International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

Bishwadeep Paudel¹, Binita Acharya², Aishwarya Kumari Shahi³, Binay Kumar Yadav´, Asmita Karkiµ, Dipika Dhimal¶, Umesh Raut·

1-6B.E. scholars, Department of Civil Engineering, Acme Engineering College, Kathmandu, Nepal 7Senior Lecturer, Department of Civil Engineering, Acme Engineering College, Kathmandu, Nepal ***

ABSTRACT - Retrofitting techniques are commonly used to enhance the performance of reinforced concrete (RCC) structures in earthquake-prone areas like Nepal. This study investigates the improvement in axial load capacity and compressive strength of RCC columns using hot-rolled steel angles fixed at the four corners along the full height of each column. Three columns (200 mm × 200 mm × 1400 mm) were cast with M25 grade concrete and reinforced with 4 bars of 12 mm diameter and 8 mm stirrups, following IS 456:2000 and SP-16 guidelines. While the theoretical axial load capacity was 553.75 kN, initial destructive testing using a Universal Testing Machine recorded peak loads of 500 kN, 430 kN, and290 kN, givinga maximum compressive strength of 12.5 MPa, lower than the theoretical 13.83 MPa due to eccentricity, flexure, and other practical imperfections. The columns were retrofitted using hot-rolled steel angles with three confinement methods: horizontal strips, horizontal strips with diagonal-alternate bracing, and vertical–horizontal strips. After retrofitting, axial load capacities increased to 590 kN, 565 kN, and 507 kN, corresponding to strength gains of 18%, 31.4%, and 74.8%, respectively. On average, retrofitting boosted axial load capacity by 41.4%, raising compressive strength to 17.68 MPa. While the vertical–horizontal striping achieved the highest gain under axial loading, real-world performance may vary under combined or eccentric loads. Overall, steel-based retrofitting proved effective in strengthening RCC columns, improving ductility, and reducing failures related to flexure and eccentricity, making it a practical approach to enhance seismicsafety inexistingstructures.

Key Words: Retrofitting, RCC Columns, Hot-Rolled Steel, Destructive Testing(DT), Eccentricity, Flexure, Bracing, Striping, Universal Testing Machine, SP-16.

In Nepal, many existing buildings, particularly older or low-income housing, were constructed without following modern seismic design codes, leaving them vulnerable to earthquake damage. Poorly detailed or non-codecompliantreinforcedconcrete(RCC)columns,whichserve as critical load-bearing members, can fail under axial or seismic loads, potentially causing diaphragm collapse and progressive structural failure. Strengthening these

columns is therefore essential for enhancing building safety. Retrofitting columns with steel jackets has proven effective in boosting both strength and ductility, allowing themtobetterresistverticalandlateralseismicloads [1] The jackets enhanced energy absorption, enabling columnstoendurerepeatedseismiccyclesandimproving overall flexibility [2]. Column with steel jacketing effectively mitigates shear-related failures in seismic conditions by increasing 35% shear strength [3]. Steel jacketingincolumnsnotonlyrestoredbutoftenexceeded the original load-carrying capacity, ensuring improved post-earthquake performance [4]. The steel jacketing is a cost-effectiveand reliablesolution and boostverticalload by 50% [5]. Combined axial and shear testing showed improvements of about 40% in axial capacity and 50% in shear resistance which confirmed that steel jacketing significantly improves seismic resilience and energy dissipationunderearthquake-likeloads[6].

This study focuses on hot-rolled steel jacketing as a practical and affordable retrofit method for RCC columns. Hot-rolled steel provides an effective means to improve load capacity, axial strength, and ductility, particularly suitable for low-income households where conventional retrofittingmaterialsmaybecost-prohibitive.

