International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

B. Rajesh*1,R. K. Asswin*2, T. Aravind*3, N. Siva Sakthi*4, G. Guhanesan*5

*1 Lecturer, Department of Mechanical Engineering, PSG Polytechnic College, Coimbatore, Tamil Nadu, India.

*2,3,4,5 Students, Department of Mechanical Engineering, PSG Polytechnic College, Coimbatore, Tamil Nadu, India

Abstract - This project focuses on the design, development, and testing of a Savonius rotor-based Vertical Axis Wind Turbine (VAWT) as a sustainable energy solution. The study aims to enhance efficiency,durability,andcost-effectivenessby optimizing blade shape and selecting suitable materials. The turbine is tested under controlled conditions to assess power output and efficiency, with the results highlighting the potential of Savonius-based VAWTs as a reliable, lowmaintenance, and environmentally friendly energy source.

Key Words: Vertical Axis Wind Turbine (VAWT), Savonius rotor, Renewable energy, Blade optimization, Aerodynamic efficiency, Power output, Durability testing, Sustainable energy.

Vertical Axis Wind Turbines (VAWTs) offer a promising alternative to Horizontal Axis Wind Turbines (HAWTs), particularly in urban areas and locations with turbulent windconditions.UnlikeHAWTs,VAWTscapturewindfrom any direction, making them adaptable to fluctuating wind patterns.TheSavoniusturbine,knownforitssimplicityand lowmanufacturingcosts,isidealforsmall-scale,low-speed applications.Advancementsinaerodynamics,materials,and controlsystemshaveimproveditsefficiency,makingitmore competitiveinthewindenergysector.VAWTs,includingthe Savoniustype,areparticularlysuitedforspace-constrained areasandurbanenvironments.Despitechallengeslikelower efficiency at higher wind speeds and mechanical stresses, ongoing research aims to improve their performance and durability.Thispaperreviewsthedesign,development,and performance of Savonius-based VAWTs, highlighting their potentialforsustainableenergygeneration.

ThemethodologyforthisstudyonSavoniusVerticalAxis Wind Turbines (VAWTs) is structured in a series of phases, each contributing to the overall design, development,andoptimizationoftheturbinesystem.The followingstepsoutlinetheprocess:

Design:

Start

DesignandModelling

ComponentSelection

FabricationandAssembly

ElectricalIntegration

PerformanceTestingandOptimization

ImplementationandMaintenance

End

Chart 1- Methodology

TheturbineisdesignedusingCADsoftware,modelingthe aerodynamic properties and optimizing geometry for variouswindconditions.

Component Selection:

Components are selected based on material properties, durability, and cost-effectiveness to balance performance andlongevity.

Fabrication and Assembly:

Componentsarefabricatedandassembledwithprecisionto ensureproperalignmentandstructuralintegrity.

Electrical Integration:

Theelectricalsystemisintegrated,connectingthegenerator to the rotor shaft and configuring power electronics for optimalenergyoutput.

Performance Testing and Optimization:

Theturbineundergoestestingtoassessefficiencyandpower output. Adjustments are made based on data to enhance performance.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Implementation and Maintenance:

After optimization, the turbine is installed, and a maintenance schedule is set for long-term performance monitoring.

Aerodynamic Efficiency

Thethree-bladedesignimprovesstabilityandsmoothpower generation. Optimized blade profiles enhance torque and self-starting ability. The rotor is designed for efficient operationinlow-speed,turbulentwindenvironments.

