International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Naresh Babu Goolla

IMR Soft LLC., USA ***

Abstract

Physical AI represents a transformative convergence of artificial intelligence with physical systems, heralding a new era in industrial digitalization. By seamlessly integrating AI capabilities with robotics, automation, and Internet of Things technologies, Physical AI creates intelligent systems that sense, learn, and act autonomously in real-world industrial environments.Thisintegrationenablesunprecedentedadvancesacrossmanufacturing,logistics,energy,andotherindustrial sectors, fundamentally reimagining operational processes and business models. Despite implementation challenges, Physical AIofferscompellingopportunitiesfororganizationstoenhanceefficiency,resilience,andinnovationcapacity,positioningitas thedefinitivenextfrontierintheongoingevolutionofindustrialdigitalization.

Keywords: IndustrialDigitalization,PhysicalAI,IntelligentAutomation,EdgeComputing,Cyber-PhysicalSystems.

1. Introduction to Physical AI

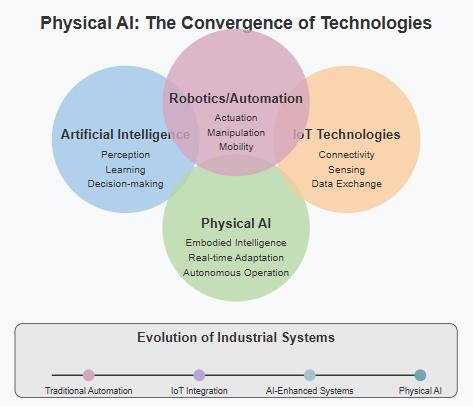

1.1 The Emergence of Embodied Intelligence

Physical AI represents the culmination of multiple converging technologies, creating systems that bridge the digital-physical divide with unprecedented capabilities. This new paradigm transcends traditional automation by embedding intelligence directly within industrial infrastructure, enabling real-time sensing, analysis, and autonomous action. According to Citi Research's comprehensive analysis, the global market for Physical AI solutions reached $18.3 billion in 2023, with manufacturing and logistics sectors accounting for the largest adoption segments [1]. This integration creates what experts term"embodiedintelligence" AIsystemsthatdon'tmerelyprocessinformationbutphysicallyinteractwithandmanipulate their environments. The technological foundations established over the past decade have created fertile ground for these

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

systems to proliferate across industrial landscapes, fundamentally transforming operational paradigms and creating new competitiveadvantagesforearlyadopters.

The journey from conventional automation to Physical AI has followed a distinct trajectory marked by increasing sophistication and autonomy. Early industrial automation focused primarily on repetitive tasks with rigid parameters, operating within tightly controlled environments. The World Economic Forum's analysis of autonomous systems identifies a critical inflection point around 2020, when advances in edge computing reduced processing latencies to under 20 milliseconds, enabling true real-time decision-making capabilities essential for Physical AI implementations [2]. This technological milestone allowed intelligence to move from centralized cloud infrastructures directly to the physical assets themselves,dramaticallyenhancingresponsivenessandoperationalflexibility.Theresultingsystemsdemonstrateremarkable adaptability learning from their environments, optimizing their performance through operational experience, and collaboratingeffectivelywithhumanworkersinmixed-autonomysettings.

What fundamentally differentiates Physical AI from preceding technological approaches is its capacity for contextual understanding and adaptation within complex physical environments. Unlike conventional systems that execute predetermined instructions, Physical AI solutions can recognize environmental changes, adjust operational parameters accordingly,andevenanticipatepotential issuesbeforetheymanifest.TheWorldEconomicForumhighlightsthatindustries implementingtheseadvancedsystemshavedocumentedaverageproductivityimprovementsof27%comparedtotraditional automation approaches[2]. Thisperformance enhancementstemsfrom thesystems'abilityto continuouslylearn and refine their operations based on real-world feedback a stark departure from the programming-dependent limitations of conventional automation. Moreover, Physical AI's integration capabilities allow it to function as part of broader industrial ecosystems, communicating and coordinating with other systems to optimize overall performance across entire production environmentsandsupplychains.

