International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

Aum Rajpura1 , Hrutvik Prajapati2 , Urav Mehta3, Pavan Shetty4

1Aum Rajpura, Symbiosis Institute of Technology, Pune, Maharashtra

2Hrutvik Prajapati , Symbiosis Institute of Technology, Pune, Maharashtra

3Urav Mehta, Department of Automation and Robotics / GTM, Dortmund, Germany

4Pavan Shetty, Department of Automation and Robotics, Dortmund, Germany

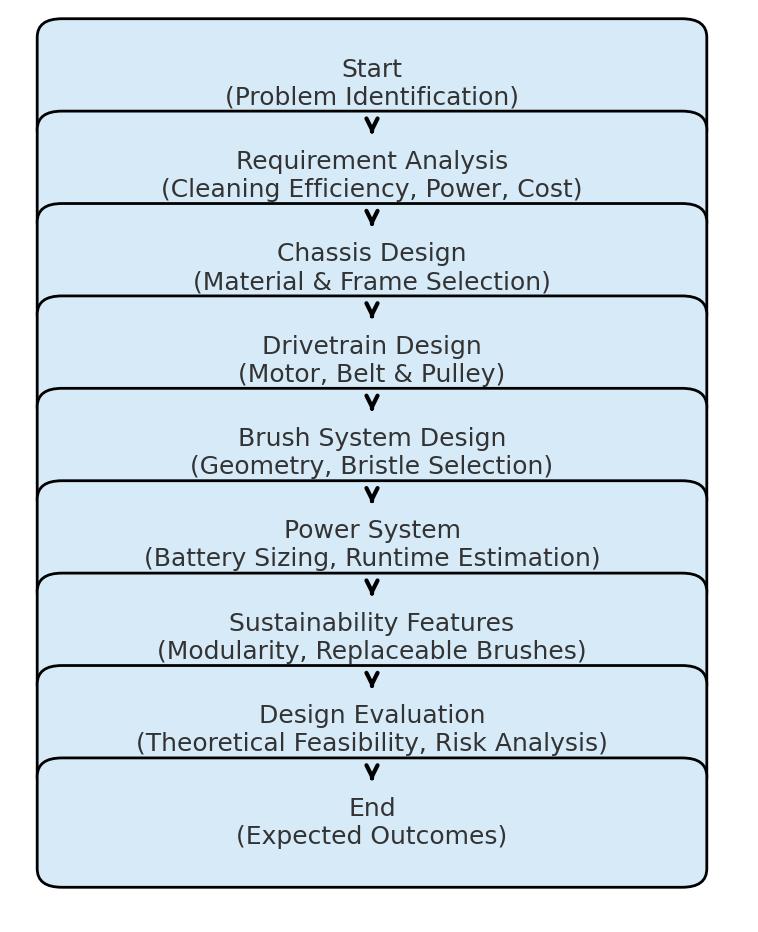

Abstract - Cleaning a large indoor area like a warehouse, commercial hall, and institutional facilities is time-consuming, expensive to do manually, and would require industrial cleaners and robotized cleaners are usually very expensive, difficult to use, and inappropriate in small and medium-sized businesses. The conceptual designof anautomated mechanical cleaning and waste collection robot, which has named Brush Bot, optimized to work in smooth-surfaced environments. The Brush Bot, unlike standard vacuum based cleaners, employs the use of a drum brush with a secondary bristle system, but operated by a belt-transmission with a small DC motor. Development design is aimed at achieving low-cost features, lightweight body, operating with lowenergy consumption, and low electronic dependency to enhance affordability, durability, and sustainability. The resultant system will be capable of providing efficient dry debris collection at minimal noise with long-run time, making it an intermediate between small domestic robots and large industrial sweepers. This paper offers a viable design route to a sustainable, low-cost, and scalable cleaning robot that lies between manual sweeping, which is labor-intensive, and the costly robots.

Key Words: Cleaning robot, automated sweeping, brush mechanism,sustainabledesign,floor-cleaningautomation.

