of

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

DEEPTI RAI

1,

AKSHAT

JAIN2,

ADMYA

JAISWAL3, AYUSH PATEL4, EPSHA NETY5 ,

KARNIKA DUBEY

6

1Assistant Professor, Department of Electrical Engineering, Shri Govindram Seksaria Institute of Technology & Science, Indore M.P

2,3,4,5,6 UG Students, Department of Electrical Engineering, Shri Govindram Seksaria Institute of Technology & Science, Indore M.P.

Abstract- Advancing the prospects of eco-friendly transportation tends to correlate with optimizing energy management. This paper describes the design and implementationofasmartBMSwhichutilizesML andIoT technologies for real-time monitoring and predicting of batteryperformancemetrics.

The methodology used involves estimating the State of Charge (SoC) and State of Health (SoH) of lithium-ion batteries with pre-trained Random Forest and Decision Tree models that draw from historical datasets and incorporate voltage, current, and capacity metrics. Unlike adaptive learning systems, this model is offline, eliminating the need for frequent retraining while still ensuringpromptandtrustedpredictions.

In its simplest form, an Arduino Uno microcontroller acts as a data acquisition unit that gathers data from the sensors to be sent to cloud. The processed data is displayedonawebdashboardwhichservesasaninterface givingtheuserrealtimedataonthebatteryperformance. This approach to battery monitoring offers an unprecedented level of responsiveness, flexibility, and affordability which improves the upkeep, lifespan, and safetyofthebatterypositioningitasafundamentalshiftin theconstructioninsmartenergy-efficientEVsystems.

Keywords: MachineLearning,SoC,SoH,RuL

In today's era, we are surrounded by electronics devices like the toothbrush we first touch in the morning to the mobileweusetoeventhecarwedrive.Everythingrunson a power source like batteries and in fact mostly these batteries are rechargeable Li Ion batteries. The charging and discharging over a long period affects the health of thesebatteriesanditbecomesveryimportanttoknowthe health of batteries for safety purposes. That’s when BMS

(Battery Management System) comes into play. A BMS is an electronic system that manages and monitors a rechargeable battery, either at the cell or pack level, by gatheringandtransmittingimportantdataonthebattery's state to an external interface where users can access it. Thisdataincludesmeasurementssuchascurrent,voltage, temperature,andcoulombcount,whichareusedtoassess the health of the battery and take necessary actions to protect it from harm. BMS are crucial for preventing overcharging, overheating and deep discharge. Proper battery monitoring improves efficiency, safety and longevity of Li-Ion batteries. [1]. A Battery Management System (BMS) plays an essential role in monitoring key parameters such as battery voltage, current, State of Charge (SoC), and State of Health (SoH). The precision of monitoring will ensure that the battery works effectively and also, at the required time, gives a signal to the user regarding whether it needs some sort of service or replacement [2]. By using IoT and Machine Learning, it is now possible to collect vast amounts of data about a battery, such as its current state, temperature, and charge/discharge cycles. This data canthen be used to develop a predictive model which can be used to predict thefutureperformanceofthebatteryandprovideinsights intohowtooptimizebatteryuse.

IoT-basedbatteryanalyticscanprovideaneffectivewayto monitor and manage battery performance. By using sensors to collect real-time data, it is possible to track the health of the battery and receive alerts when it is time to replace it. Additionally, this data can be used to develop predictive models that can be used to forecast the future performance of the battery and improve its overall efficiency. [3] Machine Learning is also an important tool for battery analytics. By using machine learning algorithms,itispossibletoanalyzethedatacollectedfrom the sensors and identify patterns and trends that can be used to improve battery performance. For example, machine learning algorithms can be used to identify the

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

optimal charging and discharging times for a battery, as well as to detect anomalies in the battery's performance thatcouldindicateapotentialproblem.

