International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Abu-Elgasim

Omer

1School of Civil Engineering, College of Engineering, Sudan University of Science and Technology, P.O. Box 72, Eastern Daim, Khartoum, Sudan

2College of Civil and Transportation Engineering, Hohai University, Nanjing 210098, China

Abstract - The use of fiber-reinforcedcomposites (FRCs) such as Glass Fiber-reinforced composites (GFRCs) and Polypropylene Fiber-reinforced composites (PFRCs) in construction activities has increased over the past years for their excellent enhancement of many properties of the concrete such as tensile strength, compres- sive strength, cracking resistance, and many others. This study is anattempt to understand the behaviour of these materials. The addition of Glass Fibers (GFs) and Polypropylene Fibers (PFs) into an ordinary Portland cement concrete mix-ture has beenstudied. This study includes a set of experimental specimens that were constructed by adding GF and PF fibers into the conventional concrete with various percentages by volume fraction, namely 0.0, 0.25, 0.35, and 0.45of GF and 0.2, 0.4, and 0.6 of PF fibers. Their effect on the compressive resistance, ten- sile resistance, and workability was recorded. The obtained results indicated that the mechanical properties of concrete were significantly improved by increasing the fiber content. It was foundthat the ratios of 0.25 GF and 0.2 PF gave the highest results for both compression and tensile resistance, whereas the rest of the ratios had a moderate positive effect on the mix incomparison to the con- trol mix. It was also observed that the workability decreases with the increase of the fiber percentage for both, GF and PF fibers. This can be related to the high-water absorption of the fibers.

Key Words: Fiber-reinforced composites (FRCs), Glass fibers (GFs), Polypropylene fibers (PFs), Compressive strength,Tensilestrength

Eventhoughconcreteisoneofthemostusedmaterialsand playsasignificantroleintheconstructionindustry,itisalso known for its brittleness in nature and poor tension in comparison to compressive strength [1]. The use of dispersion-reinforcedconcretesinbuildingstructuresthat bend and experience impact effects has a wide range of applications[2].Fiber-reinforcedcementitiousmaterialisa typeofconcreteinwhichfibersareutilizedandmixedwith otheringredients(aggregate,water,cement)andadmixtures [1]. Fibers with various geometric characteristics and chemicalpropertiesareusedtoproducesuchconcreteswith the desired mechanical properties [2]. The duc- tility of fiber-reinforcedconcretedependsontheabilityofthefibers

to bridge cracks at high levels of strain [3]. The most common fiberreinforcementsforstructural appli- cations includebasaltfiber,steelfibers,glassfibers,syntheticfibers suchaspolyvinylalcohol(PVA),polypropylene(PP),carbon fibers,andnaturalfibers[1].Theresearchoffiberglassuse asareinforcementofconcretewasfirstconductedinRussia inthe1940sandwasthenintroducedtotheworld’sbuilding industryintheearly1970sintheUnitedKingdom[4].The useofglassfibersinconcreteisbecomingmorepreva-lent nowadays.Normalconcretegiveslowstrength,whichisless resistanttocracks.Ifglassfibersareaddedtoconcrete,they impart high tensile strength, control cracking, and also reducebleedingofwater.Moreover,theuseofglassfibers yields higher flex- ural strength and improves ductility properties[5].GlassFiberReinforcedConcrete(GFRC)isa fiberglass mixture with a cement matrix. This mixture maintainsthephysicalandchemicalidentityofthefiberand even the cement matrix synergistically, reaching a combination of properties that could have never been achieved individually. The fibers retain loads while the cement matrix maintains the location of the fiber reinforcement and also protects the fibers from damage causedbythesurroundingenvironment[4].

Polypropylene is used as a fiber material in various civil engineering applications. Polypropylene fibers are chemicallyresistanttoacidsandalkalisandcanbeusedwith anytypeofPortlandcement.Polypropylenefiberisa100% polypropylene-basedartificialmaterialthatdoesnotrequire much workmanship in its production, is easy to apply, improvessomepropertiesofconcrete,andisaddedtothe concreteduringproduction[6].

