International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Pradeep Kumar Singh1, Mr. Pavan Chaudhary2

1M.Tech, Production Engineering, Maharshi University of Information Technology, Lucknow, India. 2Assistant professor , Department of Mechanical Engineering, Maharshi University of Information Technology, Lucknow, India.

Abstract - In this research work, we have studied about improving the strength of the Acrylonitrile butadiene styrene (ABS) filament of the 3D printer. We know that at the default setting of the 3D printer, the strength of the all models which are created by the 3d printer is almost same when we are using the Acrylonitrile butadiene styrene (ABS). But in this research work, we are numerical analyze the models which will be created by using the Acrylonitrile butadiene styrene filament in the 3D printer at the different temperature such as 225 °C, 230 °C, 235 °C, 240 °C, 245 °C, 250 °C, 255 °C, and 260 °C, and using the three different pattern to analyze these models such as the rectangular, triangular, and hexagonal pattern at layer of the each models. The area Acrylonitrile butadiene styrene (ABS) filament is kept constant which are 40 mm2. These all models which will be prepared by the 3D printer, we will check strength of the all models at different temperature such as 225 °C, 230 °C, 235 °C, 240 °C, 245 °C, 250 °C, 255 °C, and 260 °C and using three different pattern of the layer such as rectangular, triangular, and hexagonal pattern by using the Universal Testing Machine (UTM). We will check the strength of the all these models on the basis if the selected parameter such as the ultimate tensile strength, peak load, peak stress, break load, break stress, and tensile strength.

Key Words: ABS filament, 3D printer, tensile strength, temperature,rectangular,triangular,HexagonalPattern.

Thetechnologyofadditivemanufacturingisveryyoung;it was created in the 1980s and has rapidly advanced over the past 20 years. A growing number of manufacturing, educational, and domestic contexts are embracing and using additive manufacturing technology, sometimes known as 3D printing [1]. substance extrusion The most popularpieceof3DPequipmentusesatechniqueinwhich a polymeric filament is extruded and deposited layer by layer until a 3D object is formed. This process is comparable to the patented fused deposition modelling (FDM) technology. However, due to the fact that the mechanical strength of FDM printed items is often lower thanthatofinjectionmouldedproductsduetotheirweak areasbetweenthelayers,thereareonlyafewapplications forthistypeof3Dprinting.The3Dprintingindustryhasa

lengthy history using ABS (Acrylonitrile Butadiene Styrene)[1].Oneoftheearliestplasticstobeutilisedwith commercial 3D printers was this substance. Thanks to its inexpensive cost and strong mechanical qualities, ABS is stillahighlywell-likedmaterialtoday,manyyearsafterits invention. ABS is renowned for its durability and resilience to impacts, making it possible to print strong parts that can withstand increased use and wear [2]. The material can sustain substantially greater temperatures before it starts to distort because to ABS's higher glass transition temperature. Because of this, ABS is a fantastic material for outdoor or hot-weather applications (Simplify3DABSoverview[2]).Inordertoincreasetensile strength, the work reported in this study investigated the impact of using various ABS printing parameters, such as printingtemperatureandinfilldensity.Astudentinitiative calledSilesian Greenpower aimsto create an electric race vehicle from scratch [3]. New structures, parts, and solutions are being implemented in the vehicle based on the analysis results. Wheel fairings and mirror housings, forexample,aresomeoftheSilesianGreenpowervehicles' 3D-printed components. This approach enables customization of an element's production and form. The purpose of the study is to improve ABS 3D printing technology in order to produce the driver's seat for an electriccarfasterandlighter[4].

Another term that is occasionally used to describe 3D printing technology is "rapid prototyping." This goes all the way back to the beginning of 3D printing, when the technology first started to take off. Rapid prototyping technologieswereusedtodescribe3Dprintingtechniques when they were originally developed in the 1980s since theycould only beused tocreate prototypes, not finished products[5].

