funding will spawn 600 STEM jobs in Québec plus $1.6 billion in economic activity, both directly and through its supply chain.

The province will also house Lightspeed’s technical operations, including the Network Operating Centre, a Satellite Control Centre, the Cybersecurity Operations Centre, the Engineering Lab and an advanced Landing Station.

Quebec’s investment followed a $600 million from the Government of Canada and Telesat’s selection of Thales Alenia Space as prime contractor for Lightspeed. Thales said it will establish the final manufacturing of Lightspeed satellites at an assembly, integration and testing facility in Québec capable of delivering an average of one Lightspeed satellite per day.

Telesat has also selected MDA to manufacture the phased array antennas to be incorporated into the Lightspeed satellites. Produced by 3D printing, the beam hopping antennas will allow Lightspeed to focus broadband links into rural and remote communities. www.telesat.com

Visit design-engineering.com for the latest new products, news and industry events.

NSK MBSA Motorized Ball Screw Actuator for Compact, Accurate Linear Motion

Photo Credit: Telesat

A Different Path

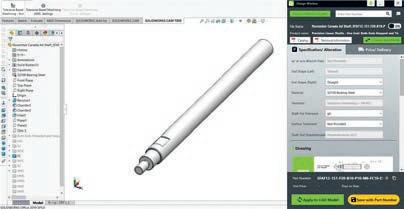

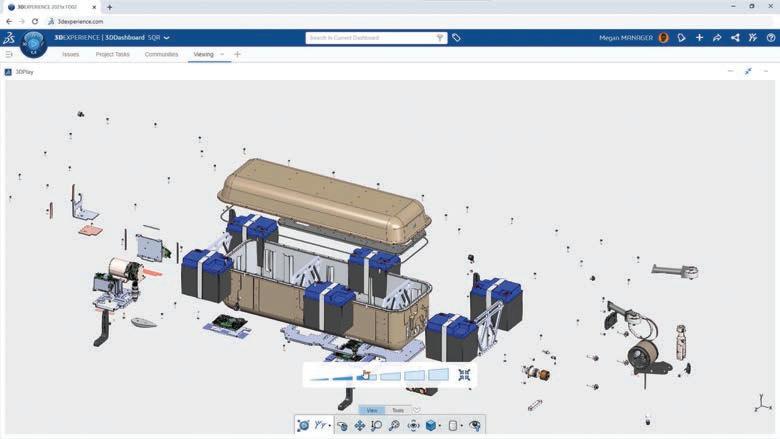

Virtual 3DExperience World 2021 event wanders farther away from Solidworks-centric roots.

BY RALPH GRABOWSKI

Last year, 3DExperience World was a first and a last. It was the first time the former Solidworks World conference operated under a new name, as well as the last in-person CAD conference before COVID-19 shut ’em all down.

“3DExperience” collectively refers to Catia and a suite of cloud-based support software. Dassault spent a decade trying to do the same with Solidworks, including changing the world’s top-selling mid-range MCAD program to “3Dexperience Solidworks.” Ultimately, the company settled on a compromise. It would continue to update the desktop-bound Solidworks while pressing home the message that running 3DExper ience is the better future.

Changing the names of Solidworks World and Solidworks, therefore, was part of the Dassault messaging campaign, “From product to platform.” Solidworks is the product, 3DExperience the platform. Dassault says the big benefits Solidworks users derive from switching to 3DExperience include built-in communication between software programs and access to Dassault’s big iron software, like Enovia and Simula.

3DExperience World 2021

For Dassault, the name change gave executives at last year’s event license to concentrate on 3DExperience and ignore Solidworks, for the most part. This year’s event proved even more disconnected from Solidworks users, as CEO Bernard Charles began his opening keynote boasting of spending “six billion dollars” on medical software.

Two years ago, Dassault acquired Medidata, for $5.8 billion. The New York firm’s cloud-based software analyzes pharmaceutical trials for drug makers, whose names we now recognize, AstraZeneca and Pfizer.

Together with its Biovia medical software, Charles made the claim that Dassault helped reduce the time to create new vaccines from 15 years to 15 months.

Instead of hearing from the main stage about what is new in Solidworks 2021, this year’s big announcements instead were for a new educational and “maker” versions of Dassault collections. Solidworks for Students (US$60/ year) ships in May, after school is over; the Makers version (US$99/year) won’t be available until the second half of 2021. Both combine Solidworks with two 3DExperience add-ons.

Also targeting start-ups, the company focused on the 3DExperience Lab, a newish incubator program that hosts start-ups as they design products using 3DExperience software in a range of categories: City, life, lifestyle, ideation and fabrication.

Selected start-ups get mentoring and an opportunity for an international product launch. Some 35 projects are underway, such as a 3D-printed violin and a robot communicator for autistic children. Labs are located in Pune, India, Boston, and at Dassault’s head office in Velizy France.

3DExperience Works

When Solidworks CEO Gian Bassi came to the virtual stage, he also largely ignored Solidworks. Instead, he began with the results of a 2020 study from McKinsey Consultants about the extent to which companies have embraced digital transformation due to coronavirus mitigation.

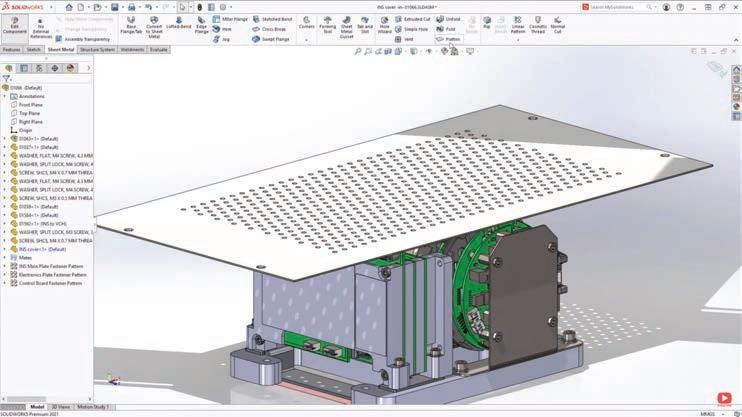

He then described a demonstration project involving six hundred people working from home on eleven thousand parts – the biggest demo Dassault had ever attempted. The result was a space station measuring two kilometers long.

Finally, Bassi said Dassault would deliver a full series of products, natively built “on our collaboration platform.” Here, use of the word ‘natively’ means not-Solidworks. This collection of products is called ‘3DExperience Works’ and consists of 3DExperience-based programs for Solidworks user s. Of them, 3D Creator and 3D Sculpture were shipped last year.

In the last few months, Dassault also delivered 3D Sheet Metal Creator, 3D Structural Creator, 3D Mold Creator, Product Document Creator and Product Communicator for marketing materials.

Solidworks CEO Gian Paolo Bassi on the virtual stage of 3DExperience World 2021.

Bassi enthusiastically described them as a “complete set of tools,” but I think we can easily see gaps in the collection. The website for 3DExperience Works lists additional modules, such as Collaborative Industry Innovator and Social Media Analyst.

While most of these programs are designed specifically for Solidworks users, they employ technology from Catia-based 3DExperience. They run in Web

browsers (including on smartphones) and communicate with 3DExperience servers, but they require hefty annual subscription fees, and are not particularly compatible with Solidworks –due to the different 3D modeling kernels involved.

New in Solidworks 2021

At 3DExperience World, what we didn’t hear about was the next release of 3DExperience

Dassault Systemes’ cloud-based design suite, 3DExperience Works, now includes tools like 3D Sheet Metal Creator, 3D Structural Creator and 3D Mold Creator.

Solidworks. The company’s website reveals that, for 2021, Solidworks gains many touch-up functions: Measuring the lengths of chain patterns, resolving lightweight components and exporting interference reports to Excel.

You’ll be also able to toggle between full and simplified views of assemblies and save defeatured models as configurations. Weldments can be mitered and non-planar edges can get edge flanges. Sheetmetal can be wrapped around bodies.