The addition of polypropylene fibers decreases the unit weight of concrete and increases its strength [5]. The inclusion of polypropylene fibers reduces the water permeabilityandincreasestheflexuralstrengthduetoits highmodulusofelasticity[5].

Polypropylene fiber reinforced concrete contains polypropylene fibers in a cemen- titious matrix. Polypropylene fibers are produced from homopolymer polypropyleneresin.Polypropylenefibersarecommercially utilized mainly to improve the toughness and shrinkage crackingresistanceofplainconcrete.Polypropylenefibers

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

areusedatlowvolumefractionstocontrolplasticshrinkage cracking of concrete. Polypropylene fibers improve the impactstrength,toughness,andductilityofconcrete[7].

Researchershavestudiedcementconcreteand glassfiber (GFRC)polypropy-lenefiber(PFRC)reinforcedconcreteand have investigated the effect of fibers on the mechanical propertiesofconcrete.Intherecentstudy,theindependent useof

polypropyleneandglassfibersinconcretehasbeencarried out.Themixturesofcon-creteincorporated0.25%,0.35%, and 0.45% glass fiber, and 0.2%, 0.4%, and 0.6% polypropylenehavebeeninvestigated.Theinvestigationis mainly done on the com- pressive and tensile strength of glassandpolypropylenefiberreinforcedconcretes.Aslump test is also carried out on each mix to ascertain the workabilityofeachmix.

2. Related work

NairandVarghese[5]studiedtheeffectoftheaddition of glass fiber and polypropylene fiber in ordinary Portland cementconcrete.Inthepresentexperimentalinvestigation, glass fibers and polypropylene fibers in different percentages have been studied. The glass fiber content varies from 0% to 2.0% and polypropylene fiber content variesfrom0.0%to0.8%byweightofcement.Theeffecton mechanical properties of concrete was evaluated by conducting compressive strength tests, flexural strength tests,andsplittingtensilestrengthtests.

Singh [8] investigated polypropylene fibers in different percentages (0.1%, 0.3%, 0.5%, and 0.7% by weight of concrete)tostudytheireffectonthestrengthpropertiesof concrete.Compressivestrengthtestsandflexuralstrength tests were carried out at 28 days for M25 grade concrete. Testresultsshowthattheadditionofpolypropylenefiberto concreteexhibitsbetterperformancethanplainconcrete.

Murthy et al. [9] studied the performance of Glass Fiber ReinforcedConcrete.Thestudyrevealedthattheuseofglass fiber in concrete not only improves the properties of concretebutalsoprovidesacost-cuttingadvantageandan easyoutlettodisposeofglassasenvironmentalwastefrom theindustry.Fromthestudy,itwasrevealedthattheflexural strengthofthebeamwith1.5%glassfibershowsanalmost 30% increase in strength, and a reduction in slump was observedwiththeincreaseinglassfibercontent.

Vishal [10] studied the effect of glass fibers in highperformance concrete. The concrete mix design prepared was M40 grade. In the experimental investigation, glass fibers were added in different percentages (1.0%, 2.0%, 3.0%, 4.0%, and 5.0%) to study their effect on the mechanical properties of concrete. Compression tests, flexural strength tests, and tensile strength tests were

carried out. The test results showed that 5.0% glass fiber concreteexhibitedhigherstrengthcomparedtothecontrol specimen. It is inferred that glass fiber imparts higher strengthandmoreductilitytotheconcretethanplainM40gradeconcrete.

Khanetal.[3]conductedacomparativeexperimentalstudy on the mechanical performance of polypropylene fiberreinforced concrete (PFRC) under compression and split tensileloading.TheM25andM30gradesofconcretemixes wereusedalongwithpolypropylenemono-filamentmacrofibersof length35mmatvolumefractionsof 0.0%,0.5%, 1.0%, 1.5%, 2.0%, 2.5%, and 3.0%. The study suggested a significantimprovementincompressiveandtensilestrength forconcretemixesreinforcedwithpolypropylenefibers.The sampleswithaddedpolypropylenefibersof1.0%and1.5% showedbetterresultsincomparisonwithothers.