Blade Design Considerations

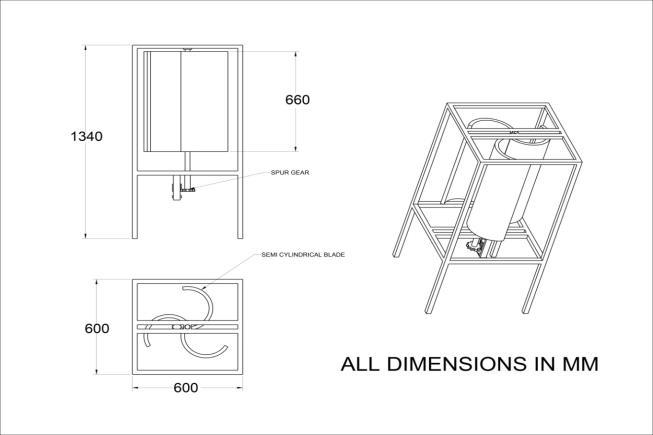

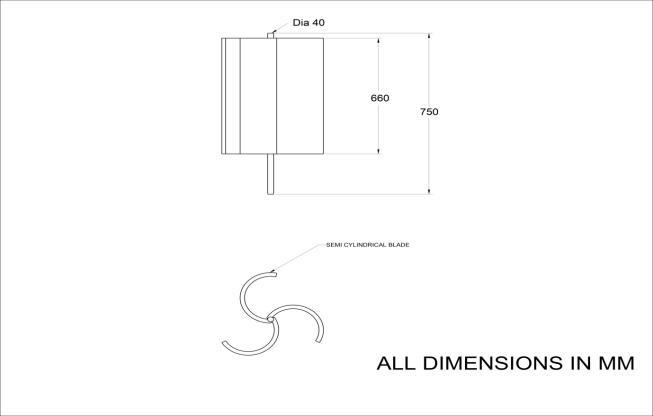

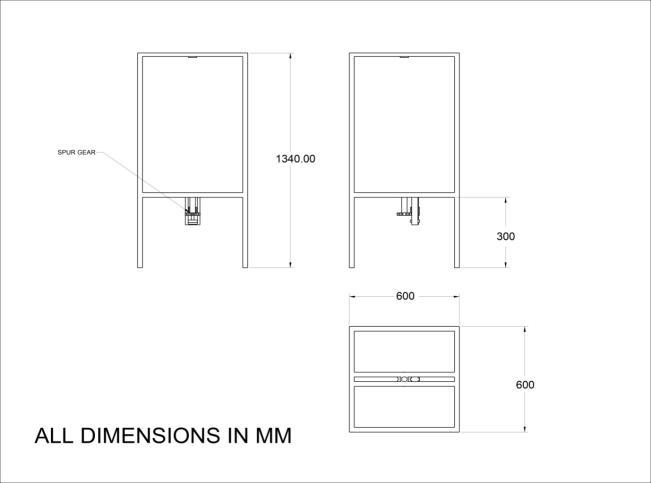

The VAWT uses a three-blade configuration with 120° spacingforbalance.Eachbladeis660mminheight,460mm beforebending,and360mmafterbending,witha0.8mm thickness.

Structural Stability

The frame is built from 1-inch and 3/4-inch mild steel squarepipesforstrength.The20mmdiameter,1040mm long mild steel shaft ensures stability under load. A 6204 deepgrooveballbearingsupportssmoothrotation,reducing mechanicalstress.

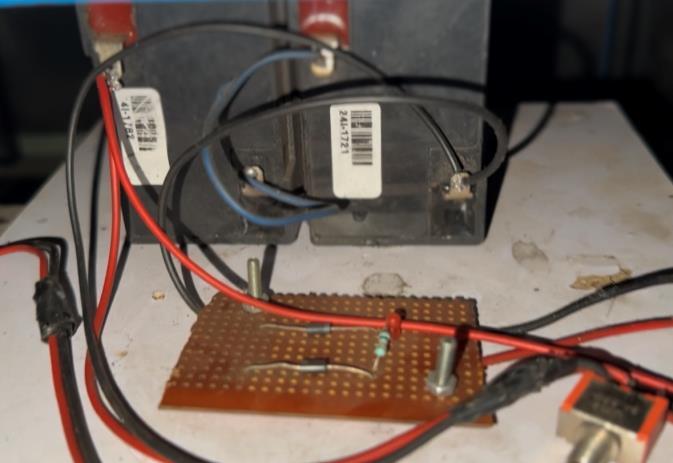

Generator and Power Transmission

A 12V DC dynamo generator converts wind energy into electricity, stored in a 12V system with two 6V lead-acid batteries.AbridgerectifierconvertsACtoDC.Copperwiring minimizespowerlossforefficienttransmission.

