International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Er Shabnum Shabir1 , Daud Chauhan2

1Assistant Lecturer in Interior design department, Swami Vivekanand Subharti University, Meerut, Uttar Pradesh (250005) India

2Assistant professor in Civil Engineering Department, Swami Vivekanand Subharti University, Meerut, Uttar Pradesh (250005) India

Abstract - Concrete is among the most widely used construction materials acrosstheglobe,withcementserving as its main binding component.However,themanufacturing of cement is not only highly energy-consuming but also a significant source of CO₂ emissions. In response to growing environmental and sustainability challenges, this study explores the potential of utilizingfinelygroundglasspowder sourced from waste glass bottles as a partial substitute for cement. Various concrete mixes weredevelopedbyreplacing cement with 0%, 2.5%, 5%, and 10% glass powder by weight. The findings revealed that a 10% replacement level yielded the best compressive strength and overall performance, while also promoting waste utilization and sustainable building practices.

Key Words: Glass powder, concrete, cement replacement, compressive strength, sustainability, green construction.

Concrete is a composite construction material mainly consistingofcement,water,andaggregates.Amongthese, cement is the costly and energy-intensive component, playing a major role in the construction sector's carbon emissions. To promote environmentally responsible building practices, numerous researchers have investigated the use of supplementary cementitious materials(SCMs)suchasflyash,silicafume,andground granulatedblast-furnaceslagaspartialreplacementsfor cement.

Recently,wasteglasspowderhasgainedattentionasan effectivesupplementarycementitiousmaterialSCMdueto itsrichsilicacontentandpozzolaniccharacteristics.When ground into a fine powder, it reacts with the calcium hydroxidepresentinconcretetoformadditionalcalcium silicatehydrate(C-S-H),whichenhancesbothstrengthand durability. In the Indian context, a large volume of glass waste is produced annually, much of which is nonbiodegradable and typically ends up in landfills. Incorporating this waste into concrete not only helps

mitigate disposal challenges but also decreases cement usage,supportingmoresustainableconstructionsolutions.

Toassesshowthepartialreplacementofcement with glass powder affects the workability of concrete

To examine the impact of glass powder on the compressivestrengthofconcreteacrossvarious curingdurations.

To determine the most effective percentage of glasspowderreplacementthatyieldsthehighest strengthperformance.

Discardedglassfromhouseholdandconsumer use

Scrap glass is generated from industrial processes

Glassdebrisrecoveredfromconstructionand demolitionactivities.

Wasteglassoriginatesfromtheautomotiveand electronicssectors.

Used glass materials from laboratories and healthcarefacilities

A. MERITS

1. Environmental Benefits

Reduces landfill waste and lowers carbon emissions by replacingpartofthecementoraggregates

2. Pozzolanic Activity

GlasspowderreactswithcalciumhydroxidetoformC-S-H, improvingstrengthanddurability.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

3. Better Workability

The smooth texture of glass powder enhances the mix's workability.

4. Cost-Effective

Wasteglassischeaperthancementandaggregates.

5. Thermal Resistance

Improvesconcrete’sresistancetoheatandfire.

1. Alkali-Silica Reaction (ASR) Risk

Silicainglassmayreactwithcementalkalis,causingcracks ifuncontrolled.

2. Processing Required

Needscleaning,grinding,andsievingbeforeuse.

3. Lower Strength at High Dosage

Over20–30%replacementcanreduceearlystrength.

4. Inconsistent Quality

Glass from various sources may contain impurities and properties.

5. Handling Hazards

Fineglassparticlescanbeabrasiveorhazardoustohandle duringmixingorprocessing.

Shao et al. (2000) Shao and his team explored the pozzolanicactivityoffinelygroundglasspowder(lessthan 38 µm) and found that it could replace up to 30% of Portland cement effectively. They reported enhanced compressive strength at later ages due to ongoing pozzolanicreactions.

Taha and Nounu (2009) Their research involvedusing bothfineandcoarseglassasaggregatesinconcrete.While early-age strength saw a slight reduction, long-term durabilityandimpermeabilityimprovedwhenglasswas usedinpowderedform.

Islam et al. (2016) Thisstudyevaluatedthemechanical behaviorofconcretewithvaryingproportions(10%,15%, 20%) of waste glass powder. The results indicated that 15%replacementyieldedoptimalcompressiveandtensile strength,comparabletoorbetterthanconventionalmixes.

Nassar and Soroushian (2012) Their work included microstructural analysis of concrete containing glass powder.SEMimagesshowedadenserstructureduetothe formation of additional C-S-H gel, leading to improved impermeability.

Corinaldesi et al. (2005) Theresearchersexaminedthe useofwasteglassasapartialsubstituteforsandinmortar. They observed a slight decrease in workability, but the compressivestrengthremainedwithinacceptablelimits.