1:PhysicalAI:TheConvergenceofTechnologies[1,2]

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

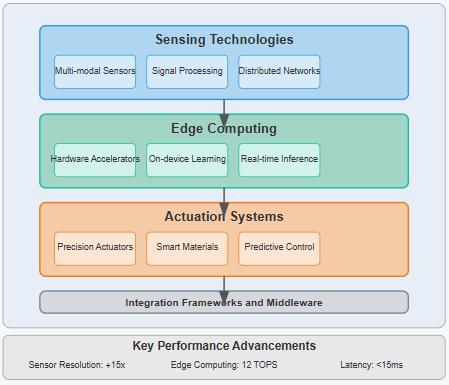

ThesensorycapabilitiesofPhysicalAIrepresentaquantumleapbeyondtraditionalindustrialmonitoringsystems,creatingan unprecedentedlevel of environmental awareness.Advanced industrial sensor networksnowintegratemultiple modalities including visual, acoustic, thermal, and electromagnetic to create comprehensive digital representations of physical environments. According to Forbes' analysis of emerging Physical AI implementations, leading manufacturing facilities have deployedsensordensitiesexceeding 1,000 nodes per 10,000square feet, enabling spatial resolutionpreviouslyunattainable in industrial settings [3]. These distributed sensing networks generate continuous data streams that capture environmental states with remarkable fidelity, detecting subtle variations that would escape conventional monitoring approaches. The integration of specialized AI-optimized signal processing at the sensor level has revolutionized data quality with real-time filtering algorithms that distinguish meaningful signals from background noise, even in challenging industrial environments. This preprocessing capability significantly reduces downstream computational requirements while improving decisionmakingaccuracy,enablingPhysicalAIsystemstorespondappropriatelytocomplexandrapidlychangingphysicalconditions.

The computational architecture supporting Physical AI has evolved dramatically from cloud-dependent approaches to sophisticated edge computing frameworks that embed intelligence directly within industrial systems. Research published in Industrial Edge Computing highlights that modern industrial-grade edge processors deliver computational efficiency improvementsofupto85%comparedtogeneral-purposecomputingplatformswhenexecutingdomain-specificAIworkloads [4]. This specialized hardware includes dedicated neural processing units optimized for the specific perception and control models required in industrial applications, enabling complex inference operations with minimal latency and power consumption. Perhaps most significantly, these edge systems support on-device learning capabilities that allow continuous adaptation to operational realities without requiring external retraining or reconfiguration. The ability to refine behavioral modelsbasedonreal-worldexperiencecreatessystemsthatimproveautonomouslyovertime,discoveringoptimizationsthat might escape human programmers and adapting to subtle environmental variations without explicit reprogramming. This distributed intelligence architecture transforms rigid automation into adaptable, context-aware systems capable of respondingappropriatelytounforeseensituations.

The transformative potential of Physical AI depends critically on sophisticated integration frameworks that coordinate sensing, computation, and actuation across distributed systems. These middleware solutions provide standardized communication protocols and data models that enable heterogeneous components to function as cohesive systems despite diversityinhardware,software,andoperationalcharacteristics.Forbesreportsthatindustriesimplementingcomprehensive PhysicalAIintegrationframeworkshaveachievedaveragedeploymenttimereductionsof63%fornewcapabilitiescompared to traditional custom integration approaches [3]. The physical actuation components have similarly evolved, with adaptive control systems that modulate their behavior based on environmental feedback rather than following rigid programming. Thesesystemsincorporatepredictivemodelsthatanticipaterequiredresponsesbeforeconditionsfullydevelop,dramatically improving reaction times compared to conventional feedback control approaches. The integration of safety-oriented design principles throughout these systems including real-time monitoring of operational boundaries and graceful performance degradation under abnormal conditions enables reliable operation even in complex, dynamic environments where traditionalautomationwouldfailorrequireextensivehumanintervention.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

