International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Dr Isha, Bhupesh Sharma

Assistant Professor, Department of civil Engineering, UIET MDU, Haryana, India Student, Department of civil Engineering, UIET MDU, Haryana, India

Abstract - This review highlights the potential of bamboo and natural fibers as sustainable materials in modern concrete applications. Engineered bamboo, bamboo scrimber, and treated bamboo fibers have demonstrated significant improvements in strength, toughness, ductility, and thermal resistance, positioning them as viable alternatives to steel reinforcement. The incorporation of bamboo leaf ash (BLA) and metakaolin (MK) as supplementary cementitious materials enhanced mechanical properties while reducing environmental impact. Studies on hybrid and fiber-reinforced concretes showed improved compressive, tensile, and flexural strengths at optimal fiber contents. Modified bamboo aggregates offered improved durability and energy dissipation, addressing the depletion of natural aggregates. Additionally, natural fibers such as coir, jute, and sugarcane contributed to enhanced workability, fracture energy, and sustainability. Overall, these findings support the integration of bamboo and agro-waste fibers into concrete to achieve high performance and environmental benefits, aligning with sustainable construction goals.

Key Words: Bamboo-reinforcedconcrete,sustainableconstruction,naturalfibers,mechanicalproperties,bambooaggregates, ductility,durability,fiber-reinforcedconcrete.

Concrete is an essential material in the construction industry, known for its durability, versatility, and high compressive strength. However, it is inherently brittle and exhibits low tensile and flexural strength, which limits its application in structuresrequiringresistancetobendingandcracking.Traditionally,reinforcementssuchassteelandsyntheticfibershave beenusedtoaddresstheselimitations.However,thegrowingemphasisonsustainableconstructionmaterialshasprompted interestinnaturalfibers,suchasbamboo,duetotheirrenewablenatureandmechanicalproperties.

Bambooisafast-growingandabundantresourcewithhightensilestrengthandflexibility,makingitanidealcandidatefor reinforcingconcrete.Itsincorporationintoconcretecanimprovemechanicalpropertiessuchasflexuralstrength,whilealso contributing to environmental sustainability. This study investigates the use of bamboo fibers to enhance the flexural performanceofconcrete,focusingonkeyparameterssuchasfibercontentandlength.

Indiaranksasthesecond-highestcountryinbamboogeneticdiversityafterChina,withthetwonationscollectivelyholding overhalfoftheglobalbambooresources.

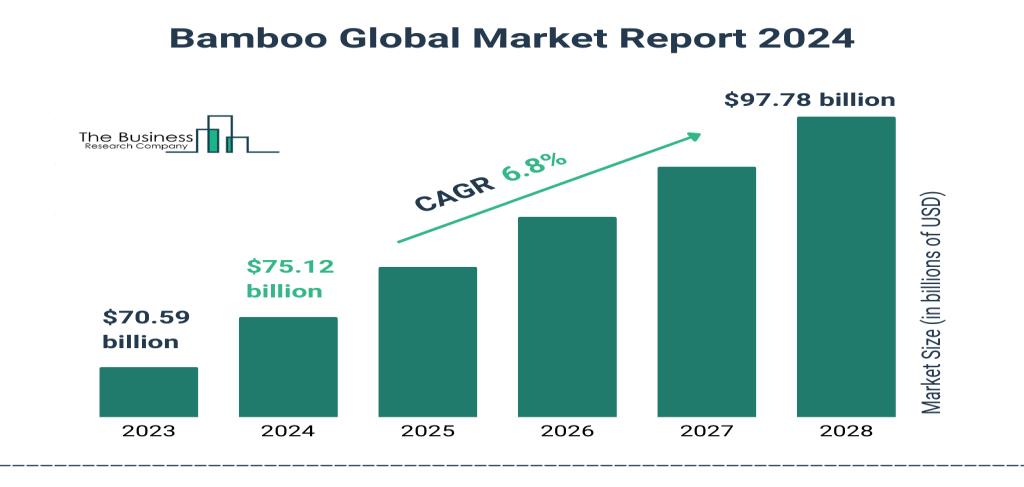

Figure Error! No text of specified style in document.:Growthforecastfortheglobalbamboomarketfrom2023to2028