3.1 Materials used

3.1.1 cement

Differentphysicalandchemicaltestswereperformedonthe cementtoascertainitsqualitybeforeuse.Thesetestswere conductedaccordingtotheBritishStandards(BS12:1996) [11]. The type of cement used in this study was Ordinary PortlandCement(OPC),whichhadafinenessof0.96%,an initial settingtimeof2hours,anda final settingtimeof 2 hoursand33minutes.TheresultsareshowninTable1

Table 1 Qualitytestsonthecement

Test Name Results Standard Range according to BS12:1996 Consistency 5mm 4–6mm Initial setting time 2hours ≥45

3.1.2

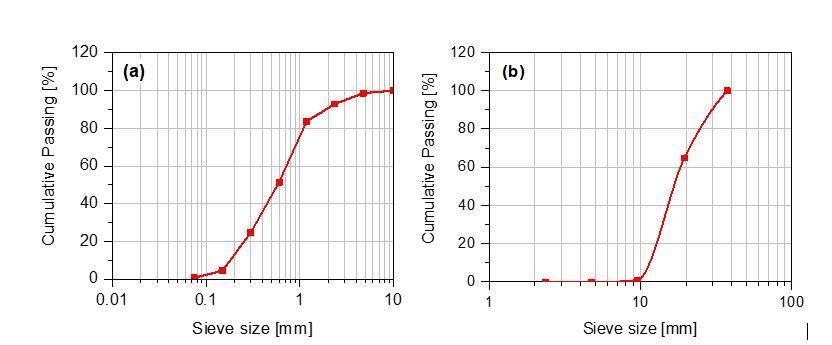

Kengernaturalsandavailableinthelocalmarketwasused asfineaggregate.Sieveanalysiswasperformedonthefine aggregatesasperBS-12-1996[11].

NaturaluncrushedconformingtoB.S.12:1996[11]wasused as coarse aggregate. The coarse aggregates had a specific gravityof2.63whilewaterabsorptionwasfoundtobe0.183 foreach.Figure1showsthesieveanalysisresultsfor both fineandcoarseaggregates.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

and(b)coarse aggregates

3.1.4 Glass Fibers GFRCs

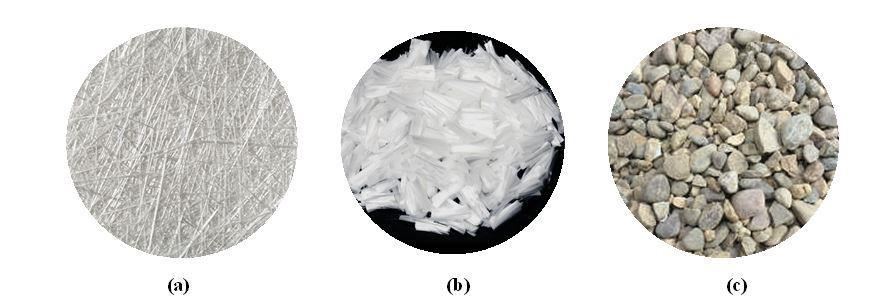

AR-D(Alkaliresistant-waterdispersed)glassfiberschopped strands obtained from China Beihai Fiberglass were used. These fibers, shown in Figure 2, have a sizing system allowingtheirgooddispersionintothewaterin10seconds. These fibers dis- perse faster and the dosage amount requiredislow.Thesearetypicallyusedinsmallamountsto preventcrackingandtoimprovetheperformanceofreadymixconcrete,gypsum,orotherspecialmortarmixes.

3.1.5 Polypropylene Fibers PFRCs

Alkali-resistant Chemrite Polypropylene Fibers chopped strandsobtainedfromImpa-tientChemicalsPrivateLimited (ICPL) were used. These fibers have low thermal conductivityandnowaterabsorption[12]

reinforced concrete (PFRC). A total of 7 mixes were examined, containing different percentages of glass fibers and polypropylene. The weight ratio of cement, sand, and coarse aggregate was kept at 1:2:4 for all mixes. The percentagesofglassfiberandpolypropylenebyweight of the concrete mix were (0.25%, 0.35%, and 0.45%) and (0.2%,0.4%,and0.6%),respectively.

