International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

D. Jayakumar1, D. Krishnadas2, Dr. C. Subramanian3

1 , 2UG Scholar, Department of Mechanical Engineering, Christ College of Engineering and Technology, Puducherry605 010

3Professor and Head, Department of Mechanical Engineering, Christ College of Engineering and Technology, Puducherry-605 010

Abstract - Aluminium alloy 7075 is a metal matrix composite which has used in the aerospace and defense industries, due to high strength and corrosion resistant. Aluminium alloy 7075 was selected as the base matrix and reinforced with Titanium dioxide and egg shell to form a hybrid composite. TiO2 was used to improve hardness, while egg shell powder, a bio-waste material rich in calcium carbonate, was added to enhance stiffness and sustainability. In this present work, we have performed two specimens. The first specimen comprised 90% Al7075, 6% TiO2 and 4% Egg shell, whilethe secondconsisted90%Al7075, 8%TiO2 and2% Egg shell particles. Stir casting method is adopted because, this is the best method to make composite mixture in the molten stage of metal to get the proper mixture of composite. This specimens were subjected to Mechanical tests such as Micro Vickers Hardness test and Compression test, Scanning Electron Microscope test were conducted to study change in structure.

Key Words: Aluminium alloy 7075, Titanium dioxide, Egg shell, Stir casting, Micro Vickers Hardness test, Compression and SEM test.

The aluminium is a chemical element with symbol Al and atomic13.Aluminiumappearsasasoft,silvery-whitemetal thatislightweightandnon-magneticbelongingtotheboron group in the periodic table. It is the third most abundant elementintheEarth’sandisprimarilyextractedfrombauxite ore.Oneofthemostimportantpropertiesofaluminiumisits low density which makes it highly desirable in industries where weight reduction is critical, such as aerospace, automotiveandtransportation.Thealuminiumhavemany serieslike(1xxx,2xxx,3xxx……,7xxx).Aluminium7075alloy isahigh-strengthaluminiumalloyprimarilyalloyedwith zinc, along with magnesium and copper, making it significantlystrongerthanmanyotheraluminiumalloysand comparableinstrengthtosomesteels.Al7075issignificantly strongerthanAl6061orAl6065alloys.Itisnearlytwiceas strongintensileandyieldstrength.Thoughaluminiumalloy 7075isnotascorrosion-resistanceassomeotheraluminium

types,itstillperformsbetterthanthe2000seriesinresisting corrosion.

Titanium dioxide is chemically inert, non-toxic, thermally stable and low cost, making it an ideal reinforcement material in metal matrix composites. When added to aluminium matrix composites (AMCs), TiO2 enhances mechanical properties such as hardness, tensile strength, wearresistanceandfracturetoughness.Itiscommonlyused in various application from pigment in paints to bone implants. The addition of TiO2 into aluminium matrix composites(AMCs)canleadto:

Increasedstrength

Enhancefracturetoughness

Enhancewearresistance

Improvethermalstability

Bettercorrosionresistance.

In India, the poultry industry plays a significant role in agriculture,contributingtoeggproductionwithanannual growthrateofapproximately6%withahenpopulationof 489million.Indiaproducesaround47billioneggsannually, making it the third-largest egg producing country globally[1].Thisresultsinthegenerationofalargeamount of egg shell waste. It is a naturally occurring bio-waste

International Research

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net

materialprimarilycomposedofcalciumcarbonate(CaCO3) along with small amount of magnesium carbonate and calcium phosphate. Around 95% of the dry eggshell is composedofcalciumcarbonateandweighsapproximately 5.5grams.Italsoincludesminoramountsofphosphorusand magnesium(eachabout0.3%)alongwithtracesofelements likesodium,potassium,zinc,manganese,ironandcopper[1].