When it comes to simulation, the new release offers improved meshing, mesh diagnostics, and improved convergence. More editing is permitted in detailing mode and dimension text can be translucent. File properties now host equations.

Dassault is the world’s largest CAD software firm, and continues to sell Catia to large manufacturers. It acquired Solidworks

Flexible supply chains

Streamlined

Concept to reality

Our

Global footprint

for the smaller manufacturing market. Dassault Systèmes’ approach to software, however, makes the company incompatible with Solidworks users.

When it comes to major releases of Catia, Dassault is upfront about deliberately breaking compatibility from one major version to the next to take advantage of advances in hardware. That practice doesn’t offend existing customers, because they can

stay on old releases for as long as projects require.

For the millions of its users, however, Solidworks maintains compatibility by running on the same class of hardware today as twenty-six years ago.

The break-it-to-move-forward mentality explains why Dassault introduced a Web-based Solidworks “V6.” That it failed reveals the different class of customer addressed by each product.

Among other new features, Solidworks 2021 now allows for sheetmetal to be wrapped around another 3D part or assembly.

Like Inventor and AutoCAD, Solidworks is reaching the limits of its capabilities. It could, potentially, be so much more if it were cloudified.

But ‘so much more’ is not what Solidworks users want; it is already filled to the brim with capabilities of which most users know they’re not taking advantage. They see no point to adding functions through cloud services that cost more and are less reliable.

For Dassault, however, Solidworks is a memory from the past ser ving as an aspiration for tomorrow. The 3DExperience replacement software from Dassault embodies “the Solidworks promise of excellence, value and ease of use,” Bassi enthused. In the meantime, Dassault hopes for a day when Solidworks users awaken to the 3DExperience enlightenment. |DE www.solidworks.com

AUTOMATION

EMBEDDED PC

Beckhoff released its CX20x3 series of embedded PCs that include devices with AMD Ryzen processors. Designed for 32-bit and 64-bit systems – TwinCAT 2 and TwinCAT 3 – the IPCs support MS Windows 10 IoT Enterprise 2019 LTSC or the TwinCAT/BSD operating system. The series two models currently include the fanless CX2033 with a 2-core, 2.3 GHz AMD Ryzen V1202B CPU and the CX2043 powered by a four-core, 3.35 GHz AMD Ryzen V1807B CPU. Both variants features integrated graphics and 8GB RAM. Interfaces include 2 Gbit Ethernet ports, four USB 3.1 Gen. 2 and one DVI-D port. The controller boots from a removable CFast flash card. The IPC series also features an operating temperature range of -25 to 60°C. www.beckhoff.com

MACHINE VISION

Teledyne Imaging has added 20 megapixel Lt Series USB3 cameras. Equipped with the Sony IMX183 20 MP CMOS sensor, the models feature rolling shutter and back illumination technology. The Lumenera Lt Series cameras offer 32 and 64-bit operating

system compatibility for Windows, Linux, Linux for embedded system platforms and single board computers (SBCs). The two added USB3 models have a resolution of 5472 x 3648 pixels color and monochrome, a pixel size of 2.4μm with back illuminated sensors and side mounted locking industrial micro USB for power and control.

www.teledyne.com

INDUSTRIAL ETHERNET SWITCHES

Antaira Technologies launched its LMP-C602G-SFP-bt(-T)-V2 and LMX-C602G-SFP(-T)-V2 series of 802.3bt industrial PoE 6-port managed Ethernet switches. Designed for applications that require up to 90W of PoE power, the LMP-C602GSFP-bt series encompasses layer 3 industrial managed Ethernet switches, with a 48 to 55VDC high voltage power input. The LMP-C602G-SFPbt-V2 is also IEEE 802.3bt compliant and has a built-in PoE DIP switch to enable or disable the PoE function. The LMX-C602G-SFP(-T)-V2 accepts a 12 to 48VDC voltage power input. Each switch industrial switch provides high EFT surge (2,000VDC) and ESD (6,000VDC) protection. There is also a built-in relay warning

function to alert maintenance when power failures occur. www.antaira.com

MOTION CONTROL

IIOT-ENABLED CONTROLLERS

WAGO has adding three IIoT-enabled Generation 2 PFC200 controllers to its 750 series, including a standard version and two XTR versions for work in harsh environments. Each PLC model comes with two standard RJ45 Ethernet ports and two 100 Mbit/s SFP slots for fiber optic modules. These configurable ports can be used as a switch or with individual IP addresses and support MODBUS TCP/UDP, EtherNet/ IP, OPC-UA protocols with additional licenses supporting EtherCAT and Sparkplug. The fiber optic ports are beneficial where high electromagnetic interference is a concern or where long distance networking is needed. www.wago.com

SERVO DRIVE

Position can be individually tuned to match the application’s motor, load inertia, supply voltage and motion requirements. Along with this model are two lower current options, the FM060-10-CM rated to 10A continuous and FM060-5-EM rated to 5A continuous, designed to the same dimensions.

www.electromate.com

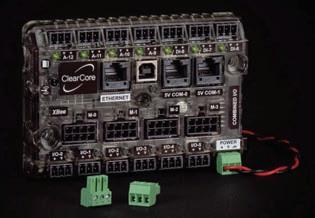

MOTION AND I/O CONTROLLER

Teknic recently launched ClearCore, a motion and industrial I/O controller that provides 4 axes of motion control, and configurable digital and analog I/O points. The controller features a 32-bit, floating point ARM Cortex-M4 processor, 192k RAM, 512k Flash, interrupt handler, and an onboard SD Card interface. It also includes

13 industrially hardened and electrically conditioned, 24V I/O points, including digital and analog inputs and outputs. The controller is compatible with XBee modules to enable wireless communications including WiFi, Bluetooth, ZigBee, DigiMesh, 802.15.4 and other protocols. www.teknic.com

ROTARY STAGE

ADVANCED Motion Controls unveiled its FM060-25-CM, a series of micro-sized, high-power servo drives. Rated to output 25A continuous and 50A peak, the digital servo drive is small enough 8 by 25.4 by 22mm (2 x 1 x 0.87 in) to fit in the tightest locations. The drive uses CANopen for network communication and can be configured to work with any servo motor because the control loops for Current, Velocity and

Optimal Engineering Systems, Inc. (OES) has introduced its AR39-AH, a miniature rotary table with a 58mm (2.283 in.) by 100.5mm (3.957 in.) footprint and includes a 2-phase 1.8 degree stepper motor. Measuring 35mm (1.378 in.) high and a diameter of

39mm (1.535 in.), the table has a precision pattern of six 8-M2x4L threaded mounting holes and an 8mm (0.315 in.) diameter through hole. Its range of travel is a full 360 degrees of continuous rotation. The table is driven by a 120:1 worm gear at speeds up to 75 degrees per second and has a resolution of 0.001 degrees (3.6 arc-sec) with a 10 micro-step per step stepper motor driver. It also features a positional accuracy of 0.05 degrees (180 arc-sec) and has a load capacity of 3kg (6.6 lbs).

www.oesincorp.com

SAFETY

SAFETY ENCODER

TWK launched its TRK38, a single-turn safety encoder with ATEX certification for explosion protection applications. In addition to the sensors for zones 2 (gas) and 22 (dust), the encoder line now includes models with a PROFINET interface that are also suitable for zones 1 (gas) and 21 (dust). They feature flame-proof aluminum or stainless steel enclosures that feature IP6x dust protection and don’t exceed 100 °C. In addition, the encoders’ cable glands feature embedded electronics. In total, the encoder line carries certification valid for ATEX, IEC-Ex, North America Class 1/2 Div. 2 and EAC-Ex, as well as SIL2/PLd. www.twk.de

