International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

S. Sneha1 , U. Vaishnavi2, J. Swathi Yadav3, Kaureen Sultana4

1Assistant professor, Electrical and Electronics Engineering, Stanley college of engineering technology for women, Telangana, India

2B.E Student, Electrical and Electronics Engineering, Stanley college of engineering technology for women, Telangana, India

3B.E Student, Electrical and Electronics Engineering, Stanley college of engineering technology for women, Telangana, India

4B.E Student, Electrical and Electronics Engineering, Stanley college of engineering technology for women, Telangana, India ***

Abstract - A key technique for increasing the efficiency of electric and hybrid vehicles in the face of the growing need for green energy is regenerative braking. This project proposes to combine the regenerative braking system (RBS) of an electric vehicle (EV) powered by an induction motor with a battery energy storage system (BESS). When the motor brakes, it converts kinetic energy into electrical energy, functioningas a generator. The DC-link voltage rises as a result, and an inverter that employs an effective switching method returns the energy to the battery. Recovered energy can be utilised to boost vehicle acceleration or to keep the battery charged during highdemand scenarios like uphill trips. A proportional integral (PI) controller is used to modify the brake current in order to ensure consistent torque braking. The performance of the recommended system is evaluated using a number of simulations. According to the results, the RBS significantly increases energy recovery and overall vehicle economy, makingit aviable choice for electric vehicleapplications.

Key Words: electric vehicle (EV), regenerative braking system (RBS), battery energy storage system (BESS), and inductionmotor(IM).

Electric and hybrid electric vehicles (HEVs), with their distinctive features including low emissions, great economy, and quiet operation, are attracting more and moreattention.Intheageofgreentechnology,electricand hybrid electric vehicles (HEVs)can take the place of conventional cars with internal combustion engines (ICEs). Consequently, they are once again contributing to increasedvehicleefficiency.However,theexorbitantprice of EVs and HEVs has prevented many of them from being used. The objective of this project is to make EV settings less complicated for users. Finding a method to boost the amount of power that can be recovered by braking is one of the main objectives of research. A control strategy for

enhancing the vehicle's overall braking performance has beencreatedusingthefindingsfromthisthesis.

Electric vehicles (EVs) are gaining a lot of attention right now because they provide a more environmentally friendly option to cars with internal combustion engines. The development of electric and hybrid vehicles is growing in popularity. Consequently, the public's awareness of global warming has grown, and the price of petrol has also increased. As a result of growing air pollution and oil prices, electric EVs have emerged as the main and last form of transportation. The main power source in a battery-operated EV is the battery, which has problems including insufficient cycles for charging and recharging and poor reactivity when it comes to driving range [2–5]. The aforementioned problems can be resolved by electrochemical batteries, flywheels, ultracapacitors,andotherenergysources[5-7].

A number of techniques have been put in place to deal with this problem, including regenerative braking. The batteryandultracapacitortranslateandstoreaportionof the vehicle's kinetic energy, which is stored during deceleration [7–10]. On a smooth road, regenerative braking is not always effective. It can be seen in places where vehicles have to apply the brake, such as speed bumps, pits in the road, and slopes. Regenerative braking isonlynoticeablewhenthebatteryiscompletelycharged; otherwise, EVs must have mechanical brakes. Electric vehicles employ mechanical brakes to enhance the roughnessofthewheelinordertodecelerate.Thislosesa lotofenergysincewhenthemechanicalbrakeisengaged, the kinetic energy of the EV is transformed back into electric energy. The motors are easy to regulate and can regenerate.Two-wheelEVsusuallyusemechanicalbrakes to reduce or halt their speed, which causes all of the kineticenergythathasbeenstoredtobelost[11–15].Itis possible to recover and store the kinetic energy lost during braking as electrical energy in batteries and ultra capacitors. This energy can be stored in the battery if the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

motor, drive, and battery are all managed and controlled appropriately. Thus far, the market has led to an increase inthedemandforelectricvehicles.