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Thefigure1displaysthegrowthforecastfortheglobalbamboomarketfrom2023to2028.Themarketsizeisestimatedat $70.59billionin2023andisexpectedtogrowto$75.12billionin2024,withaCompoundAnnualGrowthRate(CAGR)of6.8%. By2028,themarketisprojectedtoreach$97.78billion,indicatingrobustgrowthoverthefive-yearperiod.Thisexpansion highlightsincreasingglobalinterestinbambooasasustainablematerial,drivenbyitsversatilityinindustrieslikeconstruction, furniture,andtextiles,aswellasitseco-friendlyattributes.Thesteadyincreasereflectsrisingdemandforrenewableresources andsustainablepracticesworldwide.

BalaandGupta(2023)reviewedengineeredbambooandbamboo-reinforcedconcrete(BRC)assustainablebuildingmaterials, highlightingtheirsuperiorphysicalandmechanicalpropertiesforstructuralapplications.Bambooscrimberdemonstrated bettermechanicalperformancethanlaminatedbamboo,enhancingitssuitabilityforconstruction.Thestudyemphasizedthe impactofchemicalandthermaltreatmentsonbamboo,improvingitsstrength,toughness,andbondstrength,whichinsome casessurpassedsteelreinforcement.Optimalbambooreinforcementat4%wasfoundtosignificantlyenhancethestrengthand toughnessofconcrete.BRCelementsalsoexhibitedresistancetotemperaturesabove500°Cwithoutspalling,makingthemideal forlightweight,cost-effectivewallingsystems.[1]

Busari et al. (2024) explored the use of bamboo leaf ash (BLA) and metakaolin (MK) as sustainable supplementary cementitious materials for developing eco-friendly interlocking concrete paving blocks. Concrete mixtures with varying replacementlevels(0–30%)ofBLAandMKweretestedfortheirworkabilityandmechanicalpropertiesovercuringperiodsof7, 14,28,and56days.Thestudyfoundthata10%replacementoptimallyimprovedmechanicalstrengthby28.7%,meetingthe IRCstandardsforsemi-rigidpavementapplications.Thecompressivestrengthat5%and10%BLAandMKmetsemi-rigid pavementcriteria,demonstratingthepotentialofthesematerialsineco-friendlyconstruction.ThisresearchhighlightsBLAand MK as viable alternatives to traditional materials, offering environmental and economic benefits. The findings provide a framework for integrating sustainable materials into pavement construction while maintaining structural integrity and performance[2].

Chinetal.(2024)investigatedhybridfibre-reinforcedconcreteincorporatingbambooandbasaltfibres,focusingontheir effectsonmechanicalproperties.Thestudyevaluatedvariousbasaltfibrecontents(0%to1.00%)andassessedcompressive, splittingtensile,andflexuralstrengthsat7,14,and28days.Resultsshowedthatincreasedfibrepercentagesreducedslump values,indicatingdecreasedworkability,withoptimalperformanceat0.75%basaltand1%bamboofibres.Bamboofibres negativelyimpactedcompressiveandsplittingtensilestrengths,whilebasaltfibresenhancedtheseproperties;however,the negativeeffectsofbamboodiminishedwithconcreteage[3]

Fengetal.(2024)investigatedthepracticabilityandfundamentalperformanceofalkali-treatedrawbamboofiberreinforced high-performanceseawaterseasandconcrete(ABFRHPSSC).Thestudyfocusedonevaluatingmechanicalproperties,flowability, poredistribution,andenvironmental sustainability.Alkalitreatmentenhancedthetensilestrengthandelasticmodulusof bamboofiberswhilereducingwaterabsorptionandimprovingbondperformance.Thesefindingsunderscorethepotentialof ABFRHPSSCasadurable,environmentallyfriendlyalternativeforconstruction,supportingsustainabledevelopmentgoals[4]

GaofeiWangetal.(2024)assessedthepropertiesofinterface-modifiedbambooaggregatestoaddressgravel resource depletionandpromotesustainableconcrete materials.Utilizing Phyllostachys edulis(Moso) bamboo,thestudycompared unmodifiedbambootobamboomodifiedwithepoxymortar(EM)andpolyurethaneadhesive(PE).Early-stagealkalineexposure increasedbamboostrength,althoughadeclinewasnotedafterprolongedexposure.ThefindingshighlightedEM-modified bamboo as a viable, eco-friendly alternative to traditional gravel aggregates, combining enhanced durability, mechanical performance, and sustainability. This research underscores the potential of bamboo aggregates to revolutionize concrete construction,contributingtothedevelopmentofgreener,resource-efficientmaterialsintheindustry[5].