SAFETY CERTIFIED BRAKES

Nexen Group has launched its NexSafe Certified Safety Products, including the NexSafe rail brakes, servomotor brakes, and rod locks. Each carry the Intertek Functional Safety (FS) Mark and are certified to comply with ISO 13849-1, Categories B through 4 and performance levels PLa through Ple. With spring-engaged, air-released functionality, NexSafe products are default to lock, making them suited to emergency stopping

and holding applications. NexSafe rail brakes, servomotor brakes, and rod locks can be mounted to servo motors, linear devices, pneumatic cylinders, round rails, linear rods, round shafts, and linear guide systems. www.nexengroup.com

SENSORS

ANGLE ENCODERS

HEIDENHAIN introduced an upgraded versions of its RCN absolute angle encoders series that allow three times the permissible speeds of the older RCN encoders, which is useful for fast rotating axes and direct-drive motors. When paired with an EIB 5211 sensor box, the RCN encoders transfer the temperature of the

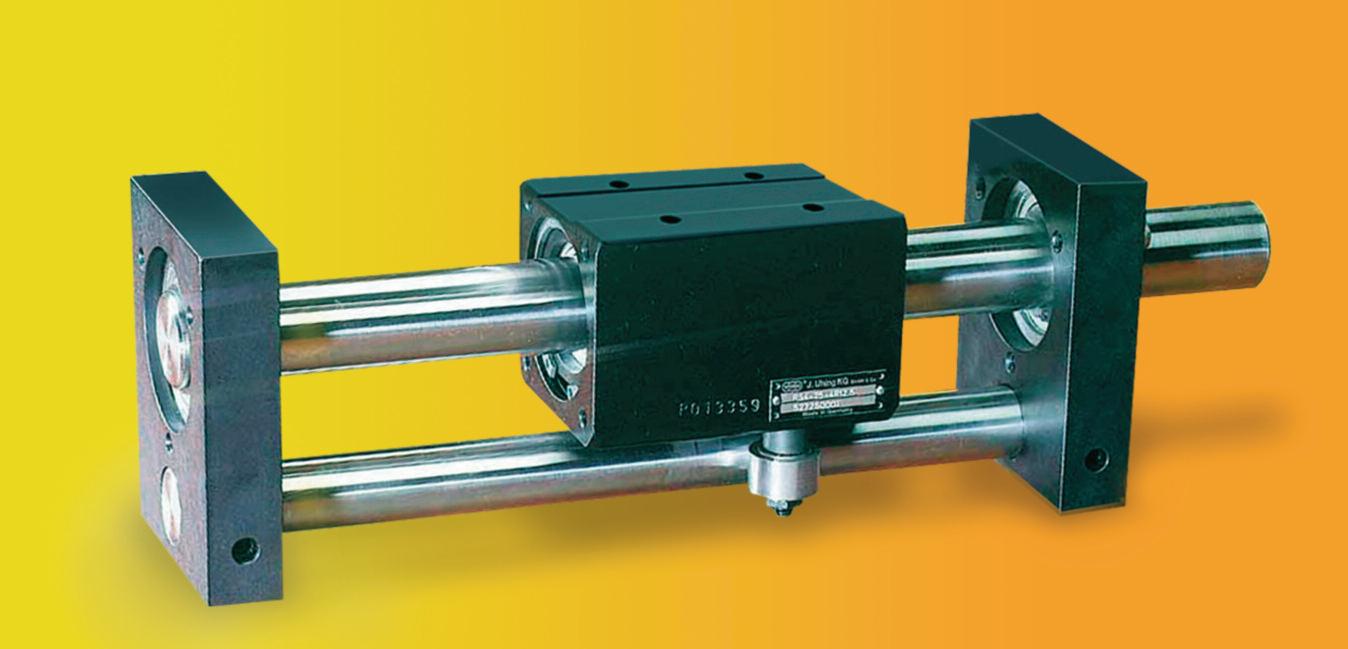

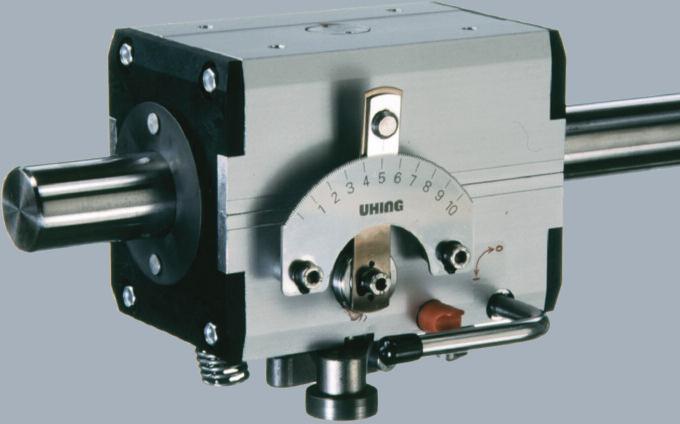

Rolling Ring

encoder and a direct-drive motor, which allows the system to be pushed to its thermal load limits. In addition, the improved RCN line features optimized scanning performance in that liquid contamination or condensation won’t affect its operation. The improved models share the same profile as previous models and feature the EnDat22 (FS), EnDat02, Fanuc05 and Mit03-4 interfaces. www.heidenhain.us

TEMPERATURE

• For applications in positioning & reciprocating motion

• Zero play –even during reversal

Uhing® Rolling Ring linear drives run on a smooth, threadless shaft that won't clog or jam. If the system is overloaded, the shaft simply slips instead of churning and grinding. The drive bearings are in constant contact with the shaft, even during reversal, thereby preventing backlash.

Example applications: metrology machines, material handling systems, spooling equipment, packaging & converting equipment. Many different sizes meet varying requirements for axial thrust & linear speed.

For more information call 1-800-252-2645

Email: amacoil@amacoil.com www.amacoil.com

Some models feature mechanical control over

No programming or electronic controls are needed.

TRANSMITTER

Endress+Hauser introduced its TMT142B HART 7 smart temperature transmitter, which incorporates Bluetooth and allows it to be commissioned, operated and serviced wirelessly from up to 20 meters. In addition, the TMT142B can be configured wirelessly without needing to pre-install device drivers, since they are incorporated into the transmitter. The single-channel transmitter features a backlit display and integrates overvoltage protection. Diagnostic information is available to the user in accordance with NAMUR NE 107. The TMT142B transmits converted signals from resistance sensors (RTD), thermocouples (TC), resistances ( ) and voltage transmitters (mV) via the 4 to 20mA or HART 7 protocols. It is designed for safe operation in hazardous areas as certified by international approvals (ATEX, CSA C/ US, IECEx). www.ca.endress.com

PANEL BUILDING

SERVER RACK ENCLOSURES

Rittal Systems Ltd. launched its TS IT Pro enclosures, network and server racks

designed to handle heavier loads and features structural reinforcements in key areas, the company says. Key features include full height rear accessory channels, easy-to-remove doors, quick-release door handles and increased cable openings. Other features include perforated single front door and split rear doors keyed alike, leveling feet, casters, roof with brush baffle cable access channels, and vertical cable walls with dual PDU mountings. www.rittal.us

AC-DC POWER SUPPLIES

CUI Inc. has added three lines – the VGS-C, VGS-D and VGS-W series – to its VGS family of chassis mount, single-out-

put AC-DC power supplies. All three series are 62368-1 safety certified with low no-load power consumption. The VGS-C series offers power ratings from 35 to 350W and carries single output voltages of 5, 12, 15, 24, 36, and 48VDC. Featuring active power factor correction and over temperature protection, models in the VGS-D series offer power ratings from 75 to

320W and carry voltages from 5, 12, 15, 24, and 48 VDC. The VGS-W series is rated from 35 to 150W and carries 5, 12, 15, 24, 36, and 48 VDC. All three series meet IEC/ EN 61558, IEC/EN 60335, and GB 4943 system requirements. www.cui.com