Differentcubeandcylinderspecimenswerecastaccording totherequirementsofthetestsandinaccordancewiththe code of practices. Concrete cubes measuring 150 mm 150 mm 150 mm were cast from all mixes for compressive strengthtestingattheagesof7and28days seeFigure 3. Threecubesweretestedateachagefor allmixes,andthe average value was taken. Thus, a total of 42 cubes were testedforcompressivestrength.

The test specimens were remolded 24 hours after casting and were kept in curing tanks until the age of testing. Cylinder concrete specimens measuring 300 mm 150 mm werecastfromallmixesfortensilestrengthtestingatthe ageof28days,resultinginatotalof21-cylinderspecimens.

-3:Materialusedinfiber-reinforcedconcrete:(a)glass fibers,(b)polypropenefibers,and(c)gravel.

3.1.6 Water

Normaltapwateravailableintheconcretelaboratoryofthe SudanUniversityofScienceandTechnology,fitfordrinking, wasusedinthisresearch.

4. Mix Proportions and casting of specimens

In this work, we studied the properties of glass fiber reinforced concrete (GFRC) and polypropylene fiber

5.

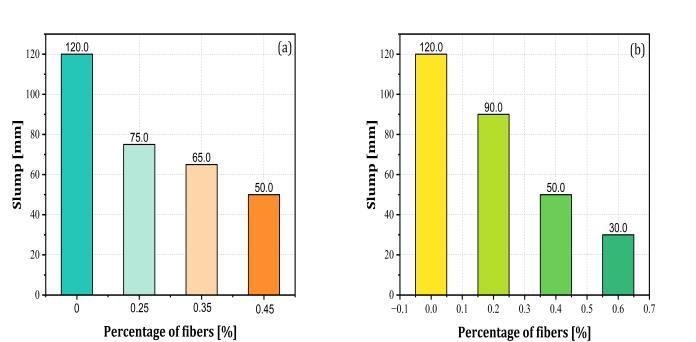

Workabilitytestswereperformedonthefreshnormal,glass fiber reinforcedconcrete(GFRC),andpolypropylenefiber reinforcedconcrete(PFRC)mix,inthefreshstatejustafter mixing,seeFigure4.Thetestresultsforslumpvaluesare giveninTable4andFigure5.Itwasevidentfromtheslump test that there was a decrease in worka- bility with the additionofglassfibersandpolypropylenefibers.Thus,fiber additionreducesworkabilityandmakestheconcretestiffer. Table 2 presents the slump values of all mixes, showing a clearreductioninworkabilityasfibercontentincreases.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Table 2 Workability

Sample

SG1

SG2

glassfibersaddedtoGFRCmixesascomparedtothecontrol mix.

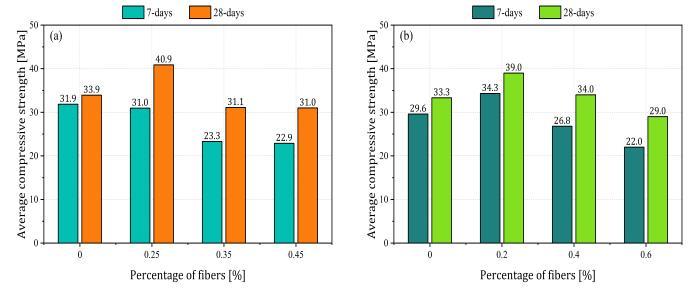

The compressive strength of concrete increases with referencetothecontrolmixwhentheglassfibersareusedat 0.25%oftheconcreteweightanddecreaseswhentheglass fibers are used at 0.35% and 0.45% of the concrete at 28 days. For the 0.25% addition, the compressive strength increasedby20.5%,whereasthe0.35%and0.45%additions showed a decrease of 8.2% and 10.4%, respectively, in strengthcomparedtothecontrolmix.Itisalsoclearthatthe 7-daystrengthofconcretedecreaseswiththeuseofglass fibers.