2. COMPOSITION AND PROPERTIES

Table 2 a) Composition of Al7075

Table 2 b) Properties of Al7075

Table 2 c) Properties of Titanium dioxide

Table 2 d) Properties of Egg Shell

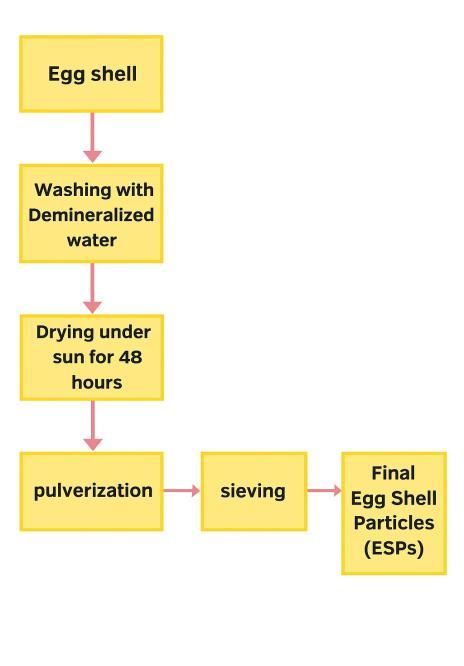

3. PREPARATION OF EGG SHELL PARTICLES

Figure 2 Preparation of Egg shell Particles[1]

The egg shell used in the study were collected from local households. Then the egg shells were thoroughly washed withdemineralizewatertoremoveanyforeignobjectsand thethinoutermembrane.Thecleanedeggshellswerethen dried under sunlight for 48 hours to ensure complete removal of moisture. After dried, the egg shells were pulverized using a grain miller operating at 400rpm to produceafinepowder.Thispowderwassievedofrequired sizetoobtaineggshellparticlesofuniformsizedistribution.

The stir casting procedure was used for the fabrication of ESP-AL-TiO2 composite.Stircastingisawidelyusedliquidstate fabrication technique for producing metal matrix composites (MMCs), particularly aluminium-based composites.Duringtheprocedure,reinforcementmaterials are gradually added to the molten metal, which is kept in motion through constant stirring to maintain even dispersion throughout. Compared to other methods like powder metallurgy, infiltration or squeeze casting, stir casting requires less complex equipment and it easier to operate.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Stircastingsetupispreheatedforhalfanhourpreparingfor casting . Then the graphite crucible is placed in to the furnace.ThecruciblegetheatedthentheAluminiumwere added to the crucible. The furnace is maintained the temperatureat1100oC.Aluminumgetsslowlymeltedinto molten stage and then injecting the calculated weight of TitaniumdioxideandEggshellparticleasareinforcementin tothemoltenmetal.Mechanicalstirrerisstirringthemolten metalfor5-6minataconstantspeedofthe60rpm.The reinforcing elements blend uniformly within the molten metalduringstirring.

Beforepouringthemoltenmetalintothedie.Rustonthedie surfaceisremovedusingemerypaperbeforethesplitdieis assembledandpreparedforthecastingprocess.Bytheuse of holder the crucible is removed from the furnace. The moltenmetalisgraduallytransferredintothediecavity.

Thenthedieiscooledtoroomtemperatureforhalfanhour, thensplitthepatternandslowlyremovethecastedrodfrom the die. This casting procedure is repeated for all test specimens.

5. CALCULATIONS

5.1 Density of materials

DensityofAl7075 =2.81g/cm3 DensityofTitaniumdioxide =4.23g/cm3 DensityofEggshell =2.02g/cm3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

5.2 Calculation of volume of die

Volumeofdie =3.14*Radiusofdie2*Lengthofthedie =3.14*12*27.5 =86.39cm3

5.3 Manual Calculation

Theoretical density=100/ (%ofAl/DensityofAl +%of TiO2/DensityofTiO2+%ofEggshell/DensityofEggshell) =100/(90/2.81+6/4.23+4/2.02) =2.82g/cm3

