International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

r1Student,DeptOfCivilEngineering,IetLucknowIndia

2 AssistantProfessor,DeptOfCivilEngineering,IetLucknowIndia

3 AssistantProfessor,DeptOfCivilEngineering,IetLucknowIndia

Abstract- Railway infrastructure forms a critical component of national transportation systems, requiring continuous monitoring to ensure safety and operational efficiency. Traditional inspection methods are manual, time-consuming, and often fail to detect subtle or emerging surface defects. This study proposes a deep learning-basedframeworkforautomatedrailwaysurface defect classification using the InceptionV3 Convolutional Neural Network (CNN) architecture. A custom dataset comprising 6,500 high-resolution railway track images wascuratedandlabeledintofiveclasses:crack,corrosion, debris, fastener failure, and healthy. Transfer learning was applied to fine-tune the InceptionV3 model for domain-specific features, supported by extensive data augmentation techniques to enhance generalizability acrossvaryingfieldconditions.Thefinalmodelachieveda testaccuracyof91.42%withhighprecisionandF1-scores across most classes, particularly excelling in detecting corrosion and fastener anomalies. The model also demonstratedrobustnesstolighting,texture,andsurface inconsistencies. Its lightweight architecture makes it suitable for deployment on edge-computing platforms suchasdronesorembeddedIoTsystems,facilitatingrealtime, on-site defect detection. Overall, the proposed system offers a scalable, AI-driven solution to enhance structural health monitoring, contributing toward predictivemaintenancestrategiesandthemodernization of railway infrastructure in line with Industry 4.0 objectives

Key Words: Railway Defects, InceptionV3, Structural Health Monitoring, Deep Learning, Crack Detection, Automated Inspection

Ensuring the structural integrity and operational reliability of railway infrastructure is paramount to the safety and efficiency of modern transportation systems. With the growing scale of railway networks and increasingtrafficdemand,thefrequencyoftrack-related

ImpactFactorvalue:8.315

failures has escalated, posing significant risks to public safety, operational continuity, and asset longevity. Early detectionandtimelymaintenanceofsurface-leveldefects such as cracks, corrosion, debris, and fastener degradation are crucial for preventing accidents and minimizing service disruptions. However, conventional inspection practices primarily reliant on manual visual surveys areinherentlylabor-intensive,inconsistent,and unable to scale across expansive or inaccessible railway environments. Moreover, human-based assessments are susceptible to errors due to fatigue, subjective judgment, andvariablefieldconditions.

In recent years, deep learning and computer vision technologies have emerged as powerful tools in the field of structural health monitoring (SHM), offering the potential to automate and optimize defect detection processes with high accuracy and repeatability. Among various convolutional neural network (CNN) architectures,InceptionV3standsoutduetoitsefficiency in multi-scale feature extraction and its proven effectiveness across diverse image classification tasks. The architecture's ability to learn complex patterns from high-resolution images makes it particularly well-suited for classifying heterogeneous and often visually ambiguousrailwaysurfacedefects.

This research presents a comprehensive CNN-based framework forautomateddefectclassificationonrailway tracks,utilizingacurateddatasetof6,500high-resolution images annotated across five classes: crack, corrosion, debris, fastener failure, and healthy. By leveraging transfer learning from a pre-trained InceptionV3 model andapplyingextensivedataaugmentationtechniques,the framework is designed to achieve robust performance acrossvariablelighting,texture,andnoiseconditions.The final model is not only accurate achieving a test accuracy of 91.42% but also lightweight, enabling deployment on embedded platforms such as drones and IoT devices for real-time, on-site monitoring. This study contributes to the evolution of AI-driven predictive maintenancesystemsinrailwayinfrastructure,aligning

ISO9001:2008Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

withthe broadervisionofIndustry4.0andintelligent transportationecosystems.

Recent advancements in computer vision and deep learning have significantly transformed the landscape of structural health monitoring (SHM), particularly in theautomateddetectionof surfacedefects.Numerous studieshaveemployedconvolutionalneuralnetworks (CNNs) and object detection models such as YOLOv5 and Faster R-CNN for identifying cracks and other anomalies in infrastructure. These models have proven effective for real-time detection tasks due to their high inference speed and accuracy in localizing objects.However,theirprimarystrengthliesinobject detection, not in fine-grained classification, which limitstheirabilitytodistinguishbetweensubtledefect types such as corrosion versus debris or fastener failure.

Toaddresstheneedfordeeperfeatureextractionand multi-scale analysis, researchers have increasingly explored Inception-based architectures. Notably, InceptionV3, developed by Szegedy et al., incorporates factorized convolutions and multiple filtersizeswithin eachlayer tocapturebothlocal and global image features. This design enables the model to perform well on complex classification tasks involving subtle texture differences and irregular patterns, making it suitable for applications such as medicalimagediagnostics,pavementdistressanalysis, andcorrosionidentification.