Du and Tan (2014) Thisstudydiscussedtheriskofalkalisilica reaction (ASR) associated with coarse glass. However, they noted that grinding glass to particles smaller than 75 microns mitigated ASR risk due to its pozzolanicbehavior.

Park et al. (2004) Park and colleagues analyzed the chemical interactions of glass powder in cement-based systems. They found that high-silica glass reacted with calcium hydroxide from cement hydration, forming additional C-S-H gel and enhancing overall strength and durability.

Limbachiya et al. (2012) Theirinvestigationfocusedon replacing fine aggregate with recycled glass. The study reported improved workability and flexural strength at 10%replacement,thoughlargerglassparticlesposedASR risks.

Patel and Shah (2015) Intheirexperiment,cementwas replacedwithglasspowderatintervalsof5%to20%.The findingsshowedthat10–15%replacementwasidealfor enhancingcompressivestrength,whilehigherpercentages ledtostrengthlossduetoreducedcementitiouscontent.

Vijayakumar et al. (2013) This study highlighted the durability performance of concrete with 15% glass powder. The results demonstrated better resistance to sulfate attack and lower water absorption, indicating enhancedimpermeability.

1. Cement:

OrdinaryPortlandCement(OPC)of43Grade,conforming to IS 8112:1989 standards, was utilized as the primary bindingagentintheconcretemix.Thiscementtypeplaysa crucial role in strength development through hydration whencombinedwithwater.Thecementusedwasfresh, consistentincolor,lump-free,andhadaspecificgravityof approximately3.15.

2. Aggregates

Aggregatesserveasinertfillers suchassand,gravel,or crushed stone making up about 60–75% of the total concrete volume. They significantly influence the mechanicalstrength,durability,andoverallstabilityofthe concrete.

a) Fine Aggregate

Well-graded,cleannaturalriversandconformingtoZoneII asperIS383:1970wasusedasfineaggregate.Itwasfree

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

fromclay,silt,andorganiccontaminants.Fineaggregates helpreducevoidsandimprovethemix'sworkability.The specificgravityofthesandwasapproximately2.63,andits finenessmoduluswas2.6.

b) Coarse Aggregate

Crushed angular granite stones of nominal 20 mm size were used as coarse aggregates. These aggregates, complying with IS 383:1970, were clean, durable, and suitableforenhancingthecompressivestrengthandbulk densityoftheconcrete.Theirspecificgravitywasaround 2.7, and water absorption values were within the acceptablerange.

3. Water

Potablewater,suitableforhumanconsumptionandfree fromharmfulsubstanceslikesalts,oils,acids,ororganic matter, was used for mixing and curing by IS 456:2000. Waterisessentialforthehydrationprocessandinfluences bothworkabilityandfinalstrength.Awater–cementratio intherangeof0.45to0.50wasmaintainedthroughoutthe study.

4. Waste Glass Powder (WGP)

Recycled waste glass was collected, cleaned, dried, and ground to a fine powder passing through a 75-micron sieve. The glass powder is rich in silica and exhibits pozzolanicproperties.Inthisstudy,itwasusedasapartial replacement for cement in varying percentages 0%, 2.5%, 5% and 10%. Using WGP not only contributes to sustainable construction but also reduces the environmental burden caused by non-degradable glass waste.

4.RESULTS AND DISCUSSION

Theadditionofwasteglasspowdertoconcreteresultedin an increase in compressive strength up to a 10% replacement level. After this point, a steady decrease in strength was observed. The rise in strength at lower percentagesismainlyduetothepozzolanicnatureoffinely ground glass powder, which interacts with calcium hydroxidetoproducemorecalciumsilicatehydrate(C-SH),enhancingtheinternalbondingoftheconcrete

However,replacingmorethan10%ofcementwithglass powderledtoareductionincompressivestrength,most likely due to a decrease in the active binding materials requiredforstrengthgain.

Overall, the findings confirm that utilizing finely ground waste glass as a partial substitute for cement can effectively boost compressive strength within certain limitswhilepromotingeco-friendlyconstructionpractices. Therefore, incorporating up to 10% glass powder in concrete offers both structural advantages and an environmentally sustainable method of recycling glass waste.

Table 1: Thecompressivetestofconcreteisconducted for0%.Thetablebelowshowsthecompressivestrength oftheconcretecube.

Figure 1: Thecompressivetestofconcreteisconducted for0%.