GaofeiWangetal.(2025)investigatedthecyclicaxialcompressionbehaviorofbamboocoarseaggregate(BCA)concrete (BAC),focusingonreplacementratesbetween0%and45%.ThestudyrevealedthatwhiletheinclusionofBCAsreducespeak stress,itsignificantlyenhancesductility,hystereticenergydissipation,andmitigatesperformancedegradationundercyclic loading.PlasticstraininBACwasgenerallylowercomparedtonormalaggregateconcrete(NAC)atidenticalunloadingpoints, andstiffnessdegradationdeceleratedasBCAreplacementratesincreased.However,stressdegradationshowednoconsistent trend,beingmorepronouncedinunmodifiedBAC[6]

Garcíaetal.(2024)conductedasystematicreviewontheuseofnaturalfibers(NFs)assustainablereinforcementinmortar andconcrete,focusingonCentralandSouthAmerica.Thestudyexamined19typesofNFs,withsugarcane,coconut,andcoir fibers being the most studied in Brazil, Mexico, and Colombia. NFs were highlighted for their eco-friendly properties and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

potentialtoreduceagriculturalwasteandlandfillaccumulation.ThefindingsrevealedthatNFsenhancemechanicalproperties suchascompressiveandflexuralstrengthwhileimprovingworkability,thoughexcessivefibervolume(above0.5%)canreduce theseproperties[7]

Guruswamy et al. (2024) investigated the use of coir fibre as a sustainable reinforcement to enhance the compressive strength(CS)ofconcrete.Thestudyutilizedresponsesurfacemethodology(RSM)toanalyzetheeffectsoffibrevolumefraction (FVF)andfibrelength(FL)onCS.OptimalconditionsformaximumCSof34N/mm²wereidentifiedasa4%FVFand10mmFL. However,increasingtheFVFbeyond4%reducedworkabilityandbondingduetothehighwaterabsorptionofcoirfibre.While FLsignificantlyinfluencedworkability,itsinteractionwithFVFonCSwasfoundinsignificant[8]

HaoWangetal.(2024)investigatedtheaxialcompressivebehaviorofbamboosheettwiningtube-confinedconcretecolumns (BSTCB),introducinganovelstructureusingbamboofibercompositesforconcreteconfinement.Thestudytested18specimens toexaminetheeffectsofbamboocompositetube(BCT)thicknessandoriginalbambootubediameteronmechanicalproperties. ResultsrevealedthatincreasingBCTthicknesssignificantlyenhancedcompressivestrengthanddeformability,withstrength improvementsrangingfrom7.7%to12.8%asBCTlayersincreasedfrom6to18,andultimatestrainrisingby6.4%to24%[9]

Kanagarajetal.(2024)investigatedtheuseofrecycledaggregateconcrete(RAC)asasustainablealternativetoconventional aggregates,integratingnaturalandsyntheticfiberssuchassteel,polypropylene,andcoconutfiberstoenhanceitsmechanical andthermal stability.Thestudyfoundthatsteel fiberssignificantlyimprovedRAC'sperformance,surpassingcoconutand polypropylene fibers in strength and durability. Fiber-reinforced RAC exhibitedcomparable strength to natural aggregate concrete,makingitviableforstructuralapplications[10].

Kiamahalleh et al. (2024) explored the mechanical, durability, and microstructural properties of waste-based concrete reinforced with sugarcane fibers. The study incorporated various dosages of sugarcane fibers (0%–4%) alongside waste materialssuchasflyash,groundgranulatedblastfurnaceslag,andrecycledaggregates.Resultsshowedthatanoptimalfiber dosageof3%improvedcompressivestrengthby16%andflexuralstrengthby35%,withadditionalenhancementsinflexural load-bearingcapacity(34%),energyabsorption(107%),andtoughnessindex(6%).Durabilitypropertiesalsoimproved,with waterabsorptionreducedby4%andchlorideionpenetrationdecreasedby23%,contributingtoadensermicrostructure[11]

