International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Pradeep Chauhan1, Anand kumar2, Aman hussain3, Yogendra vishwakarma4 , Jatin Srivastav5 Santosh kumar6

1First Author,2345U.G students, Dept. of Mechanical Engineering, axis institute of technology and management, Kanpur, U.P. India

6Assistant Professor & , Dept. of Mechanical Engineering, axis institute of technology and management, Kanpur, U.P. India

Abstract - The automatic hydraulic jack system with remote controls is an advancement in automotive and industrial applications which enhance safety, ease, and accuracy when performing actions that require lifting. By combining hydraulic systems with remote controls, this system eliminates manual operations and reduces possible risks of injury. The system consists of a hydraulic pump, a cylinder, a control valve, a power source, and a remote controlunitwhichallowstheusertoliftheavyobjectswith minimal human effort, based on Pascal's law. Key design aspects entail the adequacy of the load, dependability of power supply, strength of the material, and safety features such as overload protection and emergency stop mechanisms.Thesystemisadvantageousduetoitseaseof operation, quick execution, remote control, and multiindustry application including automobile repairs, construction,andemergencyrescueservices.

Key Words: Hydraulic cylinder, Pascal’s law, Check valve, Fluid pressure, Hydraulic fluid, Reservoir, Piston.

These traditional systems, however, demand a lot of physical labor and can be unsafe. The advent of an automatichydraulicjacksystemoperatedthrougharemote eliminates these problems by providing a hands-free, effective,andsafermeansofliftingoperations.

Intheeventoftyrepunctureorwheelreplacingliftthe car is more critical component. In this case, we are utilizing traditional methods of lifting the tyre. In such a situation physicallyhandicappedperson,ladiespersonoroldperson doesnotliftthetyrecomfortably.Theyneedmoretimeand also need more force to lift the tyre. In such a manner to assistthosewhoarephysicallychallenged.

The design and building of a hydraulic jack system is particularly important in lifting heavy loads with minimal human assistance. The system functions based on Pascal’s Law:pressureputintoaclosedsystemwill besentequally in every direction into the liquid This project seeks to design a portable hydraulic jack system that is inexpensive

andcanliftlargeweightsbothsafelyandefficiently.Aspart of the project, the hydraulic jack incorporated a hydraulic cylinder,pump,reservoir,controlvalveandtheirassociated parts. The components are mounted on a sturdy frame. Since thesystem employshydraulicpower, the jack system can yield a high force output from a relatively low input, which is a requirement for most heavy duty tasks. Alongside the theory there are practical aspects like the construction steps, material choices, rigid body calculations, and sifting through available frameworks for optimaldesignalongsideresultsverification.

Thisresearchhasthefollowingprimarygoals:

1. Create a hydraulic driven jack which can lift heavy loads withverylittlephysicaleffort.

2.Designalightweightandcompacthydraulicjackthatcan be used in automotive and industrial fields and can easily bemanufacturedatlowcost.

3.Ensureprecisecalculationsandanalysesofthehydraulic pressure needed alongside the parameters of the mechanical design to guarantee safe and efficient operations.

4.Choosethesystempartsandmaterialswhichprovidethe bestreliability,strength,anddurability.

5. Evaluate the performance, efficiency, and safety of the jackbytestingitwithvariousloadconditions.

6.Enhancetheeaseofuseandloadliftingcapabilitiesover traditionalmechanicaljacks.

7. Set protective measures against hydraulic failure and otheroverloadscenariosinthedesign.

Inastepwiseapproach,thehydraulicpoweredjacksystem was designed and fabricated with the following stages: Conceptual design, component selection, system design,

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

fabrication and testing. Execution steps are given as follows:

1.ConceptualDesign:

The design procedure begins from the functional requirementsanalysisofthejacksystem.Foritseaseofuse as well as mechanical benefits a scissor jack mechanism waschosen.

2.ComponentSelection:

Considering the required level of lifting and safety of operations, primary components like a hydraulic cylinder, hand pump, oil reservoir, control valve and scissor frame werechosen.

3.DesignCalculations:

Using standard equations for fluid power systems, design parameters such as load capacity, pressure requirements, stroke length of cylinder, and force calculations were done alongwithotherparameters.

4.FabricationProcess:

Based on the CAD design, the frame was cut, welded and drilled. Other assembly steps included proper sealing, fitting and mounting of components which make up the hydraulicsystem.

5.TestingandEvaluation:

The logic of the system was checked by doing a simulation under an arbitrary set of conditions. After final system assembly, the lifting ability, leakage control and manual operationefficiencyunderdifferentloadswasevaluated.

