International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Mabia Khatun1, Md. Ariful Islam2, Merina Akter3

1Masters of Electrical Engineering, Anhui University of Science and Technology, Anhui, China

1Masters of Mechanical Engineering, Changan University, xian, China

2Masters of Computer Science and Technology, Changan University, xian, China

Abstract: Elevators are essential for moving people and goods in multi-story buildings; however, traditional relay-based controls are prone to wear and have inflexible designs. This paper presents a PLC-based control system for a four-floor elevator that improves its functionality and maintainability. Using the Siemens TIA Portal, we developed ladder logic (LD) and function block diagram (FBD) programs to manage car calls, hall calls, motion scheduling, and door operations. The system offers automatic and manual modes with safety interlocks for the overload and door obstruction. This modern PLC implementation significantly reduces wiring complexity, enhances expandability, and increases reliability compared with conventional relay systems.

Key words: ProgrammableLogicController(PLC),LadderLogic,Elevator,FunctionBlockDiagram,Automation,Industrial Control

Elevators are vital for efficient vertical transportation in modern high-rise buildings. As structures grow taller and more complex, the demand for reliable and flexible elevator systems increases. Historically, elevator controls have relied on hardwired relay circuits, which are prone to mechanical wear, failures, and limited functionality. For example, the John HancockCenterinChicago,oneofthetallestskyscrapersintheU.S.,uses50Otis-manufacturedelevators,includinghigh-speed expresscarsthattravelupto1,800ft/min(≈9.1m/s)[1],[2].Achievingsafeandefficientoperationatsuchspeedsisdifficult for relay-based systems. In contrast, Programmable Logic Controllers (PLCs) are the industry standard for industrial automation because of their robustness and reprogrammability [3]. Unlike fixed relays, PLC programs can be updated in software,makingthemmoreflexibleandeasiertomodifythanfixedrelays.Moreover,PLCsaredesignedtotolerateharsh environments(dust,moisture,andtemperatureextremes)whileofferingextensiveinput/output(I/O)connectivity[3].

ThisstudyappliedaPLCtocontrolafour-floorelevatorsystem,achievingintelligentoperationbymanagingcarandhallcalls, determiningmotiondirection,andcontrollingdoorsandsafetyinterlocks[10].ThePLCimplementscollectivecallscheduling, whichisastandardelevatorstrategythatgroupsandsequencesrequestsinthedirectionoftravel[11].Thisfunctionalityis cumbersomewithrelaysbutisstraightforwardinsoftware.Theobjectivesoftheprojectaretwofold:(1)todesignacomplete systemarchitecture(hardwareandsoftware)thatmeetsallfunctionalrequirements,and(2)todevelopdetailedPLCprograms and wiring for implementation. The result is a flexible and reliable four-floor elevator control system that outperforms traditionalrelay-baseddesigns.

ThePLC-basedelevatorcontrolsystemintegratesvarioushardwaremodulesandlogicroutinestoensuresmooth,efficient operation.ThePLCinterfaceswithfloorsensors,callbuttons,motors,dooractuators,andsafetydevices,formingthecore controlsystem.

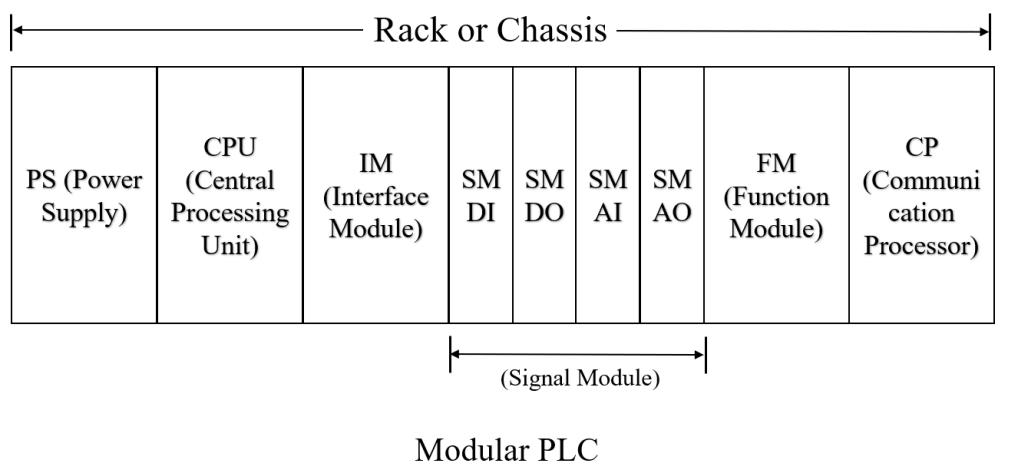

AtypicalPLCsystemcomprisesarackorchassisthatholdsseveralmodules:apowersupply,aCPU(processor)module,I/O signal modules, and optional communication or specialty modules. Figure 1 illustrates the modular rack-mounted PLC configuration.Inourcase,weusedaSiemensSIMATICS7-1200seriesCPUandthecorrespondingpower/I/Omodules.For example:

PLC hardware conponents:

Power Supply: Mountedintheleftmostrackslot,itconvertsACmainsto+24VDCanddistributespowertoallmodules viathebackplane.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

CPU: Thebrainofthesystem(e.g.SiemensSIMATICCPU1215C)containsaprocessor,ROM,andRAM.Itexecutestheuser controlprogram.

I/O Modules: Interfacecardsfordigitalandanalogueinputs/outputs.Digitalinputsconnectsensorsandbuttonstothe PLC,anddigitaloutputsdriveactuators(motors,relays,andlamps).

Communication Module (CP): Forexample,anEthernetinterfaceallowingconnectiontoanHMI(Human-Machine Interface)orhigher-levelsystems.

Fig.1showsthearrangementofthesemodulesonthePLCbackplane.ThepowermodulefedtheCPUandI/Omoduleswith +24VDC.Inputmodulesscanexternalsignals(buttons,switches,andsensors)andsendthemtotheCPU,whereasoutput modulessendcontrolsignals(e.g.motorup/downanddooropen)toexternaldevices.TheCPUwasprogrammedviaaPC usinganEthernetlink.Thismodulardesignallowseasyexpansion;addingmorefloorssimplyrequiresadditionalI/Omodules andprogramadjustments[9].

2.2 Control Logic Strategy

ThePLCprogramimplementsallelevatorcontrollogics,processestheinputs,anddrivestheoutputsaccordingly.Thesystemis connectedtothefollowingcomponents:

Car Motor: Twooutputscontrolthedrivemotordirection(UpandDown).Eachoutputenergisesarelay/contactorforthe upwardordownwardmotion.

Door Actuators: OOneoutputcontrolsthedoormechanism(openingandclosingofbothcabinandlandingdoors).

Floor Sensors: Eachfloorhasasensor(limitswitch)thatsignalsthecar’sarrival;theseresetthecurrentfloorvariablein thePLC.

Obstruction Sensor: Asensoratthedoordetectswhetherthedoorwayisblocked,inhibitingdoorclosing.

Overload Sensor: Aweight(load) sensorinthecabinsignalsifthecarisoverloaded;iftrue,theprogramdisallows motionuntilcleared.

Car Call Buttons (Inputs): Insidethecabin,thereisapushbuttonforeachfloor.Pressingonelatchesacar-callrequestto thesystem.

Hall Call Buttons (Inputs): Oneachlanding,Upand/orDowncallbuttonssethall-callrequestsinPLC.

ThePLClogicmaintainsastatemachinethatprocessestheseinputsandcontrolstheoutputs.Keyfeaturesinclude:

Collective Call Scheduling: When moving in one direction, the elevator serves all requests in that direction before reversing.Forexample,ifthecaristravellingupandtherearependingrequestsabovethecurrentfloor,itcontinues

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

p-ISSN:2395-0072

upward until they are cleared and then changes direction. This single-direction priority is efficient and standard in modernelevatorsystems.

Direction State Machine: Theprogramhasthreestates:Ascending,Descending,andStopped.Transitionsdependon pending calls and the current state. For instance, if there are ascending and no further up-calls exist above, the car transitionstoStopped,pauses,andthenchecksfordown-calls.FromStopped,itchoosesanewdirectionbasedonpending requests above or below the current position. This strategy avoids abrupt reversals and ensures that all calls are eventuallyserved

Door Control: Whenthecararrivesattherequestedfloor(detectedbyafloorsensor),thePLCopensthedoorsforafixed interval.Iftheobstructionsensoristriggeredduringclosing,thePLCreopensthedoorandwaitsuntiltheobstructionis clearedbeforeresumingclosing.Thispreventsthedoorsfromclosingpassengerdoors.

Safety Interlocks: Iftheoverloadsensorisactive,anymotioncommandsareinhibited.Similarly,ifanyunsafecondition isdetected,theprogramignoresthedrivecommandstopreventaccidents.

