p-ISSN: 2395-0072 Volume: 12 Issue: 05 | May 2025 www.irjet.net

p-ISSN: 2395-0072 Volume: 12 Issue: 05 | May 2025 www.irjet.net

Pranav Y P1 , K Vishak2 , Sanjay M3 , Vishal K M4 , Dr. Mahendra Kumar C5

1-4Student, Dept. of Mechanical Engineering, B N M Institute of Technology, Karnataka, India

5Professor, Dept. of Mechanical Engineering, B N M Institute of Technology, Karnataka, India

Abstract - This project focuses on the fabrication and analysisofanaluminiummetalmatrixcomposite(AMMC) reinforcedwithvaryingpercentagesofboronnitride(BN) particles specifically 1%, 2%, and 3% by weight. The primary aim is to understand how these different reinforcement levels influence the composite's microstructure and mechanical properties. Aluminium is chosen for its lightweight and corrosion-resistant characteristics,whileBNisselectedforitsexcellentthermal stability,lubricatingproperties,andhighhardness.

Thecompositeswereproducedusingastircastingmethod to ensure uniform distribution of BN particles within the aluminium matrix. Microstructural analysis using optical microscopy and scanning electron microscopy (SEM) was conductedtoobservethedispersionofBNparticlesandany changes in grain structure. Mechanical testing, including hardness(Brinelltest)andtensilestrengthmeasurements, wascarriedouttoevaluatethematerial'sperformance.

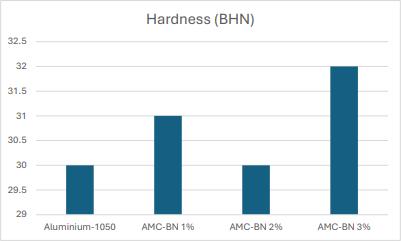

TheresultsshowedthatastheBNcontentincreased,there wasanotableimprovementinhardnessandtensilestrength uptoacertainpoint,withthe2%BN-reinforcedcomposite exhibiting the most balanced mechanical properties. However, at 3% BN, slight agglomeration of particles was observed, which affected the uniformity of the matrix and slightlyreducedmechanicalefficiency.

Overall,thisstudydemonstratesthatcontrolledadditionof BNcansignificantlyenhancetheperformanceofaluminium composites, making them suitable for applications in aerospace, automotive, and structural industries where strength,wearresistance,andweightarecriticalfactors.

Key Words: Aluminium metal matrix composite, boron nitride reinforcement, stir casting, microstructure analysis, mechanical properties, hardness, tensile strength, particle dispersion, composite materials, wear resistance.

In recent years, the demand for lightweight, high-strength materials has grown significantly, especially in aerospace, automotive,andstructuralengineeringsectors.MetalMatrix Composites(MMCs)haveemergedaspromisingmaterialsto

meet these requirements by combining the beneficial properties of metals with the enhanced mechanical characteristics of reinforcements. Among various metals, aluminium has gained substantial attention due to its low density,goodcorrosionresistance,andeaseoffabrication.

Aluminium1050,acommerciallypuregradeofaluminium, is widely used for its excellent ductility, high thermal conductivity, and corrosion resistance. However, its relatively low mechanical strength limits its use in loadbearing applications. To overcome this limitation, reinforcingaluminiumwithceramicparticlessuchasboron nitride(BN)offersaviablesolution.BNisknownforitshigh thermal stability, low density, and excellent lubricating properties, making it a suitable reinforcement to improve boththestructuralandfunctionalpropertiesofaluminium.

Thisprojectfocusesonthedevelopmentandevaluationof Aluminium1050metalmatrixcompositesreinforcedwith 1%,2%,and3%boronnitrideparticlesusingthestircasting process. The objective is to understand how BN content influences the microstructure and mechanical behavior of the composite, with the ultimate goal of optimizing the materialforreal-worldapplicationswherehighperformance andreducedweightarecritical.