SAFETY RELAY MODULE

IDEC Corporation released its HR5S safety relay module designed to meet ISO 13849 Category 2 requirements. The safety relays are available in three configurations for a range of applications. The Simple type can be used for applications up to PLc, while Standard and Off-Delay types work for designs up to PLd and add failure detection features. While most Category 3 and higher relays consume 45mm of installation width, the HR5S is only 22.5mm wide and can be mounted on DIN rails or a backpanel surface. Push-in terminals are used for installation and vibration resistance, accepting solid wires up to 16 AWG or stranded wires up to 18 AWG with ferrules. Inputs are rated for 24VDC, and outputs are rated up to 250VAC at 3A. The HR5S safety relay modules comply with many standards including EN ISO 13849-1:2015 and UL 508. www.idec.com/safety

FLUID POWER NEWS

Wajax 2020 financial results and other fluid power news p.21

GETTING A HANDLE ON GRIPPERS

The key facts and features behind several gripper types p.22

2021 FLUID POWER ROUNDTABLE

Fluid power leaders discuss the latest tech, the impact of COVID and the state of the industry p.25

FLUID POWER PRODUCT SHOWCASE

Cutting edge pneumatic and hydraulic industrial technology p.28

WAJAX 2020 FINANCIAL RESULTS REVEAL IMPACT OF PANDEMIC

Reflecting the Canadian industrial equipment market, Wajax Corporation’s year-end results revealed that the industrial products and services company’s 2020 revenue decreased 8.4%, or $130.4 million. In total, Wajax’s revenue fell to $1.4 billion, versus $1.5 billion in 2019, with net earnings dropping to $31.7 million compared to $39.5 million in 2019.

“While the challenges of 2020 were clear, the Wajax team seized on opportunities to improve in areas important to our long-term success,” said Wajax President and CEO, Mark Foote, commenting on the company’s results.

“As the pandemic unfolded, we were in constant contact with our customers to ensure we were there when they needed us,” Foote added. “We developed new ways of working with our team, using technology to increase communication, and the team did excellent work to protect the financial health of the corporation.”

According to the 163-yearold Mississauga-based firm, the decrease was due to lower sales in all regions, and nearly all product categories, except for higher engineered repair services sales in western and central Canada and higher mining equipment sales in western and easter n Canada.

Looking forward, the company says it expects revenue from i ts $99.1 million acquisition of Tundra in January 2021 to contribute significantly toward revenue growth in 2021.

At the same time, the company said it expects modest organic g rowth in the present year, considering that heavy equipment markets won’t likely fully recover to 2019 levels in 2021.

“Recognizing that the challenges we faced in 2020 have per sisted into 2021, the corporation nonetheless enters 2021 with confidence expecting that it is positioned to succeed over the longer term,” Foote said. “In 2021, Wajax remains focused on the same priorities that guided it in 2020: protecting the health, safety and well-being of its team, providing excellent customer service, protecting the corporation’s financial health and dr iving its long-term growth strategy.”

www.wajax.com www.tundrasolutions.ca

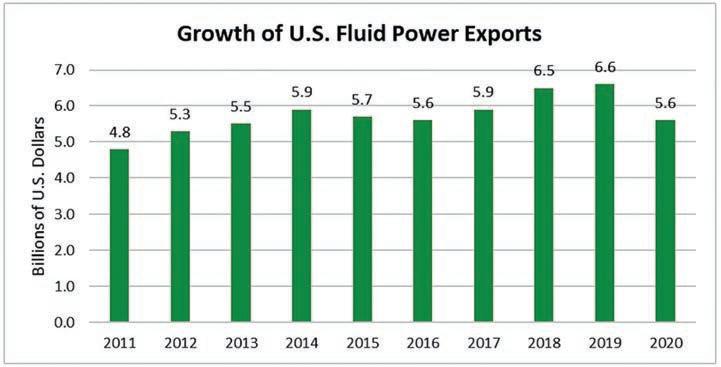

U.S. FLUID POWER PRODUCT EXPORTS DECLINE $1 BILLION IN 2020

According to the National Fluid Power association, hydraulic and pneumatic exports took a heavy hit in 2020. In total, U.S. exports declined by 14.3% compared to 2019, reaching 5.6 billion dollars in 2020. That’s a drop of nearly

U.S. fluid power exports deviated from an otherwise consistent growth trend, declining 14.3% in 2020 compared to 2019.

one billion dollars compared to 2019.

In addition to a recessionary economy brought on by the pandemic, an uncertain foreign trade environment due to unstable trade policies, unpredictable sanctions and wavering tariffs contributed to the 2020 decline.

According to association, the U.S. fluid power industry’s top five trading partners, including Mexico, Canada, China, Germany and the U.K., represent over half of the U.S. industry’s exports at 55%, while the top ten trading partners represent 72%. The remaining 28% exports is divided among 180 other countries.

Despite the grim numbers for 2020, more recent soundings show the beginnings of a comeback for the industry. In January 2021, the NFPA said shipments of mobile hydraulic, industrial hydraulic and pneumatic equipment had increased 5.4% when compared to December 2020. www.nfpa.com

Years since the founding of the Mississauga-based industrial products firm, Wajax Corporation.

