International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Revathi

1Assistant Professor, Department of Food Technology, College of Fish Nutrition and Food Technology, TNJFU, Chennai, Tamil Nadu, India

2,3,4 B.Tech. Food Technology, College of Fish Nutrition and Food Technology, TNJFU, Chennai, Tamil Nadu, India

Abstract - The growing demand for plant-based dairy alternatives has driven innovation in traditional and novel food products. Cottonseed milk is a nutrient-rich plant-based milk alternative, considered as a 'triple nutrient' due to its high content of protein, essential fatty acids and sugars. This study focuses on the formulation, standardization, and evaluation of frozen dessert (ice-cream) prepared using cottonseed milk (CSM) as a primary ingredient. Cottonseed milk was extracted and optimized for use asa dairysubstitute, with emphasis on improving flavor, texture, and nutritional quality. Various formulations were developed by adjusting sweeteners, and coconut cream to achieve desirable sensory properties. The final products was subjectedtocomprehensive evaluations including physicochemical analysis, microbial safety assessment, and sensory evaluation. Nutrient analysis revealed notable differencesincompositionbetweendairyand cottonseed milk (CSM) ice cream. CSM ice cream was found to have relatable levels of protein (3.25 %) to dairy based ice cream (3.50 % protein). In contrast, CSM had lower fat content (5.19 %), compared to dairy ice cream (9.08 %). Sensory analysis revealed a comparable consumer acceptability for CSM ice cream, with a sensory score of 8.2 and 8.5 for dairy ice cream. CSM ice cream exhibited a slightly faster meltdown rate (1.08g/min)andloweroverrun(43.6%) than dairy ice cream (0.78 g/min and 55.26 %, respectively). The results demonstrate the potential of cottonseed milk as a viable plant-based ingredient for frozen desserts, offering a nutritious and acceptable alternative for consumers.

Key Words: Cottonseed milk, Plant Based, Ice cream

In recent years, there has been a significant shift in consumer preferences toward healthier and more sustainablefoodoptions.Thischangeisdrivenbyincreased awareness of environmental concerns, animal welfare, lactose intolerance, and dietary restrictions. One area witnessing rapid innovation is the development of plantbasedalternativestotraditionaldairyproducts,particularly icecream.

Plant-based ice cream refers to frozen desserts made withoutanydairyingredients.Plant-basedmilksubstitutes,

***

derivedfromsourceslikesoy,cashew,andalmondasbase ingredientenablethecreationofdairy-freeicecream.These alternativesaimtoreplicatethecreamytexture,richflavour, andoverallsensoryappealofconventionalicecreamwhile offeringadditionalhealthbenefits.Theseplant-basedmilks offer cholesterol-free, unsaturated fat-rich alternatives, containingvitamins,minerals,andantioxidants,classifying themasfunctionalfoodsandnutraceuticals.Leahu,A.etal., (2022).

Cottonseedmilk,traditionallyreferredtoasParuthiPaalin Tamil(where"Paruthi"meanscottonseedand"Paal"means milk),isacommonhouseholdbeverageinSouthIndia,often servedaswelcomedrink.Celebratedforitsnutritionalvalue, it is considered a source of essential nutrients such as proteinandfat Praveena,M.,&Subaratinam,R.(2021).The common ingredients needed to make this nutritious beverage, which include cottonseeds (Paruthi), cardamom powder,coconutmilk,gratedcoconut,driedgingerpowder, rice or kudu millet, jaggery Kumar, M (2019) Cotton seed milk has a pH between 6.5 and 7.1, total solids content between11.8%and13%,andaciditybetween0.17%and 0.19 % and viscosity between 2.8 and 3.4 cP. Amudha, J. (2018).

Thischapterdealswiththematerialsandmethodsusedfor the preparation of cottonseed milk and various steps involvedinthemanufacturingofcottonseedmilkicecream.

Cottonseed was purchased from a local shop in Melur, Madurai.Sugar,Jaggery,Flavors,Non-Dairywhippingcream, CoconutCream,Essencewerepurchasedfromvariousstores inChennai.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Table -1: CottonseedMilkicecreamingredientsand functions

Ingredients

Cottonseed

Function

Dairy-freebasefortheicecream

Sugar Addssweetness

Enhanceflavourandpalatability

Jaggery

Fullcreammilk

Act as a natural sweetener, alternativetorefinedsugar.

