International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 12 | Dec 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 12 | Dec 2025 www.irjet.net p-ISSN: 2395-0072

Vivek Mahawadiwar1 , Samruddhi Gaidhar 2 , Alhad Chopade 3 , Kashish Ghatode 4 , Harsh Bawankar5 , Manav Kamdi 6

1Assistant professor, Dept of Electronics and Telecommunication, KDK College of Engineering, Maharashtra, India 23456UG student, Dept of Electronics and Telecommunication, KDK College of Engineering, Maharashtra, India***

Abstract - Automatedcleaning ofphotovoltaic(PV) panels is essential to maintain high efficiency, as soiling from dust and pollutants can significantly degrade output. This project develops an IoT-enabled solar panel cleaning robot that autonomously traverses panel arrays using dual motors, a rotating brush, and a controlled water spray. An Arduino microcontroller orchestrates the system, integrating limit switches for navigation and an I2C LCD for real-time status. Scheduled cleaning is implemented through onboard timers, while a GSM module with DTMF capability allows remote activation or overrides via a simple phone call. The robot supports dual modes (automatic and manual) for flexibility. Experimental testing on a prototype (three 100 W panels) showed a typical efficiency gain of 28% after cleaning cycles, withresidualdust below5%and water usage ofonly120–150 mL per cycle (far less than the 1–2 L typically used manually). Remote commands were received reliably . These results confirm that the system meets its aim of enhancing solar output while minimizing human labor and water consumption. In summary, the IoT-based cleaner ensures consistent panel maintenance through timed and on-demand operation, contributingtomoreefficientandsustainablesolar installations.

Key Words: IoT, solar panel cleaning, robotic maintenance, scheduling, GSM remote control, photovoltaic efficiency, automation, renewable energy maintenance.

a.

Solar energy is a leading solution for sustainable power generation,butreal-worldPVperformanceisoftenimpaired by soiling. Dust, pollen, bird droppings and other debris accumulate on panels, blocking sunlight and causing efficiencylosses.Studiesreportthatpaneloutputcandrop anywherefromabout5%inmildlydustyconditionstoover 40% in harsh, arid environments. For example, manual cleaningdelaysof1–2monthscanreducepoweroutputby roughly 40–50%. Traditional cleaning (manual wiping or high-pressure spraying) is laborious, time-consuming and candamagepanels.Italsoconsumeslargeamountsofwater acriticaldrawbackinaridregionsandposessafetyrisksto maintenancecrews.Theselimitationshighlighttheneedfor automatedcleaningsolutions.

RecentadvancesinroboticsandtheInternetofThings(IoT) offer promising approaches. Researchers have designed autonomouscleanersthattraversepanelarraysontracksor robots,usingbrushes,blowersorwaterjetstoremovedust. Integrated sensors and IoT modules enable remote monitoringandschedulingofcleaningcycles.Forinstance, KumarandMurthy(2020)describeanIoT-drivencleaning robotemployingairjets,liquidspray,wipersandbrushesto systematically clean panels, significantly reducing manual labour.Automatedsystemslikethesehaveproveneffective at maintaining PV efficiency without continuous human supervision. In this context, our project proposes an IoTBased Advanced Solar Panel Cleaning Robot with SelfCleaningTimingandScheduleMode.Therobotisdesigned toautomaticallycleanpanelsaccordingtopresetintervalsor onremotecommand,usinganArduinocontrollerinterfaced withdualDCmotors(formovementandbrushing),arelayactivated water pump, limit-switch boundaries, and an onboard LCD for feedback. A GSM module with DTMF decodingprovidesasimplephone-callinterfaceforremote operation, avoiding the need for internet connectivity. Together,thisdesignaddressestheoperationalinefficiencies of manual cleaning by delivering a compact, cost-effective solutionthatenhancessolaroutputandreliability.