-6 compressivestrength(a)glassfibers,and(b) polypropylenefibers

Table 3 Compressivestrengthtestresults

5.2 Compressive Strength

The compressive strength test was performed on the standard cubes made of the normal concrete and GFRC mixes.Theultimateloaduponfailurewasrecordedandthe correspondingcompressivestrengthwascalculated.Table3 andFigure6.illustratethecompressivestrengthvaluesof

5.3 Split Tensile Strength

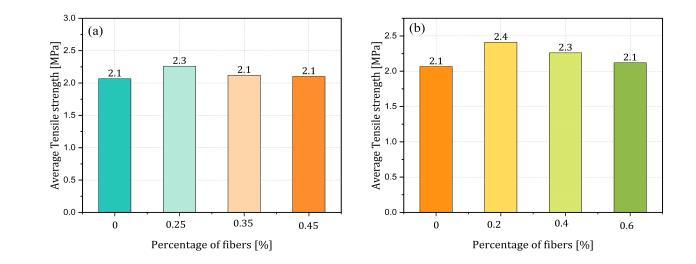

The split tensile strength test was performed on the cylindricalspecimencastfromnormalconcretewithadded glassfiberandpolypropylene.Itwasobservedthatwiththe additionof0.25%,0.35%,and0.45%glassfibers,thereisan increaseinsplittensilestrengthby9.4%,2.66%,and1.69% respectively,asshowninTable4andFigure7.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Sample

6. Failure patterns

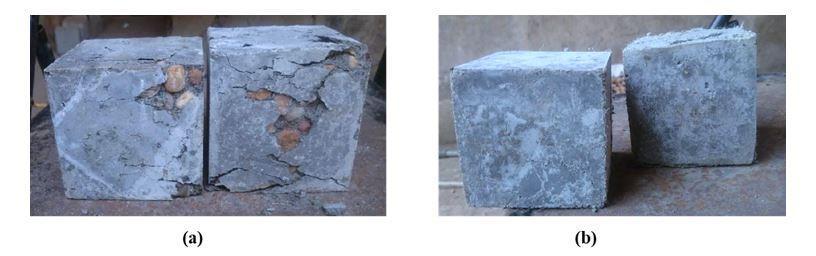

Thefailuremodesofthecompressivespecimensareshown inFigure8.Forcubecompressivespecimens,itcanbeseen thatthefailuremodeofthereferencemixwassimilartothat ofcommonconcrete.Theverticalcracksfirstappearedatthe middle height of the specimens and then extended to the corners.Initially,thecracksconcentratedonthesurfaceof theconcrete.Withtheincreaseofthecompressiveload,new cracks occurred and gradually expanded to the interior regions, accompanied by the phenomenon of concrete spalling. However, the failure modes of most glass fiberreinforced specimens were relatively intact, implying that thefiberscontributedtorestrainingthecrackgrowth.

The failure modes of the splitting tensile specimens are shown in Figure 9. A major crack appeared at the loading sectionandsplitthespecimensintotwopieces.Regarding theGFRCs-reinforcedspecimens,asecondarycrackoccurred nearthemajorone,butdidn’tdevelopthroughouttheentire cross section, and the specimens were not split into two pieces.Theseobservationsindicatethatthefiberschanged thestressdistributionsinsidetheconcreteandlimitedthe developmentofthecracks.

7. Conclusion and Recommendation

7.1 Conclusion

Based upon experimental work, normal concrete (control mix), added glass fibers (GFRCs) as 0.25%, 0.35%, and 0.45%,andpolypropylenefibers(PFRCs)as0.2%,0.4%,and 0.6%byweightconcretemixwereprepared.Allmixeswere investigated for workability tests as well as for hardened properties.Thefollowingconclusionsaredrawnbasedon resultsobtainedintheaboveinvestigation:

1.Theworkabilityofconcretedependsupontheslumpvalue of fresh concrete mix. Upon addition of glass and polypropylenefiberbyconcreteweight,theworkabilitywas foundtodecreaseduetothepresenceoffibers,makingthe concretemixstiffanddifficulttoflow.