According to the work of Y. Kim and N. Change, there are several strategies to improve the performance of hybrid energy storage systems, such as automation and design optimization. Every energy storage method has advantages and disadvantages of its own, so a hybrid approachthatcombinesbothcanbeusedtocreateahighperformance, affordable battery. Energy-efficient operating systems and new design optimization techniques are presented. The author also provides a detailed description of hybrid energy storage system prototypeatascaleof300W.

According to a study that was published in the journal Energy Storage Systems for Automotive Applications et. All [2], the ability of revolutionary cars with electric propulsion capabilities to store energy effectively and efficiently has a significant impact on their performance andfuelefficiency.[2](ESS).ThisstudylooksathowESSs are currently being used in automotive applications. With an emphasis on battery management, protection, monitoring, and balancing strategies, battery technology options are thoroughly investigated. Other ESS solutions proposedincludefuelcells,flywheels,andultracapacitors. Finally, hybrid power sources are the idea of combining two or more energy storage devices to create a more potentpowersource.Bothchoosingtheappropriatedrive train architecture and putting in place an efficient power flow control method are essential for lowering fuel consumption and emissions in plug-in hybrid electric vehicles (PHEVs), according to S. G. Wira singha and A. Emadi's classification and review of control strategies for PHEVs [3]. Although control strategies for hybrid electric vehicles (HEVs) have been developed and demonstrated, theydo not fullyutilizethe PHEV'scapacitytotravel long distances solely on electricity. This book examines and organizes the most recent control strategies. Both optimization-based and rule-based PHEV control algorithms have advantages, but they are not exclusive. The controllers are described in detail, and an evaluation of the best technique for maximizing PHEV performance under various driving circumstances is offered. Finally, a newclassificationofPHEVcontrolstrategiesbasedonthe vehicle's operation has been provided and proven by simulationresults.

The active suspension (AS) system of hybrid electric vehicles(HEVs)canbeutilisedtocreatepower,according toM.MontazeriandM.Soleymani'spaper,Investigationof the energy regeneration of the active suspension system inhybridelectricvehicleset.all.,[4].TheHEV powertrain and AS systems are simulated simultaneously in a single medium created by using simultaneous simulation and

control techniques. Ultracapacitors (UCs) and electrochemical batteries make up the proposed hybrid energystoragesystem(ESS).Themodels'findingsindicate that fuel efficiency is increased by the regeneration of the AS energy. By implementing a hybrid energy storage system (ESS), load variations from the batteries can be transferred to the UCs, further increasing battery life and efficiency.

Optimal design and real-time control for electric vehicle energymanagementetal.,byL.Wangetal.,[5]Ithasbeen demonstrated that an active combination of an energydenseLi-ionbatterywithanultracapacitor(UC)isaviable method for extending the cycle life of lithium-ion (Li-ion) batteries in electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs). This paper takes a novel approachtotheissuesofbatteryand UC sizing,aswellas theextentofhybridizationbetweenbatteryandUCpower, byusinganoptimizationproblemtominimizefueluse.To implement this ideal power sharing in real time, a novel energy management strategy based on forecast control basedondrivercommands,UCstate-of-chargeregulation, andbatterypowerreferencegenerationisrecommended.

Finally, calculations and experiments employing the flywheel+generator+regulatedloadaregiventoconfirm that the proposed method increases fuel economy and lowers battery current stress. Cheng-Hu Chen, Wen-Chun Chi, and Ming-Yang Cheng's paper, Regenerative Braking Control for Light Electric Vehicles et al., [6], detailed a straightforward yet efficient electric brake energy regeneration system for an electric vehicle's brushless DC motor (EV). A suggested method just modifies inverter switching sequences to control inverse torque during braking. This indicates that the braking energy of the battery is recovered. Through the removal of a converter, ultracapacitor, or a convoluted winding-changeover process, the suggested technique concurrently achieves the goals of energy regeneration andelectronicbraking.