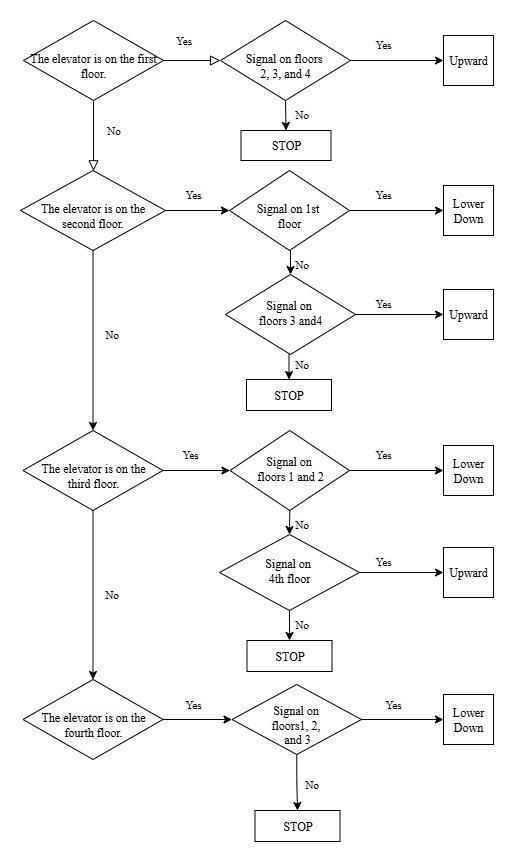

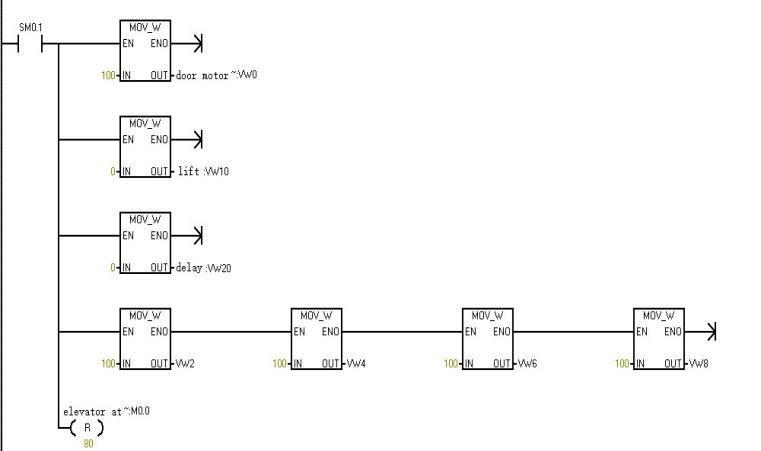

Inourimplementation,thePLCprogramwasdevelopedintheSiemensTIAPortalusingLadderLogic(LD)andFunctionBlock Diagram(FBD)languages[4].AllI/Opointswereassignedinthesoftwaretomatchthephysicalwiring.Theflowchartofthe statemachine(Fig.4)andthelogicalrelationshipsareencodedinthenetworksofladderrungs.Forexample,arungmay energisetheUpmotorcoilonlywhenanuprequestexistsandnohigherrequestsremain.Thislogicensuresthatatmostone driveoutput(UporDown)isactiveatatimeandthatsafetysignals(overload,doorobstruction)immediatelydisablethe motors.

Combined,thePLChardwareandsoftwareformacompleteelevatorcontrollerforfourfloorsofthebuilding.Themodular architecturemakesitstraightforwardtoaddfloorsbyincludingmoreI/Omodulesandadjustingtheprogram’saddressing.

Thissectiondetailsthespecifichardwaresetupforthefour-floorelevatorandtheI/O-pointassignments.Ourlab-scalesystem (orsimulation)includesatractionmotorwithapulley,carandlandingdoors,andfloorsensors.ThePLC’soutputsdrivethe motoranddoors,andtheinputsreadthesensorandbuttonsignals.Inthisdesign,twodigitaloutputscontrolthemotor’sUp andDown relays,andoneoutputcontrolsthedooropen/closeactuator.Digital inputs include onefloorsensor perfloor (detectingcararrival),anoverloadsensor,andadoorobstructionsensor[10].Car-callandhall-callbuttonswerealsowiredas inputs.

Table1showsasamplePLCI/Oaddressmappingforourfour-floorelevator.