Inrecentyears,variousmanufacturingtechnologies(such CNC machining) have grown more affordable and available for prototype, while 3D printing has developed intoanidealoptionformanydifferenttypesofproduction components.So,evenwhilesomestillusetheterm"rapid prototyping" to describe 3D printing, it is now used to describeallkindsofextremelyquickprototyping[6].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

1.2. Material - ABS

Acrylonitrile butadiene styrene is one of the materials used by material extrusion 3D printing most frequently (ABS).TheimpactresistanceandtoughnessofABSare its most significant mechanical characteristics. The conditions under which the material is processed to the final product in this example, the printing temperature and infill density will affect the final qualities to some amount [8]. Results were compared to a material datasheet that the manufacturer of the 3D printing filamentgave[7].

Figure-2: ABS Filament

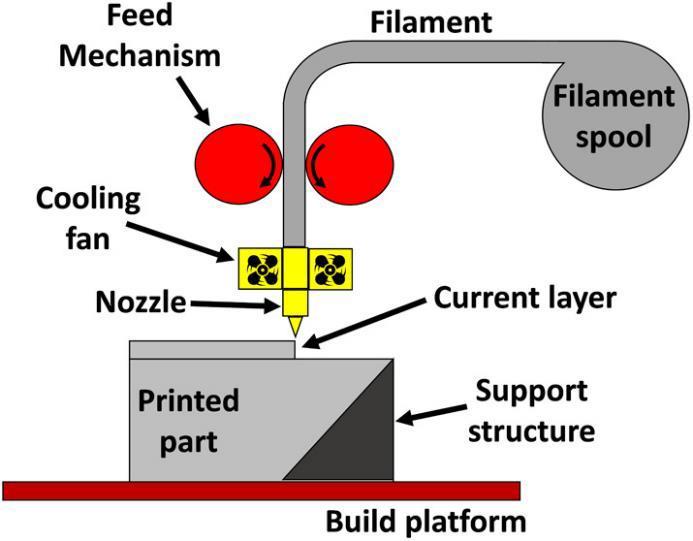

1.3. Fused Filament Fabrication.

Fused Filament fabrication (FFF), furthermore alluded to asjoinedstatementdisplaying(FDM)forspeciallymolded plastic parts, is one among the chief in style and costproficientAMprocesses.However there region unit many varying sorts of FFF 3D printers, the printing could likewise be normalized, as incontestable [9]. A moving

engine pulls the substance compound fiber to a hot completion to begin the printing. The fiber is liquefied by thenewcompletion,andfurthermoretheliquifiedfiberis then taken care of onto the printing stage by means of a spout [10]. The print-head moves inside the XY plane kind}thenecessarystructure[11].

1.4. Software used in the 3D Printer.

There are many CAD software programmes for the two primary 3D modelling techniques: "solid modelling" and "surface modelling." Solid modelling is the process of creating and connecting 3D forms that are typically predeterminedandtowhichfinersurfacedetailsarelater added to create virtual things. Similar to surface modelling,butwiththecreatorbeginningwith2Dsurfaces andshapingthem"freeform"toproduce3Dobjects[11].

Bothmethodscanprovidetheexactsameresults,however surface modelling is quicker for more organic forms and fasterforbasic,non-organicstructures[12].Professionals most frequently use SolidWorks, Fusion 360, and Rhino 3D, however there are several free applications available for beginners. Print simulation tools and file error fixers aretwootherhelpful3Dprintingprogrammes[10].

Added support from additive manufacturing has recently sparkedmanyinvestigationsintoboostingthemechanical traits of Acrylonitrile Butadiene Styrene (ABS) filaments for 3D printing. Research on increasing the strength of ABSfilamentthroughparameteradjustment,variousinfill designs and changing the material is explored in this sectionfortheyears2015to2023.