For the experimental study, three RCC columns were designed and cast according to IS 456:2000 and IS SP 16, each with four longitudinal bars of 12 mm diameter and nine stirrups of 8 mm diameter. The study employed twophase destructive testing. In the first phase, the original columns were tested under a Universal Testing Machine (UTM) to evaluate the difference between theoretical and actual peak loads. In the second phase, after repair and retrofitting of each column, the post-retrofit testing assessedtheimprovementsinloadcapacity,axialstrength, and ductility. The three retrofitting techniques applied in eachofthecolumnwere:

1. Angleswithhorizontalstrips

2. Angles with horizontal strips and diagonalalternatebracings

3. Angleswithhorizontalandverticalstrips

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

Theresultsshowedaconsiderableimprovementincolumn performance. If applied in the field, these retrofitting strategies could enhance the capacity of RCC columns and help prevent diaphragm failures, offering a scalable solutionforearthquake-proneregionslikeNepal.

2.1 Ordinary Portland Cement

Ordinary Portland Cement (Grade 43) was used as the primarybinderforcastingRCCcolumns.Theconcretemix was prepared in the ratio of 1: 2.2: 3.22: 0.45 for cement: fineaggregate: coarseaggregate: watertoachieve thedesiredworkabilityandM25gradestrength.

2.2 Fine Aggregate

Clean, well-graded river sand passing through a 4.75 mmsievewasusedasfineaggregate

Fig -2:FineAggregate(Sand)

2.3 Coarse Aggregate

Angularcrushedgravelof20mmnominalsizewasused ascoarseaggregate.

Fig -3:CoarseAggregate

Potablewaterwasusedformixingandcuringtoinitiate hydrationand water-cementratioof0.45wasmaintained to achieve proper workability and strength development inM25concrete

Fe500grade,Thermo-MechanicallyTreated(TMT)bars were employed for both longitudinal and lateral reinforcement. Each column was reinforced with four numbers of 12 mm diameter longitudinal bars and nine numbers of 8 mm diameter stirrups, providing adequate confinementandaxialstrengthforthedestructivetesting.

2.6 Hot-Rolled Steel

Hot-rolled steel angles and plates were used to retrofit thethreepreviouslytestedRCCcolumns,withfourangles placed along the height at each corner. The first column was strengthened with horizontal strips, the second with horizontal strips and diagonal alternate bracings, and the third with horizontal and vertical strips. These configurations improved axial loadcapacity,ductility, and overall strength. Hot-rolled steel offers a cost-effective solution for low-income households, and post-retrofit testing showed a notable increase in load capacity, indicating its potential to enhance column performance andpreventdiaphragmfailuresinpractice.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

Thestudyfollowedastructuredmethodology,beginning withtheselectionoftopic,literaturereview andselection ofmaterials,mixdesign,andcastingofthreeRCCcolumns with M25 concrete. Pre-retrofit destructive testing was conducted, followed by retrofitting with hot-rolled steel anglesinthreeconfigurations.Finally,post-retrofittesting andanalysiswereperformedtoevaluateloadcapacityand failurebehavior.

SelectionofTopic Literature Review Selectionof

2nd Phase DestructiveTest

Resultsand Discussion

-1:MethodologyFlowchart

4. ENGINEERING DESIGN

4.1 Mix Design

TheconcretemixwasdesignedforM25gradetocast threeRCCcolumns.

a. Concrete Volume

Vol ofasinglecolumn=1.4×0.2×0.2=0.048m³

Totalvolumefor3columns=0.048×3=0.144m³

Dryvolume(including54% increaseforvoidsand wastage)=0.144×1.54=0.222m³

b. Mix Proportion

The mix ratio adopted was 1: 2.2: 3.22 (Cement: Fine Aggregate: CoarseAggregate)witha water-cement ratioof 0.45.

Table -1: MixDesignSpecification

Fig -6:PreparationofConcreteMix

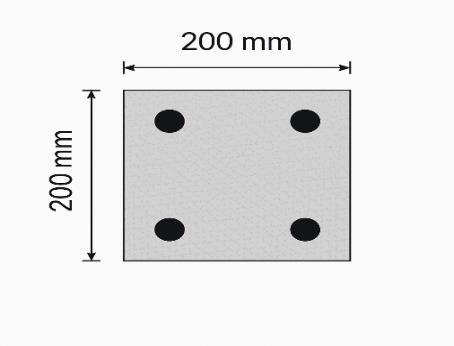

4.2 Column Design

TheRCCcolumnsweredesignedasper IS 456:2000 and SP 16 guidelinestoensureadequateload-carryingcapacity underaxialcompression.