PLC Address Description

I0.0 Floor1sensor(at1stfloor)

I0.1 Floor2sensor

I0.2 Floor3sensor

I0.3 Floor4sensor

I0.4

I0.5

I1.0

I1.1

Q0.0

Car-callButtonFloor1(inside)

Car-callButtonFloor2

Hall-callUp(1stfloor)

Hall-callDown(2ndfloor)

MotorUpoutput

Q0.1 MotorDownoutput

Q0.2

DoorOpen/Closeoutput

Q0.3 (Spare)

Type

Input

Input

Input

Input

Input

Input

Input

Input

Output

Output

Output

Output

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

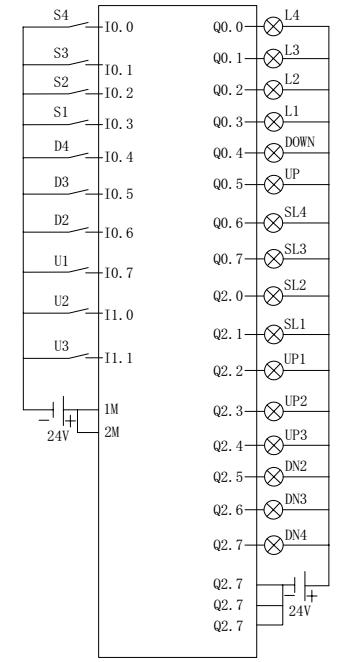

Figure2showstheI/Owiringdiagramoftheelevatorsystem.ItshowshowthePLCinputchannels(I0.0–I1.1)connecttothe floorsensorsandcallbuttons(whichsupply+24VtothePLCwhenactivated)andhowthePLCoutputs(Q0.0–Q2.7)drive lampsandactuators.Theoutputscontrolindicatorlampsforeachfloor(L1–L4),directionindicators(UP/DOWN),andhall-call lamps(UP1–UP3,DN2–DN4)arecontrolled.Eachoutputsinksorsources+24Vtotherespectivedevice.Asingle24VDC powersupplyfedboththeinputsandoutputs(withcommonrailsof1Mforinputsand2Mforoutputs).Forexample,when floorsensorS2(I0.2)istriggered,thePLCenergisesfloor-2lampL2(onQ0.2)andlanding-calllampSL2(onQ2.0).Thiswiring diagramensuresthattheelevatordirection,arrival,andcallsignalsareprocessedefficiently.Techniciansusethisdiagramto wireeachdevicetothecorrectPLCterminal,therebyenablingtheaccuratecontroloftheelevatoroperation[8].

Fig.2.I/Owiringdiagramforthefour-floorelevator,showingconnectionsfromsensorsandbuttonstoPLCinputsandfrom PLCoutputstomotors,doors,andindicatorlamps.

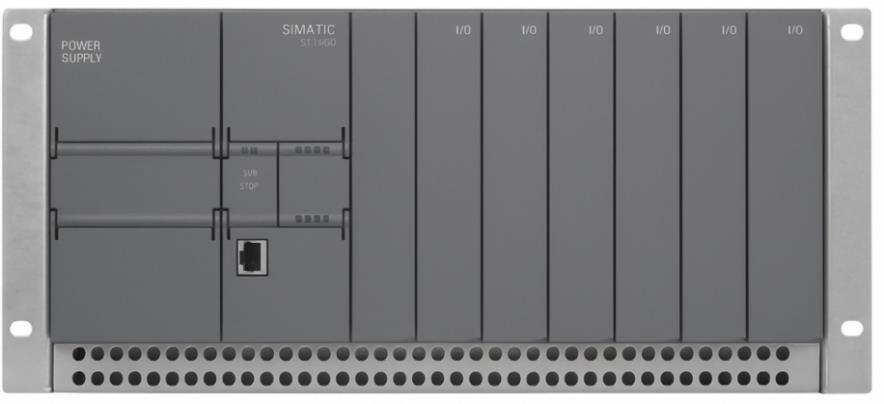

ThechosenPLChardwarewasaSiemensSIMATICS7series(S7-1200)ina9-slotrack(Fig.3).ASiemensKTP700colourHMI panelprovidedtheoperatorinterface(notshown).Inoursetup,themodules(powersupply,CPU,andI/O)weremountedin therackaspertheaddressinginTable1.

Fig.3.Rack-MountedPLCChassis(9-SlotSiemensConfiguration)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Fig.3.9-slotrack-mountedPLCchassis(backplane)usedinindustrialcontrollers.Thepowersupply,CPU,andI/Omodulesare pluggedintotheslotsonthebackplane.Inoursetup,aSiemensSIMATICPLCandI/Omodulesweremountedsimilarly.