Li et al. (2024) investigated the mechanical properties and stress-strain relationship of bamboo fiber (BF)-reinforced lightweightaggregateconcrete(LWAC),focusingonitsenvironmentalbenefitsandmechanicalperformance.Thestudyrevealed thatBFcontentandlengthsignificantlyinfluencedtensilestrength,improvingitby8.2%to23.7%,whileslightlyreducing compressivestrengthby3.6%to11.1%.BF-reinforcedLWACdemonstratedductilebehavior,withdelayedcrackpropagation andenhancedtoughness,resultingingradualfailurecomparedtothebrittlefailureofnon-fiberspecimens.Stress-straincurves indicatedimprovedplasticdeformationcapacity,andstrengthconversionequationsandconstitutivemodelsproposedinthe studyshowedgoodagreementwithexperimentaldata[12]

Linetal.(2024)exploredthemechanicalpropertiesofrawbamboofiber-reinforcedconcrete,emphasizingbamboo'secofriendly benefits, high tensile strength, and rapid maturation. The study evaluated the effects of fiber dosage, length, and aggregatesizeoncompressive,splittingtensile,andflexuralstrengths,aswellasfractureenergy.Optimalperformancewas achievedwithmoderatefibercontent,20mmfiberlength,anda10mmmaximumaggregatesize,resultingina19.8%increase insplittingtensilestrengthandan89.5%increaseinfractureenergycomparedtoplainconcrete.Earlycompressivestrength reached77.5–84.8%of28-daystrength,indicatingimprovedearly-ageperformance[13].

LucasDeSousaLeiteetal.(2024)exploredtheflexuralstrengthofreinforcedconcretebeamsincorporatingbamboosplints co-assembledwithsteelrebars,aimingtoevaluatebambooasaneco-friendlyalternativetosteelreinforcement.Usingthreepointandfour-pointbendingtests,thestudyassessedmechanicalbehaviorsundervaryingloadconditions.Resultsindicated thatbamboo-steelreinforcedconcrete(BRC)beamsexhibitedenhancedresistancetoflexuralforces,particularlyinthree-point testswheretheyslightlyoutperformedsteel-onlybeamswitha1.4%performanceincrease.However,infour-pointtests,BRC beamsshoweda7.5%decreaseinstrengthcomparedtosteel-reinforcedbeams.Notably,beamswiththreebamboosplints achievedcomparableductilitywithminimalstrengthloss(-7.6%)anda27.4%ductilityimprovement[14]

Mahdietal.(2024)examinedtheflexuralbehaviorandpost-crackingperformanceoffiber-reinforcedconcretemadewith recycledwastecardboardandpolypropylene.Thestudyaimedtoaddresstheenvironmentalimpactsofrecyclablewasteby integrating these materials into eco-efficient concrete mixtures. Experimental results showed reductions in compressive strength(36%),flexuralstrength(26%),indirecttensilestrength(20%),andmodulusofelasticity(23%)comparedtocontrol mixtures.Despitethesereductions,theconcreteretainedstructural-gradecharacteristics,demonstratingitssuitabilityforlow load-bearingapplications[15].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Özenetal.(2024)exploredtheeffectsofgrapheneoxide(GO)-coatedjutefibersonthemechanicalpropertiesanddurability of concrete mixtures,highlighting the advantages of natural fibers in reducingcostsand environmental impacts.Concrete mixtures were prepared with various fiber lengths and percentages, alongside control samples, and tested for slump, compressivestrength,flexuralstrength,modulusofelasticity,anddurabilityunderhightemperaturesandfreeze-thawcycles [16]

Renetal.(2024)investigatedtheeffectsofcellulosefibers(CFs)onshrinkage,anticrack performance,andmechanical propertiesofconcrete,addressingchallengesposedbyshrinkagecracks.UsingCFtypesCF960,CF850,andCF800atvarying contents,thestudyidentifiedCF960at1.2kg/m³asoptimalforenhancingperformance.Thisfibercontentimprovedflexural tensilestrengthby8.27–19.03%,compressivestrengthby3.80–14.54%,andsplittensilestrengthby7.19–18.10%[17]