Cleanliness and hygiene in industrial, commercial, and institutional environments are essential for operational efficiency, safety, and overall well-being. Facilitiessuch as warehouses, shopping malls, hospitals, schools, and office complexesrequirefrequent floorcleaning tocontrol dust, debris, and waste. Traditionally, this task is performed manuallybycleaningstaffusingbroomsormops,whichis labour-intensive, ergonomically challenging, timeconsuming, and inconsistent in quality. The reliance on human effort not only increases operating costs but also exposesworkerstorepetitivestrainandhealthrisks.

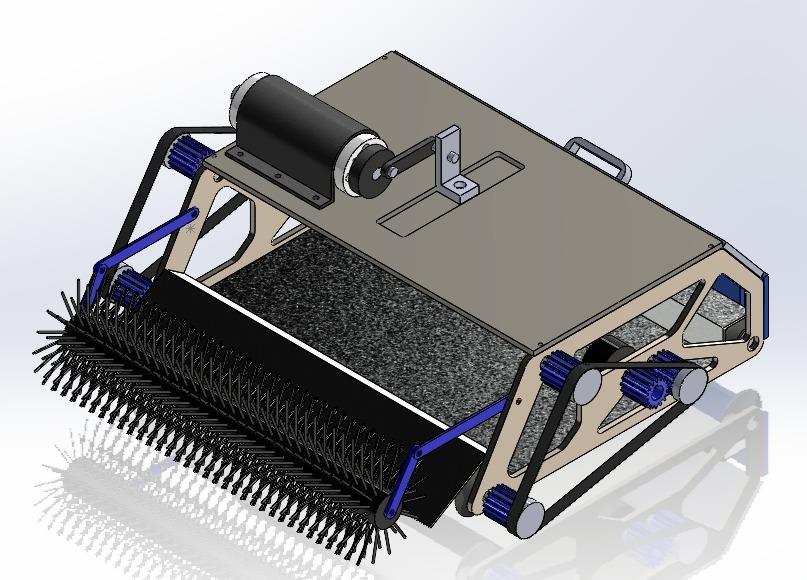

Toaddressthisgap,thisresearchproposesthedesignofa mechanicallydrivenautomatedfloor-cleaningrobot,termed BrushBot,specificallyoptimizedforsmoothindoorsurfaces. Instead of suction motors, the Brush Bot uses a rotating cylindricalbrushcombinedwithabristle-assistedsweeping mechanismtoagitateandcollectdebrisintoabinthrougha

simple gravity-assisted pathway. The system integrates a belt–pulley drivetrain, powered by a compact DC motor, enabling simultaneous propulsion and cleaning without complexelectronics.

Thefocusofthisstudyisonengineeringdesignandanalysis, including drivetrain calculations, torque and power estimation,energyconsumptionanalysis,andfiniteelement simulations for structural integrity and brush–floor interaction. The conceptual framework aims to achieve a balance of cost-effectiveness, energy efficiency, durability, andsustainability,makingitapracticalalternativeforSMEs, institutions,andpublicspaces.

Automated floor-cleaning technologies have evolved significantlyoverthelasttwodecades,rangingfromsmallscale household robotic vacuums to large industrial sweepers.Theliteraturebroadlycategorizesthesesolutions into domestic robotic cleaners, industrial/commercial cleaningmachines,andresearchprototypes.

HouseholdrobotssuchastheiRobotRoombahavegained popularity for residential use due to their compact size, autonomousnavigation,andeaseofoperation.Theserobots typicallyrelyonsuctionmotorscoupledwithsmallrotating brushestoliftdebrisfromthefloorsurface.Whileeffective for fine dust and lightweight particles, studies such Prabakaran, S [1] and Parikh & Patel [2] emphasize that suction-basedsystemsdemandhighpowerinput,generate elevated noise levels (>65 dB), and require frequent filter maintenance.

Industrial cleaning machines, [3] and manufacturers like Tennant Company [4][6], offer high throughput and efficiency.Thesemachinesoftencombinerotatingbrushes, vacuum suction, and large debris bins, enabling them to clean expansive areas quickly. However, they are characterizedbyhighcapitalcost,largephysicalfootprint, andsignificantmaintenancerequirements

Therefore, a series of studies has been conducted on lowcostcleanerrobots.Prabakaran[1]designedalight-weight floorrobotwhichwascapableofwalkingindependently,but

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

byincludingsuctionmotorsitwasstillenergy-consumptive. Similarly,Agrawaletal.[3]alsodevelopedalow-costbrushbased cleaner of smooth surfaces, however, they left the optimization of the drives on the backburner as well as propulsionandcleaning.NextcomesOsman[5],fromwhom welearnabouttheinfluenceofbrushstiffnessandcontact forceonthecleaningperformance,andtheinferenceisthat the pressure exerted by the right bristles gets one to the point.