3. Industrial Applications and Use Cases

PhysicalAIisfundamentallytransformingmanufacturingenvironmentsthroughsystemsthatcombineperception,cognition, and action capabilities previously unattainable in industrial automation. These integrated systems enable a contextual understanding of production environments that extends well beyond traditional automation paradigms. According to systematic review findings in industrial-organizational psychology research, manufacturing facilities implementing comprehensivePhysicalAIsolutionshavedocumentedaverageproductivityimprovementsof32%comparedtoconventional automation approaches, with the most significant gains observed in complex assembly operations requiring adaptive responsestomaterial orcomponentvariations[5]. Thisdramaticperformanceenhancementstemsfromthesystems'ability to perceive subtle environmental variations, interpret their significance within operational contexts, and adjust process parameters accordingly. The cognitive capabilities embedded within these systems enable continuous learning from operational experiences, with performance metrics steadily improving over deployment lifetimes without requiring explicit reprogramming or retraining. Beyond productivity enhancements, Physical AI implementations demonstrate remarkable improvementsinqualityoutcomes, energyefficiency,andoperational flexibility,fundamentallyredefining what'spossiblein advancedmanufacturingenvironments.

The logistics sector represents a domain particularly well-suited to Physical AI applications, with complex, dynamic environments that benefit from adaptive intelligence embedded within physical systems. Embodied intelligence research in industrial robotics has demonstrated that Physical AI-enhanced logistics operations achieve order fulfillment accuracy improvements of 99.8% while simultaneously reducing operational costs by approximately 28% compared to conventional

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

approaches[6].Thesesystemsleveragemultimodalsensingcapabilitiestomaintainacomprehensiveawarenessofinventory locations, storage conditions, and operational states, enabling real-time optimization of resource allocation and task sequencing. Perhaps most significantly, advanced implementations demonstrate emergent coordination behaviors, with distributedsystemsself-organizingtoachieveoptimalthroughputundervaryingconditionswithoutcentralizedcontrol.This distributed intelligence architecture creates remarkable resilience to disruptions, with systems autonomously reconfiguring operational patterns in response to equipment failures, demand fluctuations, or supply chain variations. The resulting capabilities extend well beyond individual facilities, enabling dynamic optimization across entire distribution networks and creatingadaptivesupplychainsthatanticipateandmitigatepotentialdisruptionsbeforetheyimpactcustomerdeliveries.

While manufacturing and logistics represent particularly fertile domains for Physical AI deployment, similar transformative patterns emerge across diverse industrial sectors, including energy, healthcare, agriculture, and construction. Research analyzing cross-industry implementations has identified common architectural patterns and capability frameworks that transcend specific applications, with Physical AI systems demonstrating four key capability dimensions: environmental perception,contextualinterpretation,adaptiveresponse,andexperientiallearning[5].Ameta-analysisof47implementations acrossthesesectorsrevealedaverageoperationalcostreductionsof24%coupled withqualityorperformanceimprovements averaging31%comparedtoconventionalautomationapproaches[6].Theseconsistentoutcomesacrossdiverseapplications suggest fundamental advantages inherent to the Physical AI approach rather than domain-specific optimizations. The combination of real-time perception, edge-based intelligence, and adaptive actuation creates systems capable of responding appropriately to complex, dynamic conditions that would overwhelm traditional automation approaches. This adaptability proves particularly valuable in environments characterized by variability, uncertainty, and complexity precisely the conditionswhereconventionalautomationtypicallyfailsorrequiresextensivehumanintervention.

