International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Shreyash

Hiwrale1 , Ketan Borse2 , Sambodhi Dhutaraj3 , Aditya Gaikwad4

1 Prof. Wayal Ganesh (Assistant Professor) (Department Of Civil Engineering, JSPM’s Rajarshi Shahu College of Engineering, Tathawade-411033, Pune, India) (Department Of Civil Engineering B. Tech, JSPM’s RSCOE, Pune, India) ***

Abstract - The swift industrial growth and urban expansion in the country have sparked a significant amount of infrastructure development. However, this rapid progress brings along a host of challenges, such as a shortage of construction materials and an increase in waste production. This paper focuses on the innovative reuse of waste plastics as a partial substitute for coarse aggregate in M30 concrete, which is commonly used in various construction projects. We experimented by adding waste plastics in increments of 0%, 30%, 40%, and 50% to replace an equivalent amount of aggregate.

Paver blocks, which are pre-cast blocks utilized in constructing different types of pavements, primarily consist of cement, coarse aggregate, and fine aggregate. With the rising scarcity of raw materials, the costs associated with these materials are also climbing rapidly. To tackle this issue, we proposed the idea of partially substituting coarse aggregate with plastic waste. Given the increasing presence of plastic waste in our environment and the challenges of recycling it, we aimed to effectively repurpose it by replacing some of the coarse aggregates with shredded plastic waste. The paver blocks were then cast and cured in the lab, and we conducted tests on various strength parameters to analyze the results.

Key Words: Paver Blocks, Waste Plastic, LDPE, HDPE, Coarseaggregate.

Concrete paver blocks are those handy, prefabricated units made from a mix of cement, fine aggregates, and coarse aggregates. You’ll find them widely used for creating pavements, walkways, driveways, and various outdoor surfaces. Their popularity is no accident; they’re strong, visually appealing, and super convenient when it comes to replacing individual units. Plus, the modular design makes maintenance and repairs a breeze, which is why they’re a go-to choice for both residential and commercialprojects.

One major issue we face with rapid urbanization is the growingmountainofplasticwaste,especiallythosepesky single-use plastic bags made from low-density polypropylene (LDPP). When these plastics aren’t

disposed of properly, they can lead to serious environmental problems, like clogged drainage systems andairpollutionfromopenburning.

Toaddressthedwindlingsupplyofnaturalaggregatesand the environmental challenges posed by plastic waste, this research explores an innovative solution: using shredded plastic waste as a partial replacement for coarse aggregates in making concrete paver blocks. We experimented with industrial plastic waste, particularly polypropylene (PP), at different percentages 0%, 30%, 40%, and 50% by volume to see how it affects the properties of concrete. This approach not only promotes sustainable construction practices but also offers a practicalwaytomanageplasticwasteeffectively.

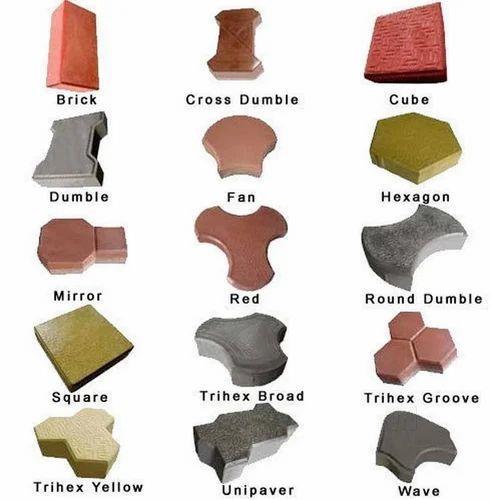

Paver blocks, also known as paving blocks or pavement blocks, come in various materials and shapes, including concrete, clay, and natural stone. Common shapes include rectangular,square,hexagonal,andinterlockingvarieties.

Made from a mix of cement, water, and aggregates like sandorgravel,thesearethemostcommonandaffordable type. They are versatile and come in various colorsandshapes.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Cement is a key binding material in concrete, bringing togetherfineandcoarseaggregatestocreateasolid,stonelike substance once it cures. For this project, we used ordinary Portland cement of grade M30 (specifically, JK super cement), which meets the standards set by IS81121989.