Table -2: ColumnDetails

LongitudinalReinforcement:4barsof12mmØ

TransverseReinforcement:9barsof8mmdia@150mmc/c

These columns were cast using the designed concrete mix and left to cure for 28 days before conducting the 1st phase destructive testing (DT)

Fig -7:Cross-sectionofallthecolumns

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

4.3 Retrofit

Threecolumnswerestrengthenedwithhotrolled steelinfollowingways:

1. Angles and horizontal strips

2. Angles and diagonal-alternate bracings

3. Angles and vertical-horizontal strips

Purpose:Toincreaseload-carryingcapacityand enhancestrength

Steel Properties:

o Hot-rolledsteel(IS800:2007compliant)

o WithparticularYieldstrength

Theslumptest,performedusinga 30 cmhighstandard slump cone as per IS 1199, measured the workability of fresh concrete by observing its vertical subsidence after removingthecone.

Table -3: Slumptest

Parameter

Value

MouldHeight 30cm

SlumpMeasured 22cm

Workability

Medium

Cubes of 150 mm × 150 mm × 150 mm were cast from the column concrete mix and cured for 28 days. Compressive strength was tested using a Compression Testing Machine (CTM) and calculated as fc = Pₚₑₐₖ / A, whereA=22,500 mm² isareaofcross section, PₚₑₐₖisPeak

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

LoadandfcisCompressiveStrength Thesetestsconfirmed themixstrengthbeforecolumncasting.

AverageCompressiveStrength=30.45MPa

FromIS-456,

fck =Meanstrength-1.64*S.D

S.D=Standarddeviation

=4forM25

so,Actual fck = 30.45- 1.64*4= 23.90 MPa which meets5 %confidencelimit.

Table -4: CubeTest

3

5.3 First Phase, Pre-Retrofit Destructive Testing

After28daysofcuring,theRCCcolumnsweresubjected to axial compression on a Universal Testing Machine (UTM). This destructive test determined the actual loadbearing capacity, observed failure modes, and compared results with theoretical IS design values, establishing a benchmarkforretrofitevaluation.

5.4 Second Phase, Post-Retrofit Destructive Testing

Once repaired and retrofitted, the columns were subjected again to axial compression tests using the UTM toevaluatetheincreaseinloadcapacity,changesinfailure patterns,andoverallstructuralperformance.

International

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net

6. RESULTS AND DISCUSSION

The experimental results from both phases of Destructive Testing (UTM) on RCC columns, pre and post retrofit, are presented, along with slump and cube test outcomes verifying mix workability and compressive strength.

6.1 Phase I: Pre-Retrofit Destructive Testing

Destructive testing was conducted to evaluate the axial load capacity and compressive strength of the RCC columns, highlighting the gap between theoretical predictions from SP-16 and actual experimental results obtained from the UTM, and emphasizing the need for suchtestingtoaccuratelyassessstructuralperformance.

6.1.1 Load Capacity

Table -5: PeakLoads(TheoreticalandExperimental) Columns

6.1.2 Compressive Strength

Table -6: CompressiveStrength(Theoreticaland Experimental)

Chart-2:CompressiveStrengthComparison(Pre-Retrofit)

6.2 Phase II: Post-Retrofit Destructive Testing

To address the deviation in peak load and gap in compressive strength observed in Phase I, the columnswereretrofittedusinghot-rolledsteel.

Subsequent testing showed a notable increase in bothaxialloadcapacityandcompressivestrength, withanaverageimprovementof41.41 %.