Photo credit: NFPA

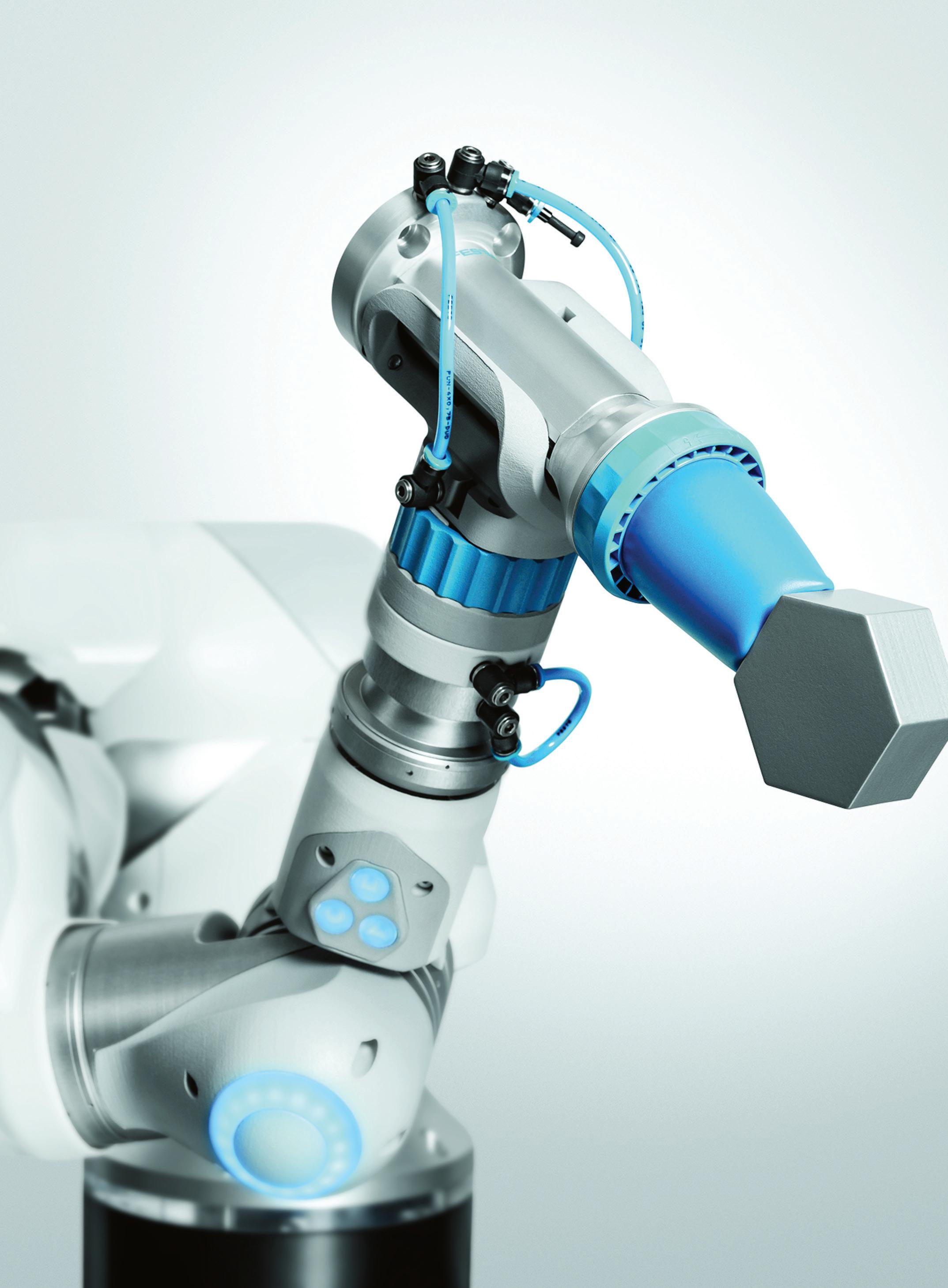

GETTING A HANDLE ON GRIPPERS

Choose the right technology with these key facts and features behind several gripper types.

BY MICHAEL GUELKER From electronics manufacturing

to automotive assembly, grippers have become an important part of material handling processes in many industries. Their recent growth is tied to the rise of robotics, including the need for robots to take on special tasks and handle increasingly complex workpieces.

The result is there are now more grippers to choose from than ever. In North America alone, the gripper market is worth roughly $100 million— and that number is expected to climb up to 5 percent each year.

With all the recent developments in robotics and gripping technology, it can be difficult to know which gripper is best for your application. The following article will provide an overview of common gripper types, including mechanical, soft, adaptive, vacuum and magnetic. It will also explore their key design features, as well as the benefits they offer in various applications.

To help you select the right gripper, it’s important to first consider the nature of the task, the operating environment and the workpiece itself, including

its size, mass and material. Other factors to keep in mind include upfront, operating and maintenance costs, as well as energy consumption.

Mechanical Grippers

When it comes to handling applications, pneumatic or electric mechanical grippers are the most common. Pneumatic grippers, which make up 90 percent of the market, tend to be more lightweight and cost-effective than their electric counterparts.

They also feature higher grip forces, can handle faster cycle rates and are more suitable for harsh environments. Electric grippers, on the other hand, offer greater precision, affording end-users with force and travel control. At the same time, they tend to be heavier due to the presence of a motor and other internal components, which also drives up their upfront costs.

Whether electric or pneumatic, mechanical grippers fall into several design classes. Parallel grippers, for example, incorporate fingers that pull directly apar t. Two-finger designs are the most common, making up 85 percent of the mechanical gripper market, while three-finger

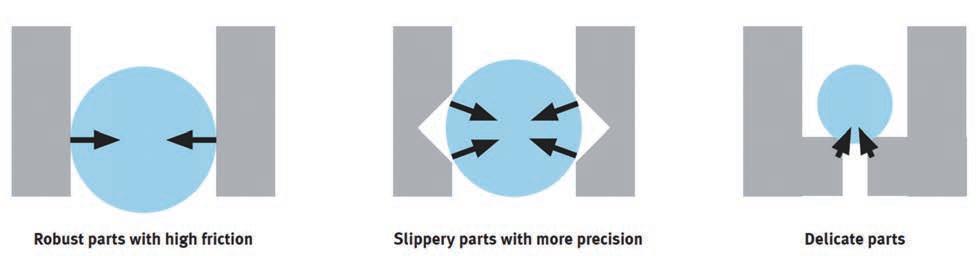

Mechanical gripper fingers accommodate various workpieces, from high friction to delicate parts.

designs are suitable for handling round objects or performing centering functions.

Other examples include radial and angular grippers, which feature fingers that open at an angle. Radial grippers open to 180 deg rees, making them suitable for applications involving varying or inconsistent workpiece sizes. Angular grippers tend to be faster than 180 degree designs and open to roughly 30 degrees.

Other important considerations include the gripping force, the guiding strength of the jaws and the design of the gripper itself—all of which depend on the nature of the workpiece. In general, the longer the gripper fingers, the longer the lever arm, which exerts more torque on the jaws. In addition, flat finger designs provide a friction-based grip for bulky or robust parts, while encapsulated designs work best for slippery parts requiring more precision.

Soft and Adaptive Grippers

Soft and adaptive grippers can handle workpieces of various shapes, sizes and orientations, enabling automation in areas where it previously didn’t exist. Because they don’t have any sharp edges, these types can handle food, glass and other delicate objects without damaging or marking the surface.

They’re also ideal for small work areas. Compared to mechanical variants, however, soft and mechanical grippers are less precise and operate at slower speeds. They are also more susceptible to dirt, oil and other contaminants

Oftentimes, soft and adaptive grippers incorporate innovative, tweezer-like designs that can adapt to the contours of various workpieces. For example, the Festo DHAS features the company’s Fin Ray structure, derived from the movement of a fish tail. Two flexible bands, which meet at the top like a triangle, are connected by ribs. Using flex

of Festo Corp

hinges, these ribs are spaced at regular intervals, creating a flexible, yet sturdy joint connection.

Available in lengths of 60, 80 and 120 millimeters, this series is ideal for pick-andplace applications involving fragile or irregularly shaped parts. It also incorporates materials that comply with FDA standards, making them a good fit for the food and beverage industry.

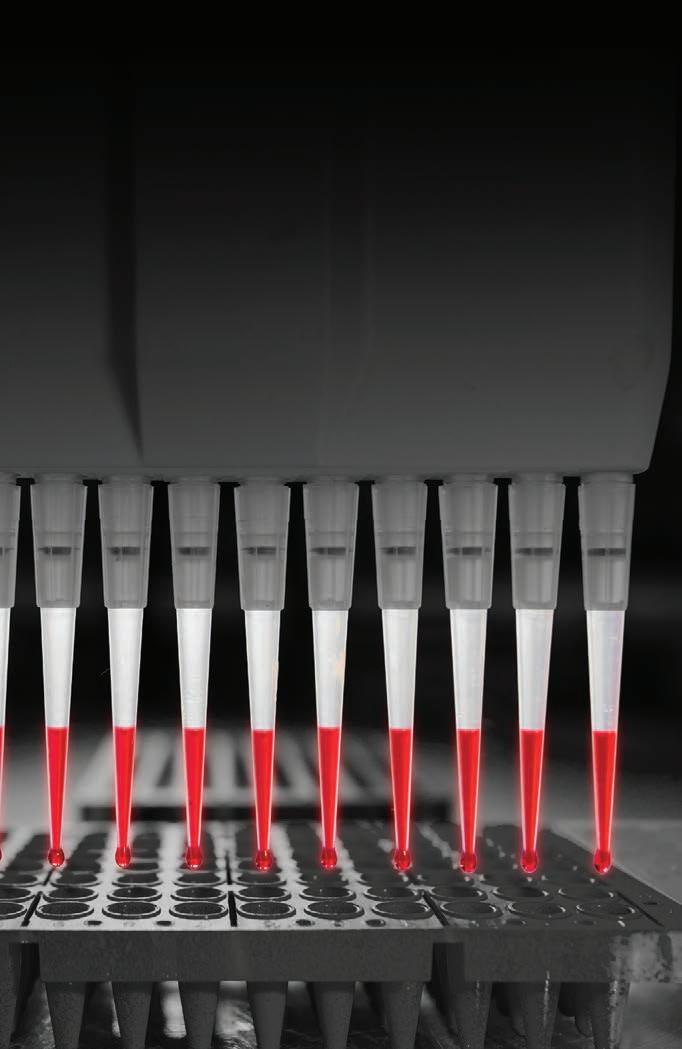

Vacuum Grippers

Another gripper technology is the vacuum gripper, which combines suction cups and vacuum generators. Compact and flexible, these grippers are ideal for limited work spaces and can handle a variety of objects at high speeds.