Self-Starting Capability

Alow-inertiabladedesignandbalancedrotorenhanceselfstarting. High-performance bearings reduce friction, allowing the turbine to start rotating even at low wind speedswithoutexternalassistance.

Wind Flow Optimization

The turbine operates efficiently at 4-10 m/s wind speeds. The 360 mm rotor diameter results in a 0.1018 m² swept area,with13.2 Wavailable wind powerat2.78m/s wind speed.Itsomnidirectionaldesignisidealforurbanareas.

Battery Level Indication

Batterylevelindicationshowsremainingcharge,oftenusing LEDsordisplays,bymeasuringvoltageandcomparingitto setthresholds.

3.

Shaft and Blade:You'reusinga20mmdiameter,1040mm longmildsteelshaftandarectangularhardenedmildsteel blade(0.8mmthickness,600mmlength,460mmbreadth). The shaft is designed to transmit rotational motion and torque, while the blade is intended for tasks requiring

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

strength,flexibility,andwearresistance,suchascuttingor bending.

Dynamo Generator and Battery System: The 12V DC dynamo generator converts mechanical energy into electrical energy. You’re also considering a battery setup with two 6V acid batteries connected in series to create a 12Vsystem.

Bearing and Gear:A6204ballbearing(20mmID,40mm OD)isusedtoreducefrictionandsupportloads.Thespur gearwillhelpinreducingspeedandincreasingtorque.

Square Pipe and Body:Mildsteelsquarepipes(1-inchand 3/4-inch)willbeusedforbaseandframeconstruction.The 1-inchpipewillprovideprimarysupport,whilethe3/4-inch pipewillreinforcethestructure.

Rectifier and Toggle Switch:Abridgerectifierwillconvert AC to DC, and a toggle switch will control the circuit by turningitonandoff.

Arduino and LCD Display: You’re using an UNO R3 SMD Arduinoboardanda16x2LCDDisplaywithanI2Cmodule for easycommunication. Thissetupisideal for embedded applicationsandIoTprojects.

Voltage Sensor and Jumper Wire Cable: The REES52 VoltageSensorwillmeasurevoltagesupto25V,andyou’ll usejumperwiresforeasycircuitconnections.

4.1. FABRICATION

Machining and Cutting:

CNCmachiningautomatesmaterialremovalusingcomputercontrolledtoolsforprecision.Lathesrotateworkpiecesfor turning,facing,andthreading,mainlyforcylindricalparts. Cuttingusessingleormulti-pointtools,influencedbyspeed, feed,andtoolmaterial.Grindingisafinishingprocessusing abrasive wheels for fine surfaces and accuracy in various applications.

Welding:

Welding joins metals by applying heat to melt and fuse them, using either consumable or non-consumable electrodes with filler material. It ensures strong, durable jointsforvariousapplications.

Bolting:

Bolting fastens materials using threaded bolts and nuts, creatingasecureconnectionthatcanbeeasilydisassembled formaintenanceormodifications.

Coatingsandtreatmentsarevitalforimprovingthe durabilityofmaterialslikemildsteelinVerticalAxisWind Turbine(VAWT)components.Paintcoatingsprotectagainst corrosion, UV radiation, and weathering. Anti-corrosive paints are applied to parts such as the frame, blades, and shafts to prevent rust and degradation, enhancing the turbine's lifespan and reducing maintenance needs while alsoimprovingitsappearance.