In the context of railway defect detection, relatively few studies have applied InceptionV3, despite its suitabilityforthisdomain.Earliereffortshavefocused onbinarycrackdetectionorcorrosionidentificationin controlled environments, often using small or imbalanced datasets. While such models have demonstrated promising results, they generally lack the scalability and robustness needed for deployment in real-world railway systems with varied environmentalconditions.

This study builds on the strengths of InceptionV3 and addresses existing research gaps by applying it to a diverse, high-resolution dataset of 6,500 annotated railway track images, covering five essential surface conditions. By incorporating transfer learning, data augmentation, and careful class balancing, this researchadvancesthestateofrailwaySHMbyoffering a high-performance model suitable for practical

p-ISSN: 2395-0072

deployment on embedded devices. This literaturegrounded approach supports the feasibility and necessity of developing a lightweight yet highly accurate deep learning system tailored to the unique demandsofrailwayinfrastructureinspection.

3.METHDOLOGY

Thisstudypresentsa deeplearning-basedframework for classifying surface-level railway defects using the InceptionV3 Convolutional Neural Network (CNN). The methodology involves four key components: dataset preparation, model architecture, training configuration, and evaluation strategy. Each component was carefully designed to ensure accurate classification, computational efficiency, and deploymentreadinessinreal-worldrailwayinspection systems.

A custom dataset was developed containing 6,500 high-resolutionimages ofrailwaytracksurfaces.The images were sourced under diverse environmental conditions to reflect real-world variability and annotatedintofivedistinctcategories:

Crack

Corrosion

Debris

FastenerFailure

Healthy

To ensure balanced representation across classes, the datasetwaspartitionedintothreesubsets:

Trainingset:70%ofthedata

Validationset:20%

Testset:10%

Eachimagewasresizedto 299×299pixels tocomply withInceptionV3’sinput requirements.Preprocessing alsoincluded:

Pixelnormalization tothe[0,1]range

Data augmentation techniques such as randomrotation,horizontalflipping,zooming, andbrightnessadjustments.

These steps aimed to increase robustness and reduce overfitting by simulating real-world variations in lighting,perspective,andsurfacecondition.

TheInceptionV3model,pre-trainedonImageNet,was employed via transfer learning. Its architecture is composed of multiple Inception modules that apply 1×1,3×3,and5×5convolutions inparallel,enabling efficient extraction of both fine and coarse features. Thearchitecturewascustomizedasfollows:

InputLayer:299×299×3RGBimage

Convolutional and Inception Modules: Deeplayersformulti-scalefeatureextraction

Global Average Pooling: Reduces dimensionality while preserving spatial features

Dense Layers: Include dropout regularization topreventoverfitting

Output Layer: Softmax activation with 5 neuronsforeachdefectclass

This architecture was selected due to its strong performance in classification tasks involving high inter-class similarity and its relatively lightweight computational profile compared to heavier models likeResNetorEfficientNet.

The model was compiled and trained using the followinghyperparameters:

Loss Function: Categorical Crossentropy (suitableformulti-classclassification)

Optimizer: Adam optimizer with a learning rateof 0.0001

BatchSize:32

Epochs:25

Callbacks: Early stopping and model checkpointing based on validation loss to avoid overfitting and retain the bestperformingmodel

Training was conducted using a GPU-enabled environment to accelerate computation. Model performance was continuously monitored using accuracy and loss curves, and evaluation was conducted on the held-out test set to assess generalization.

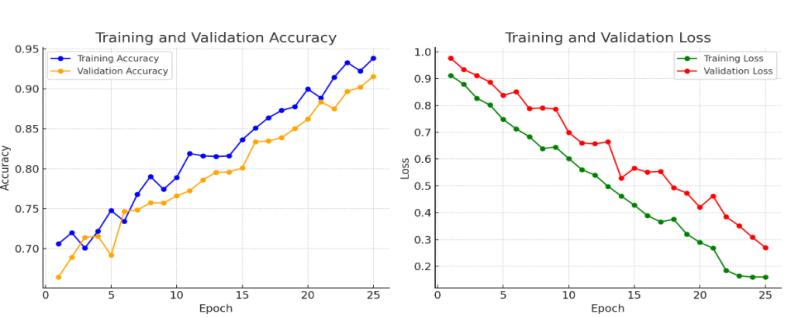

The InceptionV3 model was trained for 25 epochs using a learning rate of 0.0001 and batch size of 32. Early stopping and model checkpointing were employed based on validation loss to retain the bestperforming model. Throughout training, the model exhibited a consistent increase in accuracy and a steady decline in loss, indicating successful convergenceandgeneralizationtounseendata.

