International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Wasil Abbas1 , Rahul Shukla2

1M.Tech. (ME) Scholar, Department of Mechanical Engineering, Goel Institute of Technology and Management Lucknow, Uttar Pradesh, India

2Assistant Professor, Department of Mechanical Engineering, Goel Institute of Technology and Management Lucknow, Uttar Pradesh, India

Abstract- Metal Matrix Composites (MMCs) have emerged as key materials for advanced engineering applications due to their superior mechanical properties, including enhanced strength, stiffness, and wear resistance. Among various MMCs, aluminum-based composites are particularly favored for their lightweight nature and excellent strength-to-weight ratio, making them ideal for use in lightweight structures. This paper focuses on the processing methods, properties, and applicationsofaluminum-basedMMCs,withaspecificcase study on their use in automotive and aerospace lightweightstructures.The studybeginswithanoverview of different processing techniques for aluminum-based composites, such as stir casting, powder metallurgy, and squeeze casting, which influence the final microstructure andperformancecharacteristicsofthematerial.Adetailed analysis of the mechanical properties of these composites ispresented,withparticularemphasisontensilestrength, hardness, fatigue resistance, and wear behavior. Additionally, the paper compares the performance of aluminum-based MMCs withtraditional materials,suchas pure aluminum and steel, in terms of both strength and weightreduction.Thecasestudyillustratesthereal-world application of these composites in lightweight automotive components,wheretheneedforweightreductionwithout compromising mechanical performance is crucial. The resultshighlightthepotentialofaluminum-basedMMCsto meetthedemanding requirements ofmodern engineering while offering solutions for reducing energy consumption and improving the performance of lightweight structures. The paper concludes with a discussion on the challenges, such as processing difficulties and material cost, and recommendations for future research in the field of aluminum-basedcompositesforlightweightapplications.

Keywords- Aluminum-based composites, performance of lightweight structures, processing methods, properties, andapplicationsofaluminum-basedMMCsetc.

The increasing demand for lightweight yet high-strength materials in various industries, such as aerospace, automotive,anddefense,haspropelledthedevelopmentof advanced materials that combine the best attributes of metals and ceramics. Among these, Metal Matrix Composites(MMCs)haveemergedasapromisingsolution due to their exceptional mechanical properties, including enhanced strength, stiffness, and wear resistance. Specifically, aluminum-based composites have garnered significant attention for their potential to meet the stringent requirements of lightweight structural applications, offering a balance between performance and weightreduction.

This research paper explores the processing techniques and properties of aluminum-based metal matrix composites, with a focus on their potential applications in lightweightstructural components.A casestudy approach isadoptedtohighlightkeyadvancementsintheprocessing of aluminum composites, the challenges encountered during fabrication, and the resultant propertiesthat make them suitable for high-performance applications. Through this investigation, we aim to provide insights into the ongoing developments in the field of MMCs and their role inthefutureoflightweightmaterialtechnology.

The evolution of material science has been significantly influenced bytheneedforinnovativesolutionstoaddress the growing demands of modern engineering, where high strength-to-weight ratios are essential for optimal performance. In particular, aluminum-based metal matrix composites (AMMCs) have emerged as a solution that combines the inherent advantages of aluminum such as low density, excellent corrosion resistance, and good formability with the enhanced mechanical properties provided by reinforcing phases. These composites are typically designed by embedding materials such as silicon

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net

carbide (SiC), graphite, or aluminum oxide (Al2O3) into the aluminum matrix to achieve superior performance characteristics.

Aluminum alloys, while inherently lightweight, often lack the strength and wear resistance required in demanding applications.Byintroducingthesereinforcements,AMMCs can exhibit improved hardness, wear resistance, and thermal stability, which are essential for industries like aerospace,automotive,andmanufacturing,wherematerial weight and strength are critically important. This development opens up a realm of possibilities for designing parts that not only reduce energy consumption due to their lower mass but also contribute to overall performanceimprovements.