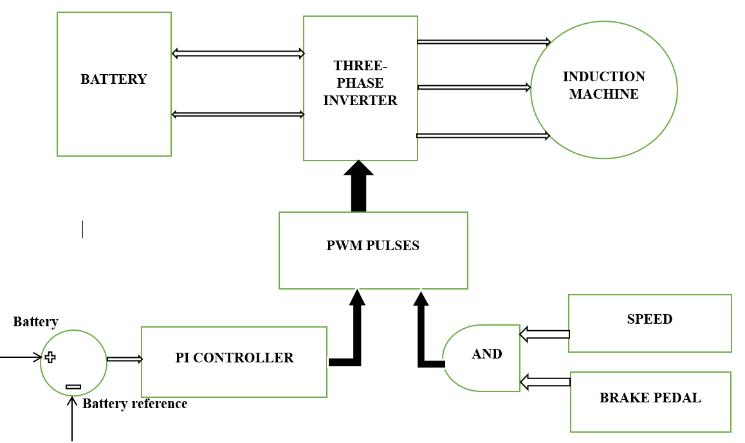

The regenerative braking systemanditsseveral partsare shown in Figure 1. The diagram below shows a battery, a three-phase inverter, and an induction motor. First, the vehicle follows a straight path; if an obstacle arises in the middle, the driver applies the brakes, and the battery stores kinetic energy as an electrolytic charge until it is full.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

1.TheProposedsystemblockdiagram

A. System Of Regenerative Braking

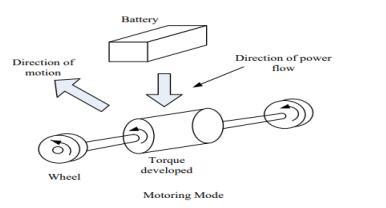

Regenerative braking allows the motor's mechanical energy to be converted into electrical energy that is then transferred back to the battery. In the regenerative braking mode, the motor slows the vehicledownward.Whenthebrakepedalisdepressed, the car slows down and the motor reverses direction. Theenginechargesthebatterybyactingasagenerator when it is travelling in the incorrect direction. The figure2 illustrates this, The car's normal operation, in which the motor draws power from the battery to movethevehicleforward.

Fig2.NormalDrivingcondition

Electric vehicles can minimize pollutants and save money on petrol by implementing regenerative braking. The electric vehicle's regenerative braking system provides the braking force while the vehicle's speedislow,minimizingtherequirementforstop-andgotrafficand,consequently,deceleration.

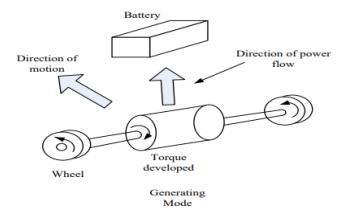

Fig3.Regenerative actionduringbreaking

The brakes work so well in such conditions that you can easily stop in urban areas. Because it controls the entire powertrain, a car's braking system and controller give it structure. The brake controller's two primary functions are to track the wheel's speed and calculate torque, power production, and rotational forcethatwillbesenttothebattery.

1.3. Control systems for EV

A. The standard mode

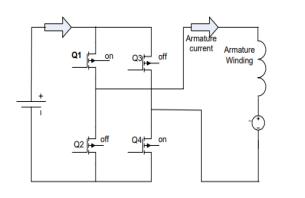

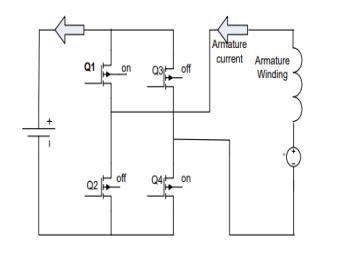

TheoperationofelectricvehiclesisshowninFigure4. The armature current flows from positive to negative voltage. Each MOSFET has a parallel connection to a diode. This type of freewheeling diode can be used to switch devices with PWM, guaranteeing optimal systemefficiency.

Fig4.DrivingMode

B. Mode of regeneration

Inordertoalter thedirectionof armature current,the battery and back-emf are linked in series during the firststageofinitialbrakingmode.Thisisdemonstrated in the battery and back-emf connections. This first braking approach allows the armature current to change directions automatically by activating Q2 and Q3 and deactivating Q1 and Q4. When the armature currentincreasesandchangesdirectiononitsown,the MOSFETs'statereturnstothepositionshowninfigure

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

5 to recharge the battery once more. This technique makesregenerativebrakingfeasible.