At the same time, however, vacuum grippers can run

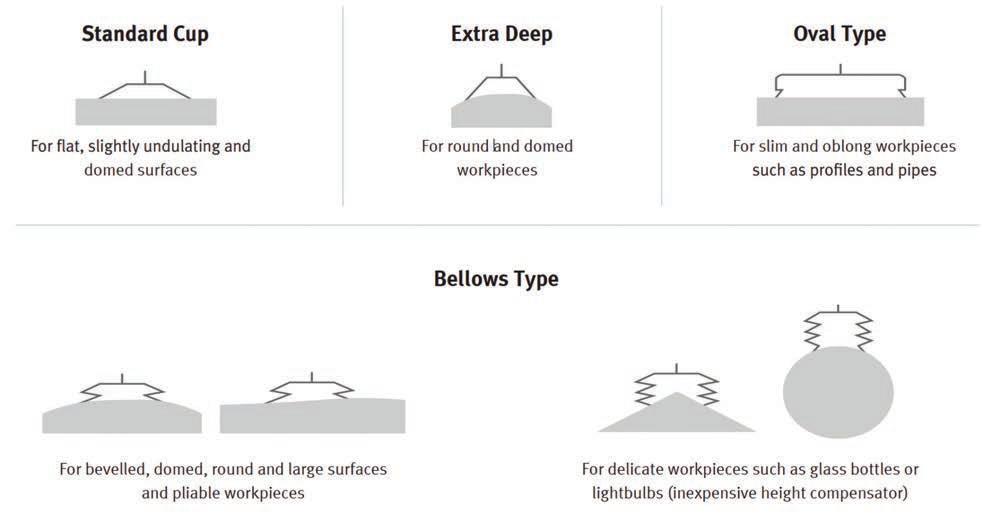

Selection of suction cup shape for vacuum grippers depends on multiple workpiece properties including shape, rigidity and surface finish.

up maintenance and operating costs; suction cups are susceptible to quick wear, while generators consume high rates of compressed air and can easily clog in the presence of dust and other contaminants.

When it comes to suction cups, it’s important to

consider the nature of the workpiece when selecting a material. Buna suction cups, for example, are ideal for oily or plain workpieces, while silicon is suitable for food, as well as hot or cold objects. In addition, polyurethane is a good choice for oily, plain and rough

workpieces; viton is suitable for oily, plain and hot workpieces; and anti-static buna is ideal for electronics

Cup shape is also an important factor, especially when it comes to gripping objects that are flat versus round, slim versus large and sturdy versus delicate.

Standard cups, for example, are suited to flat or slightly undulating surfaces. In contrast, bellows type vacuum cups are better for pliable workpieces, as well as surfaces that are bevelled, domed or round.This type is also suitable for glass bottles, light bulbs and other delicate objects. Oval type cups are ideal for slim or oblong workpieces while extra deep are designed to handle round and domed workpieces.

Vacuum sources fall into two categories: Electro-mechanical vacuum pumps/blowers, as well as compressed air-driven vacuum generators/ejectors. In general, electromechanical pumps and blowers can achieve high vacuum and suction rates – up to 99.99 percent and 1,200 cubic meters per hour, respectively.

At the same time, however, these machines tend to be heavy and large, requiring a reservoir with a complex piping system. Because they run continuously, they also consume a lot of current, which generates heat.

Compressed-air driven generators, especially single-stage units, overcome many of these challenges. Compared to electro-mechanical pumps and blowers, they are more compact, lightweight and easier to install.

They include simpler piping systems, require lower upfront costs and incor porate no electrical connections, eliminating harmful heat buildup. Although these units can run up your air consumption rates, many machines now come with energy-saving functions,

minimizing these effects.

In general, vacuum grippers are ideal for material handling applications, such as steel fabricators, conveyors, electronic assembly, industr ial robotics; food and packaging tasks, including canning, bottling, capping , tray making, filling, bagging and sealing, c onveying, box making and labeling; and printing applications, such as sheet feeding and handling.

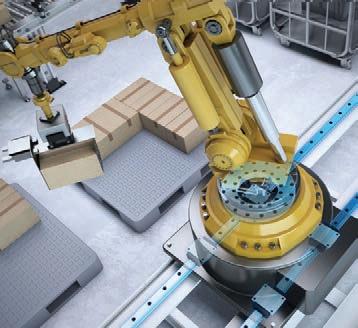

Magnetic Grippers

Lastly, magnetic grippers can handle metallic objects like sheets of metal and are ideal for tasks like de-stacking, fixture tooling and bin picking. Although these grippers are limited to applications involving ferrous metals, they require minimal air consumption to actuate

and achieve energy savings up to 90-percent compared to suction cup grippers.

In addition, magnetic grippers can exert strong gripping forces, can be switched completely on and off very quickly and provide fail-safe performance in that they won’t drop parts in the event of a power or air loss.

No matter the application, there’s an ideal gripper for it. Ultimately, the right choice depends on a number of variables, including workpiece size and shape, operating conditions, industry, energy requirements and cost. |DE www.festo.com

This article was adapted from a white paper by Michael Guelker, Product Management – Pneumatic Drives with Festo Corp., USA.

FLUID POWER ROUNDTABLE 2021

Fluid power leaders discuss the latest tech, the impact of COVID and the state of the industry.

Given the lockdown’s impact, how has business been?

Campbell Tourgis, Vice President, Wainbee Limited: No one could have predicted the ups and downs in the industry. Our core markets – oil and gas, forestry, aerospace, mining and minerals and automotive – were all significantly impacted.

From an opportunity standpoint, chaos often creates oppor tunity and we do have a product line and people who are attuned to the life sciences and food and beverage marketplace. As a result, we saw some tremendous increases in portions of our business that were always solid but not outstanding. So while we saw a drastic drop-off in some sectors, we saw realizable gains in

a few others. That helped us stay progressive during this year and provided some sense of balance on revenue for the year.

Like the last fundamental economic change, in 2008, events like the pandemic do force companies to look at what their market segments look like, what they are doing well in today, what’s at risk and what they need to start developing for the future.

Conrad Rieckhof, Business Development – Pneumatics, Festo Canada: We’ve actually done very well.We were fortunate in that we have divisions in areas like life tech, food, electrical light assembly, packaging and even process, so we’re able to spread ourselves out quite a bit.

As a result, we can pick up the highs in one market during the

lows in the others. In many of these industries, pneumatics is one of the default, go-to technologies for creating motion.

Going forward, while COVID has had a huge impact, we’ve seen a rise in medical and intra-logistics industries. For example, the need for testing, vaccine and related consumables has given that industr y a new spike in a market that was already growing before the pandemic.

On the logistics side, automated warehouse systems were another growth area for us, pre-COVID, that saw its growth accelerated due to the pandemic.

Ted O’Donnell, Business Manager, Mobile Systems, Bosch Rexroth Canada: While the business environment was challenging, we faired pretty well in 2020. During the lock-down, we were fortunate to be able to move to a work-from-home model. With social distancing, our shops remained working and we were better prepared to serve our customers when the restrictions were eased.

“Like any other company or individual, we accept that change in inevitable but we often think we can control it when it becomes personal. The reality is that change doesn’t wait for approval; it just happens.”

–

Campbell

Tourgis, Wainbee Limited

Looking forward, I ‘m optimistic. Customers are back to work in g reater numbers now. The demand for their goods and services, according to what they tell us, is there. And with the vaccines easing people’s anxieties, there’s a general expectation of a return to normal later this year or in 2022. I think we all understand and agree that “normal” will be different but, from a business sense, things will be more familiar.

Are there positive ways in which the pandemic has changed your company or the industry?

