International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Priya S. Sontakke1, Shiwani Rasekar 2 , Vishal Pimpalkar3

1P.G Student of Electrical Engineering Department, Ballarpur Institute of Technology, Ballarpur, India

2Assistant Professor of Electrical Engineering Department, Ballarpur Institute of Technology, Ballarpur, India

3Assistant Professor of Electrical Engineering Department, Ballarpur Institute of Technology, Ballarpur, India

Abstract - This Project focuses on the Simulation based Study of a three phase three-level Diode Clamped Multilevel Inverter (DCMLI), displaying eight switches and combining a closed-loop Voltage-to-Frequency (V/f) feedback strategy for the performance of three-phase squirrel cage induction motors. TheSpaceVector PulseWidthModulation(SVPWM) technique is used to analyze the implementation of the system through both simulation and experimental validation, utilizing MOSFETs as the switching devices. The V/f control loop make sure a stable voltage-to-frequency ratio, supporting steady motor operation over different speed ranges. Instantaneously to check data provide essential insights into the system's behavior, aiding in the development of energy-efficient and precise motor control solutions. Keyperformanceparameters, like TotalHarmonic Distortion (THD), power factor, dynamic response and efficiency are assessed across various operating conditions. The results of this research contribute to the enhanced implementation of multilevel inverters in industrial motor driveapplications.

Key Words: Diode Clamped Multilevel Inverter (DCMLI), V/fClosedLoop,SVPWM,MatlabSimulation

As industrial applications continue to evolve, the demand for motor control systems that are efficient, reliable, and precise is increasing rapidly. Among the various types of power electronic converters, multilevel inverters have become a preferred choice for medium and high-power applications due to their ability to produce high-quality output waveforms, with lower harmonic distortion and reducedswitchinglosses.

This study focuses on the Three-level Diode Clamped Multilevel Inverter (DCMLI) with eight switches, implementing closed-loop Voltage/Frequency (V/f) control for three-phase asynchronous induction motor drives.V/f control has long been a popular choice for industrial motor control due to its simplicity and reliability.Bymaintaininga constantvoltage-to-frequency ratio, this technique ensures proper motor magnetization acrossvariousspeedranges,preventingproblemssuchas over-fluxing at low speeds and under-fluxing at high speeds. The use of a closed-loop feedback system further

enhances the stability and dynamic response of the system, improving its performance under different load conditions.

While conventional two-level inverters have been widely used in industrial motor drive systems, they have notable drawbacks, such as high harmonic distortion, electromagnetic interference, common-mode voltage issues,andincreasedswitchingstress.Multilevelinverters provide a solution by generating AC output voltages from multiple DC voltage levels, which significantly reduces these limitations. The Three-level DCMLI strikes an optimal balance between performance improvements and system complexity, making it particularly suitable for medium-powermotordriveapplications.

Thisresearchcontributestothedevelopmentofoptimized motordrivesystems,focusingonenergyefficiency,power quality, and reliability key concerns in industrial applications. By analyzing the performance of the Threelevel DCMLI using closed-loop V/f control and Space Vector modulation, the study offers valuable insights for engineers and system designers in industries such as manufacturing automation, HVAC, water pumping, and renewableenergysystems