Imparts a unique, earthy and slightlycaramelizedflavor.

Base ingredient for Dairy ice cream.

Contributes to smooth, creamy textureandrichflavor.

Non-dairywhipping cream Vegetablefatsource

Adds a creamy texture and improvesoverrun

Coconutcream Adds a rich flavour, creamy texture

Essence Providesadistinctflavourprofile

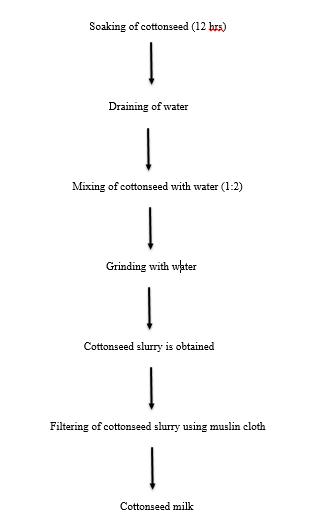

2.2. PREPARATION OF COTTONSEED MILK

Forthepreparationofcottonseedmilk,500gofcottonseed wasusedtoprepare1literofmilk.Cottonseedwassoaked for12hoursandthenthoroughlygroundinamixergrinder withawaterratioof1:2toprepareacottonseedslurry.The collected cottonseed slurry was then strained through a muslinclothintoabowltoobtainthecottonseedmilk.The extractedcottonseedmilkwasstoredinacleanglassjarin therefrigeratorforuseinproductpreparationandchemical analysis.

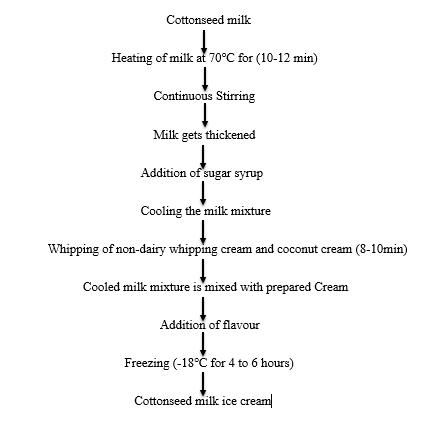

Topreparecottonseedmilk,severaltrialswereconductedto optimizethelevelsofsugarandcoconutcream.Cottonseed milk formulated with jaggery syrup as the sugar base exhibited a slightly bitter taste and a melting rate of 1.65 g/min. In contrast, ice cream prepared with sugar syrup demonstrated better palatability and melting rate. After multipletrialswithvaryingproportionsofsugarsyrupand coconutcream,theoptimalformulationwasdeterminedto be300mLofsugarsyrupand120mLofcoconutcream.

-12

minutes.Add300mLofsugarsyrupandstiruntilthemixture thickens.Oncethickened,letitcool.Inaseparatebowl,whip together200mLofnon-dairywhippingcreamand120mLof coconutcreamforabout10minutesuntilthemixtureturns lightandfluffy.Combinethewhippedcreamwiththecooled cottonseedmilkmixture,thenadd2dropsofessence.Finally, churnthemixtureandfreezeitat-18°Cfor4to6hours.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

2.4. ANALYSIS

2.4.1 pH

The pH of the ice cream was measured directly using a calibratedpHmeter(DELUXEpHmeter).

Titratable acidity was expressed as percent lactic acid, determined by titration against 0.1 N NaOH using phenolphthaleinasanendpointindicator.5mloficecream samplewasdilutedin10mLofdistilledwaterinabeaker.To this1mlofphenolphthaleinindicatorwasaddedandcontent wasmixedwithaglassrod.Thesamplewastitratedagainst 0.01 N NaOH solution till a faint permanent pink colour appears.

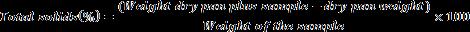

Titratableacidity%

2.4.3.

TotalsolidsisdeterminedasdescribedbySingoandBeswa, (2019).

10gofsampleswastakeninaclean,driedandpre-weighed petri dish and put in dry oven at 100º C for 2 hours till a constantweightwasobtainedandcooledindesiccator.After cooling,thelossinweightwastakenasmoisturecontentand expressedintermsofg/100g.