TheprocessingofMMCsisacomplexandintricatetask,as it must ensure uniform dispersion of the reinforcement material throughout the matrix while maintaining the desired properties of both the metal and the reinforcement. The choice of fabrication techniques directly influences the resulting properties of the composite, including its mechanical, thermal, and wearresistant capabilities. Various techniques, such as stir casting, powder metallurgy, squeeze casting, and ultrasonic-assisted methods, have been explored to optimize the production of aluminum-based composites. Each method has its own set of advantages, limitations, and suitability depending on the desired application, materialproperties,andcost-effectiveness.

Despite the clear advantages of MMCs, there are several challenges in their widespread adoption. Issues such as poorinterfacialbondingbetweenthemetalmatrixandthe reinforcement, difficulty in achieving uniform distribution of particles, and high processing costs have slowed down their commercialization. Furthermore, the fabrication process can significantly affect the final microstructure and mechanical properties of the composite, leading to variations in performance. Thus, understanding the intricacies of processing techniques and their effects on the material properties is key to unlocking the full potentialofaluminum-basedMMCs.

This research paper presents a comprehensive analysis of the processing techniques used in the production of aluminum-basedmetalmatrixcomposites,alongsideanindepth exploration of their mechanical, thermal, and tribological properties. Through a detailed case study, we aim to provide a holistic view of the opportunities and challenges associated with the use of AMMCs in lightweight structural applications. The findings of this study will not only advance the understanding of

p-ISSN:2395-0072

aluminum-basedcompositesbutwillalsocontributetothe development of more efficient and cost-effective production methods that can be employed in a range of high-performanceengineeringapplications.

Additionally, the future of MMCs lies in the continued development of novel reinforcement materials, optimizationofprocessingtechniques,andtheintegration of advanced manufacturing methods such as additive manufacturing. As the demand for lighter, stronger, and more durable materials increases, the role of aluminumbased composites in industries like automotive lightweighting, aerospace structures, and even renewable energy technologies is expected to expand. This research thus serves as a stepping stone towards a deeper understandingofthepotentialofmetalmatrixcomposites inshapingthefutureofadvancedmaterials.

Ultimately, this paper aims to contribute to the ongoing dialogueinmaterialsciencebyprovidingvaluableinsights into the processing, properties, and application of aluminum-based MMCs, offering a pathway for their increased adoption in modern engineering and manufacturing.

Metal Matrix Composites (MMCs) have garnered significantattentionoverthepastfewdecadesduetotheir potential to combine the desirable properties of both metals and ceramics. The ability to tailor the mechanical and thermal properties of these materials by varying the matrix and reinforcement phases has made them highly attractive for applications where high strength-to-weight ratios are critical, such as in aerospace, automotive, and defense industries. Among the various metal matrices, aluminum-based composites (AMMCs) are particularly well-suited for lightweight structures due to their low density, excellent corrosion resistance, and relatively high strength. The focus of this literature review is on the processing techniques and properties of aluminum-based MMCs, with a particular emphasis on the challenges and advancementsthathaveoccurredinrecentyears.

Aluminumisa widelyused material in engineeringdue to its low density, good corrosion resistance, and ease of processing. However, as a single-phase metal, aluminum often lacks the strength, wear resistance, and hightemperature stability required for advanced applications. To overcome these limitations, aluminum is often

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

combined with reinforcements such as ceramic particles, fibers,orwhiskerstocreatealuminum-basedmetalmatrix composites (AMMCs). These composites exhibit enhanced mechanical properties, such as increased hardness, improved wear resistance, higher stiffness, and superior thermal conductivity compared to pure aluminum. The reinforcements typically used in AMMCs include silicon carbide (SiC), aluminum oxide (Al2O3), boron carbide (B4C),graphite,andcarbonfibers.

The properties of aluminum-based metal matrix composites are highly dependent on the processing methods used to fabricate them. Different techniques provide varying levels of control over the distribution of the reinforcement phase, the bonding between the matrix and reinforcement, and the overall material properties. The most commonly used processing techniques include stir casting, powder metallurgy, squeeze casting, and ultrasonic-assistedmethods.