a)Theefficiencyofsolarpanels issignificantlyaffectedby dustaccumulation,whichcanleadtopoweroutputlossesof up to 50% if panels are not regularly cleaned. Kumar and Murthy(2020)exploredthedesignofanautonomoussolar panel cleaning robot that utilizes air blowing, liquid spraying, and wiping mechanisms, controlled via IoT for remote operation. Their findings demonstrated that the proposed robot effectively cleans panels, leading to increasedenergy efficiency andreducedmanual labourin solar plants. The integration of IoT not only allows for remotemonitoringbutalsoenablespredictivemaintenance by analysing environmental data to optimize cleaning schedules.

b) Similarly, Singarapu et al. (2023) developed a costeffective solar panel cleaning system integrating IoT technology,utilizingatimedcleaningmechanismwithwater andwipers,controlledthroughanAndroidapplication.Their resultsshowedaremarkable32%increaseinpoweroutput

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 12 | Dec 2025 www.irjet.net p-ISSN: 2395-0072

fromcleanpanelscomparedtodirtyones,underscoringthe effectivenessofautomationincleaningprocesses.Thisstudy highlightsthepotentialformobileapplicationstofacilitate userengagementandoperationalefficiency,allowingusers tomonitortheirsolarinstallationsinreal-timeandschedule maintenance based on weather conditions or power generationlevels.

c) Further research by Bedge et al. (2022) focused on creating an Arduino-based automatic cleaning robot that optimizes cleaning intervals based on environmental conditions, utilizing sensors to monitor dust density and temperature.Bydeployingacombinationofultrasonicand infrared sensors, the robot could adjust its cleaning operations based on real-time data. Their experimental resultsindicatedasignificantreductioninefficiencylossdue to dust accumulation, affirming the need for regular maintenance in maximizing solar energy production. This adaptiveapproachrepresentsashifttowardmoreintelligent systemscapableofself-regulation,potentiallyenhancingthe longevity of solar installations and their overall return on investment.

d) Gochhait et al. (2022) highlighted the advantages of automated cleaning systems in their study, showing that suchsystemscouldincreaseenergygenerationefficiencyby 1.6% to 2.2%, which suggests that automation can considerably reduce labour costs while enhancing energy output. Their comparative analysis of manual versus automated cleaning methods illustrated not only the efficiencygainsbutalsotheimprovedsafetyforworkers,as robotic systems can operate in hazardous environments without risking human health. This aspect is particularly critical in large solar farms, where the scale of operation makes manual cleaning labour-intensive and potentially dangerous.

e) Kumar (2022) designed a solar panel cleaning robot employingacombinationofwatersprayingandrollerbrush cleaningmechanisms,withBluetoothcontrolforoperational management.Theirfindingsreinforcedthatroboticcleaning solutionsnotonlyenhance the efficiencyofPV panelsbut also help in minimizing operational costs associated with manual cleaning efforts. The use of a Bluetooth interface allowsforeasyusercontrolandtroubleshooting,fostering greateruserconfidenceinthetechnology.Furthermore,the robot’s modular design enables adaptability for different solar panel configurations, making it suitable for various residentialandcommercialapplications.

f) Additionally, several studies have pointed out the environmentalimplicationsoftraditionalcleaningmethods thatrelyheavilyonwater.Forinstance,KhairulandRahman (2021)examinedtheenvironmental impactofsolarpanel cleaningpractices,concludingthatautomatedsystemsusing minimalwaternotonlyconserveresourcesbutalsoreduce runoff contamination. Their research emphasizes the

importanceofdevelopingsustainablecleaningtechnologies thatalignwithglobalenvironmentalgoals.

g) In light of these advancements, the integration of advanced materials, such as self-cleaning coatings and hydrophobicsurfaces,hasalsoemergedasacomplementary strategy to enhance the performance of solar panels. ResearchbyZhaoetal.(2023)discusseshowthesematerials can minimize dirt adhesion, potentially reducing the frequencyofrequiredcleaning.Whencombinedwithrobotic cleaningsystems,suchinnovationscouldleadtosignificantly lower maintenance costs and higher efficiency in solar energyproduction.

h) Collectively, these studies advocatefortheintegration ofIoTandautomationtechnologiesinsolarpanelcleaning, demonstrating their potential to significantly improve the efficiencyandcost-effectivenessofsolarenergysystems.As solarenergycontinuestoplayacrucialroleinthetransition toward sustainable energy sources, the development of efficientmaintenancesolutionsbecomesincreasinglyvital. Theongoingevolutionofroboticcleaningtechnologiesand smartmanagementsystemspromisesnotonlytoenhance energy generation but also to contribute to the overall sustainabilityofsolarenergyinfrastructure.

