Volume: 12 Issue: 08 | Aug 2025 www.irjet.net

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net

Achyut

Ghosh1 , Md. Asraf Ansari2 , Ashish Kumar 3 , Md. Asdul4 , Md. Fazal5

6B. G. Shukla

1Student of Oriental Institute of Science and Technology, Bhopal

2Student of Oriental Institute of Science and Technology, Bhopal

3Student of Oriental Institute of Science and Technology, Bhopal

4Student of Oriental Institute of Science and Technology, Bhopal

5Student of Oriental Institute of Science and Technology, Bhopal

6Assistant Professor, Dept. of Mechanical Engineering, Oriental Institute of Science and Technology, Bhopal, Madhya Pradesh, India

Abstract

In our work we designed and fabricated a solar energy based grass cutting machine which is low cost ,high efficient and more flexi ble machine. Here, with improved cut grass separation mechanism and improved blade profile the speed of cutting and power inp ut has been considerably improved. The initial cost of fabrication has been slightly increased which is negotiable due to its improv ed efficiency. The cutting mass outcome from exit is 143 kg/minute with height of cutter 8 cm from ground level of grass. The rate of cut out of grass theoretically is about 21% more than the cutter used as lawn grass cutter using petrol as fuel having same watt age input as in our work has been used.

Key words: Archemedian spiral, involute profile, deflector, reducing gear drive, 90o crank mechanism.

Therehadalwaysbeenmanyscopestoimprovetheinput,output,productionrate,service,maintenance,manufacturingcost,f lexibilityofanyproductorservicegiventoanycustomer.Inreferencetoourworkmanyresearcherstriedtoimprovethegras scuttingmachine[1-4].Thereareelectricalenergybased,petrol,dieselorLPGbasedgrasscuttingmachinesusedbyfarmers andindustrialistsforsomanyreasonsoftheirsuitabilityofuses.But,toimprovetheefficiencyofcutting,reducingmaintenanc eandincreasingtheflexibilitywedesignedandfabricatedtherequiredmachineforlawnremovingandrelatedformingpurpo ses[1-5].

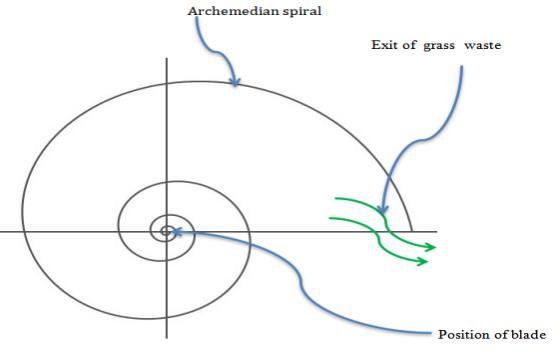

Inourwok,wefabricated acasingofgrasscuttingmachineinshapeofArchemedianspiralwhererateofseparationofcutma ssofgrassisfunctionofrateofchangeofradiusofcurvatureofspiral,thusincreasingtheseparationoutboxjustonesideoffo rmorlawnoritcanbecollectedonboxattachedtothemachine.Withtheimprovedcutterprofileofinvoluteshapeofcuttera ttachedwithseparatorpartofrectangularhyperbolicshapetypealongwithcutterincreasescuttingmassperunittimeincon nectionwithincreasedscavengingeffectduetoseparator’scentrifugalforce.Therearetwoactuatorsattachedwithonerightc rankangleknownaslifterandpusher(byellipticaltrammelmechanismconnectedwithmotorshaft)alsohelpsseparationrat ewhichisrequiredobjectiveofourworkasthecuttingthegrassmassishigherduetoimprovedbladeprofile,i.e.,theshapea ndsizeofblademechanism.thus,solarpoweredgrasscuttingmachineisadvancedmachineworkingonsolarenergybasedre sultingmoreefficientandgreendesigneddevice.Therackandpinionmechanismisusedtoadjustheightofcutterbladeabove thegrass uproot.Theactuatori.e.lifter,thefirstreciprocatingpumppushesupthecutmassofgrassat50o-60o fromhorizon talandfurtherthecutgrassmassispusheddowntoboxexitorstoreboxsituatedat45o-50o verticallydownwardataboutear thlevel.Theinvolutepassageprovideeasyscavenging ofcutgrassmass.Thelaborchargeofcollectionofwastecutofgrassis thereforereducesduetoonepointandonesideseparationofwastealong-withscatteringofmassovertheareaoffieldofgras sisreduced.