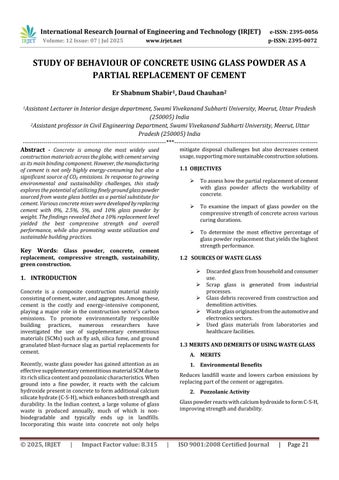

Table 2: Thecompressivetestofconcreteisconducted for2.5%.Thetablebelowshowsthecompressive strengthoftheconcretecube.

Figure 2: Thecompressivetestofconcreteisconducted for2.5%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

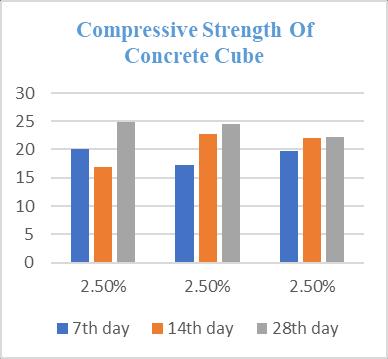

Table 3: Thecompressivetestofconcreteisconducted for5% Thetablebelowshowsthecompressivestrength oftheconcretecube.

S.NO % Replacement Cube(N/mm2) 7th day 14th day 28th day

1. 5% 1396 1924 2156

2. 5% 1871 2044 1404

3. 5% 1596 2122 1809

Figure 3: Thecompressivetestofconcreteisconducted for5%.

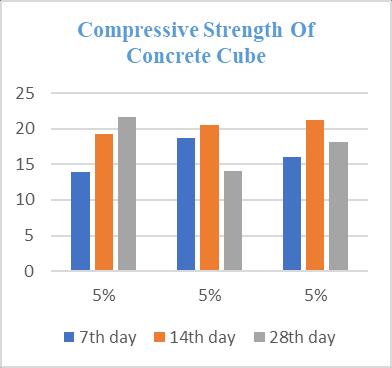

Table 4: Thecompressivetestofconcreteisconducted for10% Thetablebelowshowsthecompressive strengthoftheconcretecube.

S NO % Replacement Cube(N/mm2) 7th day 14th day 28th day

1. 10% 2514 3477 3863

2. 10% 2511 3476 3866

3. 10% 2512 3479 3817

Figure 4: Thecompressivetestofconcreteisconducted for10%.

5.CONCLUSION:

Theexperimentalfindingsrevealthatsubstituting fine aggregates with glass powder enhances the compressive strength of concrete up to a 10% replacement level. Beyond this threshold, a gradualreductioninstrengthisobserved.

The research confirms that waste glass powder canbeeffectivelyusedasapartialreplacementfor fine aggregates, leading to improvements in specific mechanical propertieswhilesupporting environmentally sustainable construction practices.

Therefore, it is concluded that incorporating wasteglasspowderwithintheoptimalrangenot onlyimprovesconcreteperformancebutalsoaids in effective waste management and resource conservationbytransformingnon-biodegradable glasswasteintoausefulconstructionmaterial.

[1] Patel, A., & Shah, N. (2017). Experimental investigationonconcretebypartialreplacementof cementwithglasspowder.InternationalJournalof Engineering Research and Technology, 6(6), 104–107.

[2] Nassar, R. U. D., & Soroushian, P. (2012). Field investigationofconcreteincorporatingmilledwaste glass.CementandConcreteComposites,34(1),25–30.

[3] Park,S.B.,Lee,B.C.,&Kim,J.H.(2004).Studieson the mechanical properties of concrete containing waste glass aggregate. Cement and Concrete Research,34(12),2181–2189.

2024, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page24

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

[4] Karamaludin, N., & Safiuddin, M. (2017). Use of wasteglassinconcreteforsustainableconstruction: Areview.ConstructionandBuildingMaterials,152, 489–498

[5] Taha,B.,&Nounu,G.(2009).Propertiesofconcrete containmixedcolourwaste,recycledglassassand, andcementreplacement.ConstructionandBuilding Materials,23(10),3061–3067.

[6] Siddique,R.,&Khatib,J.(2012).Useofrecycledglass in concrete: A review. Journal of Civil Engineering andManagement,18(6),798–806.

[7] IS 383:2016 – Coarse and Fine Aggregate for Concrete – Specification. Bureau of Indian Standards.

[8] IS10262:2019–GuidelinesforConcreteMixDesign Proportioning.BureauofIndianStandards.

[9] Chandramouli,K.,etal.(2010).Strengthproperties ofglassfibreconcrete.ARPNJournalofEngineering andAppliedSciences,5(4),1–6.

[10] Bashar, S., et al. (2020). Waste glass powder as cement replacement in concrete: A sustainable approach.MaterialsToday:Proceedings,43,1023–1027.