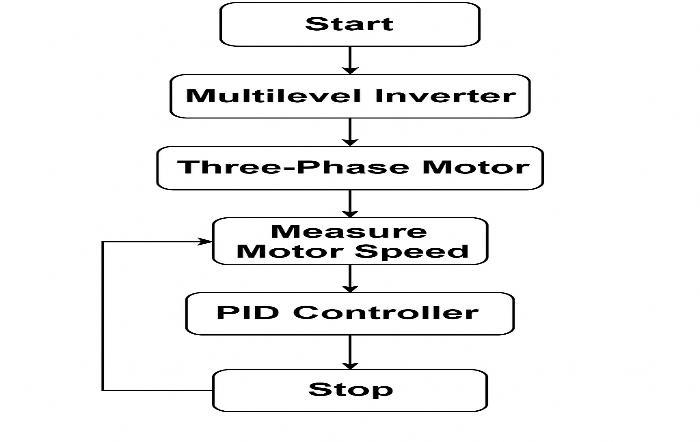

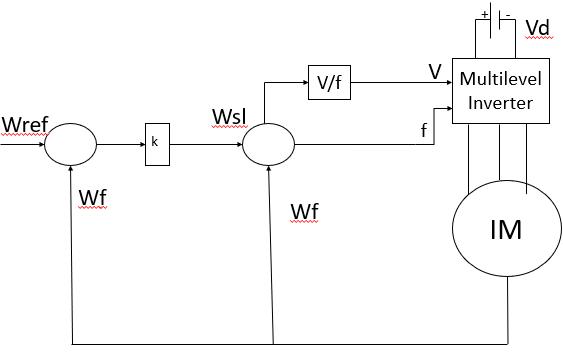

Fig1showstheflowchartofsystem

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

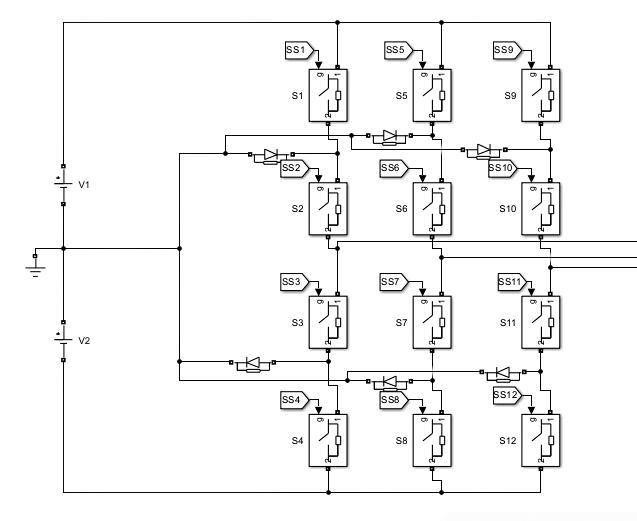

A Diode Clamped Multilevel Inverter is a device that changesDCpower(likefromabatteryorsolarpanel)into AC power, which gives a smoother and better-quality output.It’scalleddiodeclampedbecauseitusesdiodesto control thevoltagelevels.Thesediodesclamporlimitthe voltage so that the switches used in the inverter are not damaged by high voltages. This makes the inverter safer andmorereliable.

Fig1.ThreelevelDiodeClampedMLI

Figure 1 illustrates a three-phase, three-level DiodeClamped Multilevel Inverter (DCMLI), which features three inverter legs linked to a common DC bus. This DC busvoltageisevenlysplitusingaseriesofcapacitors.Each clamping diode in the circuit is designed to withstand a voltage determined by the number of switches above it, scaledbytheinputDCvoltage.Inageneral n-levelDCMLI structure, each leg includes (n−1) capacitors and (n−2) clamping diodes. To operate each leg, 2(n−1) switching devices are required. Specifically, in a three-level system, there are 12 power switches typically denoted as S1, S2, S5, S6, S9, S10, along with their complementary switches S3, S4, S7, S8, S11, and S12. The DC bus employs two capacitors,identifiedasC1andC2,whileeachlegcontains two clamping diodes, resulting in a total of six diodes for the entire inverter. These diodes play a critical role in regulating the voltage across each switch, allowing the inverter to generate a stepped AC output waveform as showninfig2.

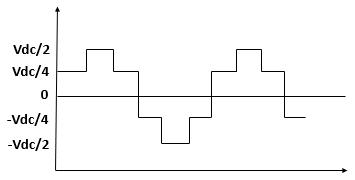

Fig.2outputwaveformof3leveldiodeclampedMLI

Advantages

BetterOutputQuality

TheoutputACvoltageissmootherandclosertoa sinewave.

Thisreducesnoiseandimprovesperformance.

LowerHarmonics

It produces less unwanted frequencies (called harmonics), which helps protect motors and devices.

ReducedVoltageStress

Eachswitchhandlesonlypartofthetotalvoltage, soitlastslongerandislesslikelytogetdamaged.

HighEfficiency

Lessheatisproduced,solessenergyiswasted.

SuitableforHighPower

Ideal forlargesystemslike factories, solarplants, andelectricvehicles.

ModularDesign

Easytoexpandtomorelevelsforbetteroutput.

Demerits(Disadvantages)

MoreComponentsNeeded

Needs many switches, diodes, and capacitors, whichmakesthedesignmorecomplex.

DifficulttoControl

More levels mean more control signals and complicatedcontrolsystems.

UnequalCapacitorVoltageBalancing

It can be hard to keep the voltage levels equal acrossallcapacitors.