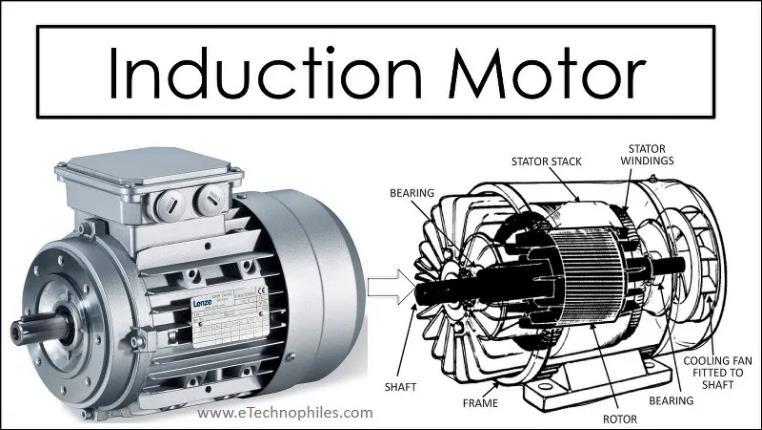

Generally speaking, an electrical motor's rotating components are where electrical power is converted into mechanical power. A dc motor is referred to as a conductionmotorbecausepoweristransferreddirectlyto the armature, the rotating portion of the motor, via a brush.Incontrast,aninductionmotorobtainsitselectrical power through induction rather than conduction, much likethesecondaryofatwo-windingtransformerdoes.For thisreason,thistypeofmotoriscalledaninductionmotor.

Aninductionmotorcanactuallybethoughtofasarotating transformer, meaning that the secondary winding is free to rotate while the primary winding remains motionless. The polyphase induction motor is the most often utilized a.c motor for a variety of industrial drives that are available. A revolving magnetic field is created when the stator windings are coupled to a three-phase supply. An e.m.f. is created in a bar on the rotor when the magnetic flux cuts it, and because the bar is connected to another bar one pole pitch away by end conducting rings, current flowsacrossthebars.

When the spinning magnetic field and the magnetic field connected to the current flowing in the bars interact, a

force is created that tends to rotate the rotor in the same direction as the rotating magnetic field. All of the rotor's conductors receive comparable forces, which results in a torquethatrotatestherotor.

Both the stator and rotor sides of an induction motor can alter its speed. Three-phase induction motor speed regulationfromthestatorsideisfurtherdividedinto:

V/Fcontrolorfrequencycontrol.

Changingthenumberofstatorpoles.

Controllingsupplyvoltage.

Addingrheostatinthestatorcircuit.

The speed controls of three phase induction motorfromrotorsidearefurth

Addingexternalresistanceonrotorside.

Cascadecontrolmethod.

Injecting slip frequency control emf into rotorside.

The SOC cannot exceed 100% if the battery is overcharged. The above-mentioned assumptions are true intheory,butinreality,theSOClimitrangesfrom20%to 40%. One of the lightest metals with good electrical qualities is lithium. Because of its stated benefits, a lithium-ionbatterymodelservedasthefoundationforthis thesis

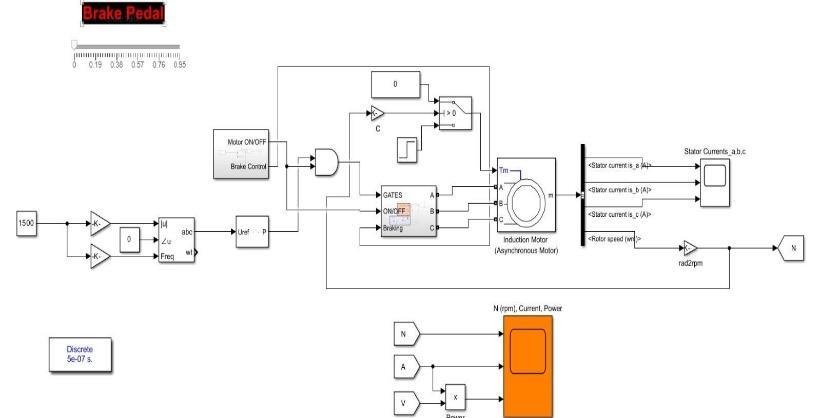

2.1Simulation Result(before braking action)