Inthisproject,weaimedtodevelopaluminiummetalmatrix compositesusingAluminium1050asthebasematerialand boronnitride(BN)powderasthereinforcement.Weadded BN in different amounts 1%, 2%, and 3% by weight to see how it affects the material’s strength, hardness, and internal structure.Theentireprocesswascarried outin a seriesofsteps:preparingthematerials, mixingthemusinga methodcalledstircasting,andthentestingthefinalproducts tostudytheirproperties.

Westartedbyselecting Aluminium 1050,whichisavery pureformofaluminium.It’slightweight,corrosion-resistant, and easy to work with. However, its natural strength is relativelylow,whichiswhyweadded boron nitride(BN) a ceramic material known for being hard, stable at high temperatures, and very smooth, like graphite. The BN powder we used was very fine, with a particle size of less than50microns.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 12 Issue: 05 | May 2025 www.irjet.net

The composite was made using the stir casting method. First,wemeltedthealuminiuminafurnace,heatingitupto around 750°C to 800°C. While that was happening, we preheated the BN powder to around 300°C to 400°C to remove moisture and help it mix better with the molten aluminium.Oncethealuminiumwasfullymelted,westirred itwithamechanicalstirreratabout 500–600 rpm tocreate a whirlpool-like motion. Then we slowly added the BN powderintothemoltenmetalwhileitwasbeingstirred.In somebatches,wealsoaddedasmallamountof magnesium tohelptheBNmixbetterwiththealuminium.Aftermixing foraround10minutes,wepouredthemoltencompositeinto preheated moulds and let it cool down at room temperature.Oncesolidified,thecastblocksweretakenout and machined into specific shapes and sizes fortesting.

To check how strong and hard the material was, we performedtwomainmechanicaltests:the Brinell Hardness Test andthe Tensile Strength Test.IntheBrinelltest,we used a ball-shaped tool to press into the surface of the sample under a fixed load and measured the size of the indentation. This gave us the Brinell Hardness Number (BHN),whichtellsushowhardthematerialis.Wedidthis test at three different spots on each sample to get an accurateaverage.

Forthe tensile test,weuseda Universal Testing Machine (UTM) topullthesamplesuntiltheybroke.Thistesthelped us understand how much load the material can handle beforestretchingorbreaking.Fromthis,werecordedvalues like Ultimate Tensile Strength (UTS), Yield Strength,and Elongation (% stretch before breaking).

Next,westudiedthe microstructure,orwhattheinsideof the material looks like under a microscope. We cut small pieces from each sample and carefully polished them to makethesurfacesmooth.Thenweusedaspecialchemical called Keller’s reagent to etch the surface and make the grain boundaries visible. These etched samples were first examined under an optical microscope to observe how evenly the BN particles were spread out and to look for defectslikeporesorclumps.

Foramoredetailedview,wealsouseda Scanning Electron Microscope (SEM).ThispowerfulmicroscopegaveushighresolutionimagessowecouldclearlyseehowwelltheBN particlesbondedwiththealuminiumandwhethertheywere

evenlydistributed.Insomecases,wealsoused EDS (Energy Dispersive Spectroscopy) to confirm that the reinforcementparticleswereindeedBN.

Overall, this methodology helped us understand how differentamountsofBNaffectedthehardness,strength,and internal structure of Aluminium 1050. It gave us a clear picture of how the composite behaves and which compositionmightbebestforreal-worldapplicationslike automotiveoraerospacecomponents.