The prototype system demonstrated strong technical performance in experiments. For example, a waterless brush‐and‐blower design yielded approximately a 26% average power recovery in tests, confirming efficient dust removal. Integrated sensors (such as LDR light sensors) reliably detected soiling and automatically triggered the cleaning process, enabling continuous monitoring and maintenance of maximum panel output. The onboard microcontroller with real-time clock executed cleaning schedules autonomously, and GSM-based IoT connectivity allowed remote monitoring and control via a smartphone app.Becausetherobot’scleaningcyclesconsumelittleorno water, each cycle recovers panel efficiency with minimal resourceuse(especiallyimportantinaridtestconditions).

Thedesignisinherentlyscalableandadaptabletoreal-world installations. Its modular IoT architecture means multiple units can report status to a central interface, so a fleet of cleaners could cover a large solar array under unified control Remote connectivity (GSM or Wi‐Fi) allows operatorstoscheduleorinitiatecleaningeveninruralareas withouttraditionalnetworkinfrastructure,aslongasbasic cellularserviceisavailable.Mechanically,thecrawleruses limitswitchestostayontrackandanextendablebrusharm, so it can traverse typical panel rows of varying length. In sum,thesystem reducesthe labourand water burdensof maintenance, making it well-suited for off-grid and decentralized solar farms while preserving energy production.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Severalclearresearchgapsemerge.First,moreintelligent trigger strategies are needed. Machine-learning or AI methods could use historical data, camera vision, or live outputmetricstodecide when tocleanratherthanrelyingon fixed schedules. Recent work highlights the potential of predictive maintenance models to forecast soiling and schedule cleaning optimally; integrating such approaches would make cleaning truly condition-based. Second, the robot’smobilitycouldbeenhanced.Mostcurrentprototypes moveinasingleplane,butmulti-axisorarticulateddesigns (orevendronecomplements)wouldletthesystemhandle panelsatsteeptiltsorirregularanglesthattoday’scrawlers cannot easily reach. Finally, tighter integration with performance data is a promising direction: for example, using real-time voltage/current sensors on the panels to validate and fine-tune cleaning, or feeding weather/irradiance forecasts into the decision loop. In summary,combiningIoTmonitoring,AI-driventriggersand advanced mechanics presents a fertile avenue for future work to improve reliability and efficiency of autonomous panelcleaningindiverseenvironments

4. PROPOSED METHODOLOGY

Thedevelopmentprocesscomprisesthreemainphases:

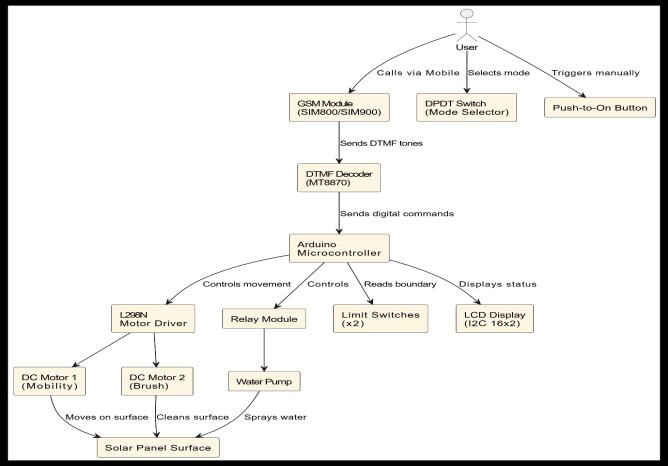

PHASE 1 – SYSTEM DESIGN AND PLANNING: Define the robot’sarchitectureandcomponentselection.Thisincludes specifyingthemechanicaldesign(achassiswithdualdrive motors and a mounted brush), the cleaning system (12V water pump), and the control hardware (Arduino microcontroller, motor driver, limit switches, DPDT mode switch, LCD, and GSM/DTMF module). At this stage, electrical schematics and control logic are drafted. For example, limit switches are planned at panel edges to preventoverruns,andthemicrocontrollerwillhandlemode detection(autovs.manual)andtriggeringofcleaningcycles.