Table -7: IncreaseinPeakLoadafterRetrofit

Where,

1st =Angles+HorizontalStripsonly

2nd = Angles+ Horizontal Strips + Diagonal-Alternate bracings

3rd =Angles+Horizontal+VerticalStrips

6.2.1 Load Capacity

The columns were tested under axial loading using a UTM, and the retrofitted column with horizontal and vertical strips which aligned to the main reinforcement achievedthehighestpeakloadbyincreasingtheaxialload capacityby74.8%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

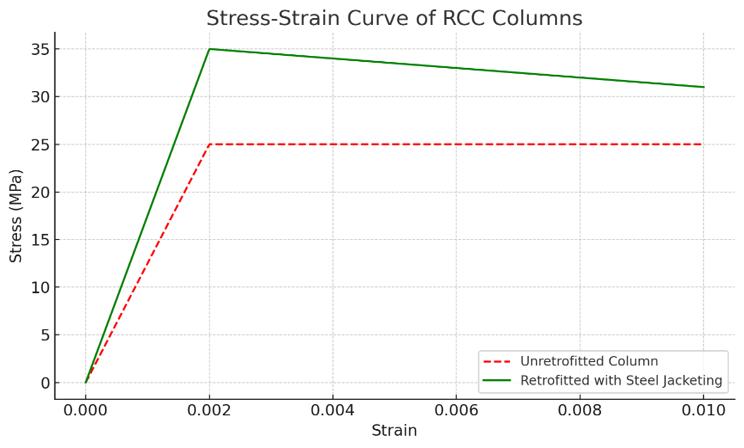

After retrofitting, the post-retrofit experimental compressivestrengthincreasedby27.8%comparedto the pre-retrofit theoretical strength also the actual experimental strength increases from 12.5 MPa to 17.68 MPa,showinga41%gain Theseresultsdemonstrate thathot-rolledsteelretrofittingsignificantlyenhancedboth the axial load capacity and compressive strength of the columnsunderUTMtesting.

Table -8: IncreaseinCompressiveStrengthafterRetrofit

Chart-3: Compressive Strength Comparison (Post-

:Stress-StrainRelationshipofRCCColumns(PreRetrofit)

Chart-5:Stress-StrainRelationshipofRCCColumns(Pre andPost-Retrofit)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

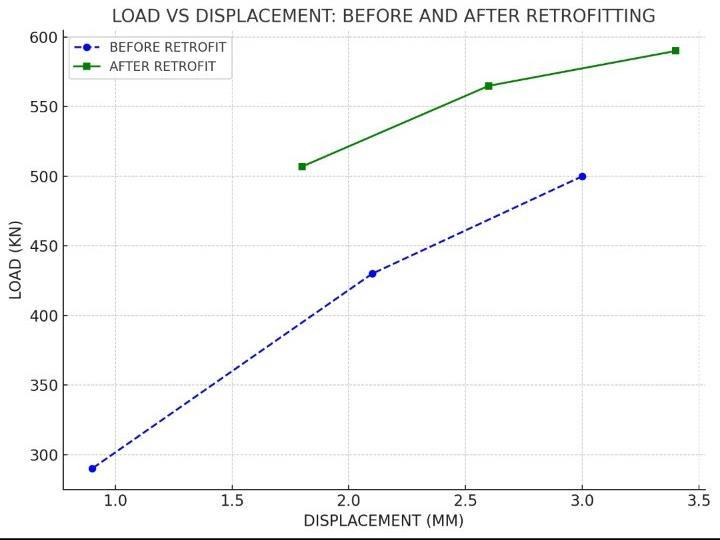

After retrofitting, all columns showed improved load capacity and stiffness, with higher loads causing only slight displacement increases-around 3.4 mm for 590 kN, 2.6 mmfor565 kN,and1.8 mmfor507 kN-demonstrating enhancedresistanceandductility.

Table -9:Loadv/sDisplacement(PreandPost-Retrofit) Columns

1

Chart-6:Loadv/sDisplacementGraph(PreandPost Retrofit)

7. CONCLUSION

The experimental investigation revealed that retrofitting RCC columns with hot-rolled steel substantially improved both axial load capacity and compressivestrength.

In both testing phases, failures occurred in the shear zones, suggesting shear failure likely caused by insufficientlateralreinforcement(stirrups).

One column, which reached only 290 kN in the firstphase DT, likely experienced unequal eccentric loading,inducingflexureandearlyfailure.

After retrofitting with vertical strips aligned to the main reinforcement, this column exhibited the greatest improvement, achieving up to 75% gain in strength and axial load, while the overall average increase across all columns was 41.4% for both load capacityandcompressivestrength.