Themodelachievedthefollowingperformance metrics:

TrainingAccuracy:93.78%

ValidationAccuracy:91.05%

TestAccuracy:91.42%

FinalTestLoss:0.2971

Theseresultsdemonstratethatthemodelnotonlyfits the training data well but also generalizes effectively to the validation and test sets, reflecting the robustness of the architecture and preprocessing pipeline.

Fig.1Trainingandvalidationaccuracyandloss curvesover25epochsfortheInceptionV3model.

As shown in Fig. 1, training accuracy progressively improved with minimal divergence from validation accuracy, suggesting that overfitting was effectively controlled through dropout regularization and early stopping. The decrease in validation loss further supportsthemodel'sstabilityandlearningefficiency.

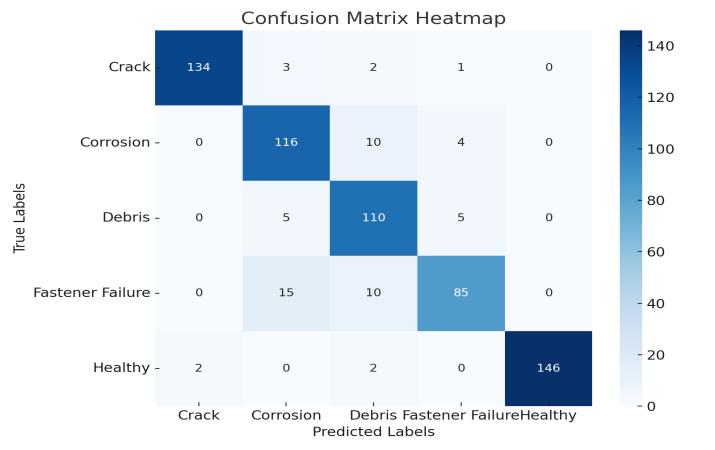

Table 1 presents the classification performance of the final model across the five defect categories. High precision and recall values, particularly for the Healthy and Crack classes, indicate excellent model

reliability. Slightly lower scores in the Fastener Failure classreflectgreater intra-classvariabilityand visualoverlapwithcorrosionanddebrispatterns.

Thisstudypresentsa deeplearning-basedframework for the automated classification of surface-level railway track defects using the InceptionV3 convolutional neural network. By leveraging transfer learning on a custom-curated dataset of 6,500 highresolutionimagesannotatedintofivecriticalclasses crack,corrosion,debris,fastenerfailure,andhealthy the model achieved a notable test accuracy of 91.42% and consistently high precision and F1scores across most classes. The architecture demonstrated strong generalization to real-world visual conditions including variations in lighting, texture,andsurfacecontamination.

The confusion matrix indicates that the model classified most instances of Healthy and Crack conditionscorrectly,withveryfewfalsepositives.The majority of misclassifications occurred between the Debris and Fastener Failure classes. This confusion islikelyduetothesimilarityinsurfacetextureandthe presenceofrust-coloredpatternsinbothclasses.

Despite minor overlaps, the model maintained balanced performance across classes, showcasing its strength in multi-class differentiation under realworld visual conditions. This highlights the value of using InceptionV3, which excels at capturing features atmultiplespatial scales.

Fig.2:ConfusionMatrixHeatmap

A key strength of the InceptionV3 model lies in its ability to extract multi-scale spatial features using inception modules, making it particularly effective for identifying subtle and visually overlapping defects. The classification results, including confusion matrix analysis and class-wise metrics, confirmed that the model performed exceptionally well for ‘Healthy’, ‘Crack’, and ‘Corrosion’ categories. Some confusion was observed between ‘Debris’ and ‘Fastener Failure’ due to their similar visual textures a challenge that can be addressed in future work through additional trainingdataormultimodalfusion.

In addition to high classification performance, the model is computationally efficient and lightweight, making it suitable for deployment on edge computing platforms such as UAVs (drones), robotic crawlers, or IoT-enabled inspection devices. This supports realtime, on-site monitoring, enabling predictive maintenance strategies and reducing reliance on labor-intensivemanualinspections.

Overall, this research validates the application of InceptionV3forrailwaytrack defectclassificationand contributestotheadvancementofAI-drivenstructural health monitoring systems. The proposed solution aligns with the goals of Industry 4.0, offering a scalable and intelligent framework for enhancing railway infrastructure safety, reliability, and maintenanceplanning.

While the proposed InceptionV3-based defect classification framework demonstrates strong performance and deployment potential, several

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

enhancements can be explored to further improve its robustness,scalability,andreal-worldapplicability.

