International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Prathmesh Shete1 , Prashant Dhutekar2 ,

1Student of master of technology, Department of Mechanical Engineering, GHRCEM, Pune 2Assistant Professor, Department of Mechanical Engineering, GHRCEM, Pune

Abstract - This project explores a sustainable redesign of vehicle sunroofs by replacing conventional glass panels with integrated solar panel systems. The aim is to turn the roof from just a part of the car into a surface that can collect solar energy and help power things like lights, the music system, air conditioning, or even charge the battery in electric and hybrid vehicles. The study focuses on the structural and mechanical feasibility of this transformation by replacing the traditional sunroof material with a lightweight plastic alternative. To evaluate its suitability, the natural frequency and stiffness of the solar roof were analyzed using both analytical and simulation methods. These parameters are essential to ensure the roof can endure vibrations and dynamic loads during vehicle operation. The findings lay the groundwork for future integration of solar technology and energy management systems in a structurally sound manner. We mainly focused on the strength and weight analysis. Simulations were carried out to see how well the roof can handle stress and how much weight it adds to the vehicle. The goal was to find a balance between being lightweight and strong enough for real driving conditions.

Key Words: Glass panel, Light Weight, Natural frequency, Energy management

This chapter provides a comprehensive overview of the project,outliningthemotivation,objectives,andscopeofthe work undertaken. It sets the stage for the detailed explorationpresentedinsubsequentchapters.

Theautomotiveindustryhaslongbeenahubforinnovation, withdesignandfunctionalitycontinuallyevolvingtomeetthe demandsofconsumersandenvironmentalchallenges.Oneof the earliest automotive design features that combined aesthetics and utility was the sunroof simple yet effective way to enhance the driving experience by offering natural lightandventilation.Overtheyears,sunroofshavebecomea commonfeatureinmanyvehicles,offeringbothluxuryand practicality.However,asglobalawarenessofclimatechange and the need for sustainable energy sources grows, the automotiveindustryisnowlookingforwaystogobeyond traditionalfeatures.Onesuchinnovationistheintegrationof

solartechnologyintovehicledesign,whichpresentsaunique opportunity to harness the sun's energy to power vehicle systems.

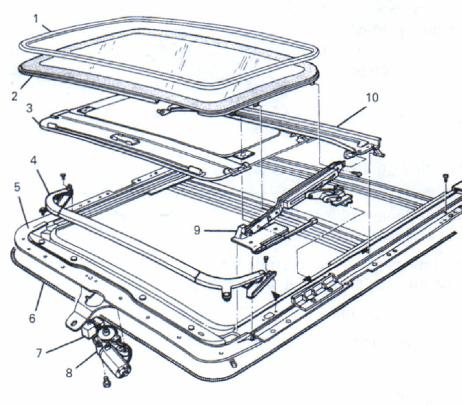

Asunroofistypicallyamovablepanelontheroofof a car that allows light and fresh air into the cabin. Traditionally made from glass or metal, sunroofs were introducedtoenhancecomfortandstyleinvehicles.While they do not serve a functional purpose beyond passenger experience,theirpopularityhasgrowninbotheconomyand luxuryvehicles.Today,withadvancementsinmaterialsand technology,thisoncesimplefeatureholdspotentialformore practical applications such as integrating solar panels to generatecleanenergyforvehicleuse.

The sunroof market has been a prominent segment in the automotiveindustryfordecades,anditcontinuestoevolve, drivenbyconsumerdemandforluxuryfeatures,improved drivingexperiences,andnewtechnologicalinnovations.In recentyears,themarkethasbeensignificantlyinfluencedby trendsinvehiclecustomization,risingconsumerexpectations for comfort and aesthetics,and an increasing emphasison sustainability.