The plastic waste we find in our everyday trash mainly includes Low-Density Polypropylene (LDPP) and HighDensity Polypropylene (HDPP). Researchers have been lookingintoindustrialwastefromPolypropylene(PP)asa potential substitutefor someofthetraditional aggregates usedinconcrete.

Coarse aggregates play a crucial role in giving strength to concrete. These aggregates are typically broken stones sourcedfromquarries,withsizesrangingfrom4.75mmto 20mm. For this research, we used locally available coarse aggregates sized at 10mm, which meet the standards set byIS:383-2007.Weconductedphysicalpropertytestsand sieve analysis on these aggregates according to the

guidelines outlined in IS2386-1963, parts III and IV, respectively.

Fine aggregates work as void filler in the concrete. Naturally available river sand is recommended as fine aggregate but because of scarcity and environmental concernnowadayscrushedsandobtainedbycrushingof stone is generally used. For this research work crushed sand conforming to IS: 383–1970 is used. Fine aggregates havesizesmallerthan4.75mm.

2.4 Admixture

Concrete admixtures are either natural or synthetic chemicalsthataremixedinto concretetoimprovecertain characteristics of both fresh and cured concrete, like workability, durability, and strength at various stages. In this study, we're focusing on an accelerating admixture calledSupercon-100.

This superplasticizer is a modified Melamine Formaldehyde Resin, specifically designed to manage the flow properties of fresh concrete. Superplasticizers play a

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

crucial role in ensuring that the cement is evenly distributed throughout the mix. They work by breaking apartcementclumps,whichreleasestrappedwaterwithin the cement grains, making it available for better workability. Typically, using a superplasticizer can increase the slump from around 5 cm to about 18-20 cm without adding any extra water. When it comes to reducing the amount of mixing water, these additives can cut water content by 15-20%, which in turn lowers the water-to-cement(W/C)ratiobythesamepercentage.This leads to enhanced strength and other beneficial properties,suchasincreaseddensityandwatertightness. For projects involving thin sections, superplasticizers can boost workability to a level that allows for pumping with minimal compaction, effectively preventing issues like honeycombing. The permeability of concrete is a key indicatorofitsdurability.Highporosityoftenresultsfrom inadequate compaction or cracks, but using superplasticizers can help mitigate these issues by improving workability while keeping the W/C ratio low. Studies have shown that the permeability coefficient of cement paste significantly decreases as the W/C ratio is reduced.

3. METHODOLOGY

1st. Material Sourcing and Preparation:

Collectionandsortingofplasticwaste;acquisition ofrecycledconstructionmaterials.

Processing of plastic waste (cleaning, shredding) andrecycledmaterials.

Preparation of any additional binding agent, if required.

2nd. Paver blocks Casting:

Developmentofmixdesignswithvaryingmaterial proportions.

Mixingandhomogenizationofthematerials.

MoldingandcompactionofthemixtureintoPaver blocks

CuringofthePaverblocks.

3rd. Performance Evaluation:

Testingofphysicalproperties(dimensions).

Testingofmechanicalproperties(compressive strength).

4th. Data Analysis and Optimization:

Collectionandstatisticalanalysisoftestdata.

Comparisonwithconventionalbrickproperties.

5th. Reporting and Future Work:

Documentationofthemethodologyandfindings.

Recommendationsforfutureresearchand applications.

Finding the perfect mix of ingredients is crucial for achieving the right strength, workability, and durability in concrete.Engineersandcontractorsoftenruntrialmixesto play around with different ratios of cement, water, aggregates, and admixtures.This experimentation ensures that the concrete produced is tailored to meet the specific needs of each project. It’s all about discovering the most efficientand cost-effective concrete mix design for a given application, ensuring that the final product meets all the necessary performance standards. For example, a nominal mix ratio of 1:1.5:27 (which translates to 1 part cement, 1.5partssand,and2.7partsaggregate)istypicallyusedfor a trial mix of M30 grade concrete intended for paver blocks.