TheproteincontentisdeterminedfromtheorganicNitrogen content by Kjeldahl method. The various nitrogenous compounds are converted into ammonium sulphate by boiling with concentrated sulphuric acid. The ammonium sulphateformedisdecomposedwithanalkali(NaOH)and the ammonia liberated is absorbed more than standard solutionofacidandthenbacktitratedwithstandardalkali. Raghuramuluetal.,(2003).

Protein (%) = Nitrogen % × 6.25

2.4.6. Ash

5gofsamplewasweighedinacrucibleandcharredovera burner. Then samples were ignited completely in a muffle furnaceat550℃ for4-5hourstogetalightgreyashresult andsubsequentlycooledinadesiccatorthenweighedsoon afterreachingroomtemperature.Raghuramuluetal.,(2003). Theweightoftheresiduewasthennotedandtheashcontent wascalculatedasfollows:

Carbohydratecontentpresentinthesamplewasexpressed “ ” . . by subtracting a sum of values (per 100g) of moisture, protein,fatashandcrudefiberfrom100.

2.4.8. Overrun

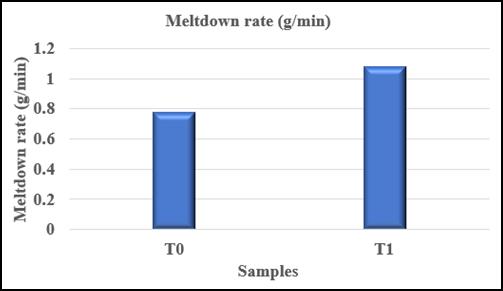

Overrun was measured as described by Daw and Hartel (2015). The measurementswere based on the weight of a certainvolumeoficecreammixandicecream.Acontainer was filled with either ice cream mix or ice cream and the weightwasrecorded.Overrunmeasurementsweretakenin triplicateandthecalculationsweredoneusingthefollowing equation:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Meltdown of the ice cream samples was determined as described by Pon et al., (2015). The sample (80.0 g) was placedona wire meshthatdrainedintoa graduated glass cylinder on top of a weighing balance at controlled temperature(25±1°C).Thedrippedvolumewasmeasured at10-minintervalsforatotalof45min.Thefirstdroptime was measured as the volume drip per minute. The data recordedwereusedtodeterminethemeltingrate(g/min).

A 50-g sample of ice cream was used to determine the texture.Icecreamtubsweretakenoutofthefreezerandleft atroomtemperaturefortwominutes.Theicecreamsamples were analyzed texturally by using TA.XT Plus texture analyzer (Stable Micro System Ltd, Surrey, UK) with P/20 probe(20mmdiameter),atriggerforceof5g,distanceof10 mmandatestspeedof5mm/s.

Theacceptabilityofice-creampreparedbyusingcottonseed milk and dairy full cream milk was assessed by 14 semi trained sensory panel members from College of Fish Nutrition and Food Technology. The appearance, taste, texture,mouthfeelandoverallacceptabilitywasassessedby using 9 point hedonic scale as per procedure described in Gaikwadetal.,(2020).

3. RESULTS AND DISCUSSION

In the chapter, the results and discussion of the research studyispresented.Physicochemicalanalysiswasconducted for both the cottonseed milk and the ice cream developed from cottonseed milk. The prepared cottonseed milk ice cream wastestedformoisture,protein,ash,carbohydrate, crudefiber,textureprofileandsensoryandcomparisonswas madetodairy-basedicecream.

Thephysicochemicalandproximateanalysisofcottonseed milk for three trials was conducted and the results (Mean±SD)areprovidedinTable2andTable3below

Table2PhysicochemicalanalysisofCottonseedMilk

Table3ProximateAnalysisofCottonseedMilk

3.2PhysicochemicalAnalysis of Cottonseed MilkIce cream

Thephysicochemicalanalysisofdairy-basedicecream(To) andcottonseedmilkicecream(T1)wasconductedand compared,andtheresultsarepresentedinTable3.