A. ConsumerDemandforLuxuryandComfort

B. TechnologicalAdvancements

C. IncreasedAdoptioninMid-rangeVehicles

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

The sunroof market has seen considerable advancements overtheyears,anditsfuturelookspromisingduetoevolving automotive technologies, consumer demand for enhanced drivingexperiences,andagrowingfocusonsustainability.As manufacturerscontinuetoinnovate,thesunroofconceptis expanding beyond a simple aesthetic or comfort feature. Belowaresomekeyareaswherethefuturescopeofsunroofs lies

A. AutomatedandGesture-ControlledSunroofs

B. SmartSunroofswithAdvancedTechnologies

C. IntegrationofSolar-PoweredSunroofs

Anotablestudyinthisdomainisthe"NumericalStudyofPreVentilation Effects on Cabin Temperature Using Solar Sunroof,"conductedbyDaewoongLeeandHoseongLee.This researchdelvesintotheeffectivenessofusingsolar-powered ventilation systems to mitigate the greenhouse effect in parkedvehicles.Thestudyemploysnumericalsimulationsto model the vehicle's cabin environment, integrating componentssuchasasolarsunroof,DC/DCconverter,and air handling system. The simulations, conducted using Dymola,arevalidatedagainstexperimentaldatatoassessthe system'sperformance.Thefindingsofthisstudyindicatethat evenaphotovoltaic(PV)cellintegratedintothesolarsunroof issufficienttopowertheventilationsystemeffectively.This setup facilitates the removal of hot air from the cabin by introducingcooleroutsideair,therebyreducingtheindoor thermalload.Theresearchalsoexplorestheimpactofcabin volume and DC/DC converter efficiency on the system's performance, providing valuable insights into optimizing solar-powered ventilation systems for automotive applications.[5]

Afterreviewingawiderangeofresearchpapersrelatedto automotivesunroofsandroofsystems,itisclearthatmany researchershavemadevaluablecontributionsinareassuch as vibration control, structural optimization, aerodynamic performance, thermal management, and safety features. Studies have explored techniqueslike experimental modal analysis,constrainedlayerdamping,fuzzycontrolsystems, virtualprototypesimulations,andsolar-reflectivematerials. A significant number have focused on improvingoccupant comfort, reducing noise and heat, and enhancing energy efficiencyinvehiclesthroughsunroofdesignenhancements.

However, a noticeable gap in the current body of research is the lack of investigation into hybrid solutions that combine both traditional glass roofs with integratedsolartechnology.Moststudiestreatsolarpanels and glass roofs as mutually exclusive elements, with no

attempttoexploretheircoexistence.Thereisalsolittletono researchevaluatingthepracticalityofreplacingtherearglass panel of a vehicle with a solar plate. This opens up an innovative research opportunity to examine whether it's structurallyandfunctionallyviabletoinstallasolarpanelin placeoftherearglasswithoutcompromisingvisibility,safety, oraestheticappeal.

A.Todesign,ModelandOptimizetheSolarpanelSun-Roof for4-wheeler.

B.ToreplacetheRearglasswithsun-roofforOptimizingthe Weight.

C. CompareGlasscostandSolarsun-roofPanelCost

Glass Roof: Thefirststepistocreatea3DCADmodelofthe existing glass roof of the vehicle. This involves accurately replicatingthegeometry,dimensions,andsurfacefeaturesof the roof, based on real-world measurements or reference designs.Oncethemodeliscreated,materialpropertiesare assignedtotheglass.

Solar Roof Panel:Forthesolarroofpanelintegration,anew 3DCADmodeliscreated,combiningboththeglassroofand thesolarpanelsystem.Thismodelincludes:

Discretizing both roof models into finite elements. Use appropriate element types (e.g., shell elements for thin structure/HexforThickelement)toensureaccurateresults. Inthecontextoftheglassroofandsolarpanelintegration, meshinginvolvesdividingthe3DCADmodelintoanetwork offiniteelementsthatcanbeanalyzedforvariousphysical phenomena,likestress,deformation.