The assembly process for the Vertical Axis Wind Turbine (VAWT) involves several critical steps to ensure optimal functionality. The base assembly begins with cutting mild steel square pipes (1 inch and 3/4 inch) to specific dimensions(300mmheight, 300mmbreadth,and600mm width),whicharethenweldedorboltedtogethertoforma rigidrectangularframethatprovidessupportfortherotor and other components, ensuring proper alignment and stability.Fortherotor,a20mmdiametershaftismarkedfor theattachmentofthreeblades,eachmeasuring660mmin height, 360mm in breadth (after bending), and 0.8mm in thickness. These blades are symmetrically attached to the shaftandsecuredusingfastenersorweldingfordurability. Ballbearingswithaninnerdiameterof20mmandanouter diameterof40mmareinstalledatbothendsoftheshaftto facilitatesmoothrotationandaresecurelymountedtoalign withtherotorshaft.The12VDCdynamogeneratorisfixed tothebaseandconnectedtotherotorshaftusingacoupling or pulley system to efficiently transfer power. For the electrical system, a 12V battery is connected in series to storethegeneratedpower,andabridgerectifierisinstalled to convert AC to DC. The system’s battery voltage is monitoredthroughaREES52VoltageSensorconnectedtoan UNO R3 SMD board, with the results displayed on a 16x2 LCD screen. The connections are made securely to ensure properdata transmissionandpreventvoltagedrops,with jumperwireslinkingallcomponents.Finally,thesystemis poweredup,andthebatteryvoltageisverifiedontheLCD display, with any necessary adjustments to calibrate the readings.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

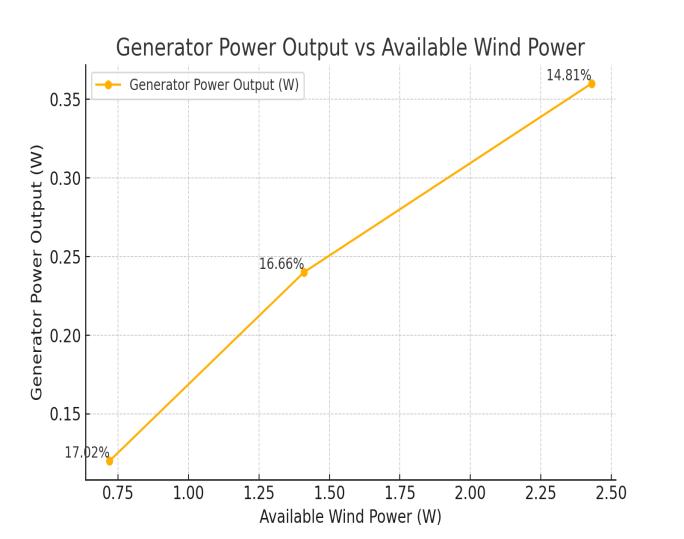

5.1. Wind Speed & Power Output

5.1.1 Wind Speed & Power Output Measurement at 10 km /hr

To test the wind speed and power output of a 12V, 12Ah batterysystemwitha12VDCdynamogeneratorconnected toaP-Njunctiondiodebridgerectifier,thewindspeedwas first checked using a weather app. The app provided the wind speed in units like m/s, km/h, or mph. If the wind speedwasinunitsotherthanm/s,itwasconvertedusing theappropriateformula.Forexample,iftheappprovided the wind speed in km/h, it was converted to m/s by multiplyingby1000/3600.Thisprovidedamoreaccurate measurementforcalculatingwindpower.

Oncethewindspeedwasobtained,theavailablewindpower wascalculated.Forinstance,ifthewindspeedreportedby theweatherappwas10km/h,itwasfirstconvertedtom/s.

Windspeed(m/s)=10km/hx(1000/3600) =2.78m/s

Next,calculatethesweptareaoftheturbine,whichdepends on the turbine diameter. Given the turbine diameter is 370mm(or0.37meters),youcancalculatethesweptarea usingtheformula:

A= x =0.1075

Then,calculatetheavailablewindpowerusingtheformula:

P wind = xAxV3

Where:

ρistheairdensity(approximately1.225kg/m³atsealevel),

Aisthesweptarea(0.1075m²),

Visthewindspeed(2.78m/s).

Substitutingthesevalues:

P wind = x1.225x0.1075x2.783=1.41watts

This gave the available wind power of approximately 1.41 watts ata windspeed of10 km/h.Next,a multimeter was usedtomeasuretheDCvoltageandcurrentoutputfromthe dynamo generator, ensuring it operated around 12V. The voltageandcurrentgoing intothe12V,12Ah battery were measured,confirmingthatitmatchedthebattery’scharging specifications.Tocalculatethepoweroutput,theformulawas used:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

P=VxI

P=12x0.02=0.24W

Comparethecalculatedwindpower1.41wattstotheactual electricalpowerbeinggeneratedandstoredin thebattery. Evaluatingthesystem'soverallefficiencybycomparingthe electrical power output to the available wind energy using formula,