@Averageof3trials((Mean±SD)

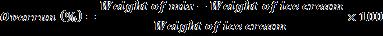

ThepHlevelsindairy-basedicecream(T0)andcottonseed milkicecream(T1)sampleswerefoundtobe6.41±0.02and 6.54 ± 0.02, respectively. Notably, T1 has a higher pH, indicating itisless acidic than T0. Thevalues obtainedfor cottonseedmilkicecreamweresimilartothosereportedby Mendonçaetal.,(2022),whofoundthepHofsoyextractice creamtobe6.15±0.05.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

3.2.2. Titratable Acidity (%)

The titratable acidity of dairy-based ice cream (T0) and cottonseed milk ice cream (T1) samples was calculated as 0.19 ± 0.02 and 0.28 ± 0.04, respectively. These values obtainedforcottonseedmilkicecreamweresimilartothose reportedbyLeahu,Aetal.,(2022),whofoundthetitratable acidityofalmondmilkicecreamtobe0.17±0.01.

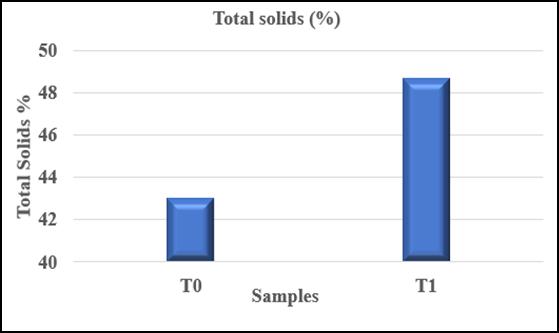

3.2.4 Meltdown rate (g/min)

The melt-down rate of dairy-based ice cream (T0) and cottonseed milk ice cream (T1) samples was calculated as 0.78±0.02and1.08±0.02,respectively.Thevalueobtained forcottonseedmilkicecreamwasclosetothevaluefoundby Srinu,Detal.,(2022),whoreportedthaticecreammadeby incorporatingspicehadameltingrateof1.20±0.03.

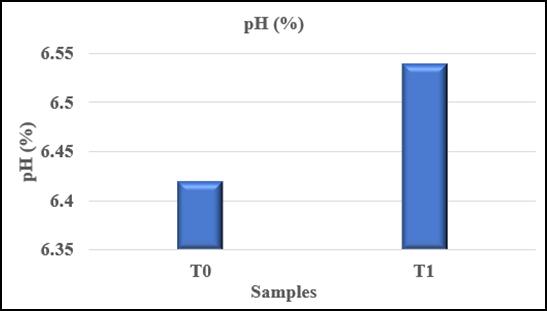

3.2.3 Total Solids (%)

The total solidscontent of dairy-basedicecream(T0)and cottonseed milk ice cream (T1) samples was found to be 43.02±0.02and48.70±0.02,respectively.Thetotalsolidsof cottonseed milk ice cream were considerably higher than those of the dairy-based ice cream (control), which correspondedwiththestudiesofSwarup,V.K.,andPoonia,A. (2022), who reported that total solids in cereal-based ice cream (36.70 ± 0.02) were higher than those in dairy ice cream(30.40±0.05).

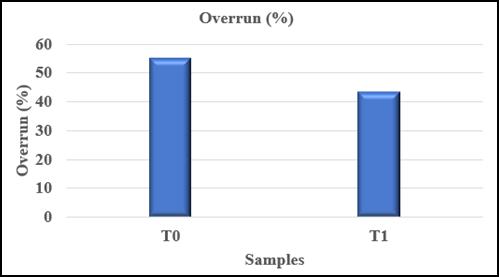

3.2.5 Overrun (%)

Theoverrunofdairy-basedicecream(T0)andcottonseed milkicecream(T0)sampleswascalculatedas55.26%and 43.6%,respectively.T1hadaloweroverrunvaluethanT0.A similar decrease in value was reported by Afriana, N and Kurnia, P (2024), who found that ice cream made with a combinationofcoconutmilkandcashewmilkhadanoverrun of47.08±3.06%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

3.3. Proximate Analysis of Cottonseed Milk Ice cream

The proximatecompositionof dairy-basedandcottonseed milkicecreamwasdeterminedandcompared,withresults showninTable4.