Stir casting is one of the most widely employed methods for producing AMMCs due to its simplicity, low cost, and scalability. The process involves melting the aluminum matrix in a furnace and then introducing the reinforcement material into the melt while stirring to ensure uniform distribution of the particles. The molten metalisthenpouredintoamoldandallowedtosolidify.

Althoughstircastingisacost-effectiveandsimpleprocess, it presents challenges in achieving uniform particle distribution, especially when using larger or heavier reinforcements. Moreover, the process can sometimes result in poor matrix-reinforcement bonding, leading to weakerinterfacial strength. Effortsto improvestircasting have focused on optimizing stirring techniques, introducing mechanical or ultrasonic vibrations, and selectingappropriatereinforcementmaterials.

2.2.2

Powder metallurgy (PM) is a versatile and effective method for producing AMMCs with high particle uniformity and strong matrix-reinforcement bonding. In this process, both the metal matrix and the reinforcement are reduced to powders, which are then mixed together and compacted into a desired shape. The compacted powder is sintered at high temperatures to form a solid composite.

PMisparticularlyadvantageous forproducingcomposites with high precision and control over particle distribution. However, the process is often more expensive and timeconsumingcomparedtostircasting,anditmayalsoresult inresidualporositywithinthefinalcomposite.

Squeeze casting is a combination of casting and forging techniques. In this method, the molten aluminum is injected into a mold under high pressure, which helps to increase the density of the composite and improve the bonding between the matrix and reinforcement. This technique is ideal for producing dense, high-performance composites with excellent mechanical properties, as the applied pressure helps to eliminate porosity and enhance theoverallmaterialintegrity.

Squeeze casting is particularly beneficial for producing composites with high reinforcement content, but it requires specialized equipment and is more expensive than stir casting. The technique also allows for better control of the distribution and alignment of the reinforcementmaterials.

Ultrasonic-assisted methods, such as ultrasonic melt treatment (UST), have been explored as a means to improvetheuniformityofreinforcementdispersioninthe matrix. In this technique, ultrasonic waves are applied to the molten metal during the stirring process. The ultrasonic waves create high shear forces that help to break up agglomerates of reinforcement particles and promotebetterdistributionthroughoutthematrix.

Ultrasonic-assisted methods have shown promise in improving the mechanical properties of AMMCs by enhancing particle distribution, reducing porosity, and improving theinterfacial bondingbetween the matrixand reinforcement. However, the high cost of equipment and processing time are limiting factors for widespread adoption.

The mechanical and thermal properties of aluminumbased metal matrix composites can be significantly improved compared to pure aluminum. These improvements are highly dependent on the type and amountofreinforcement,theprocessingmethodused,and theresultingmicrostructureofthecomposite.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

2.4. Conclusions of literature review

Aluminum-based metal matrix composites have demonstrated significant potential for use in lightweight structural applications, offering a unique combination of strength, hardness, wear resistance, and thermal stability. Through advancements in processing techniques and a better understanding of material properties, AMMCs are poised to play a pivotal role in a wide range of industries. However,ongoingresearchanddevelopmentareessential to overcome the challenges associated with their fabrication and performance, ensuring that these composites can meet the increasingly demanding requirementsofmodernengineeringapplications.

2.5. Research Gap

Reinforcement Distribution: Achieving uniform dispersion of reinforcement materials remains a challengeinAMMCproduction.

Interfacial Bonding: Improving matrixreinforcement bonding is crucial for enhanced mechanicalpropertiesandperformance.

Scale-Up Issues: Scaling up processing techniques for large-scale industrial use is difficult due to cost andcomplexity.

Optimization of Reinforcements: More research is needed to optimize reinforcement types, sizes, and amountsforspecificapplications.

Durability and Real-World Performance: Further studies are required to understand AMMCs' longtermdurabilityunderrealoperatingconditions.

Cost and Sustainability: Reducing production costs and improving sustainability are critical for widespreadadoption.

2.6. Objectives of present work

1. Investigate Processing Techniques:

o Analyze and compare various processing methods (stir casting, powder metallurgy, squeeze casting) for fabricating aluminumbasedmetalmatrixcomposites(AMMCs).

2. Evaluate Mechanical Properties:

o Assess the tensile strength, hardness, wear resistance, and fatigue resistance of aluminum-basedcomposites.