BulkySize

Because of the extra parts, the inverter can be largerandheavier.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Morepartsandcomplexityleadtoa

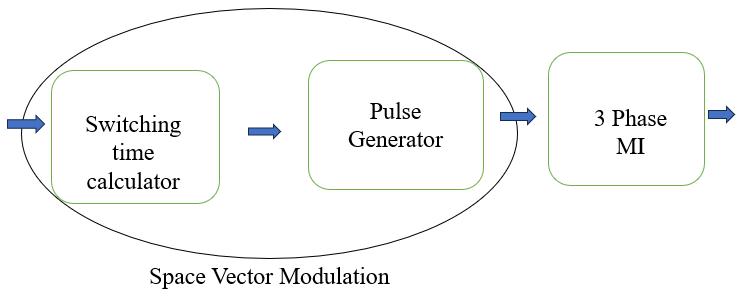

Fig.3 Blockdiagramofaspacevectormodulation

ThisdiagramoutlinestheprocessofconvertingaDCinput into a balanced three-phase AC output using a method called Space Vector Modulation (SVM) and a three-phase inverter. It involves three main stages: signal generation, modulation, and power conversion shown in fig.3.At this stage, the desired three-phase voltage waveforms are created typically sine waves for each phase A, B, and C. These waveforms represent the target output voltages that the system aims to produce at the end. Space Vector Modulation Block is responsible for converting the reference signals into switching commands for the inverter. Switching Time Calculator block calculates the exact timing for turning on and off the switches in the inverter. It works by comparing the reference voltages to available voltage vectors in the inverter to approximate the desired output. Once the switching times are calculated, Gate Pulse Generator generates gate signals (pulses) for the inverter switches . These signals ensure the power devices operate in the correct sequence to produce the intended output waveform. The inverter is madeup ofsixswitchesorganizedinto threelegs,onefor each phase. The output is shaped according to the modulation strategy to closely follow the reference waveforms. After modulation and switching, the inverter outputsthreesinusoidalvoltages,each120degreesapart. These outputs can then be used to drive AC loads like motors or industrial equipment. It efficiently manages switching to deliver smooth, sinusoidal AC power from a DCsupply.Fig.4showsthesimulationofSVPWM.