Mass =Density*Volume =2.82*86.39 =244.12g

Fromthetotalmassof244.12g

90%ofAl7075 =219.46g

6%ofTiO2 =14.65g

4%ofEggshell =9.70g

Table 5 a) Percentage table of MMC

Table 5 b) Composition table of MMC

6. RESULTS AND DISCUSSIONS

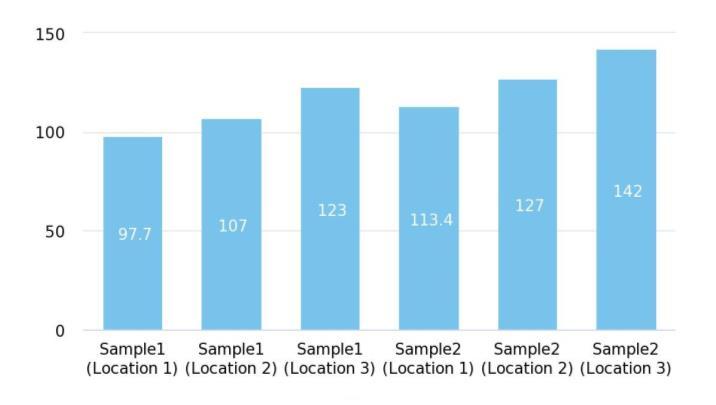

6.1 HARDNESS TEST

TheprojectweareusingmicroVickershardnesstest.Inthis methodintenderhasthematerialofdiamondintender.And intenderpenetratestheworkpieceby10to15seconds.

Wearefixafirstlocationforhardnesstestinginsample1. Aftertestingthesample1attheloadof0.5kgfwithdiamond intender,thefirstlocationvalueis97.7HV.Nowwearegoing to fix second location for finding better result. As same sample 1, at location 2, we get the value of 107 HV. The secondlocationhasbithighervaluethanfirstlocation.Then sample 1 at location 3, the value is 123 HV. And it is the highestvaluethancomparetofirstandsecondlocation.

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

We are fix a first location for hardness testing in sample2. Aftertestingthesample2attheloadof0.5kgfwithdiamond intender, the first location value is 113.4 HV. Now we are going to fix second location for finding better results. As sample 2, at location 2, we get the value of 127 HV. The secondlocationhasbithighervaluethanthefirstlocation. Thensample2atlocation3,thevalueis142HV.Anditisthe highestvaluethancomparetofirstandsecondlocation.

SampleI.

By base metal of 90% Aluminium alloy 7075 and reinforcementof8%TiO2and2%Eggshellhasthemaximum hardness values when compare to By base metal of 90% Aluminiumalloy7075andreinforcementof6%TiO2and4% Eggshell.

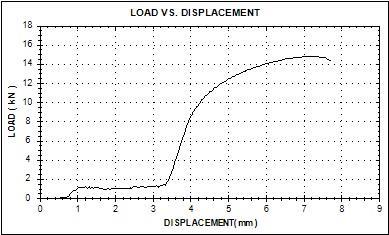

Thetestingsample8x30mmdimensionhasbeenmachined. The sample is fixed in to the Universal Testing Machine(UTM). Manual control switch is ON and the compressionloadisappliedtothesample.Duetotheeffect ofappliedloadthesamplegetsdeformed.Whenitgetsattain maximum,samplegetsreducedinitsoriginallengthandthe readingshasbeendisplaypanelofUTMmachine.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