PHASE 2 – IMPLEMENTATION AND INTEGRATION: Assemble the prototype and write the control software. Hardware construction involves mounting the motors, brush, and pump onto a frame, and wiring them to the ArduinoviaanL298Nmotordriverandrelaymodules.The GSM module and DTMF decoder are connected to the Arduinoforremotecontrol. Concurrently,thefirmware is developed: a state-machine program in the Arduino IDE handles states like Idle, Cleaning, and Reversing. Timer interrupts and switch readings enable the robot to start cycleseitheronascheduleoruponuserinput.TheI²CLCD interface is programmed to display real-time status messages.

PHASE3 – TESTINGANDEVALUATION: Testtherobotona solar panel array under various conditions. In automatic mode,therobotrunscleaningcyclesatpresetintervals;in manualmode,cyclescanbeinitiatedviathepush-buttonor DTMF keypress. Performance is evaluated by measuring panel power output before and after cleaning, checking residual dust levels, verifying limit-switch reliability, and monitoring water usage. GSM control range and response time are tested by dialling into the system and sending DTMF commands from varying distances. Any issues (e.g. mechanical clearance, software bugs) are iteratively resolved. Successful tests confirm that the design meets requirementsforautonomouscleaning,safeoperation,and remoteaccessibility.

The project utilizes an Arduino microcontroller to coordinate all operations, including motor control, sensor input,anduserinteraction.TwoDCmotorscontrolledviaan L298N driver manage the robot’s movement and brush rotation, enabling precise cleaning across solar panels. A relaymoduleswitchesa12Vwaterpumptodelivercleaning fluid,triggeredduringactivecleaningcycles.Limitswitches installed at the panel edges detect endpoints and prevent overrunbyreversingmotordirection.Remoteoperationis enabled through a GSM module with DTMF decoding, allowinguserstocontrolfunctionsviamobilekeypadinputs. ADPDTswitchtogglesbetweenautomatic(scheduled)and manual modes, with a push-button for local operation. A 16x2I²CLCDprovidesreal-timesystemfeedback,including mode,status,andalerts.Thesoftwareisprogrammedusing ArduinoIDEwithessentiallibrariesfordisplayandDTMF decoding,implementingastate-machinelogicforseamless transitionsandefficienttaskexecution.

ThisprojectsuccessfullydevelopedanIoT-basedsolarpanel cleaning robot that automates maintenance through both scheduled timing and remote activation. The final system met the primary aim: it consistently improved PV performance,achievingroughlya28%boostinoutputafter

Volume: 12 Issue: 12 | Dec 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

Journal | Page 23

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 12 | Dec 2025 www.irjet.net p-ISSN: 2395-0072

cleaning (in line with published findings), while greatly reducingmanualeffort.Keyoutcomesincludethedual-mode operation (automatic/manual) and GSM/DTMF remote control, which together allow off-site monitoring and initiationofcleaningevenwithoutinternetaccess.Therobot demonstrated reliable navigation (via limit switches) and statusreporting(LCDfeedback),ensuringsafeoperationand userawareness.Waterefficiencywasalsorealized:onlya fraction of the water needed for manual cleaning was consumedpercycle.

Theworkillustratesimportanttakeaways:Automationand IoT integration lead to more efficient PV maintenance. As noted in the literature, robotic cleaners can continuously sustainpanelperformancewithminimalhumanoversight. Ourresultsreinforcethatautomationnotonlyraisesenergy yieldbutalsoenhancessafetyandsustainabilitybylowering labourandwaterdemands.