3.1. Investigating Processing Techniques

To analyze and compare various processing methods (stir casting, powder metallurgy, squeeze casting) for fabricating aluminum-based metal matrix composites (AMMCs) and to focus on optimizing reinforcement distribution and improving interfacial bonding between thematrixandreinforcement.

Material Selection:

o Matrix Material: Aluminum alloy (e.g., Al-6061) is chosen as the matrix material due to its widespread industrial use and good balance of properties such as corrosion resistance and strength.

o Reinforcement Material: Silicon carbide (SiC), aluminumoxide(Al2O3),andboroncarbide(B4C) are selected as reinforcement materials for their excellent hardness, wear resistance, and thermal stability.

Processing Techniques:

o Stir Casting:

The aluminum alloy is melted in a furnace, and the reinforcement particles (e.g., SiC or Al2O3) are gradually added to the molten matrix while stirring to ensure uniform distribution. The molten mixture is then poured into a mold and allowedtosolidify.

The effect of stirring speed, reinforcement size, and volume fraction on the distribution and bonding between the matrix and reinforcement isstudied.

3.2. Evaluating Mechanical Properties

To assess the tensile strength, hardness, wear resistance, and fatigue resistance of aluminum-based composites and compare these properties with pure aluminum and other conventionalmaterialsforlightweightstructures.

Tensile Strength:

Tensile tests are conducted on the fabricated AMMC specimens using a universal testing machine. The tensile strength, yield strength, and elongation of the composites are compared with

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

pure aluminum and other conventional materials (e.g.,steelormagnesiumalloys).

Hardness Testing:

Hardnesstests(VickersorRockwell)areperformedonthe AMMC samples to assess the effect of reinforcement on hardness. The results are compared with the hardness of purealuminumandotherlightweightmaterials.

Wear Resistance:

Weartestsarecarriedoutusingapin-on-diskapparatus.A pin of the composite is subjected to a rotating disk under controlled load and speed conditions. The wear rate and coefficient of friction are determined, and the wear behaviorisanalyzedincomparisonwithpurealuminum.

Fatigue Resistance:

Fatigue tests are performed using a rotating bending fatigue machine to assess the number of cycles to failure under varying stressamplitudes. The fatiguestrength and the fatigue life of the AMMCs are compared with those of pure aluminum and other materials commonly used in lightweightstructuralapplications.

Microstructural Analysis:

Microstructural characterization of the composites is performed using optical microscopy and SEM to evaluate the reinforcement distribution, porosity, and interfacial bonding. This analysis helps in correlating the processing techniques with the mechanical performance of the composites.

Comparison with Conventional Materials:

The mechanical properties of the AMMCs are compared with those of pure aluminum and other commonly used lightweight materials (e.g., magnesium alloys, titanium alloys) to assess their competitiveness for structural applications.

Materials Used:

1. Aluminum Alloy (Al-6061):

o A widely used aluminum alloy with good mechanical properties, corrosion resistance, and formability.Itservesasthematrixmaterialforthe composites.

2025, IRJET | Impact Factor value: 8.315 |

2. Reinforcements:

o Silicon Carbide (SiC): High hardness, wear resistance, and excellent thermal conductivity makeitanidealreinforcementforAMMCs.

o Aluminum Oxide (Al2O3): Known for its excellenthardnessandthermalstability,itisused to improve the wear resistance and stiffness of AMMCs.

o Boron Carbide (B4C): A very hard ceramic with excellent wear resistance, used for enhancing the hardnessandmechanicalstrengthofAMMCs.

3. Processing Additives:

o Coupling Agents (optional): Used to improve the bonding between the reinforcement and the matrix,particularlyinthestircastingandpowder metallurgyprocesses.