Natural Frequency:Thesedifferencescanshiftthenatural frequencies of the system, potentially causing resonance issues if they align with common vehicle vibration frequencies.Toaddressthis,differentmodelingapproaches can be used, such as adjusting the material properties, thickness,ordesignofthesolarpanelintegration,tomatch the natural frequencies of the solar roof with those of the glassroof.Thisensuresthatbothroofsavoidresonatingat thesamefrequency.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Stiffness: The solar roof could be either stiffer or more flexiblethantheglassroof,dependingonthematerialsused forthesolarpanelanditsframe.Forexample,theadditionof solarcellsandtheirsupportingstructuremayincreasethe overallstiffnessoftheroof,makingitlesspronetodeflection underload.Conversely,iflightweightmaterialsareused,the solar roof could be more flexible. Understanding and optimizing the stiffness isimportant for ensuringthe roof canwithstandexternalforcesexcessivedeformation,while stillmaintainingstructuralintegrityandminimizingnoise orvibrationduringoperation.

Inthisproject,TheAuthoremployedCATIAV5todevelop detailed3Dmodelsand2Dtechnicaldrawings,essentialfor the design and manufacturing phases. The process commenced with creating 2D sketches, which were then transformed into 3D models. Each part was modeled separately,followedbyassemblingallcomponentstoensure proper fit and function. The design process began with comprehensive research and analysis to understand the project'srequirementsandconstraints.Afterselectingthe optimaldesignandthenproceededwiththeCADmodeling phase. Author utilized parametric modeling techniques to create 3D models, ensuring that all components were accuratelyrepresentedandproperlyconstrained

To simulate realistic behavior of the solar roof assembly under various loading conditions, appropriate boundary conditionswereappliedinAbaqus.Theroofstructurewas attached to the vehicle body using two different types of connections: bolt fixation and glue bonding the bolted connectionsweremodeledbyconstrainingallsixdegreesof freedomthreetranslational(X,Y,Z)andthreerotational(Rx, Ry,Rz)toaccuratelyreplicatetherigidattachmenttypically providedbymechanicalfasteners.Theseboltswereplaced atdesignatedmountingpointswherestructuralrigiditywas critical

The simulation results showed that the Solar roof had a slightlyhighernaturalfrequency(30.2Hzand58.9Hzfor thefirstandsecondmodes)comparedtotheglassroof(29.3 Hz and 56.0 Hz). These values are above the typical excitationrangeinvehiclesandareconsideredacceptable. The small increase with the plastic material suggests improvedvibrationresistance,makingitasuitableandsafe alternativetoglassfortheredesignedroof.

Tableno.5.1NaturalFrequencyComparison

Inthecurrentstudy,thenaturalfrequenciesofthesunroof system in the closed position were obtained through simulation,withthefirstandsecondmodeshapesappearing at 30.1 Hz and 58.3 Hz respectively.Theseresultsclosely alignwith thosereported bySimok Leeand Byeongil Kim (2024), who identified the first and second natural frequenciesofastandardsunroofglasspanelas 34.8 Hz and 53.1 Hz usingexperimentalmodalanalysis(EMA).[1]

Findings(forclosedposition):

1stnaturalfrequency:34.8Hz

2ndnaturalfrequency:53.1Hz

3rdnaturalfrequency:85.9Hz

The slight variation in the first mode can be attributed to differences in boundary conditions, material properties, and specific sunroof geometryusedinthecurrentdesign.However,theproximity ofbothmodevaluestoestablishedliteratureconfirmsthe validityandaccuracyofthesimulatedresults.Thesefindings demonstratethattheredesignedsunroofmaintainsdynamic performance within industry-accepted ranges, thereby ensuring structural safety and comfort under real-world conditions.[1]

InaccordancewithSAEJ1100– Motor Vehicle Dimensions, (the standard design load weight for each passenger is specified as 68 kg (150 lbs). This standard provides a uniform set of interior and exterior dimensions for passengercars,multipurposepassengervehicles,andtrucks, ensuring consistency in vehicle design and occupant accommodationassessments.[25]

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Usingthiscalculation,theforcetobeappliedwillbe:

68kg×9.81m/s2= 667.08 N

5.5 Iteration 1

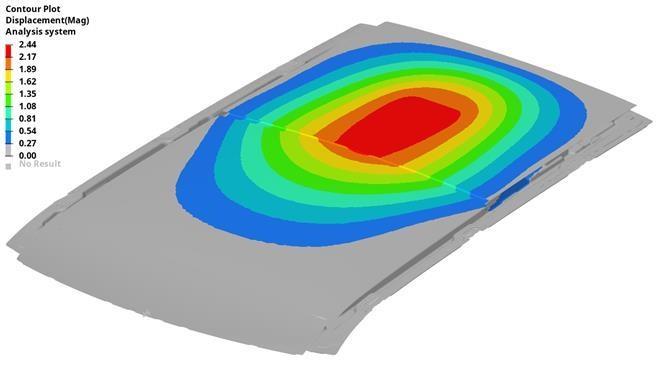

Inthefirstiteration,thestructuralanalysiswasconducted onthecurrentbaseframedesignusinga glass panel andan integrated solar panel. Under the applied vertical load of 667.08 N, the glass panel exhibited a maximum displacement of 2.44 mm,whilethe solar panel showeda significantlyhigherdisplacementof 10.27 mm.Thislarge differenceisprimarilyduetothestructuralbehaviorofthe solarpanel,which,beingmounted overabroadersurface, acts as an overhanging component, especially from the center.Asthesolarpanellackssufficientinternalsupport, the central region becomes the most flexible, leading to excessivebendinganddeformationunderload.

Theauthorsintroduceda central reinforcement toreduce displacement and enhance structural rigidity. This modificationaimedtoaddresstheidentifiedvibrationissues by providing additional support to the sunroof structure. Theimplementationofthecentralreinforcementeffectively minimized displacement, leading to improved dynamic performance and reduced susceptibility to resonance frequenciesduringvehicleoperation.

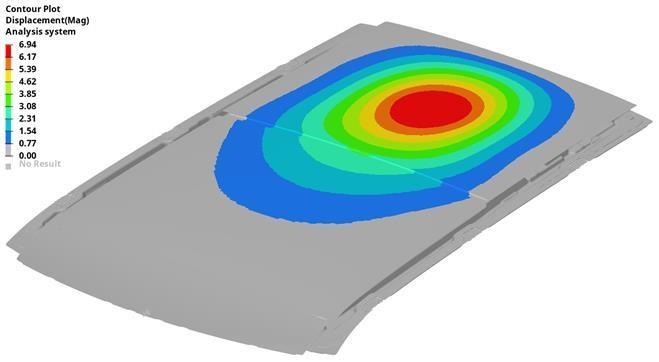

Intheseconditeration,structuralanalysiswascarriedout on a modified base frame incorporating additional cross members to enhance stiffness. The same vertical load of 667.08 N was applied to evaluate performance improvements. Compared to the first iteration, where the solarpanelexperiencedamaximumdisplacementof10.27 mm,therevisedframedesignreducedthedisplacementto 6.94 mm. While this marks a notable improvement in structural behavior due to the added support, the displacementstillexceedstheacceptablelimitsdefinedby designcriteria

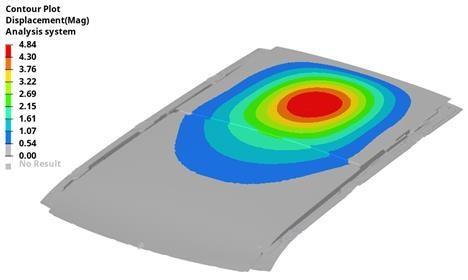

Previously, the frame design included only a single horizontalreinforcementpanel.Intheupdatediteration,two intersecting panels have been added to form a crossstructure,significantlyenhancingtheframe’sstrengthand rigidity. This intersecting configuration provides better structural support by evenly distributing the load and reducingflexibilityincriticalareas.Asaresult,theframeis expected to show improved performance under vertical loadingconditions

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Fig.No5.4DisplacementforITR3

The third iteration incorporated a modified frame design with two intersecting reinforcement panels to enhance structuralstiffness.Whensubjectedtothesameverticalload of 667.08 N, the updated structure exhibited a maximum displacement of 4.84 mm. This marks a significant improvement over previous iterations and brings the displacementwellwithintheacceptabledesignlimits.