Table-4:Proximateanalysisofdairy-basedandcottonseed milkicecream

Parameters Dairy based ice cream(T0) Cottonseed milk ice cream(T1) Moisture(%)

±0.06

±0.02

±0.02

@Averageof3trials(Mean±SD)

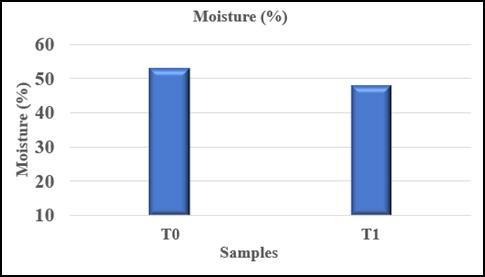

3.3.1. Moisture (%)

±

0.06

±0.02

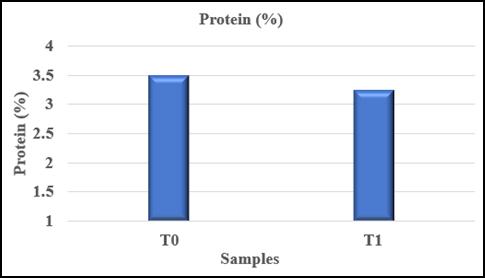

The protein content of dairy-based ice cream (T0) and cottonseedmilkicecream(T1)sampleswasfoundtobe3.50 ± 0.02 and 3.25 ± 0.02, respectively. T1 has a comparable proteinvaluetoT0.Thevalueobtainedforcottonseedmilk icecreamissimilartothevalueobtainedbyPontonio,E.et al.,(2022)forplant-basedYL(yogurt-like)icecream,which hadaproteincontentof3.52±0.15.

ProteincontentofDairybasedicecream(T0)andCSMice cream(T1)

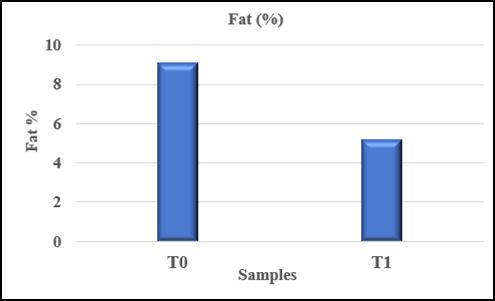

Thefatcontentofdairy-basedicecream(T0)andcottonseed milkicecream(T1)sampleswasfoundtobe9.08±0.02and 5.19±0.02,respectively.T0hadahigherfatcontentthanT1. Thevalueobtainedforcottonseedmilkicecreamwascloseto thevaluefoundbyDiniz,L.G.T.etal.,(2022),whoreported that ice cream made from barnyard millet had a crude fat contentof6.05±0.01.

The moisture content of dairy-based ice cream (T0) was foundtobe53.08±0.06,whereasthemoisturecontentin cottonseedmilkicecream(T1)wasfoundtobe48.06±0.06, whichisinagreementwiththevaluesofpeanutflavorvegan ice cream (54.24 ± 0.05) reported by Diniz, L. G. T. et al., (2022).

MoisturecontentofDairybasedicecream(T0)andCSM icecream(T1)

FatcontentofdairybasedicecreamandCSMicecream

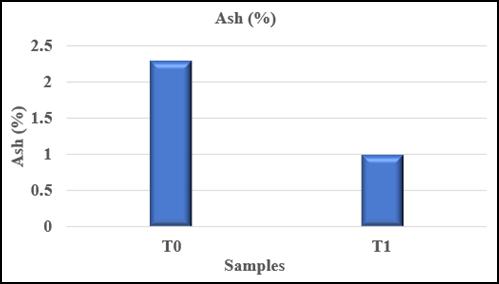

3.3.4 Ash (%)

Theashcontentofdairy-basedicecream(T0)andcottonseed milkicecream(T1)sampleswasfoundtobe2.3±0.02and 1.0 ± 0.02, respectively. The analysis results revealed a significant difference in the mineral content. The value obtainedforcottonseedmilkicecreamwasclosetotheash

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

contentofsymbioticicecreamfromcottonseedmilk,which wasreportedtobe0.89%byPidathalaSahityaetal.,(2024).