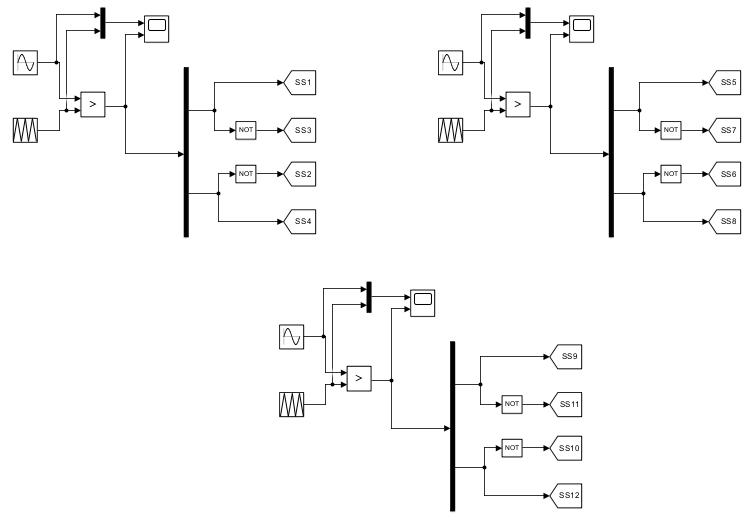

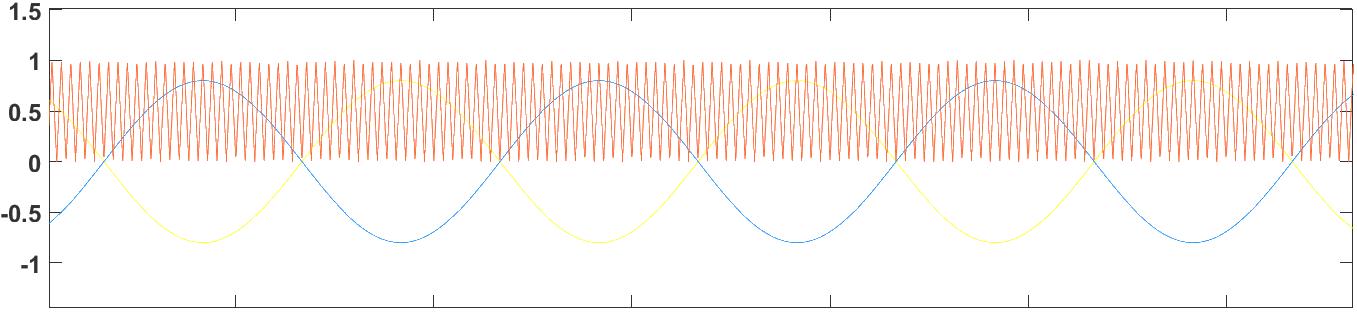

Fig4SimulationofSVPWMusingMATLAB/SIMULINK

This method facilitates the creation of a continuously rotating voltage vector that aligns with the motor control system’sperformancegoals.ThemainaimofSpaceVector Modulation (SVM) is to make sure the generated output accurately follows the reference signal during each pulsewidthmodulation(PWM)cycle,therebydeliveringreliable andhigh-efficiencymotorcontrol.

Fig5Gatepulsegenerationasaresultofcomparingthe modulationwaveandthecarrierwave.

Speed control methods for electric motors are broadly classified into two categories: open-loop control (without feedback)andclosed-loopcontrol(withfeedback).

This diagram represents a V/f (Voltage/Frequency) control system for an induction motor, specifically in an open-loop configuration. In open loop control, the system

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

doesnotusefeedbackfromthemotor.Acontrollersetthe V/f according to desired speed. The motor follow this input, but there is no correction if the speed changes due toloadasshowninfig.6.

Fig.6OpenLoopV/fControl

Closed-Loop V/f Control

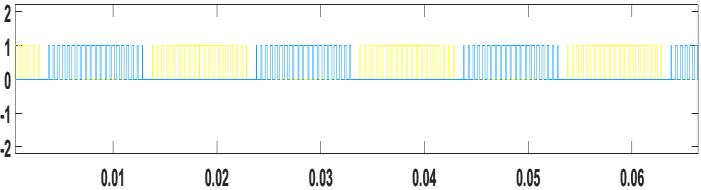

In a closed-loop voltage/frequency (V/f) control system, thespeedandtorqueofaninductionmotorarecontrolled by adjusting the applied voltage and frequency to the motor. 1.Thespeedofthe motor isdirectlyrelated to the supplyfrequency.Inthiscontrol method,thefrequencyis adjustedaccordingtothedesiredspeedofthemotor.The voltage is adjusted in proportion to the frequency to ensure that the voltage-to-frequency ratio remains constant. This prevents saturation in the motor and ensuresefficientoperationasshowninfig.7.

Fig.7ClosedLoopV/fControl

Afeedback loopcontinuouslymonitorsthemotor'sactual speed, typically using a tachometer or encoder. The feedback is compared with the reference speed, and any deviation from the desired speed triggers adjustments in the frequency and voltage supplied to the motor. The closed-loop nature of the system means that the motor speed is continuously adjusted based on feedback,

ensuring precise control and better performance, especially under varying load conditions. This approach offers smoother motor operation and improved performance compared to open-loop control, where no feedbackisused.

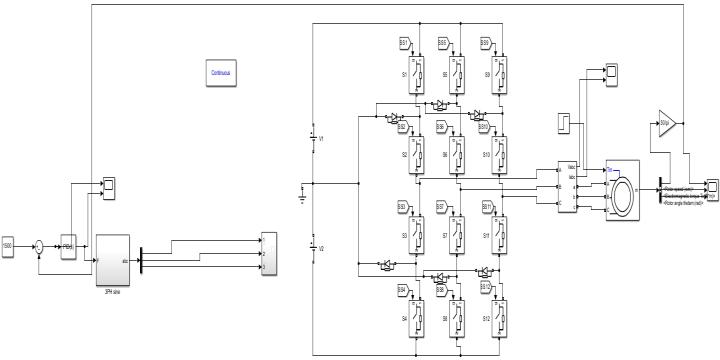

Three-level Diode Clamped Multilevel Inverter (DCMLI) with closed loop V/f driving a three-phase squirrel cage induction motor. The system start with an AC power source, rectifiedtoDCusing a diode bridge,followed by a filter to provide a stable DC bus. This DC bus is then split into three levels and fed into a DCMLI composed of 8 powerswitchesandclampingdiodes,generatingastepped three-phase AC waveform. The gate pulses for these switchesarecontrolledbySVMlogictoreduceharmonics andimprovepowerquality.AV/fcontrolloopgovernsthe output frequency and voltage according to the reference speed input, maintaining the motor’s torque stability acrossvariousspeedsasshowninfig.8.