InIteration1,thebaseframelackedinternalreinforcements andsupportedbothaglasspanelandasolarpanel.Undera verticalloadof667.08N(68KG)theglasspanelexhibiteda maximumdisplacementof2.44mm,whilethesolarpanel due to its unsupported, overhanging design showed a significantlyhigherdisplacementof10.27mm.Despitethis, both the glass and solar panels had comparable natural frequenciesof29.3Hzand30.2Hz,respectively,indicating similar dynamic behavior. To address the excessive displacement,Iteration2introducedasinglecrossmember between the side rails of the frame. This modification improved structural stiffness, reducing the solar panel's displacementto6.94mm.However,thisvaluestillexceeded theacceptablesafetythreshold.

InIteration3,asecondcrossmemberwasaddedattherear sectionoftheframetosupporttheoverhangingportionof the solar panel. This further enhanced the stiffness of the system,successfullyreducingthedisplacementto4.84mm, whichfallswithinthepermissibledesignlimits.Thenatural frequency values remained close to those observed in previousconfigurations,confirmingthestructure’sdynamic reliability

Inpursuitofenhancingvehicleefficiencyandsustainability, asignificantreductioninthesunroofweightwasachievedby replacing the conventional glass panel with a solar panel. Thismodificationresultedinaweightdecreasefrom31kg to27.6kg,markinga10.5%reduction.

The integration of lightweight solar panels not only contributes to weight reduction but also offers additional benefits such as energy generation and improved vehicle performance. This approach aligns with industry trends towards adopting lightweight materials and renewable energysolutionsinautomotivedesign.

Table6.1WeightComparisonTable

2 (Adding Reinforcement)

3 (Optimized Configuration)

In this project, Author replaced the rear glass section of a panoramic sunroof with a solar panel and evaluated the feasibilityofthismodification,focusingparticularlyonthe costaspect.Thedesignandmodelingstagesconfirmedthat the integration is technically possible without major structuralchangestothevehicle.

Fromacostperspective,replacingglasswithasolarpanel does introduce a noticeable increase in initial expenses. Whilestandardpanoramicglassisrelativelyaffordableand readilyavailable,solarpanelsespeciallythosedesignedtofit automotivecurvatureandintegratewithelectricalsystems aremorespecializedandcomeatahighercost.Additionally, theremaybeaddedexpensesforsystemintegration,suchas wiring,controllers,andsafetymeasures.Despitethehigher upfront cost, the solar panel offers long-term value by providingauxiliarypower,reducingstrainonthevehicle’s main battery, and potentially extending battery life. In electric or hybrid vehicles, it may slightly offset energy usage,whichcontributestoenergysavingsovertime.The degreeofcost-effectivenessultimatelydependsonfactors suchasthevehicle’senergyneeds,thesolarexposureinthe user’sregion,andhowthesolaroutputisutilized.

The iterative design process demonstrated that the integration of targeted structural reinforcements particularlyintersectingandrear-positionedcrossmembers substantially improves the stiffness and load-bearing

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

capabilityofa solar-integratedvehicle roof.In addition to maintaining final displacement within safety limits and achieving natural frequenciescomparabletoconventional glass panels, the final design offers an effective weight reduction over a standard solar roof. This enhancement results in a balanced outcome in terms of safety, dynamic stability,structuralefficiency,andlightweightperformance. Therefore, the final iteration is validated as a safe and structurally efficient solution, well-suited for future applicationsinsustainablevehicledesign.

Whilethecurrentstudyfocusedprimarilyonverticalstatic loading and natural frequency analysis, there remains significantpotentialforfurtherexplorationtoenhancethe structural and functional performance of the solarintegratedroofsystem.Futureworkcouldinclude:

Torsional (Twisting) Simulations with Jig Support: Evaluating the structure’s behavior under twisting loads using boundary conditions that simulate real-world mounting scenarios. This would help assess resistance to torsional deformation during cornering or uneven road conditions.