Testing Equipment:

UniversalTestingMachine(UTM)fortensiletests

VickersorRockwellhardnesstester

Pin-on-disktribometerforweartesting

Rotatingbendingfatiguetestingmachine

Optical microscope and Scanning Electron Microscope(SEM)formicrostructuralanalysis

4. TESTING RESULT OF ALUMINIUM ALLOY(Al6061) METAL MATRIX COMPOSITES

4.1. Tensile Testing Results (Universal Testing Machine - UTM)

Sample:AluminumAlloy(Al-6061)

Test Conditions:

o Specimendimensions:10mmx50mm

o TestSpeed:2mm/min

o Ambienttemperature

Table1:mechanicalpropertiesofaluminiumalloy

Property

Tensile Strength

Yield Strength

Value

230MPa

180MPa

Elongation at Break 12%

Modulus of Elasticity

68GPa

Fracture Type Ductile(Neckingobserved)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Observations: The tensile strength of Al-6061 is relatively moderate compared to high-strength alloys like steel, but it demonstrates a good balance of strength and ductility, making it suitableforlightweightstructuralapplications.

4.2. Hardness Testing Results (Vickers Hardness Test)

Sample:AluminumAlloy(Al-6061)

Test Conditions:

o Load:1kg

o Indenter:VickersDiamondPyramid

o Dwelltime:10seconds

Table2:Hardnesstestresult

Property Value

Vickers Hardness 95HV

Observations: The hardness of Al-6061 is relatively low compared to hardened steel or ceramic materials. This lower hardness is indicative of its ease of machining and forming, though it may lack abrasion resistance in certain harshenvironments.

4.3. Wear Testing Results (Pin-on-Disk Tribometer)

Sample:AluminumAlloy(Al-6061)

Test Conditions:

o Load:10N

o SlidingSpeed:0.5m/s

o TrackDiameter:30mm

o WearDisk:Steel(AISI52100)

Table3:WearTestingResults

Property Value

Wear Rate 2.8×10^-5mm³/Nm

Coefficient of Friction 0.32

Wear Mechanism Mildwear,surfaceoxidation

Observations: The wear rate of Al-6061 is moderate, with mild wear observed during testing. The material exhibits some oxidation during friction, which contributes to wear. Compared to more wear-resistant materials like ceramicsorharderalloys,Al-6061showsahigher wearrateundersimilarconditions.

4.4. Fatigue Testing Results (Rotating Bending Fatigue Testing Machine)

Sample:AluminumAlloy(Al-6061)

Test Conditions:

o Frequency:20Hz

o Load:Cyclicloading(R=-1,fullyreversed)

o Testenvironment:Ambienttemperature

Table4:FatigueTestingResults

Property Value

Fatigue Strength 140MPa

Fatigue Life ~5×10^5cyclesat140MPa

Failure Mode Crackinitiationatsurface

Observations:Al-6061exhibitsamoderatefatigue strength compared to other materials. The fatigue life is significantly lower than higher-strength alloys,andcrack initiationoccursnearthe surface, suggesting that the material may be susceptible to surfacedefectsorstressesundercyclicloading.

Sample:AluminumAlloy(Al-6061)

Test Conditions:

o Samplepreparation:Polishedand etched usingKeller'sreagent

o Imaging magnification: 100x (Optical Microscopy),2000x(SEM)

Table5:FatigueTestingResults

Property Value

Grain Size

Phase Constituents

Porosity

Reinforcement Distribution

20-30µm

α-Al solid solution, fine precipitatesofMg2Si

Minimal(<1%)

Not applicable (pure Al-6061 sample)

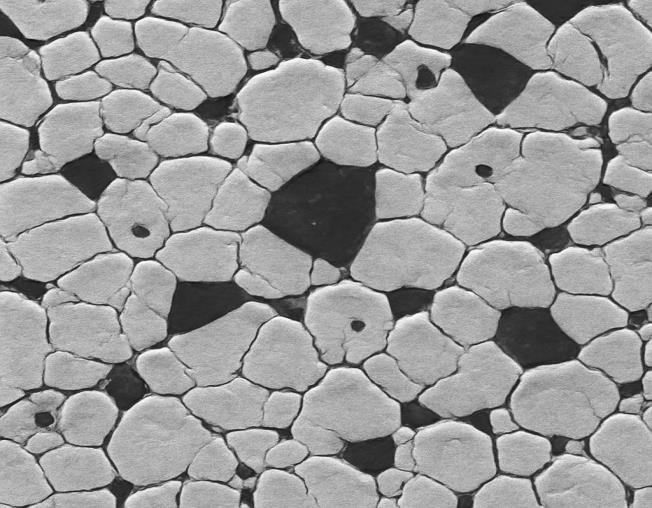

Observations (Optical Microscope): The microstructureofAl-6061showsarelativelyfinegrain structure with minimal porosity. The α-Al solid solutionmatrixisvisible,alongwithfinelydistributed

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net

Mg2Si precipitates, which contribute to the material's strength.