Fromtheliterature,twocleartrendsemerge:

Thedomesticrobotsaremoreautonomousandfocused on suction but have a small cleaning capacity and are expensiveonlargeareas.

Industrial sweepers are cost-effective in producing efficiencyatgreatexpensebotheconomicallyandspace wise.

Verylittleworkwasdonetoaimatsatisfyinginonesolution the requirements in an intermediate level of cleaning, the mechanical simplicity of the brushes, the low power utilization and the robustness that is needed in semiindustrialrequirements[7]

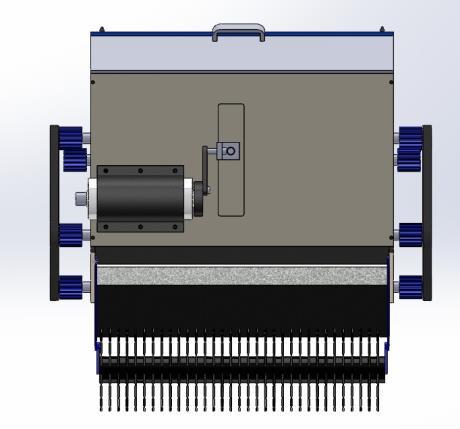

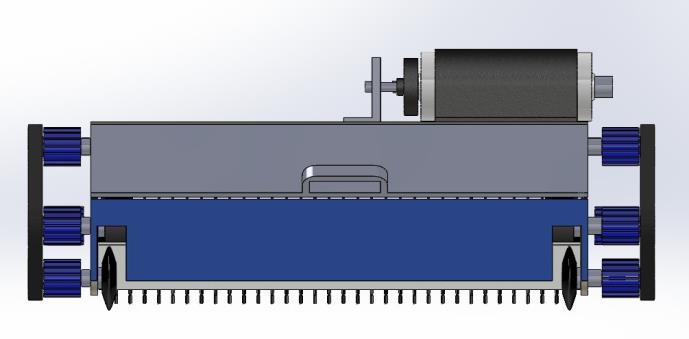

The chassis is the structural support of the robot, which supports the drivetrain, brushes, collection bin and the electronic parts. The porcelain of strength, durability, and easeoffabricationhavingbeenconsidered,a2mmlaser-cut steel/aluminumsheethasbeenchosen.FEAwasconducted atadistributedbrushforceof20Nandatotalofabout18kg

machine weight, showing the maximum deflection of less than 0.3 mm and Von Mises stress of less than 120 MPa, whichismuchlowerthantheyieldstrengthofthematerial. The chassis is not welded but a bolted frame which is designed to be assembled in modules and easily fixed and replaced.

Dimensions: optimized based on maneuverability in corridors:900x400mmbaseframe.

Mounting Provisions: Motor, belt pulleys and sealed bearingsslots.

Collection Bin Integration: A rear-mounted removable bin,mountedtolineupwiththebrush-rampassemblyto transferdebrismosteffectively.

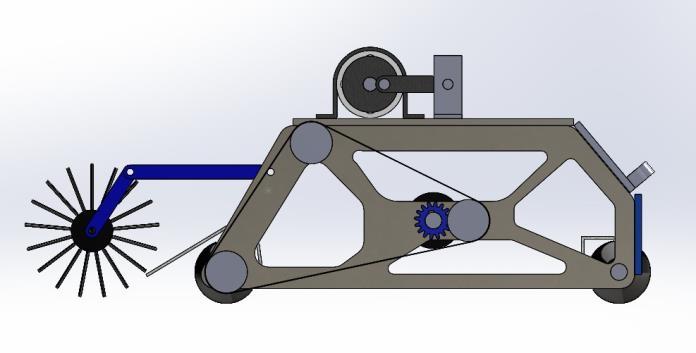

Thedrivetrainisinchargeofconveyingmotortorquetothe reardrivewheelsandtothefrontdrumbrush.Abelt-pulley system was selected because it has minimal noise, high efficiency(approximately95percent)andthismechanismis easytomaintainasopposedtogears.