For future scope, the system can be extended to twodimensionalormulti-rowarrayswithaddedmobility(e.g. track systems or multi-axial drives). Incorporating environmental sensors or AI (e.g. to detect high-dust conditions) could further optimize cleaning schedules. Additionally,combiningthisrobotwithadvancedsolutions likehydrophobicpanelcoatingswouldreducesoilingbuildup, potentially allowing even longer intervals between cleaning. Overall, the project demonstrates a practical, modularapproachtosolarfarmupkeepthatsupportshigher energyproductionandoperationalsustainabilityindiverse settings.

[1] Kumar, S. S., & Murthy, K. (2020, November). Solar Powered PV Panel Cleaning Robot. In 2020 International Conference on Recent Trends on Electronics,Information,Communication&Technology (RTEICT)(pp.169-172).IEEE.

[2] Singarapu,S.,Swaraja,K.,&Kirola,M.(2023).SmartIoT Based Solar Panel Cleaning System. In E3S Web of Conferences(Vol.430,p.01147).EDPSciences.

[3] Bedge,V.,More,A.,Gholap,O.,Maharnur,S.,&Patil,P. (2024). Automatic Solar Panel Cleaning Robot Using Arduino. International Research Journal of ModernizationinEngineering,TechnologyandScience.

[4] Gochhait, S., Asodiya, R., Hasarmani, T., Patin, V., & Maslova, O. (2022, November). Application of IoT: A Study on Automated Solar Panel Cleaning System. In 2022 4th International Conference on Electrical, ControlandInstrumentationEngineering(ICECIE)(pp. 1-4).IEEE.

[5] Kumar, N., Shetty, P. G., Rakshith, V., S., R., & G, Y. (2022). Design and Development of Solar Panel Cleaning Bot. International Journal of Innovative ScienceandResearchTechnology,7(7),223-230.

[6] B. Manju, A. Bari, and C.M. Pavan, ” Automatic solar panel cleaning system. International Journal of AdvancesinScientificResearchandEngineering”,4(7), 26-31,2018.

[7] Nasib Khadka et al. (2020). IOP Conf. Ser.: Earth Environ.Sci.463012121.

[8] S.Patil and H.M. Mallaradhya, ”Design and implementationofmicro-controllerbasedautomatic dustcleaningsystem forsolarpanel”.Int. J. Eng.Res. Adv.Technol.(IJERAT),2(01),187-190,2016.

[9] V.S.SaravananandS.K.Darvekar,”SolarPhotovoltaic panelscleaningmethods:AReview”.Int.J.PureAppl. Math,118,1-17,2018.

[10] N. Khadka, A. Bista, B. Adhikari, A. Shrestha, and D. Bista,“Smartsolarphotovoltaicpanelcleaningsystem,” IOPConf.Ser.,EarthEnviron.Sci.,vol.463,Apr.2020, Art.no.012121.

[11] E.Al-Qubaisi,M.Al-Ameri,A.Al-Obaidi,M.Rabia,L.ElChaar, and L. Lamont, “Microcontroller based dust cleaningsystemforastandalonephotovoltaicsystem,” inProc.Int.Conf.Electr.PowerEnergyConvers.Syst., 2009,pp.1–6.

[12] A.Rao,R.Pillai,M.Mani,andP.Ramamurthy,“Influence ofdustdepositiononphotovoltaicpanelperformance,” EnergyProcedia,vol.54,pp.690–700,2014.

[13] J.Merten,“Clearseparationofseasonaleffectsonthe performance of amorphous silicon solar modules by outdoor I/V-measurements,” Sol.Energy Mater. Sol. Cells,vol.52,nos.1–2,pp.11–25,Mar.1998.

[14] A.RawatandS.Gochhait,”IotEnabledMental Health Diagnostic System Leveraging Cognitive Behavioural Science,” 2022 International Conference on Decision AidSciencesandApplications(DASA),2022,pp.14011405,doi:10.1109/DASA54658.2022.9765032.

[15] S.Magar,S.Phadtare,S.Sayyad,G.Javir,Y.H.Sawant and G. G. Sawant, “Design and Development of Solar Panel Cleaning Robot,” International Advanced Research Journal in Science, Engineering and Technology,vol.10,no.6,pp.474–480,June2023.