AshcontentofdairybasedicecreamandCSMicecream

3.4. Texture Profile Analysis of Cottonseed Milk Ice cream

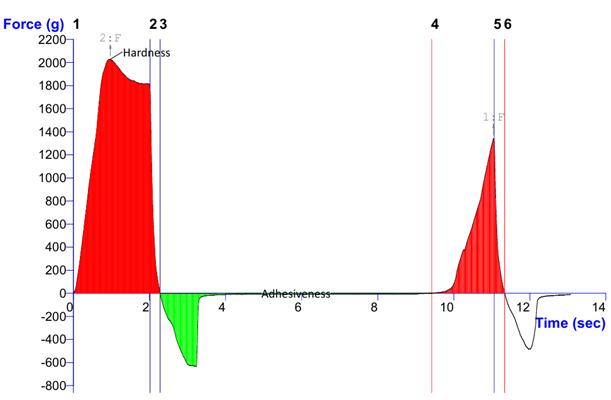

Thetexturalparameters,namelyhardness,adhesiveness, springiness, cohesiveness, gumminess, chewiness, and resilience,ofthecottonseedmilkicecream(T1)werefound tobe2027g,-463.085g,0.812mm,0.263,532.436,432.275, and0.047,respectively.Thevaluesfoundforcottonseedmilk ice cream were close to those reported by Srinu, D et al., (2022), who found that ice cream made by incorporating spice had textural parameters of hardness 2280.77g, cohesiveness0.288,andgumminess516.05g.

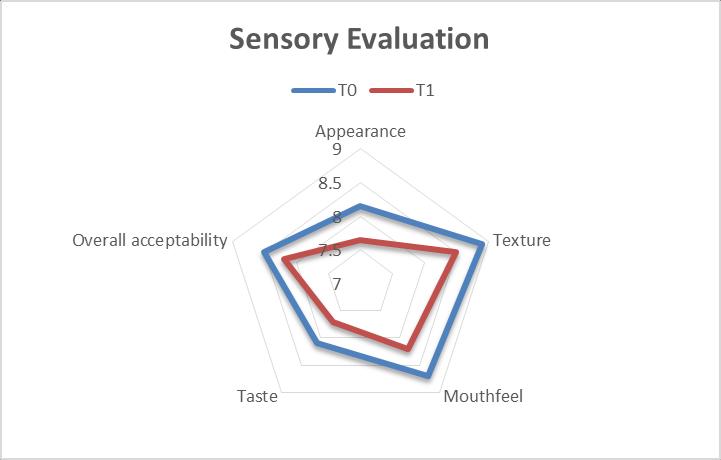

3.5. Sensory analysis of dairy based and cottonseed milk Ice cream

The formulated ice cream samples, dairy based ice cream (T0) andcottonseedmilkicecream(T1),werepreparedand evaluated for their organoleptic characteristics, namely Appearance, Taste, Texture, Mouthfeel, and Overall Acceptability,byapanelof20non-trainedmembersusinga 9-pointhedonicscale.Thescoresobtainedforeachattribute ofsensoryevaluationforthesamplesareshowninTable5.

Table-5:Dataobtainedforsensoryanalysisofdairy-based andcottonseedmilkicecream(Mean±SD)

Sensory

Based on sensory evaluation, cottonseed milk ice cream exhibitedaslightaftertastebutwascomparablypreferredto full cream milk ice cream. Although cottonseed milk ice creamscoredlowerinappearance,texture,andmouthfeel, likely due to faster melting and ice crystal formation, the additionofcoconutcreamandflavormayhavecontributedto itshighertastescore.

3.6 Microbial analysis of dairy based and cottonseed milk ice cream

3.6.1 Total plate count

Thetotalplatecount(TPC)forbothdairy-basedicecream (T0) and cottonseed milk ice cream (T1) was determined using the pour plate method. A 1 mL aliquot of 10^-4 and 10^-5dilutionsofeachicecreamweremixedwithnutrient agar medium in Petri dishes and incubated at 37°C for 24 hours. After incubation, the number of colonies that developed was counted, and the results showed that both samples had a total viable bacterial count of less than 10 Colony-FormingUnitspermilliliter(CFU/mL).

3.6.2 Coliform count

Thetotalcoliformcountforbothdairy-basedicecream(T0) andcottonseedmilkicecream(T1)sampleswasdetermined

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

using MacConkey agar, a selective medium for coliform bacteria. A 1 mL aliquot of 10^-4 and 10^-5 dilutions was inoculatedontoMacConkeyagarplates.Followingincubation at 30°C for 48 hours, the results indicated the absence of detectable coliform bacteria in both samples, which was expressed as "NIL" Colony-Forming Units per milliliter (CFU/mL).

3.7 Cost analysis of developed cottonseed milk ice cream

The production cost of the developed cottonseed milk ice creamwascalculatedbasedonvariousexpenses,including ingredients and materials, manufacturing costs such as electricityandLPGgas,laborcosts,andoperationalexpenses like packaging and logistics. Market rates were used to determinethepricesofallcomponents,andthecostofthe developedcottonseedmilkicecreamwascalculatedtobeRs. 257perliter.