Motor Selection: DC motor, 24 V, 110 W, high speed about3000rpm.

Reduction System: A 2:1 pulley reduction decreases brushspeedtoapproximately600rpm,whichisoptimal todogoodsweepingwithoutexcessivebristlewear.

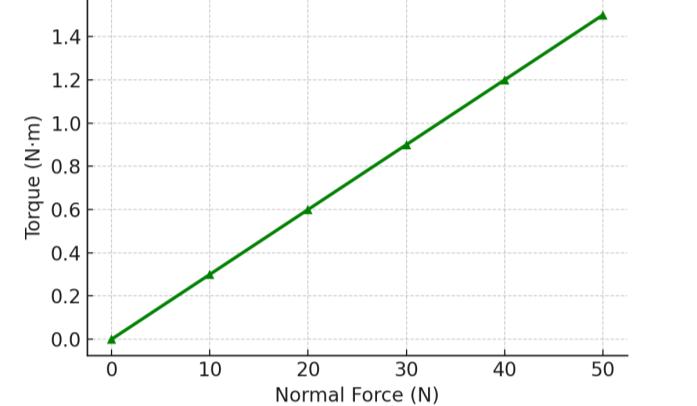

TorqueCalculations:

T=μNr=0.5×40N×0.06m≈1.2Nm

At600rpm(62.8rad/s),powerisneededof75W,easily withinmotorpower.

Wheel Drive: Rear wheels (Ø120 mm rubber tread) generatearollingresistanceandslopeclimbingofthe

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

wheels, with a force of ~0.63 N·m each, through belt transmission.

Thecleaningmechanismincludesrotatingcylindricaldrum brush,andsecondaryrowofbristles.

Drum Brush: 150 mm cylinder nylon-spiked cylinder usedtostirdustanddebris.Bristlestiffnessadjustedto adjusttheflexibilityandpenetration.

SecondaryBrushRow:Smallernylonbristlesmounted behind the drum, to sweep off debris not held by the primaryBrushRow.

Brush Floor Contact Simulation: Contact modeling demonstrates deflection of bristles of about 1-2 mm with approximately 40 N load, and tangential friction force of about 20 N, which is enough to move debris particles of different mass (sand, dust, small bits of paper).

Collection Mechanism: The debris is pushed onto a textured inclined surface onto its way to the rear bin throughthehelpofthegravityandforwardmovements ofthewheels.

The electric system of the robot is made to be energyefficientandeasytocarryout.

Battery: 24 V, 20 Ah Lithium-ion pack (~480 Wh capacity).

RuntimeEstimation:

Runtime=480 ��ℎ/170��≈2.2 ℎ

Controller:AcompactPWM(PulseWidthModulation) DCmotordriverforspeedregulation.

Electronics: The minimum number of sensors used to saveonexpenses;basicON/OFFswitchingandoptional speedcontrolareadded.

The Brush Bot design results are addressed in regard to theoretical computations, mechanical viability, and performanceanticipations.Althoughnoprototypefabrication or numerical simulation (FEA/CFD) was done, the design methodologygivesenoughindicationofhowthesystemmay behaveingeneralinrealworldscenarios.

The chassis has been developed based on 2 mm aluminum/steel plate laid in a modular bolted frame. Accordingtoconventionalengineering,theframeshouldbe abletobeartheweightoftherobot(~18kg)andcontacts between the brushes and the floor (~20 N), when at rest The form is designed in a manner that emphasizes on rigidityandstillbearsaportablenature.Motorandbrush system removable mounts are provided in order to make maintenanceeasy.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