The system includes feedback sensors for speed, voltage, and current, all feeding into the controller to ensure dynamic stability and precise speed tracking. The output drivesathree-phaseinductionmotor,andscopesareused tomonitorperformanceinreal-time.

Fig.8simulinkmodel usingMATLAB/SIMULINK

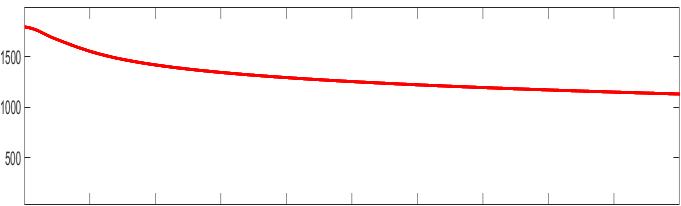

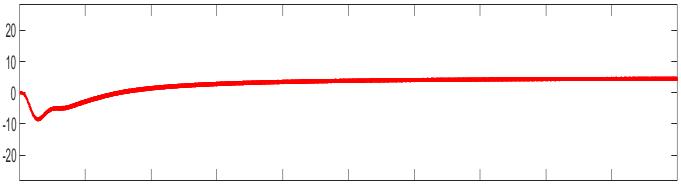

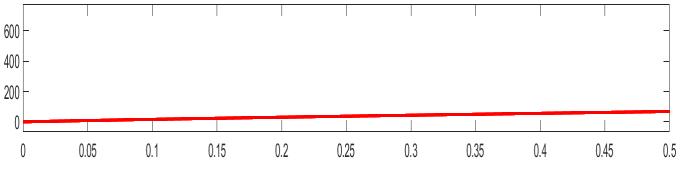

Three phase induction motor graph

The graph is given when the motor gives 10HP, 575V, 60Hz,1760RPM speed which illustrates the dynamic performance of an asynchronous motor drive system controlled by a Three-Level Diode Clamped Multilevel Inverter (DCMLI) under closed-loop V/f (voltage/frequency) control. From fig.9 the top plot represents a variable labeled as "Gain," which appears to show a controlled, monotonic decrease over time. This

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

behavior likely corresponds to a gradually decreasing reference voltage or frequency, typically applied in speed ramp-down scenarios. The smooth descent in this signal indicates stable operation without oscillatory behavior or abrupt changes. The middle plot displays the electromagnetic torque (Te) in Newton-meters. Initially, therearesignificantoscillations,withthetorqueswinging between approximately -11 N·m and +6 N·m. These transientsarecharacteristicofthemotorstartingprocess, whereitadjuststoovercomeinertiaandalignitsmagnetic fields

Fig.9showsTheThreePhaseInductionMotora)Rotor Speedb)ElectromagneticTorquec)RotorAngle

As time progresses, the torque stabilizes around a steady value near 3 N·m, suggesting that the closed-loop controller effectively dampens the oscillations and brings the motor into a controlled state with constant torque output.The bottom plot shows the rotor angle (θ) in radians. It increases linearly over time, reflecting consistentangularvelocityafterthetorquestabilizes.This linear growth indicates steady motor rotation, implying thatthesystemhasreachedauniformoperatingcondition without sudden changes in speed or torque. Overall, the graph confirms that the system achieves stable, efficient performance after initial transients, with effective damping and accurate torque regulation through closedloopV/fcontrol.