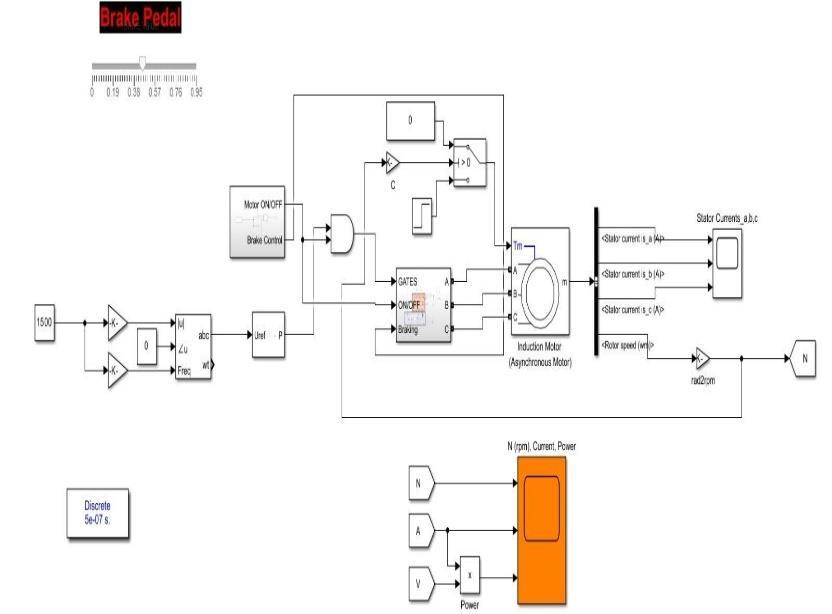

8.Simulationdiagrambeforebrakingaction

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

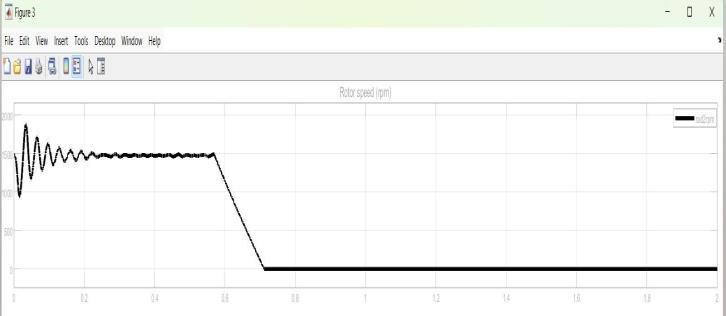

Fig 9.simulation results of stator speed before braking action

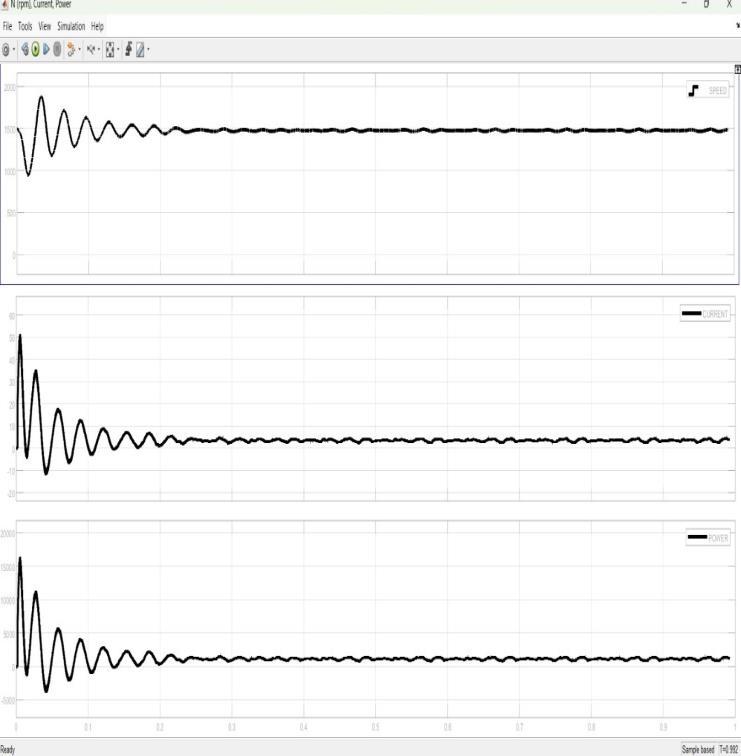

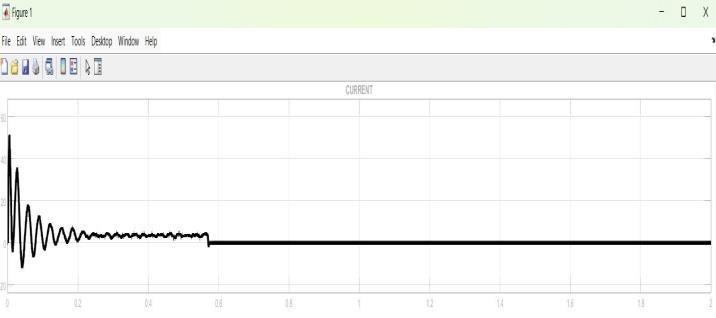

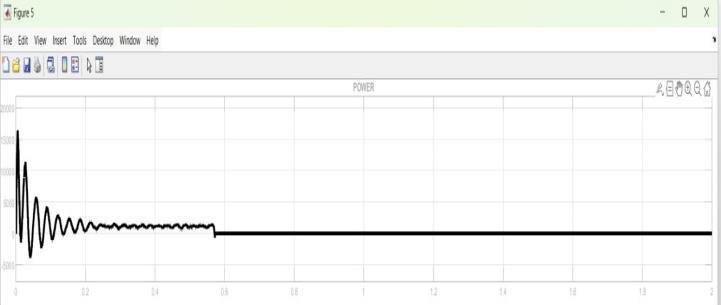

Fig10.simulationresultsofspeed,current,power

2.2Simulation Result (After Braking Action)