BycombiningIoTandMachineLearning,itisnowpossible to develop a comprehensive battery analytics system which can provide valuable insights into the performance ofabattery.Thissystemcanbeusedtoaccuratelypredict future performance and identify potential issues, allowing for more effective management and improved performance. Battery analytics using IoT and Machine Learning is an important tool for improving the efficiency and performance of batteries. By using this technology, it is possible to collect and analyze large amounts of data to identify trends and anomalies, as well as to develop predictivemodelsthatcanbeusedtooptimizebatteryuse. Byusingthistechnology,itispossibletonotonlyimprove the performance of batteries, but also to reduce the costs associatedwiththeiruse.[3]

Thereareseveralmachinelearningalgorithmsthatcanbe used in battery parameter prediction some of them are mentionedbelow:

2.1 Space Vector Machine (SVM) It is used for regression and classification, it tries to draw a smooth curve which stays close to actual points of data set points with minimum error. It is effective in high-dimensional spaces. It is not suitable for large datasets due to its high trainingtime.[9]

2.2 Artificial Neural Network (ANN) It can measure the non-linear dynamics of battery parameters, which make it suitable for SoC and SoH prediction. It requires a large amount of data to avoid over fitting. It is difficult to interpretanddebug.[10]

2.3 k-Nearest Neighbors (k-NN): Itisanon-parametric algorithm, which predicts output on the basis of majority vote. It does not give good results with noisy data. It also hasaveryslowdatapredictionspeed.[11].

2.4 Decision Tree: It split the data into branches based ontheirthresholdfeatures.Ithandlesbothcategoricaland numerical data. It is less stable, and a single tree can be pronetooverfitting.[12]

2.5 Random Forest: It builds multiple trees and accumulates their results to improve accuracy. It is very good and precise for small data sets, does not require heavytuning[13]

2.6 Justification for using Random Forest: We have chosenRandomForestAlgorithmbecause:

1. The available data set in NASA website is small and precise,alsocontainslimitedcyclesperbattery.

2. Random forest performs better on small size datasets and does not require extensive hyper parameter tuning. [13]

3. Compared to ANN and SVM it offers fast training and bettergeneralizationinsmalldatasets.

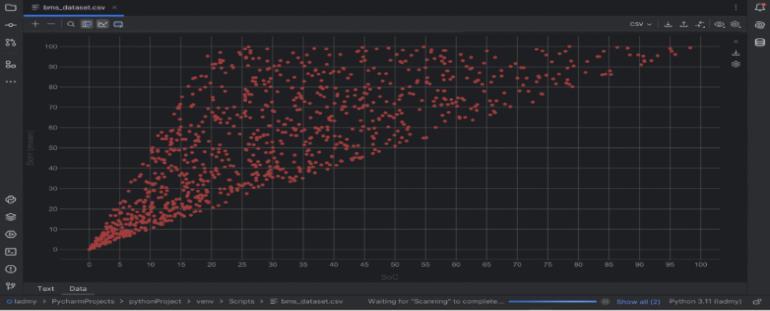

3.1 Data Collection:

The dataset is taken from NASA Prognostics Data Repository.[8]

a) Dataset description

1. Batteries were subjected to repetitive charging and dischargingcycles.

2.EachcyclecontainsmeasurementofVoltage(V),Current (A),Capacity(Ah)

b) Data processing

1.Extractdischargecyclesonly.

2.Removenoiseandincompletedata.[6][8].

Accumulateparameterssuchasaveragevoltageand capacitypercycle.

3.2 SoC and SoH estimation from dataset:

a) SoC(State of Charge) calculation [6] [ ]

Where:

b) SoH(State of Health) calculation [7] [5]: [ ]

Where:

3.3. Model Training and Evaluation:

a) Feature Set Average Voltage MaximumVoltage, MinimumVoltage,DischargeCycleCapacity

b) Training Procedure

1.Split:Training80%;Testing20%

2.Algorithm:RandomForest(100estimators)

3.EvaluationMatrices:RootMeanSquareError(RMSE)

MeanAbsoluteError(MAE).