Efficiency=(ElectricalPowerOutput/AvailableWindPower )×100

Efficiency=(0.24/1.41)/100

Efficiency=17.02%

5.1.2. Wind Speed & Power OutputMeasurementat8 km /hr

To test the wind speed and power output of a 12V, 12Ah batterysystemwitha12VDCdynamogeneratorconnected toaP-Njunctiondiodebridgerectifier,thewindspeedwas first checked using a weather app. The app provided the wind speed in units like m/s, km/h, or mph. If the wind speedwasinunitsotherthanm/s,itwasconvertedusing theappropriateformula.Forexample,iftheappprovided the wind speed in km/h, it was converted to m/s by multiplyingby1000/3600.Thisprovidedamoreaccurate measurementforcalculatingwindpower.

Oncethewindspeedwasobtained,theavailablewindpower wascalculated.Forinstance,ifthewindspeedreportedby theweatherappwas10km/h,itwasfirstconvertedtom/s.

Windspeed(m/s)=8km/hx(1000/3600) =2.22m/s

Next,calculatethesweptareaoftheturbine,whichdepends on the turbine diameter. Given the turbine diameter is 370mm(or0.37meters),youcancalculatethesweptarea usingtheformula:

Substitutingthesevalues:

P wind = x1.225x0.1075x2.223=0.72watts

This gave the available wind power of approximately 0.72 watts ata windspeed of10 km/h.Next,a multimeter was usedtomeasuretheDCvoltageandcurrentoutputfromthe dynamo generator, ensuring it operated around 12V. The voltage and current going into the 12V, 9Ah battery were measured,confirmingthatitmatchedthebattery’scharging specifications.Tocalculatethepoweroutput,theformulawas used:

P=VxI

P=12x0.01=0.12W

Comparethecalculatedwindpower0.72wattstotheactual electricalpowerbeinggeneratedandstoredinthebattery. Evaluatingthesystem'soverallefficiencybycomparingthe electrical power output to the available wind energy using formula,

Efficiency=(ElectricalPowerOutput/AvailableWindPower )×100

Efficiency=(0.12/0.72)/100

Efficiency=16.66%

5.1.3. Wind Speed & Power Output Measurement at 12 km /hr

To test the wind speed and power output of a 12V, 12Ah batterysystemwitha12VDCdynamogeneratorconnected toaP-Njunctiondiodebridgerectifier,thewindspeedwas first checked using a weather app. The app provided the wind speed in units like m/s, km/h, or mph. If the wind speedwasinunitsotherthanm/s,itwasconvertedusing theappropriateformula.Forexample,iftheapp provided the wind speed in km/h, it was converted to m/s by multiplyingby1000/3600.Thisprovidedamoreaccurate measurementforcalculatingwindpower.

A= x =0.1075

Then,calculatetheavailablewindpowerusingtheformula:

Oncethewindspeedwasobtained,theavailablewindpower wascalculated.Forinstance,ifthewindspeedreportedby theweatherappwas10km/h,itwasfirstconvertedtom/s.

P wind = xAxV3

Where:

ρistheairdensity(approximately1.225kg/m³atsealevel),

Aisthesweptarea(0.1075m²),

Visthewindspeed(2.78m/s).

Windspeed(m/s)=12km/hx(1000/3600) =3.33m/s

Next,calculatethesweptareaoftheturbine,whichdepends on the turbine diameter. Given the turbine diameter is 370mm(or0.37meters),youcancalculatethesweptarea usingtheformula:

A= x =0.1075

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Then,calculatetheavailablewindpowerusingtheformula:

P wind = xAxV3

Where:

ρistheairdensity(approximately1.225kg/m³atsealevel),

Aisthesweptarea(0.1075m²),

Visthewindspeed(2.78m/s).