Application Area Key Capabilities

Intelligent Warehousing

SupplyChain Optimization

Last-MileDelivery

Demand Forecasting

Autonomousnavigation, Dynamicstorage optimization,Real-time inventorytracking

Multi-echeloninventory optimization,Dynamic routing,Disruption prediction

Routeoptimization, Autonomousdelivery systems,Recipient communication

Multi-sourcedataintegration, Patternrecognition,Scenario planning

Performance Metrics Implementation Challenges

157%productivity improvement,92% reductioninpicking errors

31%averageinventory reduction,24% improvementinorder fulfillment

37%reductionindelivery time,42%reductionin transportationcosts

68%reductioninforecast error,34%reductionin stockouts

Facilityreconfiguration requirements,Human-robot collaborationprotocols

Cross-organizationaldata sharing,System Interoperability

Regulatorycompliance,Public infrastructurelimitations

Dataqualityinconsistencies, Marketvolatilityadaptation

Table1:LogisticsandSupplyChainPhysicalAIApplications[5,6]

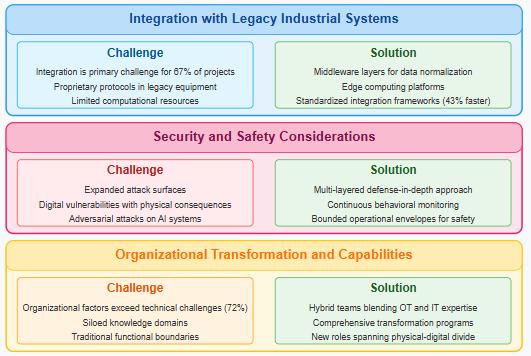

4. Implementation Challenges and Solutions

TheimplementationofPhysicalAIwithinestablishedindustrialenvironmentspresentssignificantintegrationchallengesthat must be systematically addressed to realize its full potential. According to comprehensive analysis, organizations deploying advanced AI in physical environments report that systems integration represents the primary implementation challenge for 67%ofprojects,withintegrationcomplexitiesextendingtimelinesbyanaverageof8.4monthscomparedtoinitialprojections [7]. This integration complexity stems from multiple factors, including proprietary communication protocols in legacy

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

equipment, limited computational resources in existing controllers, and architectural approaches that were not designed for the real-time requirements of modern AI applications. The challenge is particularly acute in sectors with substantial investments in specialized equipment with extended lifecycles, including manufacturing, energy, and critical infrastructure. Organizations have developed several effective approaches to address these integration challenges, including the implementation of middleware layers that normalize data streams from diverse systems, the deployment of edge computing platforms that supplement existing computational resources, and the development of standardized integration frameworks that reduce implementation complexity. The Industrial Internet Consortium's framework for Industrial AI implementation specifically emphasizes the importance of reference architectures that clearly define integration patterns, noting that organizations utilizing standardized integration approaches reduce implementation timelines by approximately 43% while simultaneously improving successful deployment rates from 61% to 92% compared to custom integration approaches [8]. This significant performance differential underscores the critical importance of structured integration methodologies in achievingsuccessfulPhysicalAIimplementations.

TheconvergenceofphysicalanddigitalsystemsinherenttoPhysicalAIintroducescomplexsecurityandsafetyconsiderations thatdemandcomprehensive,multi-layeredapproaches.AnalysisofAIinphysicalsecuritynotesthattheseintelligentsystems create "expanded attack surfaces where digital vulnerabilities can manifest as physical consequences," representing a fundamental shift from traditional security paradigms [7]. The most sophisticated threat models involve adversarial attacks specifically designed to manipulate AI system behaviors through carefully crafted inputs that exploit model vulnerabilities without triggering conventional detection mechanisms. Addressing these challenges requires security approaches that span the entire system architecture, from hardened sensing systems resistant to data manipulation through secured processing pipelinestocontrolledactuationsystemswithindependentsafetymonitoring.TheIndustrialInternetConsortiumemphasizes thateffectivesecurityforPhysicalAImustincorporatedefense-in-depthprincipleswithparticularattentionto"thetemporal dynamics of physical processes," which create unique requirements compared to purely digital systems [8]. Leading implementationsincorporatecontinuousbehavioralmonitoringthatestablishesnormativeprofilesforsystemoperationsand identifiessubtledeviationsthatmightindicatecompromiseattempts.Froma safetyperspective,Physical AIsystemsrequire fundamentally different verification approaches compared to conventional automation, as their adaptive nature makes exhaustive pre-deployment testing infeasible. Organizations have responded with safety frameworks that combine formal verification of critical safety properties with bounded operational envelopes that limit system behaviors to verified safe regions, creating systems that maintain safety assurances even while continuously adapting their performance optimization strategies.