Inthehardwarewiring,eachelevatorinputdevice(callbuttonorsensor)isconnectedtoauniquePLCinputterminal,andeach actuatorcoil(motorUp,motorDown,anddooractuator)isconnectedtoaPLCoutputterminal.Specialsafetysignals(overload and obstruction) are wired to dedicated inputs that immediately disable motion outputs when activated. All the interconnectiondiagramsfollowedthestandardPLCwiringpractices.ThePLCprogram’sI/Oaddressingisthensetsothat eachphysicalterminalmapstotheintendedvariable(forexample,I0.0=1st-floorsensor,Q0.0=MotorUpcoil).Thismapping ensuresthatwhenthePLCsetsQ0.0,theelevatorcarmovesupward.

TheelevatorcontrollogicwasimplementedintheSiemensTIAPortalusingtheLadderLogic(LD)andFunctionBlockDiagram (FBD)programminglanguages.ThesegraphicallanguagesallowthePLCtoreactdynamicallytoinputsignals,maintainthe state,anddriveoutputs.Theoverallsoftwaredesignincludedroutinesforcallprocessing,motioncontrol,doorcontrol,and safetychecks.

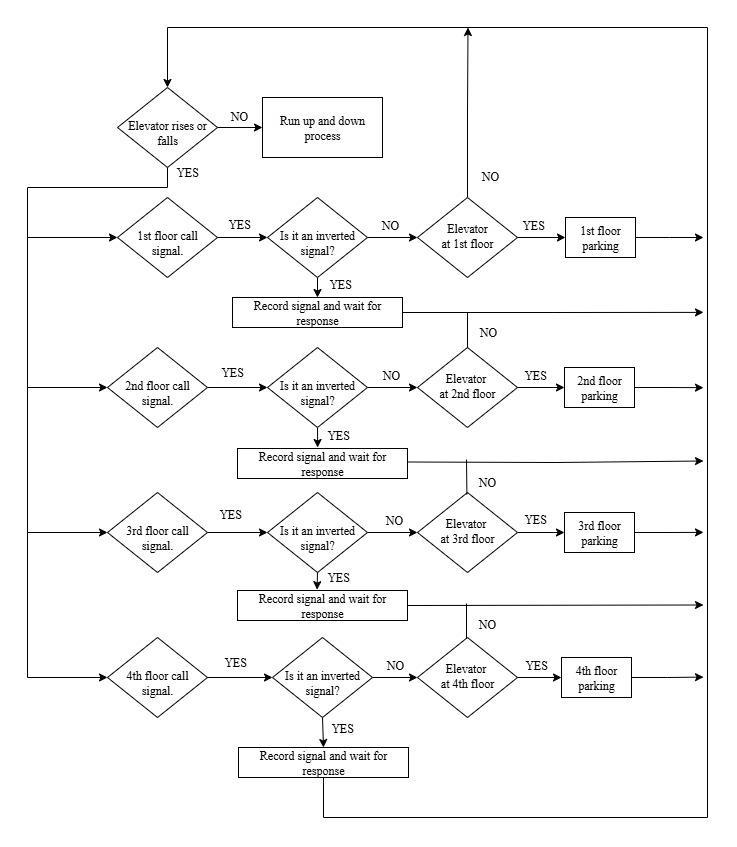

Thecorecontrollogicisimplementedasastatemachinewiththreeprimarystates:Ascending,Descending,andStopped(Fig. 4).ThePLCcontinuouslymonitorsthecurrentfloor,pendingcarandhallcalls,andthecurrentmotiondirection.Basedon theseconditions,thesystemtransitionsbetweenstatestooperatetheelevatorefficiently.Forinstance,whenacar-callorhallcallbuttonispressed,thePLClatchestherequestandprocessesitbyprioritizingthecallsinthecurrentdirectionoftravel.The elevatorservesallcallsaboveitbeforereversing,ensuringenergy-efficientoperation.Oncenocallsremaininthecurrent direction,thelogictransitionstostopped andthentotheoppositedirection,ifneeded.

Fig.4.ElevatorcontrolflowchartshowingtheAscending,Descending,andStoppedstatesandtransitions.

Fig.4ElevatorAscendingandDescendingflowchart

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Duringmotion,thePLCactivatestheappropriateMotorUpoutput:intheascending state,Q0.0(MotorDown)isenergizedif anyup-requestsexistabovethecar;inthedescending state,Q0.1(motordown)isenergizedifanydown-requestsexistbelow. Q0.0andQ0.1wereneveractivesimultaneously.Whenthecarisinthestopped state(e.g.,doorsopening),bothmotoroutputs areoff.