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

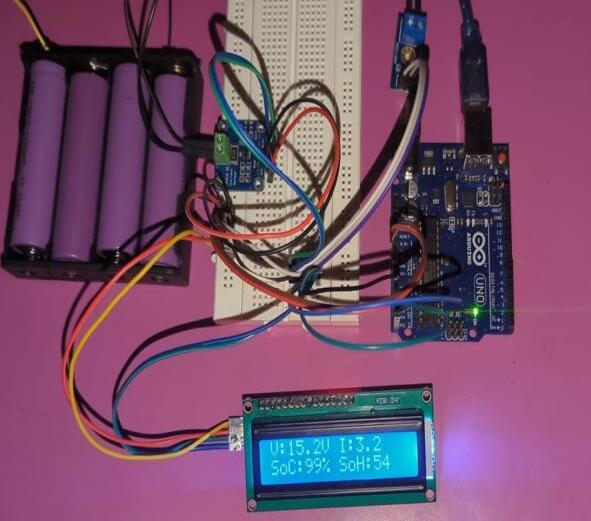

This section gives the understanding of the components and their importance such as micro controllers, sensors, battery pack, LCD and monitoring system. These components tell us about battery parameters so that we cancalculateSOCandSOHofthebattery

COMPONENT

BATTERYPACK

CURRENTSENSOR

SPECIFICATIONS

Nominalvoltage:12V, Capacity:1Ah, Chargingvoltage:13-14V, Dischargevoltage:10.5V, Cyclelife:300-500cycles, Self-dischargerate:5-10% permonth,

Operatingtemperature: Bestat25-35°C

OperatingVoltage:3.0–5.5V

InputVoltageRange:0–26V

CurrentRange:±3.2A

VOLTAGESENSOR Voltagerange:0-25V, Accuracy:±1%(ofreading)

ARDUINOUNO Microcontroller: ATmega328P

OperatingVoltage:5V

InputVoltage:7–12V

LCD Type:16*2,Operating Voltage:4.7-5.3Vat1mA

Forwardvoltage:2-2.5V

The system integrates an Arduino micro controller with sensor modules to capture real time data on the voltage andcurrent[4].Arduinoissimpleandversatileopensource microcontroller used for building complex electronic circuitswithrelativeisandconsiderablecontrol.

Arduino help us to monitor various parameters such as voltage, current and temperaturethrough various sensors in battery management system, it also helps in battery protection from overcharging and overheating and managecellbalancingeffectivelyinmulticellpack.

For the advancement, we can use raspberry pi micro controller because raspberry pi is more powerful than Arduino UNO because it comes with a large processing capacityRaspberrypihasmultiplecourse,higherRAMand supportforconnectivitybuildinsuchasWi-Fi,HDMI,USB ports, unlike Arduino with minimum memory and processing capabilities. This gives raspberry pi ability to do more advancement better than Arduino like data, logging,image,processing,andrealcommunication.InIOT projects it supports high-level programming language (python)withextensivelibrariesandsoftwaretools

Microcontroller Specification

Arduino Uno (ATmega328P) 8-bitAVR

Operatingvoltage-5v

Memory-32KB

ClockSpeed-16MHz

ESP32

32-bitXtensaDual-Core

Operatingvoltage-33v

Memory-4MB

ClockSpeed-Upto240MHz

RaspberryPi ARMCortex-A72

Operatingvoltage-5V

Memory-Upto8GBRAM

ClockSpeed-15GHz

STM32F103 32-bitARMCortex-M3

Operatingvoltage-33v

Memory-64KB

ClockSpeed-72MHz

A voltage sensor is a device used to measure electrical potential difference between two terminals of a cell or a battery pack. In a battery management system, a 25 V

International

voltage sensor module is commonly used to measure voltage of a cell or a overall battery pack, especially in systemwherevoltageleveldonotexceed25V.Thissensor converts the analogue voltage into a signal which is readable for microcontrollers like arduino enabling real time tracking of battery voltage. It also helps us to detect over voltage and under voltage conditions which ensure that battery operates within a safe limit and preventing damage. This makes the 25 V voltage sensors crucial for maintainingbatteryhealth,safety,andefficiency

4.3

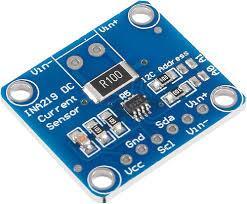

Acurrentsensorisadevicethatmeasureselectriccurrent inabatterymanagementsystem.WehaveusedanINA219 current sensor which is known for its precision of measuringcurrentandvoltageinabattery.Currentsensor checksthecharginganddischargingcurrentinrealtimeso that overcurrent can be detected for battery protection. It also helps to calculate power and energy consumption which is needed for batteries, State of charge estimation. INA219 in BMS is highly efficient and accurate for safe operation.