PrafulP.Ulhe,Manish D.Inwate,FriedD.Wankhede,KrushnkumarS.Dhakte,madesomechangesintheexistingmachineto make it applicable easily at reduced cost. They aimed to control the pollution. They advanced the machine by using remote controlforlessskilluser.Thisgrasscuttercutdifferenttypesofgrasses[1].

P,B.etal.,2017presentedmanuallyhandleddevicewhichiscommonlyusedforcuttingthegrassoverthefieldwhichcreates pollution and loss of energy.Automaticsolar grasscutter will reduce the effort required for cutting grassin thelawns. Also, Solarpower will be usedto provide the drivingforceforthecutterandvarioussensorswill beused to detect andavoidthe unnecessary objects in the field during operation. It consists of a micro-controller Arduino AT mega 328p, IR sensors, LCD Display for better response and understanding to the user. This paper projected the operation and working principle of the AutomaticGrasscutter.Also,thedesignparametersarediscussedinthispaper[2].

C. J.Shendeexplainedthatavailablegrasscuttingmachineinthemarkethassomelimittocutgrassatsomeheight.Hetried to make the new innovative concept mainly used in agricultural field. He fabricated the grass cutting machine for the use of agriculturalfield,tocutthecropsinthefieldaswellastocutthegrass[3].

D. Rajmani,A.S.,Gaonkar,A.N.,Darak,A.,Joshi,A.andMurgod,V.M.focusesoncreatingagrasscutterthatcombinessolarand battery power to address the limitations of traditional grass cutting methods.The study highlights the need for eco-friendly and efficient lawn maintenance solutions, emphasizing the shift from fossil fuel-powered equipment to more sustainable options[4].

Prof.MohdAttaliqueRabbani,MohammedAfan,AshrafMuzzammilHussain,MohammedMuzaffarAbdullah,developedalawn mowerthatwaspoweredbya12V/1.35ArechargeablebatterywhichdrivestheDCmotoruptoarotationalspeedof19,300R PM.Asaresult,thegeneratedtorquewastransferredtothecuttingheadmechanismforefficientgrasscutting.Theentireconf igurationsetupwasmountedonawoodenbasewhichattachedtogetherwithabicycleframeandasetofwheelarrangement. Thisportablelawnmowerfabricatedcanbeusedtomaintainandtrimgrassingardens,home,schoolsoryards[5].

TanmayBhalodi,NikhilBhujbal,KaranDoshi,RahulGoregaonkar,Prof.SheetalJagtap likelydiscussedthedesignanddevelop mentofasolar-poweredgrasscutterthatisconsideredenvironmentallyfriendly.Thepaperhighlightstheuseofsolarenergy asacleanpowersourcetooperatethegrasscutter,minimizingenvironmentalimpact[6].

Dr.MohamedSaleem,RoshanBahadurBhandari,YathishMG,RakshithAradhyaBCstudied,ahand-heldoperatedmachinefo rgrasscuttingthatwasdesignedandfabricatedbyusingeconomicallyavailablematerials.Importantaspectssuchasdurabilit y,strength,andlightweightweretakenintodesignconsiderationsforbetterperformancecharacteristics.Theentireconfigura tionsetupwasmountedonarollerwhichwasattachedtogetherwithaframeandasetofwheelarrangement.Thisportableg rasscuttercanbeusedtomaintainandtrimgrassingardens,home,schoolsoryards[7].

Suvain K K, developed solar-powered grass cutter that emerged as an innovative solution to tackle the issue of energy consumptioninagricultureandrelatedoperations.Thismachineoperatesimilartolawnmovers,withwheelsfacilitatingeasy movementforefficientgrasscuttingenablingfarmerstomanagetheirlive-stockmoreefficientandproductive[8].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

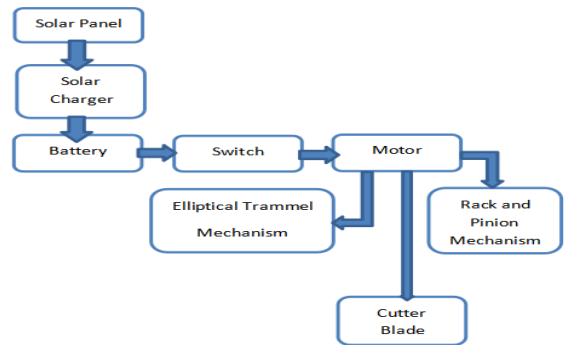

2 : Flowdiagramofworkingmechanismofmodifiedmanuallyoperatedsolarcuttingmachineunderstudy Volume: 12 Issue: 08 | Aug 2025 www.irjet.net