Fig10.simulationdiagramafterbrakingaction

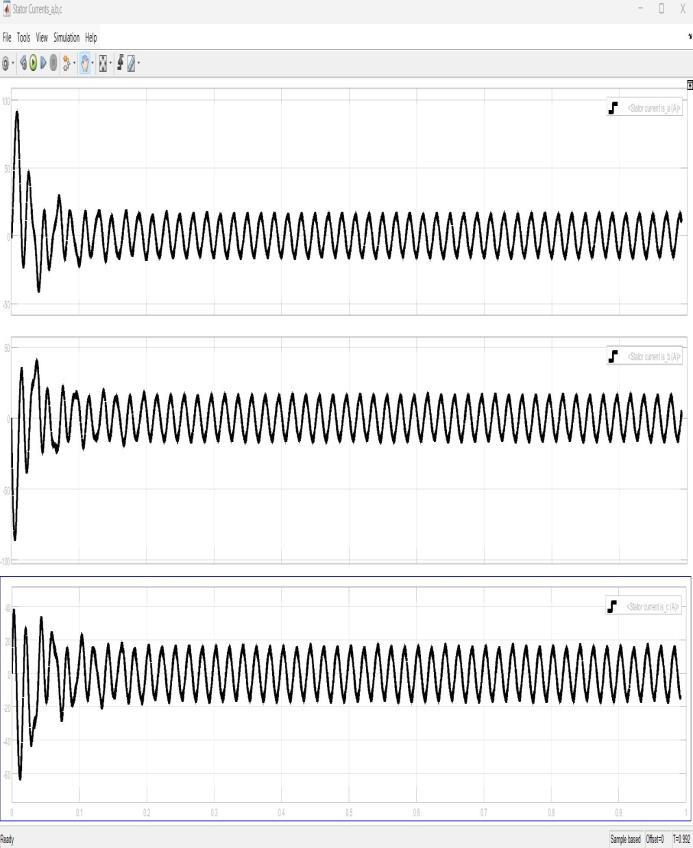

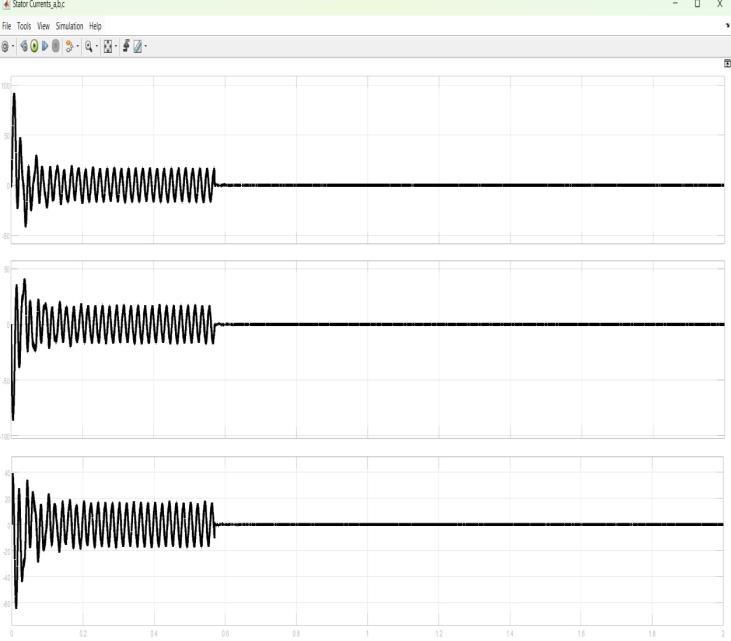

Fig11.SimulationResultOfStatorCurrentsAfterBraking Action

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page1825

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

3. CONCLUSIONS

Regenerative braking has been shown to be efficient in improving the performance and energy efficiency of electric vehicles through simulation and evaluation using MATLAB/Simulink. With energy recovery up to 85% in somecircumstances,thesystemgreatlyminimizesenergy loss and increases driving range by transforming kinetic energyintoelectricalenergyduringbrakingandreserving it in the battery. Using metrics like brake torque and motor currents, the results confirmed efficient energy regeneration,steadypowerflow,andsmoothdeceleration. According to this study, regenerative braking is an essential part of environmentally friendly electric vehicle technology that also extends battery life. In order to further maximize system performance and reliability, future improvements can concentrate on implementing real-time hardware implementation and adaptive control techniques.

4.REFERENCES

[1] Y. Kim, and N. Chang, ‘‘Design and management of energy-efficient hybrid electric energy storage systems,’’ springer,pp.19-25,2014