Tourgis / Wainbee: From the company’s perspective, Wainbee is like any other company or individual; we accept that change in inevitable but we often think we can control it when it becomes personal. The reality is that change doesn’t wait for approval; it just happens.

It’s natural to resist change but, across the company, we experienced an overwhelming response to adopt what we needed to do to keep going. Online meetings, for example, have added a huge benefit, greatly enhancing efficiency and real-time in-house communication. That holds true for clients as well. Usually one sales call can accomplish everything that needs to happen versus the back-and-forth of the old way.

From an industry standpoint, we’ve also seen a rapid adoption that data points are integral to performance improvements. Our clients have discovered that analyzing their data, processes and operations helps them improve energy management and predictive maintenance to operate at the most efficient levels.

Rieckhof-Festo: Aside from the market growth, there have been some positives with the way that people work during the pandemic. The use of digital tools could be a time and cost saver as we return to normal – generally cutting down on travel and making more efficient use of time.

It has also led to better teamwork. Now that we’re really getting comfortable with this, the ability to bring in various experts from around the world when needed has shown us how efficient and productive virtual meeting can be. Initially, we might have all struggled, but now that we’re in the second year, it has become the accepted new work life moving forward.

O’Donnell-Bosch Rexroth: Positives have definitely come from adapting to the pandemic restrictions, at least for our organization – some we may not be able to see completely just yet. It has forced companies like ours to become more efficient and find new ways to function. That will bring changes to how we work in the future, such as what space we need to occupy and how we

“Previously, the weak link in this new generation of adaptable machines was the pneumatics. Now, with the latest fluid power technology, it’s possible to digitalized pneumatics and move them into the digital age of industry 4.0.”

– Conrad Rieckhof, Festo Canada

communicate and interact with each other to conduct business.

The fact that we have been able to function in a work-fromhome environment outside of the office and without all of its equipment has changed the way we might work in the future. I still miss the ability to be face-toface with customers and people in the office. I don’t think that is going to go away completely, but it’s probably going to change.

What are the biggest challenges facing the industry currently?

Tourgis-Wainbee: There are a lot of interesting industries that have opportunities in the chaos. For example, energy development with respect to electric vehicle enhancements, beyond just traditional hydraulics, as well as hydrogen charging and refueling. Those will certainly play a major role in the present and future. How companies will support and facilitate those are pretty interesting challenges to have.

“Positives have definitely come from adapting to the pandemic restrictions, at least for our organization – some we may not be able to see completely just yet.”

– Ted O’Donnell, Bosch Rexroth Canada

From our perspective, governments and private industries will have to change the approach to attract market segments, specifically the pharmaceutical industries, to improve the supply chain and limit dependence on foreign countries. And that holds true for not just drugs but for all healthcare equipment, which we saw as a critical need at the beginning of the pandemic.

Rieckhof – Festo: Training is one area that has not yet fully adapted to the new normal. Training requires in-person components, such as hands-on activities, that haven’t been duplicated in a virtual environment.

We’re also finding that a classroom creates a more comfortable environment for questions and interaction. If you’re learning a new topic and you’ve got 15 people on a virtual meeting, nobody wants to say anything. Every time I’m doing a training

session, it’s typically pretty quiet. Festo Didactic, the training division of Festo, is working hard at developing new interactive software tools to help improve the virtual training experience.

O’Donnell-Bosch Rexroth: Education and recruiting new talent are probably the biggest challenges. For many years now, we’ve struggled with educational opportunities, specifically in the secondary education and colleges. That has limited our ability to bring in new people and created a skills gap.

By and large, we don’t have hydraulic education going on in the colleges. It has become part of a mechatronics or a millwright program and is typically a couple of weeks of education.

There are a few programs out there like BCIT in British Columbia and NAIT in Alberta, as well as Mohawk and Centennial in Ontario, but that’s not the way it used to be and it’s not primarily focused on fluid power.

I sit on the CFPA board and finding ways to bring that level of education back into our industry in Canada is a big topic for us.

Which technologies or trends are you currently excited about?

Tourgis-Wainbee: First and foremost is the integration of the electronic controls and displays with radio remotes and all the sensors to provide functionality to the hydraulics on off-road vehicles. The industry is forging ahead on this, not only in terms of energy efficiencies but also the operator and data collection efficiencies of these vehicles.

We also see a tremendous momentum in machine reliability, specifically fluid condition monitoring. With the introduction of new types of oils, we also have new contaminant challenges. So, topics such as varnish mitigation and removal of oil has generated excitement in the industry.

The third is the integration of

traditional fluid power with automation. Since we can’t have too many people within a squared circle anymore, we’re seeing an increasing adoption of cobots to help with operator interface and machine tending. With that adoption comes increased demand for complementary fluid power products such as end-of-arm tooling and pick-and-place units.

Rieckhof-Festo: We’re excited about the continued development of smart pneumatics. An example is the Festo Motion Terminal or VTEM. It’s one valve block but it can perform different pneumatic functions by using software apps to change the VTEM’s personality.

For example, instead of having a 4/2 valve, you can switch to a 4/3 or 3/2

using just the software. In addition to directional control, VTEM also allows for pressure, flow and speed controls to be changed using software but with one single set of hardware.

So, basically 50 traditional pneumatic components are replaced with the VTEM valve and software.

Machines are becoming increasingly flexible, where an operator can now make a product selection on an HMI and the machine will make the required changes automatically producing a different product variant.

For that to happen, pressure, force and actuator stroke length might have to change. So, with minimal human interaction, the VTEM software and hardware allow the machine to adapt automatically.

QUICK RELEASE COUPLINGS

Poppet Check Valves

With rubber poppet seal for improved sealing when disconnected.

Single Acting Sleeve

Manually retracted to connect, or disconnect.

Push/Pull Sleeve

Can be moved in either direction to connect, or disconnect.

Engineering excellence, customer focus and highest quality products continue to attract new clients from numerous industries. RYCO continues to provide quick release coupling solutions to meet customer demand.

RYCO carries pneumatic, hydraulic and specialty couplings in a diversified offering of ball lock, poppet, flat face and screw to connect types.

Previously, the weak link in this new generation of adaptable machines was the pneumatics. Now, with the latest fluid power technology, like VTEM, it’s possible to dig italized pneumatics and move them into the digital age of industry 4.0.

O’Donnell-Bosch Rexroth: The electrification of fluid power componentry, including connected hydraulics, the Internet of Things and ar tificial intelligence. All of these technologies are bringing new capabilities to the fluid power industry that previously weren’t available.

For example, you can have a pump that doesn’t have a traditional mechanical control but has an intelligent electronic control. When mated with the appropriate motor and knowledge of

the hydraulics involved, the pump can be optimized to ensure that a vehicles engine operates at its optimum operating point. In addition, better control of the hydrostatic transmission ensures the complete drivetrain operates at its highest efficiency.

It can do this while logging data from sensors in the system and passing that data to cloud based apps that monitor various aspects of both the components and the machine for functionality and performance.