Substitutingthesevalues:

P wind = x1.225x0.1075x3.333=2.43watts

This gave the available wind power of approximately 2.43 watts ata windspeed of10 km/h.Next,a multimeter was usedtomeasuretheDCvoltageandcurrentoutputfromthe dynamo generator, ensuring it operated around 12V. The voltage and current going into the 12V, 9Ah battery were measured,confirmingthatitmatchedthebattery’scharging specifications.Tocalculatethepoweroutput,theformulawas used:

P=VxI=12x0.03=0.36W

Comparethecalculatedwindpower2.43wattstotheactual electricalpowerbeinggeneratedandstoredinthe battery. Evaluatingthesystem'soverallefficiencybycomparingthe electrical power output to the available wind energy using formula,

Efficiency=(ElectricalPowerOutput/AvailableWindPower )×100

Efficiency=(0.36/2.43)/100

Efficiency=14.81%

5.1.4.

Calculating the average efficiency, we need to take the efficienciesforeachwindspeed(10km/h,8km/h,and12 km/h) and find the mean. Here are the efficiencies you provided:

At10km/h:17.02%

At8km/h:16.66%

At12km/h:14.81%

Now,tocalculatetheaverageefficiency:

AverageEfficiency=(17.02+16.66+14.81)/3

AverageEfficiency=16.16%

Efficiency

5.2.

Rotation & Mechanical Testing checks for resistance, misalignment,andwearbyrotatingtheturbine,inspecting bearings, and measuring speed. It helps identify faults, improveefficiency,andreducemaintenance.

VisualinspectionofaVAWTchecksfordamage,wear,and misalignmentinkeycomponentslikeblades,tower,wiring, bearings, and foundation. Regular inspections prevent failures,reducemaintenancecosts,andextendtheturbine's lifespan.

5.4.

Electrical system testing in wind turbines involves measuringvoltage,current,andpoweroutputtoassessthe dynamo,rectifier,battery,andcircuitry.Itensuresefficient ACtoDCconversion,preventsovercharging,andevaluates system efficiency for optimal performance. A battery indicatorisalsousedtomonitorthebattery'svoltagelevels, providing real-time feedback on its charging status and ensuringproperfunctioning.

Vibration and noise testing in wind turbines ensures mechanical stability and acoustic compliance. Using accelerometers,vibrationsintheturbine'sstructure,blades, and generator are measured to detect issues like misalignment or imbalance. Noise testing checks sound levelstoensuretheymeetenvironmentalstandards.These tests help minimize vibrations and noise, enhancing the turbine'slifespan,performance,andregulatorycompliance.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Residential Energy Generation: Used for small-scale energyproduction,particularlyinurbanorsuburbanareas withlimitedspace.

Marine Applications: Suitable for offshore and marine environments,includingboatsandoffshoreplatforms,where winddirectionishighlyvariable.

Agricultural Applications: Powering water pumps for irrigationinareaswherewindresourcesareavailable.

Roadways: VAWTs can be integrated into roadway infrastructure,suchasalonghighwaysorroads,toharness wind energy from passing vehicles or prevailing winds, contributingtoroadsidepowergeneration.

Urban Wind Energy Solutions: VAWTs are ideal for installationonbuildingrooftops,parkinglots,orotherurban spaces, where they can harness wind energy from the surroundingturbulentconditions.

This journal highlights the potential of Savonius-based Vertical Axis Wind Turbines (VAWTs) as an efficient, sustainableenergysolutionforsmall-scaleapplications.The design optimization, material selection, and performance testing have shown promising results in terms of power output,efficiency,anddurability.VAWTsareadaptablefor various applications, including residential, agricultural, urban, and roadway energy generation. While challenges remain, ongoing research can improve efficiency and durability, making VAWTs a competitive option for decentralizedrenewableenergy,particularlyinareaswith variablewindconditions.

1. Baker, C. A. (2014).Verticalaxiswindturbines:Design, analysis,andapplication.Springer.

2. Kämpf, J., & Schmitz, M. (2017).Windenergysystems: Theoryanddesignofverticalaxiswindturbines.Wiley.

3. Santos, D. A., & Lopes, L. S. (2019). Design and performanceofverticalaxiswindturbinesforsmall-scale applications.Elsevier.

4. Kumar, S.,& Patel, M. (2020).Verticalaxiswindturbine (VAWT):Concept,design,andapplicationsinrenewable energysystems.CRCPress.