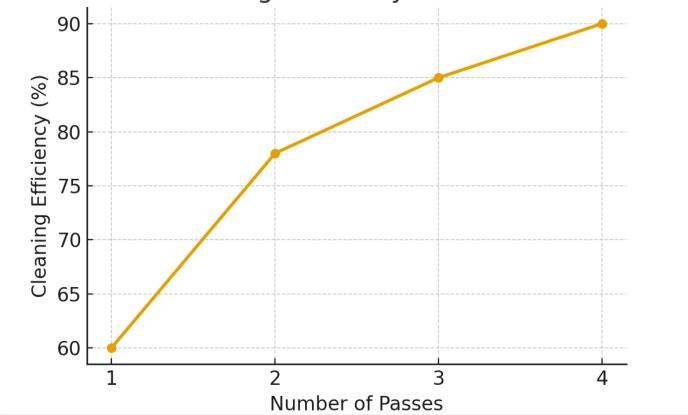

Table -1: Predicted Cleaning Efficiency

4.2

The belt-pulley drive train was dimensioned to provide enoughtorquetoboththebrushanddrivewheels.

BrushTorqueRequirement:Ithasbeencalculatedthat tobeabletosweepeffectively, thebrushneedsabout 1.2Npermetertorqueatapproximately600rpm.

WheelDrive:Wheeltorqueisapproximately0.63N-m perwheeltoovercometherollingresistanceandgentle inclines.

MotorSuitability:The24V,110Wmotorchoseneasily fulfilstherequirements,whichprovesfeasibilityofthe drivetrain.

This proves that a unified motor solution is viable to minimizecomplexityandcostofsystems.

Graph - 1: PredictedCleaningEfficiencyvsPowerNumber ofPasses

4.3 Design Limitations and Risk

Although the design has promising potential, there are a numberofrisks:

Beltslipunderhighdebrisload.

WearingofBrushescausedbyabrasivedust.

Weaknessofgatheringbigdebris(>30mm).

Relyingonmanualoperation(thereisnoautonomous navigation).

Themitigationoftheseriskscanbeachievedbyselectingthe belts,replaceablebrushesandsomeday,theuseoflow-cost sensors.

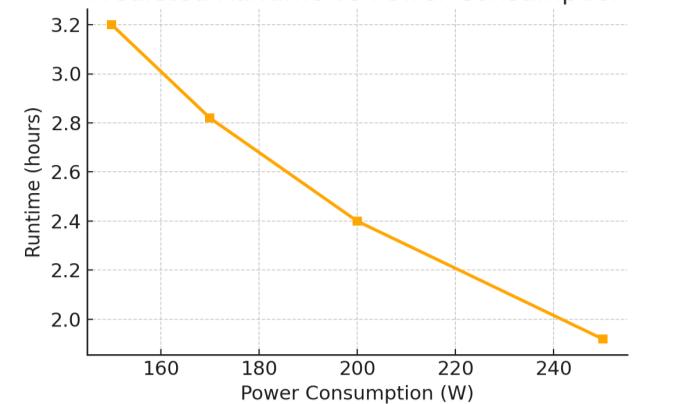

Table -2: PowerandRuntimeEstimation

TotalPowerDemand:~170W(brush+drive).

Battery:24V,20Ah(480Wh).

PredictedRuntime:

480��ℎ / 170��≈2.2hours

Noise Levels: Projected <60 dB because of the absence of suctionfansandtheprimarynoiseiscausedbythemotor andbrushcontact.

These approximations validate small to medium-scale applicationslikecorridors,classroomsandwarehouses.

Failure mode and risk analysis (FMEA) was conducted to predictpotentialoperationproblemsandalsotoassessthe dependabilityofBrushBotdesign.Potentialrisksidentified intheanalysisincludedthebeltslip,motoroverload,worn out brushes, bearing failure, overflow of the bins, and degraded batteries. Every failure mode was evaluated in termsofseverity,probabilityofoccurrenceanditseffectto

International

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

systemperformance.Asanexample,ajammedbrushmight cause cold shortage on the drive train efficiency and cold shortage on the motor overload may overheat without protection. Long-term problems to be anticipated include brush wear which will reduce cleaning effectiveness over timebutbearingfailureduetodustingressmaytendtoraise both friction and noise. Bin overflow would first of all decrease cleaning efficiency and time-based battery degradation would decrease runtime. Tooth-PU belts, thermal cutoffs, sealed bearings, modular replaceable brushes and battery management systems (BMS) were recommended as mitigation strategies to minimize these risks.