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

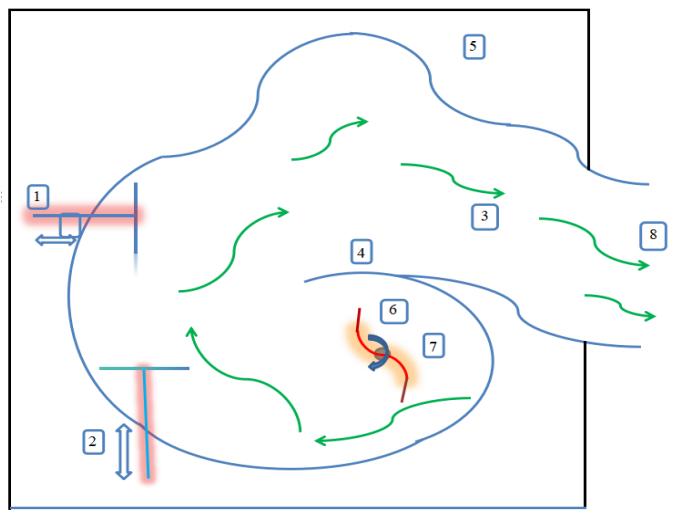

Fig.3: Topviewofcuttingandseparatingmechanismofgrasscuttingmachine

1: Pushingram, 2: liftingramatrightanglecrankwithpushingram, 3: cutoutgrassmovement, 4: Archemedianspiralprofile of casing of grass cutting machine, 5: rectangular box or housing of machine, 6: cutter profile, 7: deflector, 8: one side separationofcutgrass.

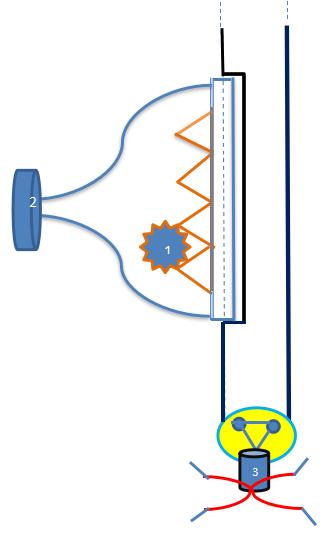

Fig. 4: Rackandpinionmechanismofgrasscuttingmachine

1: Rackandpinion, 2: pushingmechanismof machine, 3: cutterbladeassembly.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page210

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net

Fig.5: Archemedianspiralshapeofcasingorcontainerofgrasscuttingmachine

4. DESIGN CALCULATIONS

Themaximumcuttingforceproducedinmanuallyoperatedbatterypoweredwas8.9N.

Forceforcuttingorshearingoffthegrassisgivenby-

F = Twisting moment or motor shaft torque /operating radius of grass cutting blades = T/r

0.138 = 2.23 N-m

Thepowerdevelopedbymotorshaftisgivenby-

P = 2πNT/60 = 2×3.14 ×9800 ×2.23 =2287.38 Watt.

Solarpanelvoltage, V=22.7Vanditswattage,W=40Watt,thereforeelectriccurrentinputtothestorage batteryisgivenby-

I=Wattage/Panelvoltage=40/22.7=1.762A=1762mA.

Thetheoreticalelectricalpoweroutputbyone12Vbatteryisgivenby-

Pt =12×1.5=18W.

Thebatteryoperationtimeisabout5.5-7hours.

Thecentrifugalforceatmaximumspeedofmotorshaftisgivenby-

Fc = m1 × ω2 × ravg

Where,m1 = massofcutgrassseparation/time, ravg =( rmax + rmin)/2 .

Here,rmax and rminmaximumandminimumradiiofspiral.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page211

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

Maximumpowersuppliedbybatterytothemotorshaft=12×7Watt= 84 Watt.

Withtheavailabletorqueatshafttocirculatetheshreddingmass ofgrass(10-15%powerisutilizedinactuatingtheelliptical trammelmechanism)= 75.6 W.

Therefore,maximumangularspeedofbladesisgivenby-

ω = Available power/ Average torque

Massofcutmassseparationisdirectlyproportionaltotherateofchangeofradiusofspiralcasingi.e. (d/dt) (rmax - rmin)⍺ cut grass separation.