2.The compressive strength of GFRCs increases by 20.5% duetotheadditionofglassfiberas0.25%anddecreasesby 8.2%and10.4%duetotheadditionofglassfiberas0.35% and 0.45% by weight, as compared to the compressive strengthof the normal mix. Thisindicatesthe presence of fibersincreasesthetoughnessofconcrete,hencepreferable forconcretemix.

3.The compressive strength of PFRCs increased by 17.0% and 2.0% due to the addi- tion of polypropylene fibers at 0.2%and0.4%respectivelyanddecreasedby13.0%dueto theadditionofPFRCsas0.6%byweight,ascomparedtothe compres-sivestrengthofthenormalmix.Thisindicatesthe presenceoffibersincreasesthetoughnessofconcrete,hence preferableforconcretemix.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

4.The split tensile strength of GFRCs increased by 9.4%, 2.66%,and1.69%duetotheadditionofglassfiberas0.25%, 0.35%,and0.45%byweight,ascomparedtothesplittensile strengthofthenormalmix.Fiberadditionhasreducedthe crackpropagationinconcrete,makingitmoredurableand sustainablefortensilestresses.

5.The split tensile strength of PFRCs increased by 16.7%, 9.44%,and2.66%duetotheadditionofglassfiberas0.2%, 0.4%,and0.6%byweightrespectively,ascomparedtothe splittensilestrengthofthenormalmix.

7.2 Recommendation

A0.25%additionofglassfiberand0.2%ofpolypropylene fiberforconcretemixisrecommendedformaximumvalue ofcompressivestrengthandsplittensilestrength.

References

[1]Calis,G.:Investigationeffectoffibertypeoncompressive strength of concrete. Journal of Engineering Research and AppliedScience9(2),1451–1458(2020)

[2] Ruslan,I.,Ruslan,B.,Evgenij,K.:Theeffectofmetaland polypropylene fiber on technological and physical mechanical properties of activated cement compositions. CaseStudiesinConstructionMaterials16,00882(2022)

[3] Khan, S., Khan, R.A., Khan, A.R., Islam, M., Nayal, S.: Mechanical properties of polypropylene fibre reinforced concrete for m 25 & m 30 mixes: A comparative study. InternationalJournalofScientificEngineeringandApplied Sciences1(6)(2015)

[4] Kushartomo, W., Ivan, R.: Effect of glass fiber on compressive, flexural and split- ing strength of reactive powder concrete.In:MATECWebofConferences, p.3010 (2017)

[5] Nair, M.J., Varghese, R.: Influence of glass fiber and polypropylenefiberonm30gradeconcreteanditsdurability study. Int J Innov Res Sci Eng Technol 6(5), 9138–9145 (2017)

[6] Latifi,M.R.,Biricik,,MardaniAghabaglou,A.:Effectofthe addition of polypropylene fiber on concrete properties. J AdhesSciTechnol36(4),345–369(2022)

[7] MUNIR, M.J., QURESHI, L.A., MUNAWER, S.: Effect of mixing polypropylene and glass fibers on compressive strengthofconcrete.JournalUnknown(2020)

[8]Singh,V.K.:Effectofpolypropylenefiberonpropertiesof concrete.IntJEngSciResTechnol3(12),312–317(2014)

[9]Murthy,Y.I.,Sharda,A.,Jain,G.:Performanceofglassfiber reinforcedconcrete.InternationalJournalofEngineeringand InnovativeTechnology1(6)(2012)

[10]Vishal,E.:InfluenceofGlassFibresonHighPerformance Concrete(2014)

[11]BritishStandardInstitution:SpecificationforPortland Cement vol. BS 12. British Standard Institution, London (1996)

[12] Hake, S.L., Shinde, S., Bhandari, P.K., Awasarmal, P., Kanawade, B.: Effect of glass fibers on self-compacting concrete. In: E3S Web of Conferences, vol. 170, p. 06018 (2020).EDPSciences