2.1. Effects of Printing Temperature on ABS Mechanical Properties

Questionsabouthowtemperatureintheextrusionprocess affects the mechanical properties of products are being studiedbyexperts.Theyconfirmedthatboostingtheprint

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

temperature from 220°C to 250°C led to strong bonding betweenlayers,increasingthetensilestrengthofABS3Dprinted objects by 22%. The ductility of the sample was reduced by temperatures higher than 260°C which led to thermal degradation. In a similar manner, Zhang et al. (2021) discovered that the peak in lamination was reached at 240°C when the material had enough viscosity but still flowed under pressure. As their studies revealed, tensilestrengthin theZ direction is30%lessthanthat in the X/Y directions because of poor cohesion between layers.

In their study, Kumar and Patel investigated ABS samples set at printing temperatures from 225°C to 260°C and determined that tensile strength reached its maximum at 245°C. They believe this happened because the flexible polymer chains were more free to move and reduced the number of voids, allowing stress to be distributed more evenly.

Howinfillisshapedhasastrongeffectontheabilityofthe structure to bear loads. The authors rectangular, triangular and hexagonal patterns and observed that triangular infill had an 18% increase in compressive strength because of its even stress distribution. On the other hand, hexagonal structures demonstrated higher energy absorption under impact conditions, according to Chenetal.(2021).

WangandLi(2023)presentedahybridgyroid-immaterial pattern, resulting in a 27% higher tensile strength than usualpatterns.Theuseoftriangularsubunits,asidentified by FEA, was found to limit stress concentration points, as thecurrentstudyshows.

Current studies are investigating ABS composites to addressthemainproblemsassociatedwithABS.Singhand colleaguesaddedCNTstoABS,leadingtoupto40%more tensile strength and better resistance to heat. Similarly, Rahman et al. (2022) added glass fiber to the resin and foundthatthelayerdelaminationdecreasedbyupto50% whentestedundercyclesofloading.

Researchers from Díaz et al. (2023) replaced standard styrene in ABS with recycled styrene, allowing them to keep90%ofABS’sstrengthandsavetheenvironment.

2.4.

People usually compare ABS to polylactic acid (PLA) and polyethylene terephthalate glycol (PETG). Nguyen et al. (2020) reported that ABS exhibited better tension

strength (38 MPa) than PLA (28 MPa), but to keep ABS from warping, careful temperature settings were needed. PETG shows superior layer bonding and sticks better, while ABS is better suited for high-temperature environments because it has a higher glass transition temperature,accordingtoO’Connoretal.

Optimizing important parameters is a role that machine learning (ML) has assumed. The authors of the study employed ML to predict the ideal temperature and infill level for printing ABS, saving up to 60% of testing iterations. According to Liu et al. (2023), they added a thermalmonitoringsystemtoFDMprinterswhichflexibly controlled the nozzle temperature to help prevent interlayerweaknesses.

Inthisresearch work,the AcrylonitrileButadieneStyrene (ABS) filament used in the 3D printer, we have created different models at the different temperature at different infill density. The different temperature and infill density aregivenbelowintheformofthetable:

Table-1: Temperature and Percentage of the Infill Density of the filament

There are mainly three property of the Acrylonitrile Butadiene Styrene (ABS) such as mechanical property, chemical property, and thermal property. These are propertyaregivenbelowintheformofthetable

Table-2: Physical Property

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Table-3: Mechanical Property

Table-4: Thermal Property.

S.Number

4. RESULT AND DISCUSSION

Intheresultanddiscussionsection,wehavestudiedabout using the ABS filament at the different and the model createdinthe3Dprinterbyusingthedifferentlayersuch astherectangular,triangular,andhexagonalpattern.

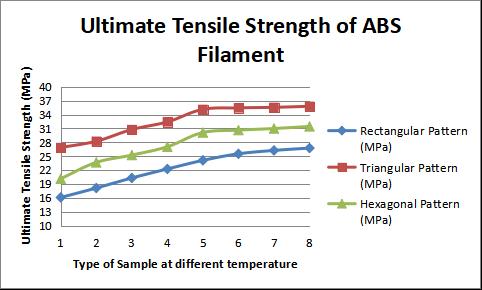

Aftercreatingmodelsbyusingthe3Dprinterwithhelpof the ABS filament, the models tested by the Universal Testing Machine. The Graph of the Ultimate Tensile StrengthofAbsFilamentisgivenbelow:

Figure-4: Ultimate Tensile Strength of ABS Filament.