Withhyperbolicdeflector,outletvelocityofseparation,voisgivenby-

vo = 3/vi

Where,vi =velocitycreatedbycentrifugalforce, Fc = m1 vi2 ri

Thereciprocatingpressureforcetoliftthecutmassbyfirstactuatorisgivenby-

Fp = Fc × (π/4) d2 (neglectingthegravityeffect)

Whered=diameterofpistonofactuator.

The pusher piston connected with lifter has approximately equal pushing force because of equal piston diameter as that of pusherone.

Table 1: Technicalspecificationofmaincomponentsof grasscuttingmachine

S No Items

1 Solarpanel 12Vand18W 1

Powersupplyforbattery

2 Battery 12Vand72AH 1 Powersupplyforcircuit

3 Blademotor 7000to13,000RPM 1 Rotatetheblades 4 Gearmotor 2000-10,000RPM 1 Rotatethewheels

5 Reducing gear mechanism MOSFETIRF3205’s 1 Controls thegearmotor

6 Reciprocating pistons (plasticmaterial)

7 Rack and piston gears (plasticgears)

8 Tank or casing of machine (Archemedian spiralprofile)

Pressure =1.6 kg/cm2 , pistondiameter=15cm, strokelength=16cm 2 Pushesgrasswastemassoutwards

Maximum rack height = 20cm 1

Settheheightofcutabovetheearth

Minimum radius = 24 cm, maximum radius = 76cm 1 For increasing the rate of separation of cut massofgrass

5.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN:2395-0072

Table 2: Comparativevaluesofstraightandcurvedbladesofcutter

6.

Withtheobjectives toreducethemanualpowerinput,easyseparationofcutmassof grass,requiredsizecutoutofgrass and morefastcutting&removalofmassofgrasswemodifiedthegreensolarenergybasedlowrunningcostgrasscuttingmachine. Withchangeinseparationmechanismandbladeprofilethismachinehashighoutputwithminimummaintenancecost.This machineisreplacementoffuelpoweredlikepetrol,diesel,gasolineordirectelectricenergy.Forbestmanuallyoperateduseof solarbasedmanuallyoperatedcutterdifferentmodificationscanleadefficientandproductivemachine.Byimprovingshape,si ze,materialandoperationalprocessmechanismswefurthercanimprovethebasicgreendesignofsolarbasedgrasscutter.

[1]PrafulP.Ulhe,ManishD.Inwate,FriedD.Wankhede,KrushnkumarS.Dhakte,‘ModificationofSolarGrassCuttingMachine’, International Journal for Innovative Research in Science & Technology, Vol. 2, 2016, 711-714.

[2]P,B.etal.,2017,‘DesignandImplementationofAutomaticSolarGrassCutter’, International journal of advanced research in electrical, electronics and instrumentation engineering, 6(4), p. 2433.

[3] C.J. Shende ‘Literature Review of Grass Cutter Machine’, International Journal of Emerging Technologies in Engineering Research (IJETER) Volume 6, Issue 2, February (2018).

[4]Rajmani,A.S.,Gaonkar,A.N.,Darak,A.,Joshi,A.andMurgod,V.M.,2019.DesignandFabricationofHybridOperatingGrass Cutter, International Journal of Engineering Research & Technology

[5]Prof.MohdAttaliqueRabbani,MohammedAfan,AshrafMuzzammilHussain,MohammedMuzaffarAbdullah,Fabricationof automated Solar grass Cutting Machine, International Journal of Scientific Research & Engineering Trends, Vol. 6, 2020, ISSN-25 81-5792.

[6]TanmayBhalodi,NikhilBhujbal,KaranDoshi,RahulGoregaonkar,Prof.SheetalJagtap,EnvironmentalFriendlySolarGrass Cutter, International Journal of Research in Engineering, Science and Management, Vol. 3, 2020, 2581-5792.

[7] Dr.MohamedSaleem,RoshanBahadurBhandari,YathishMG,RakshithAradhyaBC‘GrassCuttingandCollectingMachin e’, International Journal of Latest Engineering Research and Applications (IJLERA) ISSN: 2455-7137 Volume – 07, Issue – 06, June 2022, PP – 33-36.

[8]SuvainKK,InternationalJournalofResearchandAnalyticalReviews(IJRAR)April2023,Volume10,Issue2,‘Areviewon performanceandoperationofgrasscutter’.