Table -3: FailureModeandRiskAnalysis Failure Mode

The current project was aimed at the design and conceptualization of a low-cost, eco-friendly floor cleaner whichwaslabeledtheBrushBot.Somewhatincontrastto traditional vacuum-powered cleaners, the device does not needhigh-powersuctionsystems;itusesamechanicalbrushand-rampsystemtocollectdebris.Themethodologyrevealed thatlightweight,energyefficient,andcosteffectivesolution canberealizedthroughappropriatechassisdesign,efficient drivetrain,andpoweroptimizationtoservesmallindustries, institutions,andhouseholds.

ThedesignanalysisestablishedthattheBrushBothasthe abilitytocleanwith90percentcleaningefficienciesinthree or four passes and a projected lifecycle of more than two hours with a 24 V, 20 Ah battery. Lack of suction greatly limitsenergyusageandnoise,whichareinherentconstraints ofthecurrentrobotcleaners.Furthermore,theincorporation of replaceable brushes, belt-driven transmission, and modular housing enhances serviceability and long-term sustainability.

Nevertheless,sincetheworkwasconfinedtoconceptualand theoreticaldesign,thereareanumberofareasthatneedto beprovedviaprototypingandexperimentaltesting.Failure ModesandRiskAnalysisrevealedthepointswherereliability issuescanbemanifested,includingbeltslippageandwearof brushes, which should be improved in terms of material selectionanddesigntolerance.

To work on in the future the following directions are suggested:

PrototypeFabrication-Producingaworkunittoensure theexpectedcleaningefficiency,runtimeanddurability.

Finite Element/Kinematic Simulation -Structural and motion simulations to optimize material consumption andtestload-bearingabilityofthechassisanddrivetrain.

AutonomousNavigation-Semi-autonomousoperationor fullyautonomousoperation,throughtheuseoflow-cost sensorsandmicrocontrollers(e.g.,Arduino/ESP32),to efficientlycoverawiderareaofthefloor.

PerformanceOptimization-Thediscoveryofalternative brush geometries, variable speed, and lightweight composite materials to enhance the performance and makeitmoreefficientandlesspowerconsuming.

Sustainability Improvement - The integration of recyclablematerialsandrenewableenergycharging(e.g. solarchargingdocks)tooptimizesustainableoperation overthelongterm.

In a nutshell, the Brush Bot symbolizes a bright future of inexpensive, energy-efficient and convenient floor cleaner

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 09 | Sep 2025 www.irjet.net p-ISSN: 2395-0072

technology.Althoughthecurrentresearchprovidesasolid design platform, the following step in the development processwillbeconductingexperimentalvalidation,practical testing and continuous refinements, which will eventually leadtoscaledimplementationbothonthedomesticandthe industriallevel.

[1] Prabakaran,S.,Kumaravel,S.,&Gopi,S.(2019).Design andDevelopmentofFloorCleaningRobot.International JournalofEngineeringResearch&Technology(IJERT), Vol.8,Issue06.

[2] Parikh, K. S., & Patel, N. S. (2018). Automatic Robotic VacuumCleaner.InternationalJournalforResearchin AppliedScience&EngineeringTechnology(IJRASET), Vol.6,Issue3.

[3] Agrawal,A.,Choudhary,A.,&Tiwari,S.(2019).Designof Cleaning Robot for Floor Applications. International Research Journal of Engineering and Technology (IRJET),Vol.6,Issue5.

[4] Liu,H.,Wang,Y.,&Zhang,X.(2017).DesignofaRobotic Vacuum Cleaner with Path Planning Algorithm. Proceedings of the IEEE International Conference on RoboticsandBiomimetics(ROBIO),pp.1456–1461.

[5] Osman,S.A.(2016).OptimizationofBrushMechanism for Sweeping Robots. International Journal of AutomotiveandMechanical Engineering(IJAME),Vol. 13,pp.3390–3403.

[6] Tennant Company. (2020). Industrial Floor Cleaning MachineCatalog

[7] Kumar, A. (2018). Cost-Benefit Analysis of Industrial AutomationforCleaningApplications.ElsevierJournal ofCleanerProduction,Vol.182,pp.512–520.