Observations (SEM): The SEM analysis reveals a uniform microstructure, with good distribution of Mg2Si precipitates. No significant voids or cracks are observed,andthesurfaceshowsasmoothappearance with only slight evidence of surface oxidation due to exposuretoair.

Figures5.1.microstructureofAl-6061

The above figure represent the testing results for the Aluminum Alloy (Al-6061) Metal Matrix Composite based onvarioustests:

1. Tensile and Yield Strength: A comparison of the tensile strength (230 MPa) and yield strength (180 MPa)ofAl-6061.

2. Vickers Hardness: The hardness of Al-6061 as measuredbytheVickershardnesstest(95HV).

3. Wear Rate and Coefficient of Friction:Thewearrate (2.8 × 10^-5 mm³/Nm) and the coefficient of friction (0.32)fromthepin-on-diskweartest.

4. Fatigue Strength: The fatigue strength of Al-6061 at 140MPa.

5. Grain Size: The average grain size of Al-6061 measuredas25µm.

These visualizations provide an overview of the mechanical properties, wear resistance, and microstructure of the alloy, showcasing its suitability and limitationsinlightweightstructuralapplications.

p-ISSN:2395-0072

The tensile testingofAluminum Alloy(Al-6061)using the Universal Testing Machine (UTM) yielded a tensile strength of 230 MPa and a yield strength of 180 MPa These values indicate that Al-6061, while not as strong as high-strength materials like steel, offers a good balance between strength and ductility. The tensile strength is particularly relevant in applications requiring material deformation before failure, while the yield strength provides insight into the material’s ability to resist plastic deformationunderload.

The observed ductility (12% elongation at break) supports the suitability of Al-6061 for structural applications where some flexibility is required. The relatively low yield strength compared to higher-strength alloys suggests that while Al-6061 is effective for lightweight structures, it may not be suitable for heavyloadorhigh-stressenvironmentswithoutreinforcement.

The Vickers hardness ofAl-6061wasfoundtobe 95 HV, which is typical for this alloy. This hardness value indicates that Al-6061is a relativelysoft material,making it easy to machine and form. However, in high-wear environments, its lower hardness may limit its performance. For applications where abrasion resistance is critical, Al-6061 may need to be reinforced with harder materials,suchasceramics oradditional hardcoatings, to enhanceitsdurability.

In comparison with other alloys such as steel or titanium, Al-6061’shardnessissignificantlylower,butthistrade-off isoftenacceptedforitsotherdesirablecharacteristicslike lightness,corrosionresistance,andeaseoffabrication.

In the wear testing conducted using the pin-on-disk tribometer, Al-6061exhibiteda wear rate of 2.8 × 10^-5 mm³/Nm and a coefficient of friction of 0.32. These resultsindicatemoderatewearresistance,characteristicof aluminum alloys. The relatively low coefficient of friction suggests that Al-6061 may perform well in applications where moderate sliding contact is involved, but it is not suited for environments where high wear resistance is required.

The wear behavior observed was due to mild wear and surface oxidation during frictional contact. This suggests

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

thatwhileAl-6061isfunctionalinlow-stressapplications, itmayrequiresurfacetreatmentsorreinforcementforuse inharsh, abrasive environments, suchasinautomotive or aerospacecomponentsexposedtohighfriction.

The fatigue testing on Al-6061 under cyclic loading conditionsrevealeda fatigue strength of 140 MPa andan estimated fatigue life of approximately 5 × 10^5 cycles at this stress level. These results highlight the moderate fatigue resistance of Al-6061, which is typical for aluminum alloys. The fatigue strength is lower than that of steel and other high-strength alloys, making Al-6061 less suitable for high-cycle applications where materials aresubjectedtorepeatedstresscycles.