AlthoughINA219canmeasurebothvoltageandcurrent,a separate voltage sensor - 25 V voltage sensor module is used in the battery management system to improve the accuracyandflexibilitywith thissensor.INA219 ismostly usefulwhenitcomestocurrentsensingand thevoltageof a shunt resistor will drop across which is not so great for direct monitoring of higher battery voltage. The 25 V voltage sensors has built in voltage dividers so that it is safer and simpler to interface with microcontrollers like Arduino.UsingadedicatedvoltagesensorwiththeINA219 helps to measure cell voltage properly and ensure proper batteryprotectionandmanagementwithaccuracy.

CurrentSensor INA219

CurrentSensor ACS712

±3.2A(default) 0-26V(bus voltage)

±5A,±20A, ±30A (dependingon model)

Temperature Sensor LM35 -55°Cto +150°C Temperature Sensor DS18B20

Temperature Sensor NTC Thermistor

to +125°C

Variesby model

We have used lithium ion cells for battery packs because these are rechargeable cells. Lithium ion batteries have high energy density which can store more energy in compact size. It also has low self discharge rate and fast chargingcapability

LCDs are used to display output and desired result obtainedbythecurrentsensorandvoltagesensorthrough theuseofmicrocontrollerarduino;itshowsthecalculated resultSOCandSOH.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

This paper introduces an end-to-end and low-cost predictive battery health monitoring solution through integrationofoffline-trainedRandomForestmodelsand IoT-enabled real-time sensing. Through using historical battery performance data sets and incorporating the embedded sensor systems, we were able to estimate importantbatteryhealthmarkers StateofCharge(SoC) and State of Health (SoH) with high accuracy. The employment of Random Forest, being parameter-tuning insensitive and robust, was especially useful with small datasets like those in the NASA Prognostics Repository. The system proposed provides a feasible alternative to morehardwareandcomputationallyexpensivesolutions and is therefore strongly indicated for scalable deployment on Electric Vehicles (EVs), Renewable Energy Storage, and Smart Grid applications. This researchpavesthewaytowardsfutureadvancementsin adaptive learning, multi-cell balancing, and digital twin technologytoopenupnewfrontiersformoreintelligent andautonomousbatterymanagementsystems.

The BMS framework proposed is the foundation for intelligent, real-time battery monitoring. In spite of this, a few modifications can significantly enhance its flexibilityandprecision,aswellasitsintelligence:

1. Wireless connectivity through CAN Bus or BLE: The adoption of a wireless communication protocol (suchasBLE,Zigbee,orWi-FioverESP32)bydevelopers would enhancethe system's flexibilityandcompatibility with distributed battery packs in EVs. Integration with the vehicle's CAN Bus also facilitates data sharing with onboardECUs.

2. Real-Time Adaptive Learning: Online learning models that continuously use live battery performance data can be used in future versions, rather than pretrained static datasets. Incremental Random Forest, Online Gradient Boosting, and Reinforcement Learning are algorithms that can be used to improve prediction accuracybytakingintoaccountthecontextinwhichitis applied.

3. RUL (Remaining Useful Life) Prediction: Theuse of time-series data analysis and survival regression models (such as LSTM, XGBoost, or Cox Proportional HazardModel)canresultinthepredictionofRUL,which is an essential metric for fleet operators and EV manufacturerstoplanpreventivemaintenance.