3. RESULTS AND DISCUSSIONS.

2395-0072 Volume: 12 Issue: 05 | May 2025 www.irjet.net

Table 5: Brinell Hardness Test Results of 0% BN

Table 1: Tensile Test results for 0% BN

Table 6: Brinell Hardness Test Results of 1% BN

Table 2: Tensile Test results for 1% BN

Table 7: Brinell Hardness Test Results of 2% BN

Table 3: Tensile Test Results of 2% BN

Table 4: Tensile Test Results of 3% BN

Table 8: Brinell Hardness Test Results of 3% BN

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

Volume: 12 Issue: 05 | May 2025 www.irjet.net

4.CONCLUSION

Inconclusion,theincorporationofBoronNitride(BN)asa reinforcement material in Aluminium Matrix Composites (MMCs) significantly enhances both tensile strength and hardness,asdemonstratedbytheresultsofthisstudy.The additionofBNparticlesleadstoamarkedimprovementin the mechanical properties of the composite, making it a promisingcandidateforapplicationsrequiringhighstrength, wearresistance,andthermalstability.Theincreasedtensile strengthcanbeattributedtothereinforcementprovidedby the BN particles, which serve to resist deformation under stress.Similarly,theenhancedhardnessislikelyaresultof BN's high intrinsic hardness and its ability to distribute stress more effectively throughout the composite. These improvementsinmaterialpropertiescouldmakeAluminium MMCs with BN suitable for demanding applications, including in the aerospace, automotive, and electronics industries,wherematerialsaresubjectedtohighmechanical stress and wear. While the results are promising, the full potentialofthesecompositeswillberealizedonlythrough continuedresearchandoptimization.Futurestudiesshould focus on refining the fabrication techniques and reinforcementstrategiestofurtherenhancetheperformance ofthesecomposites.Moreover,exploringtheimpactofBN reinforcement on other properties such as thermal conductivity,fatigueresistance,andcorrosionresistancewill provide a more comprehensive understanding of the material'spotentialforreal-worldapplications.Overall,this study paves the way for the development of advanced composite materials that combine the advantages of both aluminium and Boron Nitride, offering a balanced performanceintermsofstrength,hardness,anddurability. With continued research and development, Aluminium MMCswithBNreinforcementcouldbecomeaversatileand reliable material solution for a wide range of industrial applications.

1. Kumar, A., & Sood, D. (2011). "Tensile and Hardness PropertiesofAluminiumMatrixCompositesReinforcedwith Boron Nitride." Journal of Materials Science & Technology, 27(9),854-858.

2. Ravi, V., & Sathish, T. (2017). "Effect of Boron Nitride Reinforcement ontheMechanicalProperties ofAluminium Matrix Composites." Materials Science and Engineering A, 686,243-253.

3.Madhusudhan, N., & Suresh, S. (2015). "Microstructural andMechanicalCharacterizationofBoronNitrideReinforced AluminiumMatrixComposites."JournalofMaterialsScience, 50(5),2312-2321.

4.Mishra,R.K.,&Pradhan,A.(2013)."MechanicalProperties and Wear Resistance of Aluminium-Based Boron Nitride Composites."Wear,303,187-194.

5. Sakthivel,P., &Prakash,M.(2017)."Microstructureand Tensile Behavior of Boron Nitride Reinforced Aluminium Matrix Composites." Materials Science and Engineering B, 223,13-20.

6. Saha, P., & Ghosh, S. (2019). "Microstructural Evolution and Mechanical Properties of BN Reinforced Aluminium MatrixComposites."MaterialsCharacterization,155,47-55.

7. Chawla, K. K., & Kewalramani, S. (2014). "Tensile Properties and Microstructural Characterization of Aluminium-BoronNitride Composites." Journalof Alloysand Compounds,592,62-69.

8.Wang, X.,&Li,W.(2018)."InfluenceofBoron Nitride ontheHardnessandWearResistanceofAluminiumMatrix Composites." Journal of Materials Engineering and Performance,27(6),2751-2757

9. Ghosh, S., & Kothari, A. (2015). "Microstructural and Mechanical Properties of AMMCs Reinforced with Boron Nitride:AReview."MaterialsandDesign,65,120-137

10. Banu, M. S., & Jayaraman, V. (2017). "Mechanical Propertiesand Microstructureof BoronNitride Reinforced Aluminium Matrix Composites: A Comprehensive Review." CompositesPartB:Engineering,124,132-145.

11. Sivakumar, D., & Kumar, S. (2016). "Effect of Boron Nitride Particles on the Microstructure and Tensile Strength of Aluminium Matrix Composites." Materials Research Express,3(6),065306.