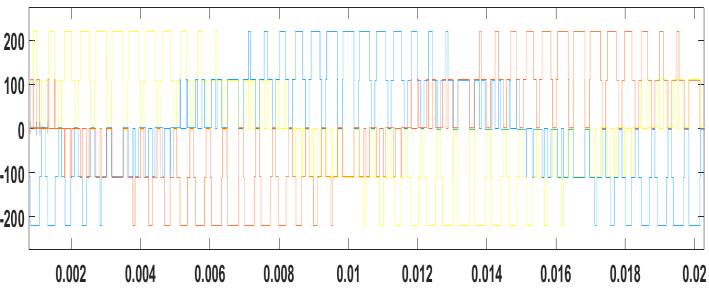

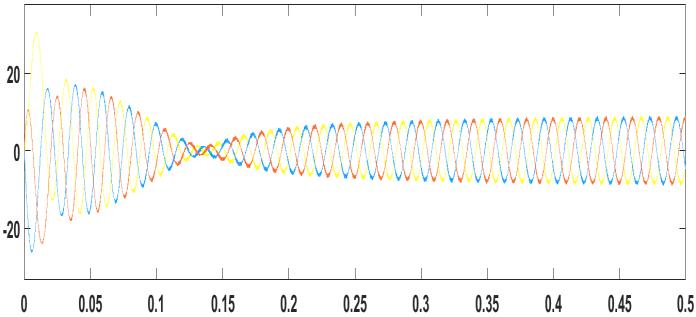

Output voltage and current waveforms comparision

Fig.10Outputvoltagefromthreeleveldiodeclamped multilevelinverter

Fig.11OutputCurrentfromthreeleveldiodeclamped multilevelinverter

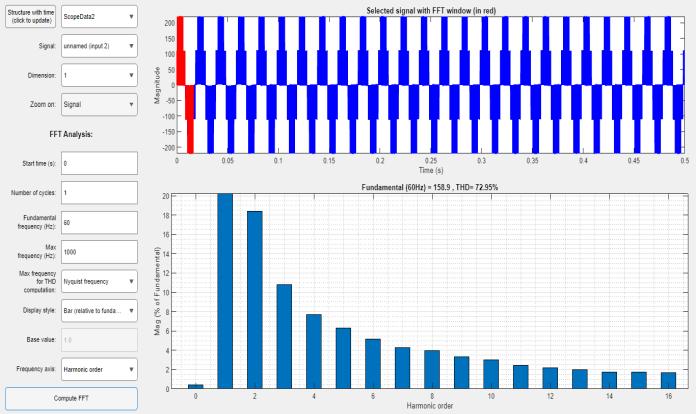

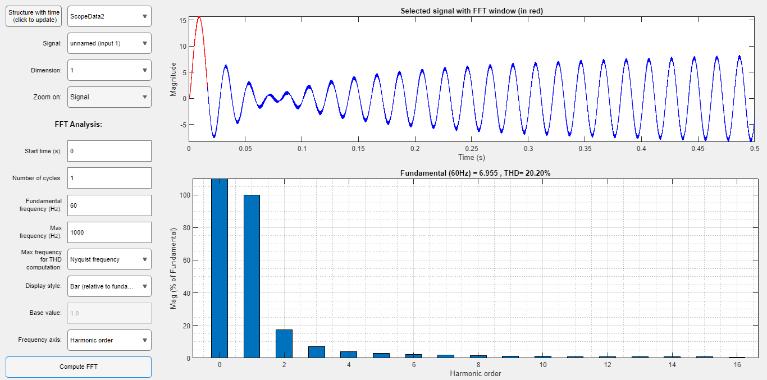

Fig.12THDforthreeleveldiodeclampedmultilevel invertervoltageoutputwithclosedloop

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Fig.13THDforthreeleveldiodeclampedmultilevel inverter currentoutputwithclosedloop

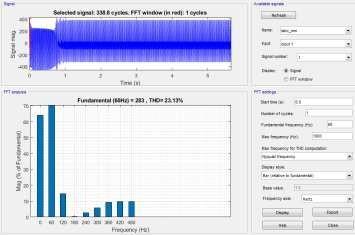

Fig.14THDforThreeleveldiodeclampedmultilevel inverterVoltageoutputwithopenloop

Output Current from three level diode clamped multilevel inverter From the given fig.10 upper graph shows the motor's three-phase stator currents, which begin with transient oscillations and then stabilize into clean, balanced sinusoidal waveforms, indicating effective control and smooth motor operation. The lower graph displays the inverter's multilevel PWM voltage output, withdistinctsteppedwaveforms

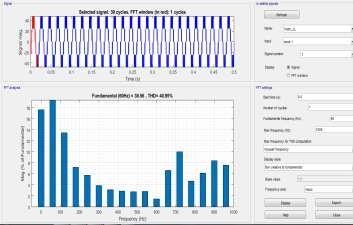

Fig.15THDforThreeleveldiodeclampedmultilevel invertercurrentoutputwithopenloop

THDdataforthreeleveldiodeclampedmultilevelinverter withclosedloopandopenloopV/fcontrol

3level DCMI THD%

ClosedloopV/fcontrol 20.20

OpenloopV/fcontrol 23.13

Table.1

From the output graph, the inverter voltage waveform fig.10 shows distinct multilevel switching patterns with levels peaking approximately at +220V and -220V verifying the stepped nature of the DCMLI, which minimizes total harmonic distortion (THD). The stator current waveforms in fig.11 for phases R, Y, and B gradually stabilize into balanced sinusoidal curves, with peak values reaching approximately ±8A after initial transientssubsidearound0.05seconds.