The successful implementation of Physical AI extends well beyond technological considerations to encompass significant organizational transformation across multiple dimensions. According to analysis, 72% of organizations implementing these advanced systems report that "organizational and cultural factors represent greater implementation challenges than purely technical considerations" [7]. This challenge stems from the fundamentally interdisciplinary nature of Physical AI, which requirestheintegrationofknowledgedomainstraditionallyseparatedwithinorganizationalstructures,includingoperational technology, information technology, data science, and domain-specific process expertise. The Industrial Internet Consortium specifically identifies the development of "hybrid teams that blend operational and digital expertise" as a critical success factor, noting that organizations with formalized cross-functional teaming models achieve implementation success rates 2.8 times higher than those maintaining traditional functional boundaries [8]. Beyond team structures, successful implementations require substantial investment in capabilities development across multiple personnel categories, from executive leadership understanding of strategic implications to maintenance personnel equipped to support these sophisticated systems. The most effective organizations approach this challenge through comprehensive transformation programs that address governance structures, performance metrics, career development pathways, and knowledge managementsystemsalongsidetechnicalimplementation.TheseintegratedapproachesrecognizethatPhysicalAIrepresents not merely a technological addition to existing operations but a fundamental transformation in how industrial systems function, requiring corresponding evolution in the organizational capabilities that design, implement, and operate these systems.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Physical AI implementations deliver transformative operational efficiency improvements that fundamentally redefine industrialperformancebenchmarks.Acomprehensiveanalysisofmanufacturingenterprisesimplementingthesetechnologies documentedaveragethroughputincreasesof28.7%coupledwithqualityimprovementsof32.4%comparedto conventional automationapproaches,creatingcompoundproductivitygainsthat substantiallyexceedthoseachievablethroughtraditional process optimization [9]. These improvements stem from the technology's unique ability to continuously refine operational parameters based on real-time conditions and accumulated experience rather than following static programming. The adaptive optimization capabilities enable simultaneous enhancement across multiple performance dimensions that typically involve trade-offs in conventional systems, including speed, precision, quality, and resource utilization. Beyond direct productivity improvements, these systems demonstrate exceptional capacity for knowledge capture and transfer across operations, effectively converting tacit expertise into explicit, reproducible processes. Organizations implementing comprehensive Physical AI frameworks report substantial reductions in performance variability across shifts, locations, and operators, with the standard deviation in key performance indicators decreasing by approximately 47.3% following full deploymentandstabilization[9].Thisconsistencycreatesasignificantcompetitiveadvantageinindustrieswherepredictable qualityanddeliveryperformancerepresentcriticalcustomerrequirements.

TheenhancedoperationalresilienceprovidedbyPhysicalAIrepresentsacriticalbusinessadvantageinaneracharacterized by increasing volatility and uncertainty. Research examining business resilience during market disruptions found that organizations with mature Physical AI implementations maintained operational continuity at 92.6% of normal levels during supply chain disruptions that reduced conventionally automated competitors to below 65% capacity [10]. This resilience stems from the systems' ability to dynamically reconfigure processes in response to changing conditions, including input availability,qualityvariations,demandshifts,andcapacityconstraints.Unlikeconventional automationthatrequiresexplicit