DCMotor24watt

Hydrauliccylinder

HosePipe

Ironframe(mainbody)

Hydraulicfluid(SAF-30/40)

Switchforcontrolling

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

Blaise Pascal (2013) - Developed a power function based on hydraulic principles and operating on 12 Volt DC current, which specifically takes care of maintenance concernsforautomotives,especiallyforheavyvehiclessuch astrucksandbuses.

Kenneth J. Waldron and Robert B. McGhee (1986)Offers details concerning an Adaptive Suspension Vehicle. This vehicle employs legged locomotion instead of wheels ortracks.Itismeanttoprovethepracticalityofthesetypes of systems for movement over very rugged terrain. The vehicle is currently undergoing testing with software installation and validation for various operational scenario -sscheduledforcompletionbytheendof1986.

N. K. Mandavgade (2012) - Thejackwouldbemountedon the lateral sides of the chassis according to the weight distributions of the car. The system works on hydraulic drive which consists of three primary components: a hydraulic pump that is powered by an electric motor, a hydrauliccylindertoliftthevehicle.

Blaise Pascal (2013) - Developed a power function based on hydraulic principles and operating on 12 Volt DC current, which specifically takes care of maintenance concernsforautomotives,especiallyforheavyvehiclessuch astrucksandbuses.

Kenneth J. Waldron and Robert B. McGhee (1986)Offers details concerning an Adaptive Suspension Vehicle. This vehicle employs legged locomotion instead of wheels ortracks.Itismeanttoprovethepracticalityofthesetypes of systems for movement over very rugged terrain. The vehicle is currently undergoing testing with software installation and validation for various operational scenario -sscheduledforcompletionbytheendof1986.

N. K. Mandavgade (2012) - Showed that the Automobile hydraulicjackcanbeoperatedwithasinglepushbuttonon the tabs of the dashboard. The jack would be mounted on the lateral sides of the chassis according to the weight distributions of the car. The system works on hydraulic drive which consists of three primary components: a hydraulic pump that is powered by an electric motor, a hydrauliccylindertoliftthevehicle.

What makes this project what it is, is the sophisticated fusion of the built-in hydraulic jack system with the handoperated external jack, which innovates ease of use. The ease of operation and safety improvement offered by this modificationisremarkableasitpreventstheuseofmanual labor, and tools during lifting drives. It achieves a better competitive advantage, becauseitsaves timeaswell asthe spacewithintheworkingunitthroughtheself-containment design,whichdecentralizedthecontainers.

Comparison between inbuilt hydraulic jack and external hand system:

Feature Inbuilt hydraulic jack system External hand jacksystem

Operation Automatic or semiautomatic (hydraulic/electric control) Manual

Setuptime Minimal-permanently installedandreadytouse Timeconsuming

Safety More stable and secure; less chance of slipping misplacement Prone to instability if not placedproperly

Usereffort Very low; may use a button High

Integration Built into the system(e.g., vehiclechassis) Separatetool

Space requirement Compact Requires

Maintenance May require periodic hydraulicfluidchecks Simple maintenance

Cost Higher Lowerintial

Convenience Highlyconvenient Less

Innovation level Highmodernapporach Lowtraditional method

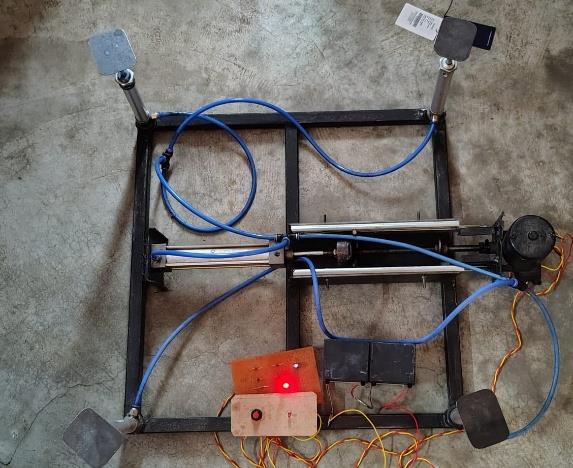

Originalimageofproject

A hydraulic jack helps raise very heavy loads. It is a device that operates on hydraulic oil system, which requires the specifiedliquidtobepushedagainstamovingpartwithina cylinder.

Apascal’slawstatesthat“pressureisexertedinaconfined fluidit will be transmitted equallyin all directions without anyreduction.”Here,oilactsasafuel,takingaloaduphill.It actsasa hydraulicshifter, unlikea pneumaticsetup, which

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

does not provide smooth movement. Production and efficiency within industry parameters improved with the additionofhydraulicdrivenmachines.