Lu et al. (2021) evaluated the fracture toughness of bamboo fiber-reinforced high-performance lightweight aggregate concrete(HPLAC)toaddressbrittlenessissuesassociatedwithhighstrength.Thestudyinvestigatedtheeffectsofvaryingfiber volumecontentsandlengthsoncompressivestrength,splittingtensilestrength,andfractureproperties.Resultsshoweda15% reductionincompressivestrengthat0.5%fibervolumeand15mmlengthcomparedtoplainHPLAC,whilesplittingtensile strengthincreasedbyupto39%underthesameconditions.FracturemodetransitionedfromsuddenfailureinplainHPLACto multi-point cracking in bamboo fiber-reinforced HPLAC, with shear cracking proportions rising from 7.2% to 51%. Initial crackingtoughnessandunstablefracturetoughnessimprovedby67.3%and52.1%,respectively,withtheBF-0.5-22.5mixture showingoptimalresults[18].

Shietal.(2024)investigatedtheimpactresistanceofpolyvinylalcohol-polypropylenefibertoughenedfoamedconcrete, focusingonitsperformanceundervaryingimpactspeedsandmaterialcompositions.Cubedropweightimpacttestsrevealed thattheadditionofpolyvinylalcohol(PVA)andpolypropylenefiberssignificantlyenhancedimpactresistance,withultimate bearing capacity, total absorbed energy, and dynamic increase coefficients initially increasing before declining at higher concentrations.Atanimpactspeedof1.6m/s,ultimatebearingcapacityroseby107.8%,totalabsorbedenergyby119.7%,and dynamicincreasecoefficientby31.6%.At2.0m/s,thesevaluesincreasedby134.2%,87.9%,and50%,respectively[19]

ShukorLimetal.(2024)investigatedtheengineeringpropertiesofnaturalfibre-reinforcedone-partgeopolymerconcrete (NFROPGC),emphasizingitsmechanicalstrengthandsustainability.Thisinnovativematerial,activatedbyadryalkalisource, offersamoreuser-friendlyandeco-friendlyalternativetotraditionaltwo-partgeopolymerconcrete.Fibresfromkenaf,coconut, andoilpalmweretreatedandincorporatedatvaryingpercentages,enhancingperformance.Resultsshowedthat0.75%fibre contentoptimallyimprovedflexuralstrength(kenaf:7.87MPa,coconut:6.04MPa,oilpalm:5.85MPa)andsplittingtensile strength(kenaf:4.95MPa,coconut:4.37MPa,oilpalm:3.79MPa),while1%fibrecontentmaximizedimpactresistance(kenaf: 122.11%,coconut:98.33%,oilpalm:88.33%)[20].

Wangetal.(2024)examinedthephysicalandmechanicalpropertiesofbambooaggregateconcrete(BAC)asasustainable alternative to natural aggregate concrete (NAC). The study proposed using biomass bamboo aggregates (BAs) to address environmentalconcernsandimproveconcretetoughness.Surfacemodificationwithepoxymortarwasintroducedtoenhance adhesionbetweenbambooaggregatesandcement.Resultsindicatedthatabambooreplacementrate(r)of35%orhigher providedgoodworkability,althoughincreasedwaterabsorptionandreduceddensitywereobservedathigherreplacement rates.BACexhibitedslowerearlystrengthgrowthbutfasterlaterstrengthdevelopment,meetingtherequirementsfornon-loadbearingstructures[21]

Wangetal.(2024)investigatedthepotentialofmosobambooasasustainablecoarseaggregateinconcrete,focusingon replacingnaturalaggregatestoaddressresourceshortagesandreducecarbonemissions.Monotonicaxialcompressiontests revealedthatbambooaggregateconcrete(BAC)exhibitsuniquemechanicalproperties,includinglowercompressivestrength and elastic modulus compared to natural aggregate concrete (NAC). However, the ultimate strain increased with higher replacementrates,indicatingenhanceddeformationcapacity.Thestudyhighlightedthatepoxymortarmodificationsignificantly improvedthestrengthandductilityofBAC,particularlywhenthebambooreplacementratewas15%ormore,meetingstrength requirementsfornon-specialstructuralcomponents[22]