Thedoorcontrolsubsystemensuresthatthedoorsoperatesafelyateachstop(Fig.5).Whenthecararrivesattherequested floor(indicatedbyafloorsensor),thePLCtriggersQ0.2toopenthedoorsforafixeddwelltime(e.g.,3s).Aftertheinterval,the PLCsignalsthedoortoclose.Iftheobstructionsensorbecomesactiveduringclosing,theprogramreopensthedoorsand restartstheclosingtimer,preventingthedoorsfromclosingonanyobstruction[5].Doorsonlyopenifthereisavalidrequest forthatfloorandremainclosedotherwise.

Fig.5.Dooroperationflowchart.Thedoorsopenuponarrivalattherequestedfloor.Ifanobstructionisdetected,thedoor reopensandwaitsuntilthepathisclearbeforeclosing.

4.3

Primary ladder logic networks perform the following tasks:

State monitoring: Detectsthecurrentmotionstate(Up,Down,Stopped)andfloorarrivalviasensors.Whenthecar reachestherequestedfloor,thedoor-controlroutineistriggered.

Call Handling: Latchcar-callandhall-callinputs.Thelogicscansthependingrequestsinthecurrentdirectionoftravel.

Direction Control: Decidewhentocontinuemoving,stop,orreverse.Allcallsinthecurrentdirectionareservedbefore thedirectionischanged.

Output Control: EnergizeQ0.0(upmotor)whenascendingorQ0.1(downmotor)whendescending,basedonpending requests.IntheStoppedstateorduringdooropening,bothmotoroutputsareoff.

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page480

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Door and Safety: When a floor is reached, Q0.2 is activated to open doors for the set interval (Fig. 5). During door opening,themotoroutputsaredisabled.Ifanobstructionisdetected,thedoorsarereopened,andtheclosingtimeris restarted.Iftheoverloadinputistrue,themotoroutputsareinhibiteduntiltheconditionclears[5].

Duringtesting,thePLCprogramcorrectlymanagedvariouscallsequences,ensuringthattheelevatorstoppedsmoothlyatall requestedfloors.Theladderlogicwascompactandeasytodebugforthisdiscretecontroltask[6].Anyfuturechanges(e.g., adjusting door-openingopen time or adding an extra floor) would require only software updates rather than hardware rewiring.

PLC Ladder Diagram of the Elevator Control:

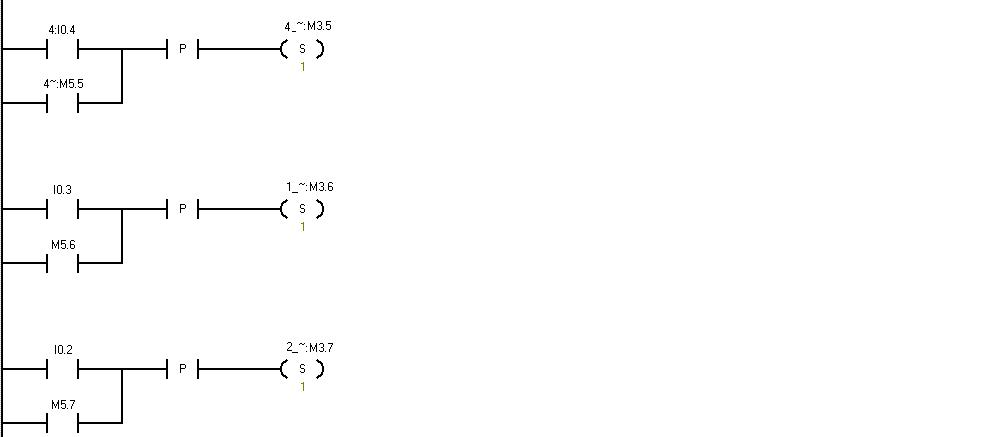

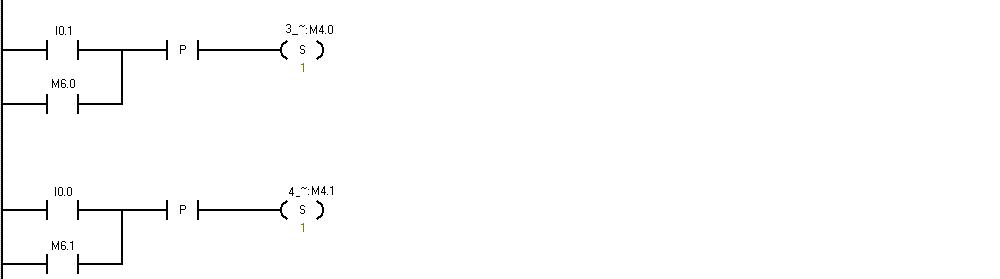

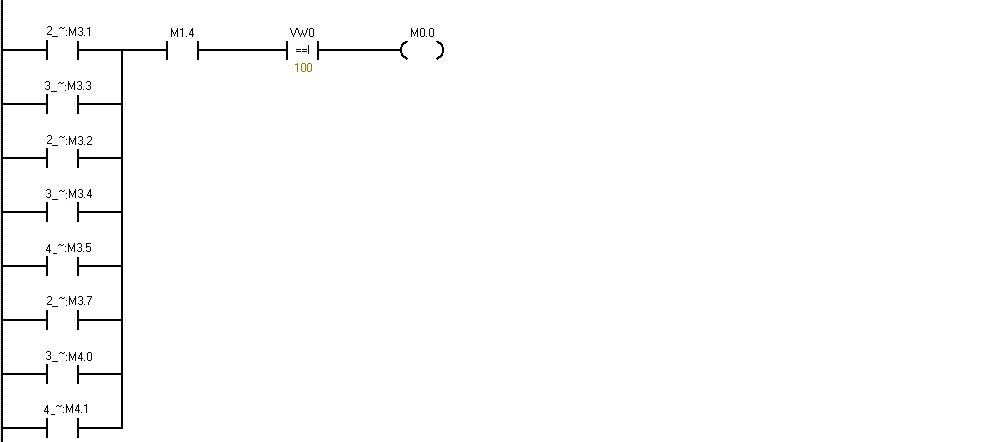

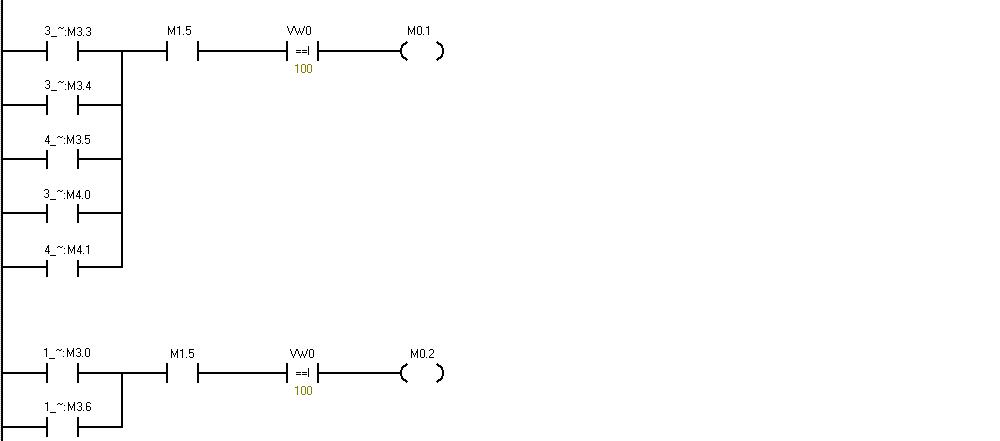

Figure6illustratestheladderlogicusedtocontrolthefour-floorelevatorsystem.Thediagramincludeskeyfunctionalblocks, suchasfloorcallregistration,callreset,directioncontrol(up/down),doorcontrol,elevatormovementcontrol,floorindication, andsafetyinterlocks.Eachrungoftheladdercorrespondstoaspecificoperation.Forexample,whenacar-callorhall-call buttonispressed,theinputislatchedandstoredinamemoryregisterforfuturereference.Theprogramthenevaluatesthe currentstateandactivateseithertheUporDownmotor(Q0.0orQ0.1),dependingontherequesteddirection.Simultaneously, thefloorsensorsupdatedthecar’sposition,andthedooroutput(Q0.2)wastriggereduponarrival.Theladderlogicensures thatonlyonedirectional outputisactiveatanytimeandchecksforoverload andobstructionconditionsbefore allowing motion.Thestructureofthisdiagramhelpsvisualizeandvalidatetheprogramflow,makingiteasytotroubleshootandmodify theprogram.

CallRegistration

Reset

Handling

MovementControl

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Interlock

PLC-basedcontrolwasvalidatedbysimulatingvariouscallscenariosintheTIAPortalenvironment.Inonetest,thecar-call buttonsforfloors1,3,and4werepressed.Startingfromfloor1,theelevatorascended,stoppedatfloor3toopenthedoors, andthenproceededtofloor4.Inanothertest,hall-callUponfloor2andhall-callDownonfloor4wereentered;theelevator movedupfrom1to2,thenreverseddirectionandstoppedat4.Inallscenarios,thedoorsopenedfortheprogrammedinterval ateachstop,andthesimulatedobstructionoroverloadsignalswerehandledcorrectly(doorsreopenedormotionhalted)[7].

