International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395-0056

Volume: 04 Issue: 07 | July -2017

p-ISSN: 2395-0072

www.irjet.net

Review on study of waste heat utilization techniques in vapour compression refrigeration system Dhananjay Parmar1, Neelesh Soni2 1Research

Scholar, Department of Mechanical, ITM University, Gwalior, India Professor, Department of Mechanical, ITM University, Gwalior, India ---------------------------------------------------------------------***--------------------------------------------------------------------2Assistant

Abstract - To review the design of working research model

environment, just as the situation of the most standard aircooling models, as well as to drinking water moving from an air conditioning tower system. In the fast-developing nation like India, the majority of the vapour compression-based refrigeration, air-conditioning and high temperature pumping devices continue to keep operate on halogenated refrigerants credited for their superb thermodynamic and thermo-physical properties aside from the low priced [2].

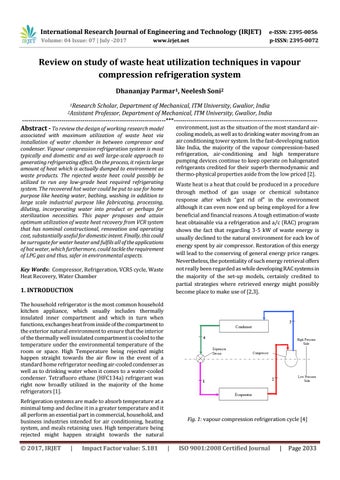

associated with maximum utilization of waste heat via installation of water chamber in between compressor and condenser. Vapour compression refrigeration system is most typically and domestic and as well large-scale approach to generating refrigerating effect. On the process, it rejects large amount of heat which is actually dumped to environment as waste products. The rejected waste heat could possibly be utilized to run any low-grade heat required refrigerating system. The recovered hot water could be put to use for home purpose like heating water, bathing, washing in addition to large scale industrial purpose like fabricating, processing, diluting, incorporating water into product or perhaps for sterilization necessities. This paper proposes and attain optimum utilization of waste heat recovery from VCR system that has nominal constructional, renovation and operating cost, substantially useful for domestic intent. Finally, this could be surrogate for water heater and fulfils all of the applications of hot water, which furthermore, could tackle the requirement of LPG gas and thus, safer in environmental aspects.

Waste heat is a heat that could be produced in a procedure through method of gas usage or chemical substance response after which “got rid of� in the environment although it can even now end up being employed for a few beneficial and financial reasons. A tough estimation of waste heat obtainable via a refrigeration and a/c (RAC) program shows the fact that regarding 3-5 kW of waste energy is usually declined to the natural environment for each kw of energy spent by air compressor. Restoration of this energy will lead to the conserving of general energy price ranges. Nevertheless, the potentiality of such energy retrieval offers not really been regarded as while developing RAC systems in the majority of the set-up models, certainly credited to partial strategies where retrieved energy might possibly become place to make use of [2,3].

Key Words: Compressor, Refrigeration, VCRS cycle, Waste Heat Recovery, Water Chamber

1. INTRODUCTION The household refrigerator is the most common household kitchen appliance, which usually includes thermally insulated inner compartment and which in turn when functions, exchanges heat from inside of the compartment to the exterior natural environment to ensure that the interior of the thermally well insulated compartment is cooled to the temperature under the environmental temperature of the room or space. High Temperature being rejected might happen straight towards the air flow in the event of a standard home refrigerator needing air-cooled condenser as well as to drinking water when it comes to a water-cooled condenser. Tetrafluoro ethane (HFC134a) refrigerant was right now broadly utilized in the majority of the home refrigerators [1]. Refrigeration systems are made to absorb temperature at a minimal temp and decline it in a greater temperature and it all perform an essential part in commercial, household, and business industries intended for air conditioning, heating system, and meals retaining uses. High temperature being rejected might happen straight towards the natural

Š 2017, IRJET

|

Impact Factor value: 5.181

Fig. 1: vapour compression refrigeration cycle [4]

|

ISO 9001:2008 Certified Journal

|

Page 2033