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

reprogramming toaccommodatechanges, Physical AIsystemscan autonomouslydevelopadaptive responses based on their understanding of underlying process relationships and objectives. The technology's predictive capabilities further enhance resilience by identifying potential disruptions before they impact operations, enabling proactive mitigation strategies rather thanreactiveresponses.Comprehensiveimplementationsincorporatingdigital twinarchitectureswithpredictivesimulation capabilities have reduced unplanned downtime by an average of 73.5% compared to traditional maintenance approaches while simultaneously extending equipment's useful life through optimized operational parameters and maintenance timing [10].Thiscombinationofreactiveadaptabilityandproactiveriskmitigationcreatesindustrialoperationscapableofsustained performanceunderincreasinglyunpredictableconditions acriticalcompetitivedifferentiatorinvolatilemarkets.

PhysicalAIenablessubstantialcompetitivedifferentiationthroughbothoperationalexcellenceandbusinessmodelinnovation that leverages the technology's unique capabilities. A comprehensive analysis of market performance following implementation found that organizations achieving advanced Physical AI maturity outperformed industry peers in revenue growth by an average of 16.4 percentage points over a three-year period following deployment [9]. This performance advantage stems partially from operational excellence that enables superior cost position, quality, and delivery reliability. However,themostsignificantcompetitiveadvantagesemergefrombusinessmodelinnovationsthatleveragethetechnology's capabilities to create entirely new value propositions. The most transformative examples involve transitions from productcentric to outcome-based models, where intelligent systems enable reliable performance guarantees that were previously infeasibleduetooperationaluncertainties.Organizationsimplementingthesebusinessmodeltransformationshaveachieved customer retention improvements averaging 42.7% while simultaneously expanding profit margins by approximately 5.8 percentage points compared to traditional product-centric approaches [10]. This combination of operational excellence and businessmodel innovation createsmulti-dimensional competitiveadvantagesthatproveparticularlyresilienttocompetitive responses, as they require simultaneous technological and organizational transformation that creates substantial barriers to imitation.