1

2

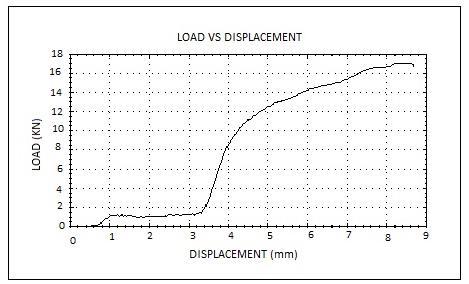

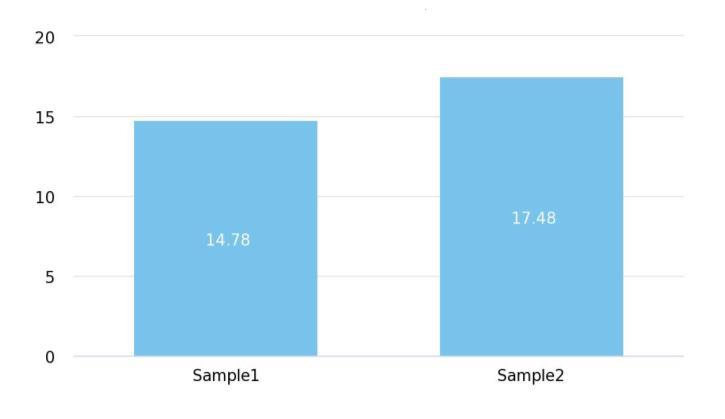

Atthesample1,theinitialareaisbecome51.02mm2 where as for sample 2 the initial area is 50.04mm2. The slightly different may occur in the area of the samples due to the increasewithincreasein%ofthereinforcement.Withthe maximum stress of 0.29 kN/mm2, the ultimate load withstandsbythesample1is14.79kNwiththemaximum displacementof7.71mm.Compressiontestingisoftendone toabreak.Therefore,thebreakingloadofthesample1isto 14.33kN. After the compression test conducted on the sample 1, the final gauge length is 25.52mm.With the maximum stress of 0.35 kN/mm2, the ultimate load withstandsbythesample2is17.48kNwiththemaximum displacementof8.63mm.Andthemaximumbreakingloadof the sample 2 is to 17.25 kN. After the compression test conducted on the sample 1, the final gauge length is 24.34mm.

13 Graph plotted against load and displacement for sample 1

Figure 14 Graph plotted against load and displacement for sample 2

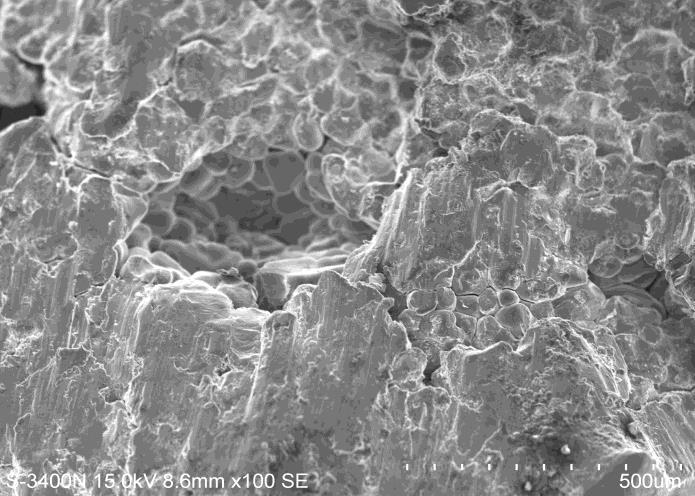

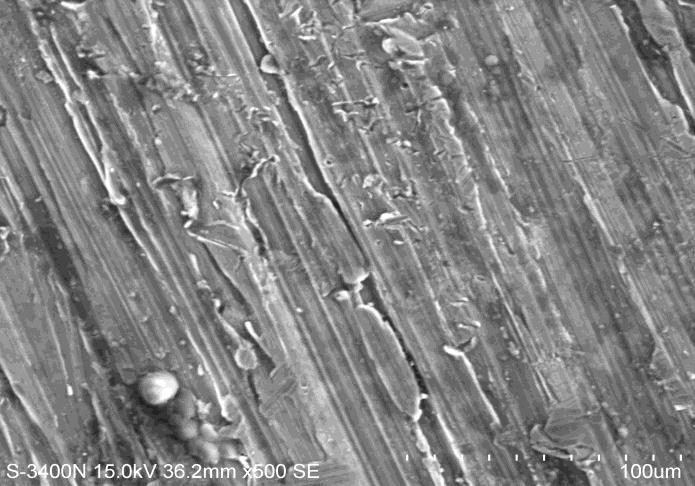

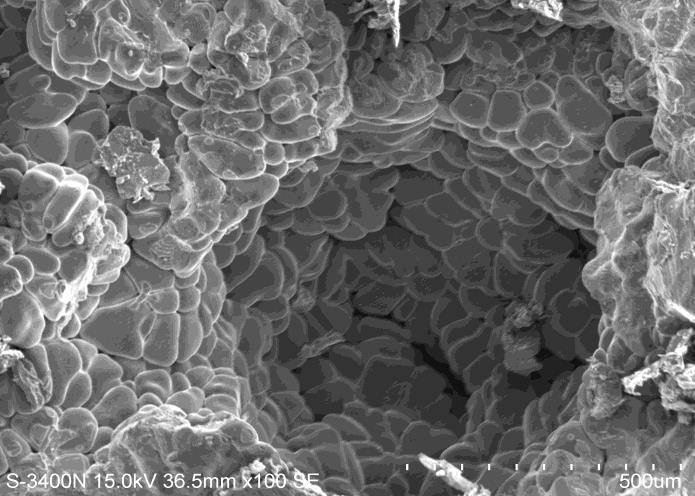

SCANNING ELECTRON MICROSCOPY ANALYSIS

A scanning electron microscope (SEM) generates detailed imagesbydirectingaconcentratedelectronbeamoverthe specimen. The beam interacts with the sample’s atoms, releasing signals that reveal surface structure and composition.