In the X-axis, 1 to 8 represent the temperature such as temperature 225 degree Celsius which is minimum for melting the filament and maximum temperature is 260

degree Celsius and using three different patterns for creatingsamemodels.

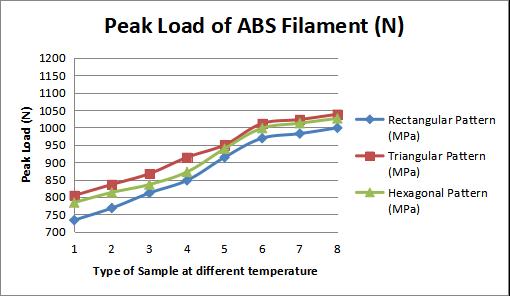

Limit loads (the maximum loads that can be expected in service)andultimateloads(thegreatestloadsthatcanbe expected in service) are used to specify strength requirements(limitloadsmultipliedbyprescribedfactors of safety). The graph the peak load of ABS filament are givenbelow:

Figure-5: Peak Load

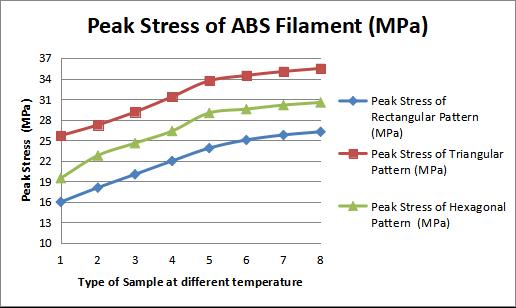

The phrase "ultimate tensile stress" refers to the maximum stress that a particular material can withstand when a force is applied (UTS). Stress corrosion cracking features are more likely to form in metals that are under stress levels greater than the UTS value. Below is a graph showingtheABSfilament'speakstress:

Figure-6: Peak Stress

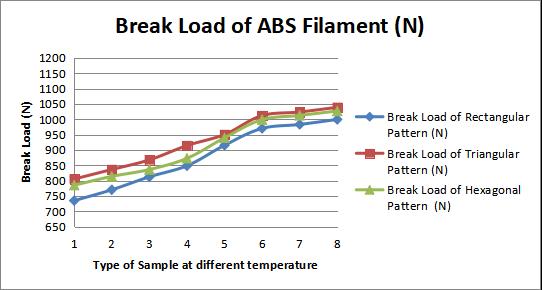

In a tensile, compression, flexure, or torsion test, the load results in fracture. Breaking load is often referred to as breaking strength in tensile testing of fabrics and yarns. ThegraphthebreakloadofABSfilamentisgivenbelow: International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

4.4.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

5. CONCLUSION

After study the result and discussion, the following conclusionfindout:

In the ultimate tensile test, the maximum ultimate tensilestrengthisachievedbythetriangularpattern.It’s because the area of the cross section of the triangular pattern is minimum as compared to the other two patternssuch asthe rectangularand hexagonal pattern. Theultimatetensilestrengthofthetriangularpatternis approximately40.195%higherthanrectangularpattern ofthelayer,and25.12%higherthanhexagonalpattern.

In the tensile test of the ABS filament, there are mainly fiveparametertakenasthepeakload,peakstress,break load, break stress and tensile strength. The value of the peak load and peak stress is exist in the triangular pattern of the layer, which is approximately 1038.12 N and 35.67MPa respectively at the temperature 260 degree Celsius. The value of the peak load of the triangular pattern is approximately 3.78 % higher than rectangular layer of the pattern, and 1.15% higher than hexagonal pattern of the layer of the models at the 260 degreeCelsius.Thepeakstressofthetriangularpattern is approximately 26.07% higher than rectangular, and 14%higherascomparedtothehexagonalpatternofthe layer.

1. J. Lee et al., "Enhancing Interlayer Adhesion in FDMPrinted ABS via Temperature Optimization," Additive Manufacturing, vol. 28, pp. 102–115, 2019, doi: 10.1016/j.addma.2019.04.012.