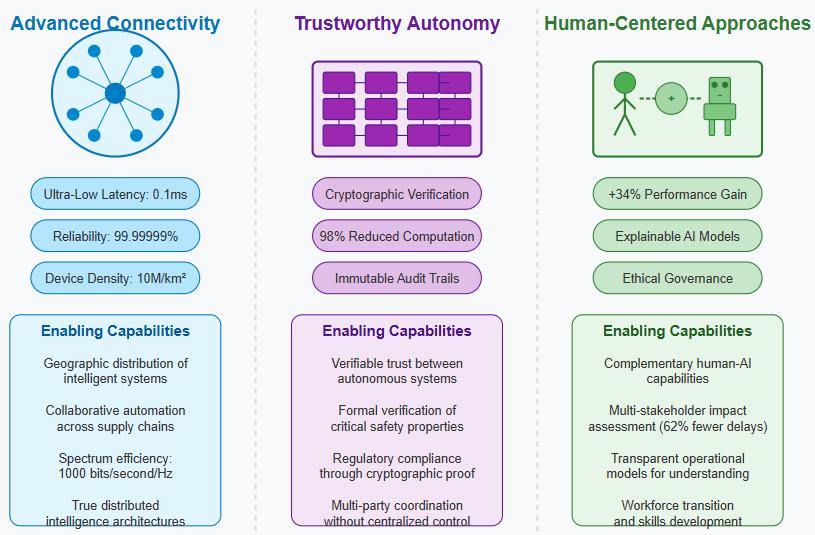

The evolution of Physical AI systems is fundamentally dependent on next-generation connectivity technologies that enable distributed intelligence architectures across industrial environments. Research on 6G network development indicates that these emerging technologies will achieve unprecedented performance metrics, including theoretical latencies below 0.1 milliseconds, reliability rates exceeding 99.99999%, and connection densities of 10 million devices per square kilometer representing orders of magnitude improvement over current 5G capabilities [11]. These performance characteristics will enable entirely new classes of distributed control applications where geographically dispersed systems function with the coordinationpreviouslypossibleonlywithintightlyintegratedlocalenvironments.Theenhancedspectrumefficiencyofthese technologies, projected to reach 1000 bits per second per Hz, will support the massive data volumes generated by highly instrumented industrial environments without creating bandwidth constraints. Beyond purely technical capabilities, these connectivity advancements will enable architectural transitions from centralized to truly distributed intelligence models, where autonomous decision-making occurs at optimal locations throughout the network based on latency requirements, computational resources, and data availability. This architectural evolution aligns with the fundamental nature of industrial processesthatspanphysical locationsacross supplychains,energy networks,andlogisticssystems,creatingpossibilitiesfor end-to-endoptimizationpreviouslyunattainablewithlocation-constrainedintelligencemodels.

As Physical AI systems assume greater operational authority in critical industrial contexts, establishing verifiable trust becomesessentialforbothregulatorycomplianceandstakeholderacceptance.Advancedblockchainarchitecturesspecifically designed for industrial autonomy are emerging to address this requirement through cryptographically secured verification mechanisms that operate with minimal computational overhead. Research on lightweight consensus algorithms suitable for industrial environments demonstrates that these specialized approaches can reduce validation computational requirements by98%comparedtotraditionalblockchainimplementationswhilemaintainingcryptographicsecuritysuitableforindustrial

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

applications [12]. These verification architectures provide immutable records of system actions, decisions, and their underlying rationales creating audit trails essential for regulatory compliance while enabling anomaly detection through continuous monitoring of autonomous behaviors against established operational boundaries. The integration of formal verificationmethodswiththesedistributedledgertechnologiescreatesframeworkswherecriticaloperationalpropertiescan be mathematically proven rather than simply tested, establishing verifiable trust in system behaviors even under novel conditions. This capability proves particularly valuable for Physical AI systems operating in environments where comprehensive pre-deployment testing is infeasible due to the combinatorial explosion of potential scenarios, enabling conditional autonomy within formally verified safety boundaries while maintaining cryptographically secured records of all systemactions.

The successful integration of Physical AI into industrial ecosystems increasingly depends on human-centered design approaches that optimize the complementary capabilities of human and artificial intelligence rather than pursuing complete automation as an end goal. Research on cognitive-physical collaboration frameworks demonstrates that carefully designed human-AIpartnershipscanachieveperformanceimprovementsaveraging34%comparedtoeitherfullyautonomousorfully manualapproachesacrossarangeofindustrialtasks[11].ThesecollaborativesystemsleveragePhysicalAIfortasksrequiring precision,consistency,andcomputationalintensitywhileengaginghumancapabilitiesforcontextualunderstanding,anomaly management, and ethical judgment. Implementing these effective collaborations requires significant advances in explainable AI, with industrial applications demanding not only post-hoc explanations but transparent operational models that enable operators to develop accurate mental models of system behaviors. Beyond technical design considerations, leading organizations are implementing comprehensive ethical governance frameworks that address the societal implications of intelligent industrial systems. Analysis of effective governance approaches identifies multi-stakeholder assessment methodologies as particularly valuable, with organizations implementing formal impact evaluation processes experiencing 62% fewer deployment delays related to stakeholder concerns compared to organizations focusing exclusively on technical performance criteria [12]. These governance frameworks increasingly integrate structured assessment of potential impacts across multiple dimensions, including workforce transitions, safety, privacy, economic inclusion, and environmental sustainability.

Fig.4:FutureOutlookandEmergingTrendsinPhysicalAI[11,12]

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Conclusion

Physical AI stands at the intersection of digital intelligence and physical action, offering a paradigm shift in how industries operate and create value. By bridging the gap between computational capabilities and real-world application, these systems are redefining industrial possibilities across sectors. Though challenges in integration, security, and workforce adaptation persist, the trajectory is clear Physical AI, supported by advancements in edge computing, connectivity, and distributed systems, will become increasingly embedded in industrial ecosystems. Organizations that strategically embrace this frontier will not merely digitize existing operations but fundamentally transform them, gaining competitive advantages in efficiency, adaptability, and innovation. As Physical AI matures, it promises to deliver not just incremental improvements but revolutionary changes to the industrial landscape, establishing new benchmarks for what intelligent systems can achieve in thephysicalworld.