The development of ice cream using cottonseed milk presentsapromisingalternativetotraditionaldairy-based products,particularlyinthecontextofincreasingconsumer demandforplant-based,sustainable,andlactose-freefoods. This study successfully formulated and evaluated an ice creamusingcottonseedmilk,demonstratingitsnutritional viabilityandsensoryacceptability.

Thecottonseedmilkicecream(T1)showedcomparable proteincontentandconsumeracceptabilitytoconventional dairyicecream(T0),whileofferingdistinctadvantagessuch aslowerfatcontentandaplant-basedcomposition.Although it exhibited a slightly higher meltdown rate and lower overrun, these differences were within acceptablesensory thresholds, especially with the addition of coconut cream. Physicochemical,microbial,andsensoryanalysesconfirmed thenutritionaladequacy,safety,andappealoftheproduct. This plant-based formulation could serve as a valuable productforlactose-intolerantindividuals,vegans,andhealthconscious consumers. Further research can focus on enhancing texture and shelf-life, incorporating functional additives,andscalingproductionforcommercialviability.

[1] Afriana, N., & Kurnia, P. (2024). Effect of coconut and cashew milk on overrun of plant-based ice cream. JournalofDairyAlternativesResearch,12(1),45–52.

[2] Amudha, J. (2018). Physicochemical properties of cottonseed milk and its potential applications. South IndianJournalofFoodScience,6(2),110–115.

[3] Daw, M., & Hartel, R. W. (2015). Ice cream: Melting, recrystallization, and sensory perception. Journal of DairyScience,98(3),1234–1244.

[4] Diniz, L. G. T., Mendes, C. A., & Silva, R. M. (2022). Formulationandqualityevaluationofbarnyardmilletbased vegan ice cream. International Journal of Food Studies,11(4),399–407.

[5] Gaikwad, R., Patil, S., & Jadhav, A. (2020). Sensory analysisofdairyproductsusinghedonicscalemethod. JournalofSensoryEvaluation,5(1),22–28.

[6] Kumar, M. (2019). Traditional preparation and health benefits of Paruthi Paal. Tamil Nadu Food Heritage Review,3(1),34–40.

[7] Leahu,A.,Popa,D.,&Ivan,S.(2022).Physicochemical andsensory characteristics ofalmond milk icecream. Plant-BasedFoodsJournal,10(2),85–92.

[8] Mendonça,A.,Silva,F.,&Oliveira,J.(2022).Evaluation of soy extract as a base for non-dairy ice cream. BrazilianJournalofFoodTechnology,25(3),210–218.

[9] Pidathala, S., Reddy, B., & Kumari, M. (2024). Development of symbiotic ice cream from cottonseed milk.AsianJournalofDairyScience,8(1),28–35.

[10] Pon,A.K.,Narayanan,K.,&Suresh,P.(2015).Meltdown analysis of ice cream using image processing and gravimetric techniques. Indian Journal of Food Engineering,7(3),201–208.

[11] Pontonio,E.,Rizzello,C.G.,&Coda,R.(2022).Nutritional and sensory quality of plant-based yogurt-like fermented ice cream. Foods, 11(2), 189. https://doi.org/10.3390/foods11020189

[12] Praveena, M., & Subaratinam, R. (2021). Cottonseed milk:Atraditionaldrinkwithmodernappeal.Journalof TraditionalIndianFoods,9(4),88–93.

[13] Raghuramulu, N., Madhavan Nair, K., & Kalyanasundaram, S. (2003). A manual of laboratory techniques.Hyderabad:NationalInstituteofNutrition, ICMR.

[14] Singo,M.,&Beswa,D.(2019).Methodsformeasuring total solids in food samples. African Journal of Food ScienceandTechnology,10(2),65–70.

[15] Srinu,D.,Narayana,R.,&Pavithra,M.(2022).Effectof spicesonthequalityoffunctionalicecream.Journalof CulinaryInnovations,4(1),44–52.

[16]Swarup,V.K.,&Poonia,A.(2022).Physicochemicaland sensory evaluation of cereal-based ice cream. International Journal of Nutrition and Food Sciences, 11(3),115–120.