17 Micrograph of sample containing Al 90% + TiO2 6% + Egg shell 4% (100μm)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

18

19

20

The significant conclusions of experiment on Aluminium alloy7075,Titaniumdioxide,andEggshellhybridcomposite wereasfollows.

The stir casting techniques were successfully performedinthepreparationofAluminiumalloy 7075,Titaniumdioxide,andEggshell.

AddingreinforcementmaterialstotheMMCsled toenhancedhardnessandcompressivestrength properties.

ThebestaveragevalueofHardnesscomesoutto be of sample containing 90% Aluminium alloy 7075andreinforcementof8%TiO2 and2%Egg shell.i.e.,142.0HV.

ThebestaveragevalueofCompressioncomesout tobeofsamplecontaining90%Aluminiumalloy 7075andreinforcementof8%TiO2 and2%Egg shell.i.e.,17.48kN.

The micro structure and the SEM results reveal that the Egg shell and Titanium dioxide reinforcementisproperlyandevenlydistributed in the matrix phase and has a good bonding between the reinforcement particles and the aluminiumalloy7075.

From the studies in overall it can be concluded thatAluminium7075,TitaniumdioxideandEgg shell composite exhibit comparatively higher mechanicalproperties.

[1] L. Subash, U. Natarajan. Investigation of Egg shell and AluminaReinforcedwithMagnesiumMatrixComposite. InternationalJournalofInnovativeScienceandResearch Technology.

[2] Anjali,RaziaMalik,ShivaniBhandari,AnkurPant,Arpit Saxena, Seema, Nitin kumar, Nikhil Chotrani, Dheerah Gunwant,P.L.Sah.,FabricationandMechanicalTesting of Egg shell Particles Reinforced Al-Si Composites. InternationalJournalofMathematical,Engineeringand ManagementSciences.

[3] Mahendra K.C., Rahul David B, Virupaksha Gouda H, Channaveera Swamy J.M., A comparative analysis of wearandhardnesscharacteristicsusingFSWonTiO2 reinforced AL alloys, International Journal of EngineeringResearchandTechnology.

[4] Hashmi, Dr L Looney, The Production of metal matrix compositesUsingthestir casting technique, Schoolof

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

MechanicalandManufacturingEngineeringDublinCity UniversityIreland,August,1999

[5] Yasothai R, Kavithaa N.V.(2014), Eggshell waste is a calciumsourceforlayers:Review,InternationalJournal ofScience,EnvironmentandTechnology,

[6] Surappa M.K. (2003), Aluminium matrix composites: challengesandopportunities.Sadhana.

[7] Paul I. A, Bem N. G, Justine N. L and Joy O. N. Investigation of egg shell waste as an enhancer in the carburization of mild steel. American Journal of MaterialsScienceandEngineering.

[8] HuntonP. (2005).Research on eggshell structureand quality: an historical overview. Revista Brasileria de CienciaAvicola.

[9] Hassan S. B and Aigbodion V. S. (2015). Effects of eggshellonthemicrostructuresandpropertiesofAl-CuMg/eggshell particulate composites. Journal of King SaudUniversity-EngineeringSciences.

[10] Vikasverma,Nishant,Mandeepgill,etal,(2018),Effects of waste eggshells and Silicon carbide addition in the synthesisofaluminiumalloy6061hybridgreenmetal matrix composite, International Research Journal of EngineeringandTechnology

[11] ShashiPrakash,NagendraKumar,Manish(2019).Effect of Uncarbonized Egg shell weight Percentage on mechanicalpropertiesofcompositematerialdeveloped byElectromagneticstircastingTechnique,International InformationandEngineeringTechnologyAssociation.

[12] www.sciencedirect.com