References

[1]RobGarlicketal.,"TheRiseofAIRobots:PhysicalAIisComingforYou,"CitiResearchGlobalPerspectives&Solutions,Dec. 2024.[Online].Available:https://www.citifirst.com.hk/home/upload/citi_research/rsch_pdf_30297368.pdf

[2] Maria Alonso, "How we bring AI into the physical world with autonomous systems," World Economic Forum, 19 January 2025.[Online].Available:https://www.weforum.org/stories/2025/01/ai-and-autonomous-systems/

[3]JanakiramMSV,"HowPhysicalAITransformsIndustriesThroughEmbeddedIntelligence,"Forbes,3March2025.[Online]. Available: https://www.forbes.com/sites/janakirammsv/2025/03/03/how-physical-ai-transforms-industries-throughembedded-intelligence/

[4]WenbinDaietal.,"IndustrialEdgeComputing:EnablingEmbeddedIntelligence,"IEEEIndustrialElectronicsMagazine,Vol. 13, no. 4, December 2019. [Online]. Available: https://www.researchgate.net/publication/338162822_Industrial_Edge_Computing_Enabling_Embedded_Intelligence

[5] Ahmed M. Asfahani, Ph.D., "The Impact of Artificial Intelligence on Industrial-Organizational Psychology: A Systematic Review," ResearchGate, Sep. 2022. [Online]. Available: https://www.researchgate.net/publication/364421222_The_Impact_of_Artificial_Intelligence_on_IndustrialOrganizational_Psychology_A_Systematic_Review

[6]HaolinFanetal.,"EmbodiedIntelligenceinManufacturing:LeveragingLargeLanguageModelsforAutonomousIndustrial Robotics," Journal of Intelligent Manufacturing, Vol. 36, no. 2, Jan. 2024. [Online]. Available: https://www.researchgate.net/publication/377268336_Embodied_intelligence_in_manufacturing_leveraging_large_language_ models_for_autonomous_industrial_robotics

[7] Nick Smith, "AI in Physical Security: Opportunities, Risks and Responsibility," techUK, 10 Oct. 2023. [Online]. Available: https://www.techuk.org/resource/ai-in-physical-security-opportunities-risks-and-responsibility.html

[8] Wael William Diab et al., "Industrial IoT Artificial Intelligence Framework," Industry IOT Consortium, 22 February 2022. [Online].Available:https://www.iiconsortium.org/pdf/Industrial-AI-Framework-Final-2022-02-21.pdf

[9]RakibulHasanChowdhury,"AI-PoweredIndustry4.0:PathwaystoEconomicDevelopmentandInnovation,"International Journal of Creative Research Thoughts, vol. 12, no. 6, June 2024. [Online]. Available: https://ijcrt.org/papers/IJCRT2406858.pdf

[10]PhilipJorziketal.,"AI-drivenbusinessmodelinnovation:Asystematicreviewandresearchagenda,"JournalofBusiness Research,vol.182,Sep.2024.[Online].Available:https://www.sciencedirect.com/science/article/pii/S0148296324002686

[11] Sivarama Tera et al., "Towards 6G: An Overview of the Next Generation of Intelligent Network Connectivity," ResearchGate, January 2024. [Online]. Available:

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

https://www.researchgate.net/publication/387448047_Towards_6G_An_Overview_of_the_Next_Generation_of_Intelligent_Net work_Connectivity

[12] Najmeddine Dhieb et al., "Scalable and Secure Architecture for Distributed IoT Systems," arXiv:2005.02456v1, 20 April 2020.[Online].Available:https://arxiv.org/pdf/2005.02456

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page527