1. Dataset Expansion and Diversity: The model's performance can be significantly improvedbyexpandingthedatasettoinclude more diverse examples, especially for underrepresented and visually ambiguous classessuchas‘Debris’and‘FastenerFailure’. Futuredatasets mayincorporateimagesfrom different geographic regions, rail types, and weatherconditions toimprovegeneralization acrossvariedoperationalenvironments.

2. Synthetic Data Generation using GANs: Generative Adversarial Networks (GANs) can be employed to generate synthetic defect images, particularly for rare or hard-tocaptureconditionslikeadvancedcorrosionor structural deformation. This augmentation strategycanhelpaddressclassimbalanceand improvemodelsensitivitytominorityclasses.

3. Temporal and Sequential Monitoring: Integrating temporal image sequences over time would allow the system not only to detect current defects but also to track the progression of deterioration. This would enabletrue predictivemaintenance,offering early warnings before defects reach critical levels.

4. Edge Deployment and Hardware Optimization:Testingthemodelonreal-time edge devices such as NVIDIA Jetson Nano, Raspberry Pi, or Google Coral will help evaluate its performance in resourceconstrained environments. Optimizing the model using techniques like quantization or model pruning can reduce memory usage andinferencetimeforembeddeddeployment.

5. Multimodal Sensor Fusion: Future versions of the system can integrate non-visual data such as vibration signals, acoustic emissions, and thermal imaging to enhance detection accuracy, particularly for subsurfacedefectsorareaswithocclusion.

6. Drone-Based Real-Time Monitoring System:Developing a complete aerial inspection system using drones equipped with onboard processing and high-resolution cameras will enable large-scale, autonomous monitoring of railway lines, especially in remoteordifficult-to-accessregions.

By addressing these directions, the framework can evolve into a fully autonomous, scalable, and

intelligent railway health monitoring system that significantlyreducesinspectioncosts,enhancessafety, and aligns with the vision of smart infrastructure underIndustry4.0.

[1] Cha, Y.J., Choi, W., & Büyüköztürk, O. (2017). Deep learning-based crack damage detection using convolutional neural networks. Computer-Aided Civil and Infrastructure Engineering, 32(5), 361–378. https://doi.org/10.1111/mice.12263

[2] Zhuang, X., Tran, T. V., Nguyen-Xuan, H., & Rabczuk, T. (2023). Deep learning-based postearthquake structural damage level recognition. Computers and Structures, 315, 107761. https://doi.org/10.1016/j.compstruc.2023.10 7761

[3] Zhang,R.,Chen,Z.,&Sun,H.(2019). Deeplong short-term memory networks for nonlinear structural seismic response prediction Computers & Structures, 220, 55–68. https://doi.org/10.1016/j.compstruc.2019.05 .006

[4] Liang, X. (2019). Image-based post-disaster inspection of reinforced concrete bridge systems using deep learning with Bayesian optimization. Computer-Aided Civil and Infrastructure Engineering, 34(5), 415–430. https://doi.org/10.1111/mice.12425

[5] Ghosh Mondal, T., & Jahanshahi, M. R. (2020). Deep learning-based multiclass damage detection for autonomous post-disaster reconnaissance. Structural Control and Health Monitoring, 27(2), e2507. https://doi.org/10.1002/stc.2507

[6] Dorafshan, S., Thomas, R. J., & Maguire, M. (2018). Comparison of deep convolutional neuralnetworksandedgedetectorsforimagebasedcrackdetectioninconcrete.Construction and Building Materials, 186, 1031–1045. https://doi.org/10.1016/j.conbuildmat.2018. 07.142

[7] Kim, B., Yuvaraj, N., Park, H. W., et al. (2021). Vision-based steel frame damage detection using deep learning. Automation in Construction, 132, 103941. https://doi.org/10.1016/j.autcon.2021.10394 1

[8] Pham, H. T., & Han, S. (2023). Natural language processing with multi-task classification for predicting risk-handling

ImpactFactorvalue:8.315 ISO9001:2008Certified Journal Page 154

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 p-ISSN: 2395-0072

actions in construction contracts. Journal of Computing in Civil Engineering, 37(3), 04023027.

https://doi.org/10.1061/JCCEE5.CPENG5218

[9] Tan, M., & Le, Q. V. (2019). EfficientNet: Rethinking model scaling for convolutional neural networks. Proceedings of the 36th International Conference on Machine Learning (ICML), 6105–6114. https://arxiv.org/abs/1905.11946

[10] Szegedy, C., Vanhoucke, V., Ioffe, S., Shlens, J., & Wojna, Z. (2016). Rethinking the Inception architecture for computer vision. Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), 2818–2826. https://doi.org/10.1109/CVPR.2016.308