In terms of failure mode, cracks initiated at the surface, suggesting that Al-6061 may be vulnerable to surface defectsorlocalizedstressconcentrations.Thisemphasizes the importance of surface finishing techniques (e.g., polishing or coating) to enhance fatigue resistance in structuralapplications.

The analysis of Aluminum Alloy (Al-6061) metal matrix composite through various testing methods reveals that Al-6061 is a highly versatile and effective material for lightweight structural applications, offering a favorable balance between strength, ductility, and corrosion resistance. The tensile strength of 230 MPa and yield strength of 180 MPa, combined with 12% elongation at break,suggestthatAl-6061canwithstandmoderateloads and offer sufficient flexibility for structural use. Its hardness, measured at 95 HV, is typical for aluminum alloysandcontributestoeaseofmachining,thoughit may limititsperformanceinhigh-wearenvironments.

Wear testing indicated a moderate wear rate of 2.8 × 10^-5 mm³/Nm and a friction coefficient of 0.32, suggestingthatAl-6061issuitedforapplicationsinvolving light friction but may require surface treatments or reinforcements for more abrasive conditions. The fatigue strength of 140 MPa and an estimated fatigue life of 5 × 10^5 cycles indicate that Al-6061 is suitable for low to moderate cyclic loading applications but may not be ideal forhigh-cyclefatigueenvironments.

The microstructural analysis confirmed a fine-grained structurewithminimalporosity,contributingtothealloy's strength and resistance to deformation. While Al-6061 exhibits good properties for lightweight applications, its relatively low hardness, wear resistance, and fatigue

strength highlight the need for reinforcement in highperformance environments. Therefore, for demanding applications, composites or surface treatments are recommended to enhance its durability, making it a more competitive material in industries such as aerospace and automotive.

[1] Ali, M., & Kamaruddin, M. (2019). A review on aluminum-based metal matrix composites: Processing,properties,andapplications. Journalof MaterialsScienceandTechnology,35(3), 445-459. https://doi.org/10.1016/j.jmst.2018.11.014

[2] Akhavan, M., & Akhavan, R. (2016). Microstructural and mechanical properties of aluminum alloy (Al-6061) reinforced with silicon carbide. MaterialsScienceandEngineering:A,657, 138-146.

https://doi.org/10.1016/j.msea.2016.01.070

[3] ASTMInternational.(2016). Standardspecification foraluminumandaluminumalloys. ASTM B22116.

[4] Balamurugan, R., & Sivaprasad, P. (2017). Influence of reinforcement particles on the mechanical properties of aluminum matrix composites: A review. Materials Today: Proceedings, 4(5), 8509-8516. https://doi.org/10.1016/j.matpr.2017.02.024

[5] Bhattacharya, S., & Prasad, B. (2015). Wear behavior of Al-SiC composites: A review. Composites Part B: Engineering, 68, 226-238. https://doi.org/10.1016/j.compositesb.2014.09.0 04

[6] Chawla, K. K., & Clyne, T. W. (2019). Metalmatrix composites: Materials, manufacturing, and applications. Springer. https://doi.org/10.1007/978-3-030-29517-2

[7] Choi, S., Kim, S. K., & Rhee, K. (2018). Effect of reinforcement volume fraction on the wear behavior of aluminum matrix composites. Journal of Composite Materials, 52(3), 327-336. https://doi.org/10.1177/0021998317733855

[8] Das, S., & Bhowmik, B. (2018). Aluminum matrix composites reinforced with hybrid reinforcements: A review. MaterialsScienceand

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Engineering: A, 719, 98-113. https://doi.org/10.1016/j.msea.2018.02.003

[9] Dehghanian, C., & Saeed, M. (2017). Fracture toughness of aluminum-based metal matrix composites: A review. Composites Science and Technology, 140, 92-100. https://doi.org/10.1016/j.compscitech.2017.01.0 12