Maintaining the right water-cement ratio is also essential to ensure easy compaction and minimize porosity in the final blocks.Theaggregatesarecarefullygradedtoensure they pack well and reduce voids, which ultimately contributestogreaterstrength.Interestingly,plasticwaste issometimesusedasa partial replacementforaggregates, anditseffectsonthemixarecloselymonitored.Eachbatch is mixed thoroughly to achieve a uniform consistency and preventsegregationofmaterials.

Once the paver blocks are cast, they are demolded and cured under standard conditions to evaluate their performanceatvariousages. The insights gained fromthe trial mix play a vital role in finalizing the proportions for large-scaleproductionofeco-friendlypaverblocks.

The mix design ratio for 30% plastic with aggregate is 1:1.5:1.89:0.81

1 part of cement, 1.5 part of sand, 1.89 part of coarse aggregatesand0.81partofplastic

The mix design ratio for 40% plastic with aggregate is 1:1.5:1.62:1.08

1 part of cement, 1.5 part of sand, 1.62 part of coarse aggregatesand1.08partofplastic

International Research Journal of

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net

The mix design ratio for 50% plastic with aggregate is 1:1.5:1.33:1.37

1 part of cement, 1.5 part of sand, 1.33 part of coarse aggregatesand1.37partofplastic

1 Compressivestrengthat28 days 30N/mm2

2 Slump

3 Typeofcement

4

5

6

7

8 Typeofcoarseaggregate 10–16mm

9 TypeofPlasticWaste LDPP&HDPP

Table no..1 MixdesignofM30

5. Test Results: Compressive Strength Test Table no.2 TestResult

1. Shred Plastic is an innovative alternative material forconstructionpurposes.

2. Using Shred Plastic paver blocks is an effective way to dispose of plastic waste, which in turn helpsprotectourenvironment.

3. They demonstrate impressive qualities, such as reducedweight.

4. These blocks are suitable for light traffic roads or footpaths.

5. Plus,theyrequirelesstimetomanufacture.

6. The cost of paver blocks is lower compared to traditionalconcretepaverblocks.

7. However,theircompressivestrengthisnotashigh asthatofconcretepaverblocks.

8. Theycanalsobeutilizedinbuildingconstructions withlighterloadrequirements.

9. Additionally, they are used in the construction of compoundwalls.

In this experiment, we created paver blocks by partially replacingcoarseaggregates.WeusedM30concretemixfor casting these blocks, experimenting with 0%, 30%, 40%, and50%plastic.Theresultsshowedthatthecompressive strength of the blocks increased steadily up to a 30% and 40% replacement of plastic aggregates, but then it started to decline at the 50% mark. From our analysis, we can conclude that the compressive strength of concrete improves gradually up to 30% and 40% plastic coarse aggregatereplacement,butitdecreaseswhenwehit50%. Additionally, when we treated the concrete with an admixture, it significantly boosted the compressive strength. Interestingly, the strength of the plastic paver blocks tends to rise with more plastic content, which also results in lighter blocks. For reference, a conventional paverblockweighsabout6.850kg,whileourplasticpaver blockcomesinatjust6.00kg.Thismakesitacost-effective alternative, with conventional blocks priced at 20 Rs each comparedto17Rsfortheplasticones.

1. K Shingate, Aman Kumar Singh, Vishal Kumar (2022) “Plastic Waste Used In Plastic Paver Blocks”InternationalJournalofAdvanceResearch andInnovativeIdeasinEducation.(IJARIIE).

2. Priyanka Nalwade, (2022) “Waste Plastic Used In Paving Block With Replacement Of Fine Aggregate”. International Research Journal of EngineeringandTechnology.(IRJET).

Figure 7 Test result

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

3. Shrikant. T. Patil, Yash Shinde (2022) “Prepare Pavement Block Using Waste Plastic” International Journal Of Creative Research Thoughts(IJCRT).

4. Toshan Singh Rajput, Kuldeep Sahu (2022) “Utilization Of Waste Plastic In Manufacturing Of Paver Blocks” International Journal For Research in Applied Science & Engineering Technology (IJRASET)

5. Pritam Gupta, Arpit Bele, Aditya Surkar (2021) “StudyonEffectsofPlasticWasteinPaverblocks” International Journal of Innovative Research in Technology(IJIRT).

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008