Fig.12 and Fig.13 shows the THD for three level diode clamped multilevel inverter voltage and current output with closed loop .Fig.14 and Fig.15 shows the THD for three level diode clamped multilevel inverter voltage and current output with open loop. This shows a comparision ofThreeleveldiodeclampedMIwithopenandclosedloop V/fcontrol.Asaresult,theClosedloopV/fControlsystem operateswithbetterpowerquality,reducedharmonicand effects lower switching losses effects, to supply of voltage and current by motor, which helps it produce smooth torqueandtomaintainproperspeedascomparedtoOpen loopV/fcontrol.

V/f controlled three-phase induction motor using a Diode Clamped Multilevel Inverter DCMLI simulation demonstrates that the multilevel inverter is highly effective in delivering high-quality voltage waveforms to the motor. The voltage waveform clearly shows multiple discrete levels, which confirms the precise control of switchingstateswithintheDCMLItopology.Theinverter's stepped output reduces harmonic content significantly compared to traditional two-level inverters, as evidenced by the smooth and symmetrical sinusoidal current waveforms observed after initial transient damping. The voltage waveform clearly shows multiple discrete levels, which confirms the precise control of switching states withintheDCMLItopology.

The stabilization of current waveforms around ±8A and the multilevel voltage profile peaking at ±220V support the effectiveness of this control strategy in providing dynamic performance and speed control. The motor reaches steady-state operation quickly, showcasing the reliability of V/f control in maintaining a constant ratio betweenvoltageandfrequencytomakesuresteadymotor

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

flux.Thecombinationofdiodeclampedmultilevelinverter with V/f control gives improving Power quality while decreasing electromagnetic interference and mechanical stressonthemotor.

1. P. R. Bana et al. "Closed-Loop Control and Performance Evaluation of Reduced Part Count MultilevelInverterInterfacingGrid-ConnectedPV System" in IEEE Transactions Digital Object Identifier 10.1109/ACCESS.2020.2987620

2. Arkan A. Kadum, "PWM control techniques for three phase three level inverter drives ," iTelecommun Comput El Control, Vol. 18, No. 1, February2020:519-529

3. Azeem A, Ansari MK, Tariq M, Sarwar, Ashraf I. DesignandModelingofSolarPhotovoltaicSystem UsingSeven-Level Packed U-Cell (PUC)Multilevel Inverter and Zeta Converter for Off-Grid Application in India. Electrica, 2019; 19(2): 101112.

4. Karaarslan, . Arifoğlu, E. Beşer and S. Çamur, "Single phase series active power filter based on 15-level cascaded inverter topology," 2017 4th International Conference on Electrical and Electronic Engineering (ICEEE), Ankara, Turkey, 2017, pp. 37-42, doi: 10.1109/ICEEE2.2017.7935789.

5. D. C. Huynh, M. W. Dunnigan, “Development and comparison of an improved incremental conductance algorithm for tracking the MPP of a solar PV panel,” IEEE Trans. Sustain. Energy, vol. 7,no.4,pp.1421-1429,2016.

6. V. Karthikeyan, R. Gupta, “Varying phase angle control in isolated bidirectional DC-DC converter for integrating battery storage and solar PV systeminstandalonemode,”IETPowerElectron., vol.10,no.4,pp.471-479,Mar.2017.

7. M. Tariq, A. I. Maswood, C. J. Gajanayake, A. K. Gupta, “Aircraft batteries: current trend towards more electric aircraft,” IET Electr. Syst. Transp., vol.7,no.2,pp.93-103,2017.

8. R. Errouissi, A. Al-Durra, S. M. Muyeen, “Design and Implementation of a Nonlinear PI Predictive Controller for a Grid-Tied Photovoltaic Inverter,” IEEETrans.Ind.Electron.,vol.64,no.2,pp.12411250,Feb.2017.