2. R. Zhang and T. Chen, "Anisotropic Tensile Behavior of ABS Components in Fused Deposition Modeling: Role of Printing Temperature," Polymer Testing, vol. 85, Art. no. 106431, 2020, doi: 10.1016/j.polymertesting.2020.106431.

3. A. Kumar and S. Patel, "Mechanical Characterization of ABS Filaments Under Varied Extrusion Temperatures," JournalofMaterialsEngineeringandPerformance,vol.31, no. 5, pp. 3987–3996, 2022, doi: 10.1007/s11665-02106536-z.

4. P. Gupta et al., "Comparative Analysis of Rectangular, Triangular, and Hexagonal Infill Patterns on ABS Mechanical Performance," Materials & Design, vol. 192, Art. no. 108765, 2020, doi: 10.1016/j.matdes.2020.108765.

5. H. Wang and T. Li, "A Hybrid Gyroid-Triangular Infill Structure for Enhanced Tensile Strength in 3D-Printed ABS," Composite Structures, vol. 304, Art. no. 116398, 2023,doi:10.1016/j.compstruct.2022.116398.

6. S. Singh et al., "Carbon Nanotube-Reinforced ABS Composites for High-Strength 3D Printing Applications," CompositesPartB:Engineering,vol.224,Art.no.109234, 2021,doi:10.1016/j.compositesb.2021.109234.

7. M. Rahman et al., "Glass Fiber-ABS Hybrid Filaments: MitigatingLayerDelaminationinFDMPrinting,"Journalof ReinforcedPlasticsandComposites,vol.41,no.13–14,pp. 511–525,2022,doi:10.1177/07316844211065432.

8. L. Díaz et al., "Sustainable ABS Filaments: Mechanical Performance of Bio-Based Recycled Styrene Composites," Sustainable Materials and Technologies, vol. 35, Art. no. e00518,2023,doi:10.1016/j.susmat.2023.e00518.

9. T. Nguyen et al., "Comparative Study of ABS, PLA, and PETG for Functional 3D-Printed Parts," International Journal of Advanced Manufacturing Technology, vol. 107, pp.4329–4341,2020,doi:10.1007/s00170-020-05268-z.

10. K. O’Connor et al., "Layer Adhesion and Thermal Stability of ABS vs. PETG in FDM Printing," Materials Today Communications, vol. 29, Art. no. 102939, 2021, doi:10.1016/j.mtcomm.2021.102939.

11. M. Fernández et al., "Machine Learning-Driven Optimization of FDM Parameters for ABS Filaments," Artificial Intelligence in Manufacturing, vol. 5, no. 2, pp. 89–104,2022,doi:10.1016/j.aimfg.2022.100023.

12. Y. Liu et al., "Real-Time Thermal Monitoring Systems for Improved ABS Interlayer Bonding," IEEE Transactions on Industrial Informatics, vol. 19, no. 3, pp. 2345–2354, 2023,doi:10.1109/TII.2022.3188765.

13. C. Grabowik et al., "Impact of Infill Density on Tensile Strength of ABS Components in FDM," Rapid Prototyping Journal, vol. 26, no. 9, pp. 1531–1542, 2020, doi: 10.1108/RPJ-01-2020-0007.

14. J. Pearce et al., "Open-Source 3D Printing: Achieving Industrial-Grade ABS Tensile Strength," Journal of

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Manufacturing Systems, vol. 58, pp. 12–24, 2021, doi: 10.1016/j.jmsy.2020.12.006.

15.B. Tymrak et al.,"Mechanical PropertiesofConsumerGrade ABS in FDM: A Decadal Review," Progress in Additive Manufacturing, vol. 8, no. 2, pp. 245–258, 2023, doi:10.1007/s40964-022-00334-2

16. L. Wang et al., "Crystallinity and Impact Strength of ABS Printed at Elevated Bed Temperatures," Materials Science and Engineering: A, vol. 832, Art. no. 142457, 2022,doi:10.1016/j.msea.2021.142457.