[2] S. M. Lukic, J. Cao, R. C. Bansal, F. Rodriguez, and A. Emadi, “Energy storage systems for automotive applications,”IEEETransactionsonIndustrial Electronics, vol.55,no.6,pp.2258–2267,June2008.

[3] S. G. Wirasingha, and A. Emadi, ‘‘Classification and review of control strategies for plug-in hybrid electric vehicles,’’IEEETrans.Veh.Technol.,vol.60,no.1,pp.111122, Oct. 2010. [4] M. Montazeri, and M. Soleymani, ‘‘Investigation of the energy regeneration of active suspensionsysteminhybridelectricvehicles,’’IEEETrans. Ind.Electron.,vol.57,no.3,pp.918-925,Oct.2009

[5] L. Wang, E. G. Collins, and H. Li, ‘‘Optimal design and real-time control for energy management in electric vehicles,’’ IEEE Trans. Veh. Technol., vol. 60, no. 4, pp. 1419-1429,Mar.2011.

[6] Cheng-Hu Chen, Wen-Chun Chi, Ming-Yang Cheng, “ Regenerative Braking Control for Light Electric Vehicles “ IEEEPEDS2011,December5-8,2011.

[7] B. Enache et al., “Comparative study for generic battery models used for electric vehicles,” 8th InternationalSymposiumonAdvancedTopicsinElectrical Engineering(ATEE),pp.1-6,23-25May2013.

[8] H. L. Chan, “A new battery model for use with battery energy storage systems and electric vehicles power systems,” in Proc. 2000 IEEE Power Engineering Society WinterMeeting,vol.1,pp.470-475,2000.