Horizontal and diagonal bracing also enhanced performance, but to a lesser extent than vertical alignment.

These results demonstrate that hot-rolled steel retrofitting is an effective, practical, and cost-efficient strategy, particularly suitable for low-income households, providing a reliable approach to strengthencolumnsandenhanceseismicresiliencein earthquake-proneareassuchasNepal.

The authors express their sincere gratitude to their supervisor, Er. Umesh Raut, and HOD, Er. Mahadev Singh Saud, along with the Civil Engineering Department at ACME Engineering College, for their guidance, support, and financial assistance. The authors acknowledge Mr. Sahash

NathAdhikariandMs.PragatiDahal(RiskAnalysisOfficer, Global IME Bank) for their generous financial support throughself-fundingandCSRfundingrespectively.Special

thanks are extended to mates Ankit Regmi and Arun Adhikari for assistance with mixing and column fabrication, and to Mr. Man Bahadur Gurung for his contribution in rod frame preparation, retrofitting, and logistical support. The authors also appreciate the staff of the Central Material Testing Laboratory for facilitating destructive testing and acknowledge their families for unwaveringsupportthroughouttheproject.

[1] M.F.Belal,H.M.Mohamed, andS.A.Morad,“Behavior of reinforced concrete columns strengthened by steel jacket,” Engineering Structures, vol. 56, pp. 47–60, 2014.

[2] H. M. Mohammed, H. A. Ibrahim, and H. Al-Zoubi, “Seismic retrofit of reinforced concrete columns using steel jacketing,” Structural Engineering and Mechanics, vol.66,pp.281–294,2018.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

[3] H. Yildirim and E. Kalkan, “Steel jacketing for the improvement of shear strength of reinforced concrete columns under seismic loading,” Journal of Structural Engineering,vol.145,no.4,p.04019019,2019.

[4] W. Zhang, X. Li, and X. Zhang, “Effectiveness of steel jacketing on the seismic performance of reinforced concrete columns,” Earthquake Engineering & StructuralDynamics,vol.49,pp.119–132,2020.

[5] L.T.TranandM.N.Pham,“Improvingaxialandlateral resistance of reinforced concrete columns through steel jacketing,” Journal of Civil Engineering and ConstructionTechnology,vol.12,pp.10–22,2021.

[6] C.Liu,Z.Xu,andX.Cheng,“Strengtheningofreinforced concrete columns using steel jackets: Experimental study,” Advances in Structural Engineering, vol. 25, pp. 1073–1087,2022.

[7] M. A. Shah and P. D. Patel, “Enhancement of axial, lateral, and shear strength of concrete columns with steel jacketing,” Construction and Building Materials, vol.319,p.126346,2023.

[8] A. Bhatti and A. Javed, “Lateral load resistance enhancement of concrete columns using steel jackets underseismicloading,”StructuralConcrete,vol.24,pp. 298–310,2023.

[9] R. M. Nascimento, L. M. Costa, and M. A. Oliveira, “Performanceevaluationofsteeljacketingfordamaged reinforced concrete columns,” Engineering Structures, vol.248,p.113000,2023.

[10] C. Tunc and M. Koc, “Seismic retrofitting of reinforced concrete columns using steel jackets: A practical approach,” Journal of Earthquake Engineering, vol. 27, pp.167–182,2023.

[11] R. Gupta and A. Gupta, “Steel jacketing for reinforcing concrete columns under seismic loading conditions,” Journal of Structural Engineering, vol. 150, p. 04022218,2024.

[12] J. Choi and Y. Kim, “Impact of steel jacketing on the seismic resistance of reinforced concrete columns,” Journal of Civil Engineering Research, vol. 22, pp. 220–230,2024.

[13] V. K. Patel and A. Soni, “Restoring the strength of damaged concrete columns with steel jacketing: An experimental approach,” Journal of Structural Rehabilitation,vol.17,pp.67–78,2025.

[14] S. Singh and P. Sharma, “Steel jacketing as an effective retrofit method for improving seismic resistance of

concrete columns,” Journal of Structural and Civil Engineering,vol.50,p.045063,2025