Weietal.(2024)examinedthecompressiveperformanceofbambooscrimberandconcrete-filledsteeltubecolumns(BCFST) toreduceconcreteusageandweight,testing90BCFSTand18CFSTspecimensunderaxialcompression.ResultsshowedBCFSTs achieveda3.9%higherultimateloadonaveragethanCFSTs,withamaximumincreaseof43.9%attributedtolargerbamboo scrimber dimensions. Increased concrete strength significantly enhanced ultimate load capacity, with C80 concrete outperformingC50by22.2%[23].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Zhaoetal.(2024)conductedanexperimentalstudyonbamboofiber-reinforcedultra-highperformanceconcrete(UHPC), highlightingbamboofiberasasustainablereinforcementmaterial.Theresearchevaluatedtheeffectsofvariousfiberlengths(6 mm,12mm,18mm)andvolumecontents(0.5%,1.0%,1.5%,2.0%)onworkability,mechanicalproperties,andporestructure. Resultsshowedthatbamboofiberssignificantlyenhancedcompressiveandflexuralstrengths,withoptimalperformanceat specificconfigurations.A21.9%increaseincompressivestrengthwasobservedwith18mmfibersat1.0%content,anda40.5% increaseinflexuralstrengthwith18mmfibersat1.5%content[27]

Recentstudiesconfirmthegrowingpotentialofbambooandnaturalfibersassustainablealternativesinconcreteconstruction. Bamboo, in forms such as scrimber, aggregates, and treated fibers, has demonstrated improved mechanical strength, toughness,ductility,andheatresistance.Bamboo-reinforcedconcrete(BRC)achievedsignificantperformancegains,with optimalreinforcementenhancingstructuralcapacityevenunderextremetemperatures.Supplementarymaterialslikebamboo leaf ash and metakaolin improved compressive strength while reducing cement dependency, promoting eco-friendly construction.Hybridfiberconcretesincorporatingbamboo,basalt,orcoirshowedincreasedtensileandflexuralstrengths, althoughexcessivefibercontentcouldreduceworkability.Alkalitreatmentofbamboofibersfurtherenhancedtheirbondwith concrete,whilemodifiedbambooaggregatesservedasviablesubstitutesforgravel, offeringgoodenergyabsorptionand durabilityundercyclicloads.Additionally,bamboo-basedreinforcementsinbeamsandcolumnsenhancedstructuralresilience andflexibility.Naturalfiberslikesugarcane,coconut,andjuteimprovedfracturetoughnessandreducedenvironmentalimpact. Ingeopolymerandultra-high-performanceconcretes,bamboofibersshowedsubstantialstrengthandductilityimprovements atoptimallengthsanddosages.Despitesometrade-offsincompressivestrength,theoverallfindingsadvocateforbambooand naturalfibersasviable,eco-consciousmaterialscapableofreducingcarbonfootprintwhilemaintainingconcrete’sstructural performance.

1. Bala,A.;Gupta,S.EngineeredBambooandBamboo-ReinforcedConcreteElementsasSustainableBuildingMaterials:A Review. Constr. Build. Mater. 2023, 394,132116,doi:10.1016/j.conbuildmat.2023.132116.

2. Busari,A.A.;Loto,R.T.;Ajayi,S.;Oluwajana,S.D.;Eletu,A.DevelopmentofSustainableInterlockingConcretePaving BlocksUsingBambooLeafAshandMetakaolin. Heliyon 2024, 10,e31845,doi:10.1016/j.heliyon.2024.e31845.

3. Chin, S.C.; Shaaban, I.G.; Rizzuto, J.P.; Khan, S.U.; Mohamed, D.; Roslan, N.I.M.; Aziz, A.A. Predictive Models for Mechanical Properties of Hybrid Fibres Reinforced Concrete Containing Bamboo and Basalt Fibres. Structures 2024, 61, 106093,doi:10.1016/j.istruc.2024.106093.

4. Feng,Z.;Li,H.;Ge,L.;Liu,S.;Corbi,O.;Liu,Y.;Li,R.;Duan,Y.PracticabilityandFundamentalPerformance ofAlkali TreatedRawBambooFiberReinforcedHighPerformanceSeawaterSeaSandConcrete. Constr. Build. Mater. 2024, 446,137965, doi:10.1016/j.conbuildmat.2024.137965.