Thesystemoperatedefficientlyandwithouterrors.Ladderlogicprogrammingmaintainsthecontrollogicorganizedandis easytotroubleshoot.Anymodificationtothelogic(forexample,changingdoortimingsoraddinganotherfloor)onlyrequires editingtheprogram,notrewiring.Overall,thePLC-controlledelevatormetallthedesignspecificationsanddemonstrated higherreliabilityandflexibilitythanacomparablerelay-basedsystem.

This study demonstrates a PLC-based intelligent control system for a four-floor elevator, which replaces the traditional hardwiredrelaylogic.Theresultingsystemoffersenhancedreliability,flexibility,andimprovedmaintainability.Usingladder logicandfunction-blockdiagrams,thePLCprogramwascompactandeasytodebug,whichsimplifiedfuturemodificationsand expansion.Inalab-scalesimulation,thesystemperformedasexpected.Infuturework,thedesigncouldbescaledtomore floorsoraugmentedwithfeaturessuchaspredictivemaintenanceorremotemonitoring.PLC-basedelevatorcontrolsprovide significantadvantagesformodernbuildingsbecauseoftheirscalability,easeofmodification,androbustnessagainstharsh conditions.

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page482

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

References

[1]G.Shi(ed.), Electrical Control and Programmable Controller Technology.Beijing,China:ChemicalIndustryPress,2012.

[2]G.Yu, Principles and System Design of Programmable Controllers.Beijing,China:TsinghuaUniversityPress,2004.

[3]Q.Wu, Practical Guide to Integrated Application Technology of Inverter, Programmable Controller and Touch Screen,2nded. Beijing,China:ChinaMachinePress,2010.

[4] G. Shi and Y. Ju, Electrical Control and Programmable Controller Technology Training Course. Beijing, China: Chemical IndustryPress,2010.

[5]Y.Li,“DesignofRemoteIntelligentMonitoringSystemforTrafficIntersectionSignalsBasedonGPRSandPLC,”M.S.thesis, InnerMongoliaUniv.ofSci.&Tech.,2012.

[6] L. Xu, “Application of FluidSIM Simulation Software in the Teaching of Electromechanical Equipment Installation and CommissioningCourse,”Dissertation,NanjingVocational&TechnicalCollegeofMech.&Elec.Eng.,2017.

[7]P.ZhaoandH.Jing,“DesignofTrafficLightMonitoringSystemBasedonPLC,”M.S.thesis,YulinUniv.,2016.

[8]X.Zhang,“ComplexTrafficLightControlSystemBasedonS7-200,”M.S.thesis,XianyangNormalUniv.,2010.

[9]Y.Cui,“ApplicationofPLCTechnologyin‘CrossroadsTrafficLightControl’,”Thesis,FularjiBranch,HeilongjiangRadio&TV Univ.,2011.

[10]H.Li, Elevator Control Technology.Beijing,China:ChinaMachinePress,2002.

[11] “Programmable logic controller,” Wikipedia, The Free Encyclopedia. [Online]. Available: https://en.wikipedia.org/wiki/Programmable_logic_controller(accessedJuly2025).

BIOGRAPHIES

Mabia Khatun received the Bachelor's Degree in Electrical Engineering form Nanjing UniversityofInformationScienceandTechnology,Jiangsu,China.Sheiscurrentlypursuing Master's degree in Electrical Engineering from the Anhui University of Science and Technology, Anhui, China. Her current research interests include, PLC-based elevator controls,BayesianOptimizationMachineLearning,DC-DCCircuits,SoftFault.Shecanbe contactedatemail:mabiakhatun.njpichina@gmail.com.

Md. Ariful Islam received the Bachelor's Degree in Electrical Engineering form Nanjing UniversityofInformationScienceandTechnology,Jiangsu,China Heiscurrentlypursuing Master'sdegreeinMechanicalEngineeringfromtheChanganUniversity,Xian,China His currentresearchinterestsinclude,ResearchontheCompilationMethodofTransmission ShaftLoadSpectrumforZL50WheelLoaderUsedinMines.Hecanbecontactedatemail: arifkhan271848@gmail.com.

Merina Akter receivedtheBachelor'sDegreeinSoftwareEngineeringformJiangsuNormal University,Jiangsu,China SheiscurrentlypursuingMaster'sdegreeinComputerScience& TechnologyfromtheChanganUniversity,Xian,China Hercurrentresearchinterestsinclude, Data Science and Artificial Intelligence for Ethical and Scalable AI Solutions She can be contactedatemail:merinahawla1999@gmail.com.