1. Simok lee; byeongil Kim’ Enhanced Design of Sunroof System through Parametric Study ConsideringVibrationPhenomenonduringVehicle Operation(Apr2024)

2. AnyuCheng;ZhiYang;LixinYang(2023)‘Designof anti-pinch control strategy for vehicle sunroof basedonHallmotor’202335thChineseControland DecisionConference(CCDC)

3. AlexeyKrasnov , Textured glass as an optical materialforautomotivesunroofs(Jan2023)

4. XiaoxiaXu;ZhiwuHan;YingchunHan(2020)The optimizationdesignandFEAanalysisincarsunroof design(International Conference on Mechatronic Science,ElectricEngineeringandComputer(MEC)

5. DaewoongLee;andHoseongLee,Numericalstudyof Pre-VentilationeffectsoncabintemperatureUsing theSolarRoof(2019)

6. Xiaoxia Xu;Yingchun Han (2019)‘Simulation and analysis of passenger car sunroof motion mechanism.’

7. RongjiangTang ;HongbinHe, ‘Control of Sunroof Buffeting Noise by Optimizing the Flow Field CharacteristicsofaCommercialVehicle’(2021)

8. Hailing Huang, Yuxiang Zhang, Hua Sui, ‘Design StrategyforFixedSunroofSystem’(Feb2021)

9. QuanzhouZhangabc,YansongHe,‘Computational study on the passive control of sunroof buffeting usingasub-cavity’(2019)

10. Shi Minjie (2018) Design and Implementation of Fuzzy Control and Anti-Pinch Strategy for AutomotiveElectricSunroof[D].

11. XiaoxiaXu,JingbinZhao,YingchunHan(2008)The Design Study of Automotive Sunroof Motive Mechanism Based on the Virtual Prototype Technology

12. Xiaoxia Xu (2008) Automotive Sunroof Motion MechanismDesignBasedonVirtualPrototype

13. Jizhen Fan, Guilin Qin, Jiangfeng Luo (2024) The Structure,ControlPrincipleandRepairofElectrical CarSunroof

14. JohnRugh,LarryChaney,LaurieRamroth,Matthew Rose(2013)ImpactofSolarControlPVBGlasson Vehicle Interior Temperatures, Air-Conditioning Capacity,FuelConsumption,andVehicleRange

15. J.P. Rugh, L. Chaney, J. Lustbader, J. Mayer, M. Rustagi, K. Olson, R. Kogler Reduction in Vehicle TemperaturesandFuelUsefromCabinVentilation, Solar-Reflective Paint, and a New Solar-Reflective Glazing

16. Lee, Ki-Hwa; Kim, Chan-Mook (2004) An Optimal Placement of Passive Constrained Layer Damping TreatmentforVibrationSuppressionofAutomotive Roof

17. Choi,G.Shin,D.Choi,S.;Jeong,S.(2015)AStudyon the Structural Analysis of Automotive Sunroof System

18. Ha, J. Choi, S. Jeon, B. Ra, M. Jeong, S. (2015) OptimumStructuralDesignTubelessFrameSystem oftheSunroofontheCarBody

19. Kim,I.;Lee,S.;Heo,S.J.;Jeong,J.I.(2010)AStudyfor EvaluationMethodofSunroofSystem’sStructural Performance

20. Kim,H.; Kang, Y.; Park,H.(2019) Identificationof Dynamic Characteristics of Vehicle Parts using ExperimentalModalAnalysis

21. Lee,S.W.;Shin,S.;Choi,E.S.;Yi,J.(2018)Analysisof Flow Characteristics around the Sunroof Opening VariationwithSunroofDeflectorAngle

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

22. U.S. Patent No. 5,089,764, issued on February 18, 2015,toBobier

23. LatestGlobalMarketInsights,"AutomotiveSunroof globalmarketreport2004,"Feb.2024.

24. Brayan López, Hollandia 700-II Comfort: Full FeatureDeluxeInbuiltSunroof

25. SAEJ1100,SocietyofAutomotiveEngineers(SAE). (2001)MotorVehicleDimensions

26. Automobile sunroof: types and actuation system.CLR

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008