5. Wang,G.; Wei, Y.;Wang,J.; Zhou,Z.;Chen,S.;Zhu,B.AssessmentofthePropertiesofInterface-ModifiedBamboo AggregatesforSustainableConcreteConstruction. J. Build. Eng. 2024, 94,110069,doi:10.1016/j.jobe.2024.110069.

6. Wang,G.;Wei,Y.;Zhu,B.;Chen,S.;Wang,J.;Huang,S.ANovelBiomassBambooCoarseAggregateConcrete:CyclicAxial CompressionBehaviourandModelling. Soil Dyn. Earthq. Eng. 2025, 188,109096,doi:10.1016/j.soildyn.2024.109096.

7. García,G.;Cabrera,R.;Rolón,J.;Pichardo,R.;Thomas,C.NaturalFibersasReinforcementofMortarandConcrete:A SystematicReviewfromCentralandSouthAmericanRegions. J. Build. Eng. 2024, 98,doi:10.1016/j.jobe.2024.111267.

8. Guruswamy,K.P.;Thambiannan,S.;Anthonysamy,A.;Jalgaonkar,K.;Dukare,A.S.;Pandiselvam,R.;Jha,N.CoirFibreReinforcedConcreteforEnhancedCompressiveStrengthandSustainabilityinConstructionApplications. Heliyon 2024, 10, e39773,doi:10.1016/j.heliyon.2024.e39773.

9. Wang,H.;Li,Q.;Wei,Y.;Lin,Y.;Ding,M.AxialCompressiveBehaviorofBambooSheetTwiningTube-ConfinedConcrete ColumnswithanInnerOriginalBambooTube. Case Stud. Constr. Mater. 2024, 20,e03327,doi:10.1016/j.cscm.2024.e03327.

10. Kanagaraj,B.; Shaji,S.; Jafrin,M.;RajR, S.;Anand,N.;Lubloy,E.Natural and SyntheticFiberReinforcedRecycled AggregateConcreteSubjectedtoStandardFireTemperature. Heliyon 2024, 10,e39676,doi:10.1016/j.heliyon.2024.e39676.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

11. ValizadehKiamahalleh,M.;Gholampour,A.;Ngo,T.D.;Ozbakkaloglu,T.Mechanical,DurabilityandMicrostructural Properties of Waste-Based Concrete Reinforced with Sugarcane Fiber. Structures 2024, 67, 107019, doi:10.1016/j.istruc.2024.107019.

12. Li,H.;Wei,Y.;Meng,K.;Zhao,L.;Zhu,B.;Wei,B.MechanicalPropertiesandStress-StrainRelationshipofSurfaceTreated Bamboo Fiber Reinforced Lightweight Aggregate Concrete. Constr. Build. Mater. 2024, 424, 135914, doi:10.1016/j.conbuildmat.2024.135914.

13. Liu,X.;Lin,F.;Leng,G.;Liu,M.;Feng,J.;Bai,Y.;Guo,Z.;Xu,Y.;Sun,Z.;Huang,Z.;etal.AHighThermalConductive Composite Phase Change Film for Flexible Solar/Electro-Thermal Energy Conversion. J. Energy Storage 2023, 73, doi:10.1016/j.est.2023.108959.

14. deSousaLeite,L.;Souza,M.T.;daSilva,E.J.;Benvenuti,T.;deCastroPessôa,J.R.;Amado,F.D.R.AssessingtheFlexural Strengthof ReinforcedConcreteBeams withBamboo SplintsCo-Assembled toSteel Rebarsunder Three- andFour-Point FlexuralStrengthTesting. Case Stud. Constr. Mater. 2024, 20,1–15,doi:10.1016/j.cscm.2024.e02933.

15. Mahdi,S.;Venkatesan,S.;Gravina,R.J.FlexuralBehaviourandPost-CrackingPerformanceofPolypropyleneFibreReinforcedWasteCardboardBlendedConcrete. Case Stud. Constr. Mater. 2024, 21,e03806,doi:10.1016/j.cscm.2024.e03806.

16. Özen,S.;Benlioğlu,A.;Mardani,A.;Altın,Y.;Bedeloğlu,A.EffectofGrapheneOxide-CoatedJuteFiberonMechanical andDurabilityPropertiesofConcreteMixtures. Constr. Build. Mater. 2024, 448,doi:10.1016/j.conbuildmat.2024.138225.