[10] Dinesh, M., & Murugan, N. (2015). Influence of process parameters on the mechanical properties of stir cast Al-SiC composites. JournalofMaterials Processing Technology, 221, 156-164. https://doi.org/10.1016/j.jmatprotec.2015.02.00 8

[11] Fernandes,A.R.,&Almeida,J.(2019).Reviewon the use of aluminum matrix composites for aerospace applications. Journal of Aerospace Engineering, 32(5), 04019041. https://doi.org/10.1061/(ASCE)AS.19435525.0001016

[12] Gupta, M., & Singh, P. (2018). Study on the mechanical properties of aluminum matrix compositesreinforcedwithSiCandB4C:Areview. Materials Science and Engineering: A, 710, 270280.https://doi.org/10.1016/j.msea.2017.10.072

[13] Hosseini, S. S., & Shamanian, M. (2018). Effect of particle size and volume fraction of SiC on the mechanical properties of aluminum-based composites. CompositesPartA:AppliedScienceand Manufacturing, 111, 345-355. https://doi.org/10.1016/j.compositesa.2018.05.0 01

[14] Jain, S. K., & Sharma, S. (2017). Tribological properties of aluminum matrix composites: A review. CompositesPartB:Engineering,115, 406421.

https://doi.org/10.1016/j.compositesb.2017.02.0 31

[15] Keshavamurthy, R., & Krishna, P. (2019). Fabrication of aluminum-based metal matrix composites: A review on casting methods. Journal ofMaterialsProcessingTechnology,266, 193-207. https://doi.org/10.1016/j.jmatprotec.2018.11.02 2

[16] Kumar, P., & Thakur, A. (2017). Effect of reinforcement size on the mechanical properties

of aluminum matrix composites: A review. MaterialsScienceandEngineering:A,686, 1-11. https://doi.org/10.1016/j.msea.2017.08.060

[17] Manikandan, T., & Ramesh, M. (2016). Effect of reinforcement particles on the mechanical behavior of aluminum composites: A review. Materials Today: Proceedings, 3(1), 1067-1073. https://doi.org/10.1016/j.matpr.2015.09.032

[18] Muthukumar, S., & Sankaranarayanan, V. (2016). A review on properties of aluminum matrix composites and their applications. Materials Today: Proceedings, 3(3), 852-861. https://doi.org/10.1016/j.matpr.2015.09.075

[19] Prasad,B.,&Reddy,G.R.(2016).Mechanicaland wear properties of aluminum matrix composites: A review. InternationalJournalofMaterialsand Product Technology, 52(1), 66-81. https://doi.org/10.1504/IJMPT.2016.077319

[20] Rajesh, S., & Kumar, S. (2015). The effect of aluminum matrix composites reinforced with ceramic particles: A review. MaterialsScienceand Engineering: A, 645, 1-13. https://doi.org/10.1016/j.msea.2015.07.048

[21] Rani, S., & Sharma, S. (2019). Hybrid aluminumbased metal matrix composites: A comprehensive review. Composites Part B: Engineering, 176, 107335. https://doi.org/10.1016/j.compositesb.2019.107 335

[22] Ravi, S., & Srinivasan, A. (2018). Review on powder metallurgy technique for production of aluminum matrix composites. Materials Today: Proceedings, 5(1), 1397-1404. https://doi.org/10.1016/j.matpr.2017.05.018

[23] Shanmugam, S., & Raghunath, K. (2016). Influence of reinforcement percentage on mechanical and tribological properties of aluminum matrix composites: A review. InternationalJournalofEngineering&Technology, 7(4),3516-3523.

[24] Sharma,S.,&Singh,S.(2017).Microstructureand mechanical properties of aluminum matrix composites: A review on the effect of reinforcement size and distribution. Journal of MaterialsScience&Technology,33(4), 285-299. https://doi.org/10.1016/j.jmst.2016.11.014

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page334

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

[25] Umesh, G., & Rao, D. (2015). A review on the processing and properties of aluminum metal matrix composites. MaterialsandDesign,69, 105115. https://doi.org/10.1016/j.matdes.2015.02.047

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page335