4. Improved Self-Healing Alerts and Fault Detection Systems:This allows the system to use sensor fusion techniques combined with anomaly detection algorithms (such as Isolation Forest or Auto encoders) to detect and alert for patterns of thermal runaway, overcharging and cell degradation before they occur.

5. Cloud-AI Hybrid Architecture: The development ofsuchasystemcouldinvolvebothreal-timeprediction usingedgecomputingandtheintegrationofcloud-based AI platforms (such as AWS IoT Analytics, AzureML) for modelretraining,fleetwideanalytics,andOTAupdates).

6. Multi-Cell balancing and Control System: The integrationofactive/passivecellbalancingalgorithmsin thesystemcanenhancethemonitoringandregulationof multi-cellbatterypacks.

7.The use of Battery Digital Twin Models: Future research may involve the use of a digital twin, i.e, an online virtual physical battery system, for real-time simulation, stress testing, and optimization using both liveandhistoricaldata

7. REFERENCES

1) Automatic Battery Health Monitoring Using Machine LearningforE-Vehicle.

2) Nagaraja S R1, ReddamJagadeswar Reddy, VarikutiSampath Kumar Reddy, KalimisettySujith, NitturuNikhilSai,DumpaSriVardhanReddy;“ABattery Monitoring System based on IoT for Electric Vehicles”, International Journal of Engineering & Technology 7(4.31):(2018)505-510.

3) Siba Prasad NaikBehera, et al. “IOT Based Battery Analytics through Machine Learning”,GIET university journal,(2023)Vol.2,No.2,PP.06

4) Advanced battery management system enhancement using IOT and ML for predicting remaining useful life in LIbatteries

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

5) Gopal Krishna, Rajesh Singh, AnkitaGehlot, WasimAkram Shaikh, BhekisiphoTwala, and Neeraj Priyadarshi; “IOT based real time analysis of battery management system with long range communication andFLoRa”,(2022)Vol.23,1-19.

6) Zhang, Y., et al. "A review of machine learning in lithium-ion battery management systems." Energy Reports3(2017):131–144.

7) Watrin, N., Blunier, B., &Miraoui, A. "Review of adaptive systems for lithium batteries state-of-charge and state-of-health estimation." IFAC Proceedings Volumes44.1(2011):10064-10069.

8) NASA Prognostics Data Repository. https://www.nasa.gov/content/prognostics-center-ofexcellence-data-set-repository

9) Smola, A. J., &Schölkopf, B. "A tutorial on support vectorregression."Statisticsandcomputing14.3(2004): 199–222.

10) Severson, K. A., et al. "Data-driven prediction of battery cycle life before capacity degradation." Nature Energy4.5(2019):383–391.

11)Altman,N.S."Anintroductiontokernelandnearestneighbor nonparametric regression." The American Statistician46.3(1992):175–185.

12) Quinlan, J. R. "Induction of decision trees." Machine Learning1.1(1986):81–106.

13)Breiman,L."Randomforests."Machinelearning45.1 (2001):5–32.

BIOGRAPHIES

Mrs. Deepti Rai is an Assistant Professor in the Department of ElectricalEngineeringatShriG.S. Institute of Technology and M.E. degree in Electrical Engineering with a specialization in Digital Techniques & Instrumentation, fromSGSITS,Indorein2011

Akshat Jain- UG Students, Department of Electrical Engineering, Shri Govindram SeksariaInstituteofTechnology& Science,IndoreM.P.(2025-ESD)

Admya Jaiswal- UG Students, Department of Electrical Engineering, Shri Govindram SeksariaInstituteofTechnology& Science,IndoreM.P..(2025-ESD)

Ayush Patel- UG Students, Department of Electrical Engineering, Shri Govindram SeksariaInstituteofTechnology& Science,IndoreM.P.(2025-ESD)

Epsha Nety- UG Students, Department of Electrical Engineering, Shri Govindram SeksariaInstituteofTechnology& Science,IndoreM.P.(2025-ESD)

Karnika Dubey- UG Students, Department of Electrical Engineering, Shri Govindram SeksariaInstituteofTechnology& Science,IndoreM.P.(2025-ESD)