17. Ren,G.;Guo,Y.;Shen,A.;Pan,H.;Wu,H.;Deng,S.EffectsofCelluloseFiberonShrinkage,AnticrackPerformance,and MechanicalPropertiesofConcrete. Constr. Build. Mater. 2024, 451,138824,doi:10.1016/j.conbuildmat.2024.138824.

18. Lu, J.X.; Shen, P.; Ali, H.A.; Poon, C.S. Development of High Performance Lightweight Concrete Using Ultra High Performance Cementitious Composite and Different Lightweight Aggregates. Cem. Concr. Compos. 2021, 124, 104277, doi:10.1016/j.cemconcomp.2021.104277.

19. Shi,X.;Ning,B.;Wang,J.;Cui,T.;Zhao,W.;Li,A.ImpactResistanceofPolyvinylAlcohol-PolypropyleneFiberToughened FoamedConcreteunderLow-VelocityImpact:Experimentsand3DMeso-ScaleModelling. Case Stud. Constr. Mater. 2024, 21, e03976,doi:10.1016/j.cscm.2024.e03976.

20. Ayeni,I.S.;Lim,N.H.A.S.;Samad,M.EngineeringPropertiesofNaturalFibre-ReinforcedOne-PartGeopolymerConcrete. Constr. Build. Mater. 2024, 456,139161,doi:10.1016/j.conbuildmat.2024.139161.

21. Wang,G.;Wei,Y.;Zhu,B.;Wang,J.;Chen,S.;Huang,S.Stress-StrainRelationshipofBiomassConcretewithBambooas CoarseAggregatesunderUniaxialCompression. J. Mater. Res. Technol. 2024, 32,1011–1027,doi:10.1016/j.jmrt.2024.07.218.

22. Wang, G.; Wei, Y.; Ding, M.; Wang, J.; Zhu, B. Physical and Mechanical Properties of Sustainable Bamboo Coarse AggregateConcrete. Constr. Build. Mater. 2024, 431,136605,doi:10.1016/j.conbuildmat.2024.136605.

23. Zhang,Z.;Wei,Y.;Yi,J.;Wei,B.;Lin,Y.;Huang,S.ExperimentsandDesignofLaminatedBambooandConcrete-Filled SteelTubeColumnsunderAxialCompression. Eng. Struct. 2024, 318,118692,doi:10.1016/j.engstruct.2024.118692.

24. Zheng,Y.;Zhou,C.;Zhang,P.;Wang,Y.ComparisonofMechanicalPerformanceUncertaintiesforSustainableHighPerformanceBamboo/WoodComposites. Constr. Build. Mater. 2023, 403,doi:10.1016/j.conbuildmat.2023.132740.

25. Xie,C.;Feng,P.NovelBamboo-Raft-TypeFloatingStructure(BRT-FS)AssembledbyFRPReinforcedConcreteTubes: ConceptualDesignandAnalysis. Eng. Struct. 2024, 318,118705,doi:10.1016/j.engstruct.2024.118705.

26. Yan, Z.; Wei, Y.; Du, H.; Chen, J.; Ding, M.; Li, G. Experimental and Theoretical Study on Flexural Performance of ReinforcedBamboo-ConcreteCompositeBeams. Eng. Struct. 2025, 325,doi:10.1016/j.engstruct.2024.119503.

27. Zhao,H.;Tang,J.;Zhou,T.;Li,Z.;Xiong,T.;Wang,B.EffectsofHybridSteel/BambooFibersontheStaticPerformance andMicrostructureofUHPC. Constr. Build. Mater. 2024, 457,139326,doi:10.1016/j.conbuildmat.2024.139326.

28. Zhao,H.;Tang,J.;Li,Z.;Zhou,T.;Xiong,T.ExperimentalStudyontheStaticPropertiesofBambooFiberReinforced Ultra-HighPerformanceConcrete(UHPC). Constr. Build. Mater. 2024, 453,138974,doi:10.1016/j.conbuildmat.2024.138974.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

29. Ahmad,J.;Zhou,Z.;Deifalla,A.F.StructuralPropertiesofConcreteReinforcedwithBambooFibers:AReview. J. Mater. Res. Technol. 2023, 24,844–865,doi:10.1016/j.jmrt.2023.03.038.

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page192