These kinds of technologies will allow our industry to change in ways that will allow fluid power users to continue to innovate and develop new machines that solve the problems they are going to come across tomorrow. |DE

PNEUMATICS

I/O SYSTEM

AutomationDirect launched its NITRA Pneumatic Automation Link (PAL), a field I/O system that can include electrical I/O or pneumatic valves, or a combination of both. The system can be controlled either by an Ethernet/IP master or direct wiring for exclusively pneumatic valves. All components are rated IP65, intended to be machine mounted, and can be split into multiple subsystems that use only one master connection. Each assembly can support up to 40 I/O modules and 40 valve bases to control the most complex systems. Power, I/O and network connections are made via standard M8 or M12 connections. www.automationdirect.com

PRESSURE REGULATOR

Festo released its VPPI proportional pressure regulator featuring a large, liquid crystal display that can communicate using complete words and not just abbreviations or fault codes. Up to five VPPIs can be connected together on a common pressure supply without the need for a

separate manifold. Whether mounted on a DIN rail or another option, pressure can be regulated via an analog (0 to 10V/4 to 20ma) or digital setpoint. The digital setpoint feature eliminates the need for an analog card. With only three standard output signals from a master controller, it is possible to select seven custom setpoints. Four preset performance levels are also possible, for small volumes, large volumes, continuous flow or custom applications. www.festo.com

SOLENOID VALVES

Emerson has launched its ASCO Series 256/356, a range of two-way and three-way solenoid valves with a smaller footprint. In addition, the company says the valve line reduce power consumption by 40 percent and increased pressure ratings by up to 30% compared to the previous versions. The Series 256/356 offers an expanded selection of body materials, including lead-free brass, stainless-steel and an engineered composite material. The valves are dust-tight, IP67-rated and submersible in up to one meter of water. Third-party approvals

include NSF 169 and EC 1934 for food and beverage applications. The series also offers multiple end-connector options and electrical connections.

www.emerson.com

ELECTROHYDRAULIC LINEAR ACTUATOR

Thomson introduced its H-Track electro-hydraulic linear actuators designed for industrial applications, including ag sprayer booms, snow plow blades, patient lifts and mower deck lifts. The

sealed and contaminant-free H-Track features shock load resistance and self-contained hydraulics, and is maintenance-free for the life of the actuator, the company says. The actuator provides the performance of hydraulics without the space requirements and expense of a full-size hydraulic system, the company says.

www.thomsonlinear.com

PRESSURE TRANSMITTER

Hoskin Scientific released its DMP 336 pressure transmitter, which features a high overload capacity and resistance to

pressure spikes. Optionally, the device is available with ATEX approval in an intrinsically safe, explosion-proof version for zone 0. The transmitter has a nominal pressure of 0 – 16 up

to 0 – 1000 bar and supports media temperatures of -40 to 125°C. The unit also measures pressure with an accuracy of 0.5% FSO but is insensitive to pressure peaks, the company says. It is oil and grease free according to ISO 15001. www.hoskin.ca

GRIPPERS

Festo released its OGVM, a family of vacuum suction cups designed to handle heavy, oily and dry sheets. Available in diameters from 30 to 125mm, in three basic shapes, the suction cups’ inside structure enables them to absorb high transverse forces, ensure minimum suction times and exhibit high inherent stability, including on oiled surfaces. The large strokes of some variants make them ideal for workpieces with complex structures. OGVM benefits include making handling solutions energy

efficient, with optimum suction ergonomics for maximum process reliability, the company says.

www.festo.com

HYDRAULICS

VFDS

Single Phase Power Solutions (SPPS) has partnered with Yaskawa America to incorporate their VFD and digital single-phase converters within SPPS’ engineered power systems to deliver three-phase power from single phase utility service. In many areas, it’s prohibitively expensive to extend three-phase power, forcing customers to choose between static or rotary phase

converters, or derating three-phase VFDs. The partnership with Yaskawa provides an IEEE 519 compliant product with total harmonic distortion of less than 10% which reduces installation costs. In addition, accurate drive sizing eliminates the need to oversize. www.sppowersolutions.com

PUMP MOTOR SYSTEM

Nidec Motor Corporation introduced its ID300 Fusion Integrated Motor Drive that combines a U.S. MOTORS brand 1-10HP UL-certified induction

motor with all of the functions of a customizable variable frequency drive (VFD) drive. According to the company, this integration provides superior control and monitoring capabilities that help with real-time pump management and intelligence analytics. It also allows user to embed the pump curve information into the drive. An onboard PLC can regulate the pressure (constant pressure/variable flow) and perform sensor-less constant pressure control. One ID300 Fusion can control up to three additional constant speed backup pumps. www.nidec-motor.com

DIAPHRAGM PUMP

KNF introduced its FP 70 that combines the low pulsation of a gear or centrifugal pump with the advantages of a diaphragm pump, the company says. The pump delivers up to 850 ml/ min while producing up to 29.4 PSIG (2 bar) pressure under continuous operation. Due to its patented 4-point valves, the KNF FP 70 is reliably self-priming, even at low motor speeds. The KNF FP 70 also integrates

pulsation dampening technology, eliminating the need for pulsation dampening elements and tubing. The FP 70 is available with a selection of

Self-guiding rollers to minimize friction

Highly effective double-lip seals keep lubricants in and contaminants out

Made of super-clean and tough steel with an upgraded heat treatment

Guide rings to keep the rollers in optimal position outside the load zone

Pre-lubricated with specially formulated SKF grease

motors, from high-end BLDC to lower-end DC motors. www.knf.com

LVIT SUBSEA SENSORS

Alliance Sensors launched its SSx-7 series of LVIT subsea position sensors. Available in full scale ranges from 1 inch (25mm) up to 36 inches (900mm), the sensors are made from AISI 316 stainless steel to operate at depths of 10,000 feet (3,000 meters). The SSx-7 body style fits into an SAE O-ring port in the end of a hydraulic cylinder and is terminated with the micro-circular subsea connector. Since some subsea position measurements require a customized sensor, the company also offers short

www.skf.com/ca/en

run sensor customizations including high pressures materials and seals, non-flammable EHC fluid compatibility and alternate analog I/Os. alliancesensors.com

SIGNAL CONDITIONER

NewTek unveiled its NTC-6000 Qwik-Cal LVDT signal conditioner, which allows AC-LVDTs to convert position feedback into readable output for use by computers, PLCs, data acquisition systems and data loggers. Compatible with both new and legacy AC-LVDTs, RVDT or LVRT half-bridge sensors, the NTC-6000 offers a variety of selectable excitation frequencies, analog output types (0-10V, 0-5V, 0.5 – 4.5V, +5V, +10V, 4-20mA) as

well as digital communications to a host computer via RS-485 output. The RS-485 port also supports the hot swapability of sensors by saving set-up parameters and automatic excitation synchronization for multiple unit systems. The signal conditioners also feature self-diagnose for LVDT failure and cybersecurity lockout and tamper detection to protect against hacks. www.newteksensors.com

FLOW CONTROL VALVE

Sun expanded its FLeX Series valves line with the addition of the FREP solenoid-operated, 3-way proportional flow control valve. The line combines an electro-proportional adjustable orifice and pressure compensator in one valve and can provide a constant priority flow rate independent of load

pressures. The compact single valve features a 30-gpm (120-L/min) rated input in

versions with priority flow up to 22 gpm (88 L/min) in three ranges – A range: 0-8 gpm (0-30 L/min), B range: 0-15 gpm (0-60 L/min) and C range: 0-22 gpm (0-88 L/min). The three ranges allow the designer to dial-in the best resolution for the application and to balance the needs for priority flow and bypass flow. The FREP can split one input into two flows that are controlled proportionally, allowing motors and cylinders to operate on both port 3 and port 2. www.sunhydraulics.com

RELIEF VALVE

Eaton introduced a sectional load sense relief valve (LSRV) for its CLS mobile hydraulic control valve. The patented LSRV limits individual section pressure through feed oil reduction. Once the LSRV stops oil flow and a function reaches a specific pressure, that flow is available to other sections at full system pressure. The LSRV also minimizes the power losses that occur when using work port reliefs for feed-side pressure control. Unlike work port reliefs, which dump all oil flow to the tank, the LSRV discharges only 2 to 4 L/min. of flow to the tank, reducing energy consumption and heat generation. Eaton.com

OUR QUALITY GOES DEEP

FMM

In-line high-pressure filter is specifically designed for mobile applications. It is lightweight, compact and suitable for working with various types of fluids.

MPLX

Return filter, available with MYclean design, ideal for heavy-duty applications in the industrial sector. Tank-mounted filter expected.

ICU

Device for monitoring the contamination of hydraulic fluids, ideal for systems where there is limited space for installation and continuous analysis of the state of the fluid is required.