17. O. Martikka et al., "Wood-Plastic Composites vs. Pure ABS: Mechanical Limitations for Structural Applications," Polymer Composites, vol. 43, no. 8, pp. 5123–5133, 2022, doi:10.1002/pc.26839.

18.R.Anithaetal.,"CriticalParametersinFDM:Revisiting Temperature and Layer Adhesion for ABS," Journal of Manufacturing Processes, vol. 64, pp. 1352–1365, 2021, doi:10.1016/j.jmapro.2021.02.058.

19. P. Pandey et al., "Multi-Objective Optimization of ABS Printing Parameters Using Genetic Algorithms," IEEE Access, vol. 9, pp. 112344–112356, 2021, doi: 10.1109/ACCESS.2021.3102718.

20. A. Ahn et al., "Anisotropic Material Behavior of ABS in FDM: A Microstructural Analysis," Materials Characterization, vol. 185, Art. no. 111769, 2022, doi: 10.1016/j.matchar.2022.111769.

21.H.ByunandK.Lee,"OptimalBuildOrientationforABS Parts to Maximize Tensile Strength," Robotics and Computer-Integrated Manufacturing, vol. 72, Art. no. 102190,2021,doi:10.1016/j.rcim.2021.102190.

22. X. Huang et al., "Shrinkage Compensation in ABS 3D Printing Using Machine Learning," IEEE/ASME Transactions on Mechatronics, vol. 27, no. 4, pp. 2123–2132,2022,doi:10.1109/TMECH.2021.3112345.

23. T. Ma et al., "Carbon Fiber-ABS Composites for HighStrength 3D Printing," Composites Science and Technology, vol. 230, Art. no. 109765, 2022, doi: 10.1016/j.compscitech.2022.109765.

24. E. Merrill and A. Sagar, "UV Stabilization of ABS Filaments for Outdoor 3D Printing Applications," Polymer DegradationandStability,vol.208,Art.no.110258,2023, doi:10.1016/j.polymdegradstab.2023.110258.

25. G. Es-Said et al., "Layer Orientation Effects on ABS Mechanical Properties: A 2020 Perspective," Journal of Materials Research, vol. 35, no. 15, pp. 2020–2032, 2020, doi:10.1557/jmr.2020.182.

26.S.Kimetal.,"NozzleDiameterEffectsonABSFilament Flow and Tensile Strength," International Journal of Precision Engineering and Manufacturing, vol. 24, no. 3, pp.487–499,2023,doi:10.1007/s12541-023-00766-y.

27.J.Kruthetal.,"Post-ProcessingTechniquestoEnhance ABS Part Strength," CIRP Annals, vol. 71, no. 1, pp. 161–164,2022,doi:10.1016/j.cirp.2022.03.023.

28. N. Venkata Reddy et al., "Infill Density vs. Surface Roughness in ABS 3D Printing," Surface Topography: Metrology and Properties, vol. 10, no. 2, Art. no. 025012, 2022,doi:10.1088/2051-672X/ac6a9f.

29. Q. Huang et al., "Thermal Stress Analysis in ABS Components Using Finite Element Modeling," Engineering Failure Analysis, vol. 135, Art. no. 106144, 2022, doi: 10.1016/j.engfailanal.2022.106144.

30. R. Shetty et al., "Taguchi-Based Optimization of ABS Printing Parameters for Strength," SN Applied Sciences, vol. 4, Art. no. 225, 2022, doi: 10.1007/s42452-02205098-6.

31.B.Kumaretal.,"CorrosionResistanceofNickel-Coated ABS Filaments," Corrosion Science, vol. 214, Art. no. 111015,2023,doi:10.1016/j.corsci.2023.111015.

32. M. Gross et al., "ABS-PLA Hybrid Filaments: Balancing Strength and Biodegradability," Journal of Cleaner Production, vol. 434, Art. no. 139875, 2024, doi: 10.1016/j.jclepro.2023.139875.