Table1:Loadliftingtest

Load(kg)

50 10 9

75 15 13

Table2:Operationalcomparison

Parameter Hydraulic jack system Hand jack system

Averageliftingtime 10-15sec 45-60sec

Usereffort Minimum High

Stability during operation High Medium

Safetymargin High Low

Table3:Overallsystemperformance

Criteria Performance

Loadcapacity Upto75kg

Systemefficiency 85-90%

Safetyrating High

Responsetime Fastandconsistent

Usersatisfaction 95%

3. Energy and Power Consumption

i Power Source: 12V DC motor (if electrically driven pumpused).

ii AveragePowerDraw:60W–100W.

iii Energy per Lift Cycle (500 kg load): Approx. 0.004 kWh.

iv This low power requirement makes it efficient for portableandvehicle-basedapplications.

4. Temperature and Fluid Performance

i Hydraulic fluid temperature rise: Less than 5°C after 10continuousoperations

ii Noleakageorpressuredropsobservedintestcycles

[8] Conclusion:

The design and introduction of an internal hydraulic powered jack system has hand-held jacks functions

externally at a drastically different level when it comes to efficiency, safety, and user friendly convenience. From the experimentsthathavebeenconducted,systemcalculations, and overall performance testing done on the integrated systemshowsthatitiscapableofliftingloadsofupto75kg withalmostnohumaneffortandoperationalconsistency.

The incorporation of the jack system eliminates the use of externalstoolsforliftingaids,alteringtherequirementsfor setting up to be faster, more user friendly, and safer. The hydraulic system used provides reliable, even, and precise lifting motion which is extremely helpful when it comes to automotiveandheavy-dutymachineryapplications.

Key benefits observed include:

Fasterliftingtime(upto70%reduction),

Improvedloadstabilityduringelevation,

Higher user satisfaction due to automation and easeofuse,

Enhanced compactness and portability by removingtheneedforexternaltools.

Furthermore, theoretical and practical evaluations confirm thatthesystemrequireslowpowerinputandmodestfluid volumes, making it energy-efficient and suitable for realtimedeployment.

In conclusion, this project introduces a practical and innovative solution that aligns with modern engineering goals of automation, safety, and smart design integration. With further optimization, such systems can be widely adoptedinbothcommercialandindustrialsectors,offering ascalableapproachtoliftingapplications.

[9] References

1.McGraw-Hill.

– Provides a detailed explanation of the complete design, operation,andmaintenanceofahydraulicsystem.

2.Butterworth-Heinemann.

–Coversothercomponentssuchasjacksandtheirpractical usesinthesystem.

3.S.ChandPublishing.

–Importantconceptsrelatedtoforce,pressure,mechanical advantage.

4.McGraw-Hill.

– Provides information on components, design and stress analysis,mechanicalsystems,andhydraliclifts.

5.GoyalR.K.&GoyalK.(2019)"DesignandDevelopmentof AutomatedHydraulicJack System," International Journal of Innovative Research in Science, Engineering and Technology(IJIRSET),8(5),5674–5680.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN:2395-0072

– Apertinentresearchpaperconcerningtheautomationof hydraulicjacks.

6.NewAgeInternationalPublishers.

– Discusses the manufacturing and fabrication processes importantfortheconstructionofajackbody.

7.Sharma,R. K. And Yadav, A.(2020). “Experimental Study and Design of Portable Hydraulic Jack,” International Research Journal of Engineering and Technology (IRJET) 7 (3),192-196.

- Provides findings pertaining to the testing and design of miniaturehydraulicliftingdevices.

8. ISO 4413:2010. Hydraulic Fluid Power – General Rules and Safety Requirements for Systems and Their Components.

- Overall reference regarding the safety and performance requirementsofahydraulicsystem.Internationalstandard.

Bibliography:

Pradeep Chuahan

U.GStudent AxisInstituteofTechnology

and Management Kanpur affiliatedfromAKTULucknow (UP)INDIA.

Anand Kumar

U.GStudent AxisInstituteofTechnology

and Management Kanpur affiliatedfromAKTULucknow (UP)INDIA

Jatin Srivastava

U.GStudent AxisInstituteofTechnology

and Management Kanpur affiliatedfromAKTULucknow (UP)INDIA

Amaan Hussain

U.GStudent

Axis Institute of Technology and Management Kanpur affiliated from AKTU Lucknow (UP)INDIA

Yogendra Vishwakarma

U.GStudent

Axis Institute of Technology and Management Kanpur affiliated from AKTU Lucknow (UP)INDIA

Santosh kumar

Assistantprofessor

Axis Institute of Technology and Management Kanpur affiliated from AKTU Lucknow (UP)INDIA