[9] H. L. Chan, “A new battery model for use with battery energy storage systems and electric vehicles power systems,” in Proc. 2000 IEEE Power Engineering Society WinterMeeting,vol.1,pp.470-475,2000.

[10] Lijun Gao et al., “Dynamic lithium-ion battery model for system simulation,” IEEE Trans. Compon. Packag. Technol.,vol.25,no.3,pp.495-505,Sep2002.

[11] H. A. Hairik et al., “Proposed scheme for plugging three-phase induction motor,” 15th IEEE Mediterranean Electro technical Conf., MELECON, pp. 1-5, 26-28 April 2010.

[12] H. A. Hairik et al., “Proposed scheme for plugging three-phase induction motor,” 15th IEEE Mediterranean Electro technical Conf., MELECON, pp. 1-5, 26-28 April 2010.

[13]Okan TUR,Ozgur USTUN, Member IEEE, and R.Nejat TUNCAY, “An Introduction to Regenerative Braking of Electric Vehicles as Anti- Lock Braking System”,IEEE june 13-152007.

[14] Beck et al., “Plugging an Induction Motor,” IEEE Trans.IndustryandGeneralApplications,vol.IGA-6,no.1, pp.10-18,Jan.1970

[15]A.Fazeli,M.Zeinali,andA.Khajepour,‘‘Applicationof adaptive sliding mode control for regenerative braking torque control,’’ IEEE/ASME Trans. Mechatronics, vol. 17, no.4,pp.745-755,April2011.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

[16] S. de la Torre, A. J. Sánchez-Racero, J. A. Aguado, M. Reyes,andO.Martianez,‘‘OptimalSizingofEnergyStorage for Regenerative Braking in Electric Railway Systems,’’ IEEETrans.PowerSyst.,vol.30,no.3,pp.1492-1500,Aug. 2014.

[17] M. Mortazavi, M. Mastali, and A. A. Safavi, ‘‘Enhanced Neural Network Based Fault Detection of a VVER Nuclear Power Plant With the Aid of Principal Component Analysis,’’ IEEE Trans. Nucl. Sci., vol. 55, no. 6, pp. 36113619,Dec.2008.

[18] K. Inoue et al., “A Study on an Optimal Torque for Power Regeneration of an Induction Motor,” Conf. IEEE Power Electronics Specialists, pp. 2108-2112, 17-21 June 2007.

[19] S. D. Sudhoff et al., “An induction machine model for predicting inverter-machine interaction,” IEEE Trans. EnergyConvers.,vol.17,no.2,pp.203-210,Jun2002

[20] O. Wasynczuk et al., “A voltage control strategy for current-regulated PWM inverters,” IEEE Trans. Power Electron.,vol.11,no.1,pp.7-15,Jan.1996.

[21]M.Ehsanietal.,“Propulsionsystemdesignofelectric andhybridvehicles,”IEEETrans.Ind.Electron.,vol.44,no. 1, pp. 19- 27, Feb. 1997. [39] N. Mutoh et al., “A torque controller suitable for electric vehicles,” IEEE Trans. Ind. Electron., vol. 44, no. 1, pp. 54-63, Feb. 1997 [22] G. Hongwei, G. Yimin, and M. Ehsani, ‘‘A neural network basedSRMdrivecontrolstrategyforregenerativebraking inEVandHEV,’’ElectricMachinesandDrivesConference, pp.571-575,June2001

[23] Yang, M.-J.; Jhou, H.-L.; Ma, B.-Y.; Shyu, K.-K. A costeffective method of electric brake with energy regeneration for electric vehicles. IEEE Trans. Ind. Electron.2009,56,2203–2212.

[24]M.K.Yoong etal.,“Studiesofregenerativebrakingin electric vehicle,” Conf. IEEE Sustainable Utilization and Development in Engineering and Technology (STUDENT), pp.40-45,20-21Nov.2010.

[25] M. Collie, Electric and Hybrid Vehicles. Energy Technology Review No. 44, New Jersey, USA, Noyes Data Corporation,1979