International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 04 Issue: 07 | July -2017

www.irjet.net

p-ISSN: 2395-0072

A STUDY ON STRENGTH PROPERTIES OF CONCRETE MADE WITH WASTE READY-MIX CONCRETE AS COARSE AGGREGATE AND PARTIAL REPLACEMENT OF CEMENT BY GGBS Krishna Chaitanya E1, Dr K Manjunatha2, Harish B A3 1PG

Student, Department of Civil Engineering, UBDT College, K.A., INDIA Department of Civil Engineering, UBDT College, K.A., INDIA 3Assistant Professor, Department of Civil Engineering, GMIT College, K.A., INDIA ---------------------------------------------------------------------***--------------------------------------------------------------------Abstract. Using waste materials for ne w products is a quarrying of natural aggregate to the increased disposal costs 2Professor,

of waste materials. Recently, these aggregates started to be used for intermediate utility applications, such as foundations for buildings and roads. The advantages of recycling construction and demolition waste are (1) it reduces the amount of construction and demolition waste entering landfill sites; and (2) it reduces the use of natural resources.

global trend undergoing rapid development. Recycling materials allows for a more efficient life cycle and contributes to environmental protection. In the construction field, this trend has gained importance because of the shortage of natural resources and because of environmental problems caused by storing building-demolition wastes and concrete wastes. This situation has led to the search for new applications for these wastes, and their use as aggregates in concrete is an interesting alternative. In this paper, some characteristics of recycled coarse aggregates obtained by crushing waste ready-mix concrete, as well as the mechanical properties of recycled concretes made by using various aggregates percentages and also with GGBS with various proportions, are presented.

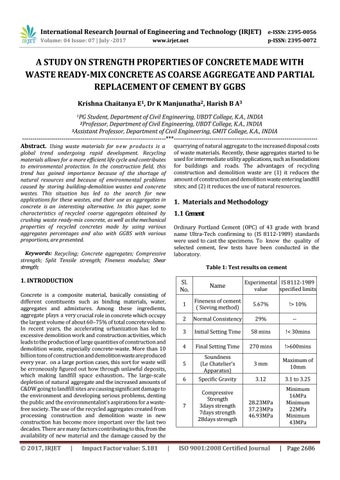

1. Materials and Methodology 1.1 Cement Ordinary Portland Cement (OPC) of 43 grade with brand name Ultra-Tech confirming to (IS 8112-1989) standards were used to cast the specimens. To know the quality of selected cement, few tests have been conducted in the laboratory.

Keywords: Recycling; Concrete aggregates; Compressive strength; Split Tensile strength; Fineness modulus; Shear strength;

Table 1: Test results on cement

1. INTRODUCTION Concrete is a composite material, basically consisting of different constituents such as binding materials, water, aggregates and admixtures. Among these ingredients, aggregate plays a very crucial role in concrete which occupy the largest volume of about 60–75% of total concrete volume. In recent years, the accelerating urbanization has led to excessive demolition work and construction activities, which leads to the production of large quantities of construction and demolition waste, especially concrete-waste. More than 10 billion tons of construction and demolition waste are produced every year. on a large portion cases, this sort for waste will be erroneously figured out how through unlawful deposits, which making landfill space exhaustion.. The large-scale depletion of natural aggregate and the increased amounts of C&DW going to landfill sites are causing significant damage to the environment and developing serious problems, denting the public and the environmentalist’s aspirations for a wastefree society. The use of the recycled aggregates created from processing construction and demolition waste in new construction has become more important over the last two decades. There are many factors contributing to this, from the availability of new material and the damage caused by the

© 2017, IRJET

|

Impact Factor value: 5.181

|

Sl. No.

Name

1

Fineness of cement ( Sieving method)

5.67%

2

Normal Consistency

29%

3

Initial Setting Time

58 mins

!< 30mins

4

Final Setting Time

270 mins

!>600mins

5

Soundness (Le Chatelier’s Apparatus)

3 mm

Maximum of 10mm

6

Specific Gravity

3.12

3.1 to 3.25

7

Compressive Strength 3days strength 7days strength 28days strength

Experimental IS 8112-1989 value specified limits

28.23MPa 37.23MPa 46.93MPa

ISO 9001:2008 Certified Journal

!> 10% --

Minimum 16MPa Minimum 22MPa Minimum 43MPa

| Page 2686