International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Shashidhara E1 , Virancha M2, K.V.S.B Raju3

1Post graduate student, Dept. of Civil Engineering, UVCE College (University), Bengaluru

2 Post graduate student, Dept. of Civil Engineering, UVCE College (University), Bengaluru

3Associate Professor, Dept. of Civil Engineering, UVCE College (University), Karnataka, India-560056

Abstract - Helical piles have emerged as a reliable deep foundation solution in geotechnical engineering, prized for their ease of installation and superior performance under uplift and tensile loads. This study presents an experimental investigation into the axial and oblique pullout behavior of helical piles embedded in both homogeneous andlayeredsand beds. The primary aim is to assess how key parameters such as sand relative density, number of helices, helix spacing ratio (S/Dh), and loading angle influence uplift performance. A total of 54 small-scale model tests were conducted on monopiles and helical piles with one, two, and three plates, embedded in dry sand at relative densities of 30% and 60%. Tests were also carried out in layered profiles consisting of a loose upper layer over a denser lower layer. Load inclination angles of 0°, 30°, and 45° were applied to simulate axial and oblique pullout scenarios. The results show that pullout capacity increases with higher relative density, more helices, and greater embedment depth. Multi-helix piles performed significantly better when helix spacing reduced plate interaction, particularly at S/Dh = 3. Beyond this spacing, gains incapacity were marginal, indicating a shift from cylindrical shear to individual plate bearing. Layered soils offered improveduplift resistance due to the confining effect of the denser layer. These findings provide experimental validation for theoretical models and offer practical insights for optimizing helical pile design in uplift-critical applications.

Key Words: Helical Pile, Pullout Capacity, Oblique Loading, Relative Density, Inter-Helix Spacing, Individual Plate Bearing, Cylindrical Shear, Homogenous, Sand Bed.

Incivilengineering,manystructures suchastransmission towers,solarpanels,andtallchimneysrequirefoundations capable of resisting significant uplift forces. Traditional footingsoftenfallshortundersuchtension,promptingthe needformoreefficientsolutions.Helicalpileshaveemerged asacost-effectiveandsustainablealternative,offeringquick installation and minimal environmental disruption. These deepfoundationsystemsareespeciallysuitedforresisting pull-outloadsduetotheirscrew-likegeometry.Enhancing thesurroundingsoilcanfurtherimprovetheirperformance underuplift.Whiletheiruseisexpanding,acomprehensive understanding of their behavior under axial and inclined

loading remains essential. In particular, the effects of soil density and load angle on pullout resistance need deeper investigation. This study addresses these gaps by experimentally analyzing helical piles in varied sand conditions.Thefindingsaimtoinformbetter,morereliable foundationdesignsforreal-worldapplications.

Theuseofhelicalpiles,or“screwpiles,”datesbacktothe 1830s when Alexander Mitchell, an English brick maker, patentedthedesignin1833.Hefirstapplieditsuccessfullyin thefoundationoftheMaplinSandsLighthouse,constructed onunstablegroundneartheRiverThames.Thefoundation featuredcastironhelicesandwroughtironshaftsarrangedin an octagonal layout, manually installed to a depth of 6.7 meters. Mitchell’s 1848 paper, On Submarine Foundations, wasthefirsttechnicalpublicationonscrewpiles,highlighting theirabilitytoresistbothverticalandupliftforces.Modern research gained momentum from 2003 to 2005 with the introductionoffiniteelementmodeling,whichhelpedreduce costsandadvancedesignmethods.Between2012and2020, global studies explored the influence of material types, configurations, and soil conditions on pile performance. Recentinvestigationshavefocusedonlateralcapacity,group behavior, and offshore applications, underscoring the growing importance of helical piles in contemporary geotechnicalengineering.

Helical piles offer a versatile and efficient foundation solution suitable for a wide range of soil conditions, including soft, loose, or waterlogged soils. Their quick installation process requires minimal excavation and equipment, reducing time, cost, and site disruption especiallyvaluableinurbanorrestricted-accessareas.With lownoiseandvibrationduringinstallation,theyareidealfor environmentally or noise-sensitive sites. Helical piles provide immediate load-bearing capacity, allowing faster project timelines. They are available in various sizes and configurationstomeetdifferentloadandsiterequirements and offer excellent resistance to both vertical and uplift forces,makingthemsuitableforstructuresexposedtowind, seismic, or flood loads. Additionally, they can be easily removed, reused, or extended, contributing to sustainable andcost-effectiveconstructionpractices.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Whilehelicalpilesoffermanyadvantages,theyalsohave limitations that must be considered. Their load-bearing capacity is generally lower than other deep foundation systems,makingthemlesssuitableforheavystructureslike high-rise buildings. Certain soil types such as rocky ground,highlyplasticclays,orloose,collapsiblesoils can hinder installation and performance. Installation depth is also limited by equipment torque and pile strength, restrictingtheiruseinverydeepfoundations.Incorrosiveor acidicsoils,durabilitycanbeaconcern,requiringprotective measures and ongoing maintenance. Proper installation demandsspecializedequipmentandskilledoperators,which may not be available in remote areas. Additionally, in seismically active zones, helical piles may lack sufficient lateral resistance unless modified, increasing cost and complexity. While cost-effective for small to medium projects, their economic benefits decline for large-scale applications.Understandingthesechallengesisessentialfor selecting the right foundation system and ensuring safe, efficientdesign.

2.1

Inthepresentstudyclean,dryriversandisusedforthe foundationbed.Variouslaboratorytestsareconductedon thesandtodetermineitspropertiesaspertheISStandards. TheobtainedpropertiesaretabulatedinTable-1

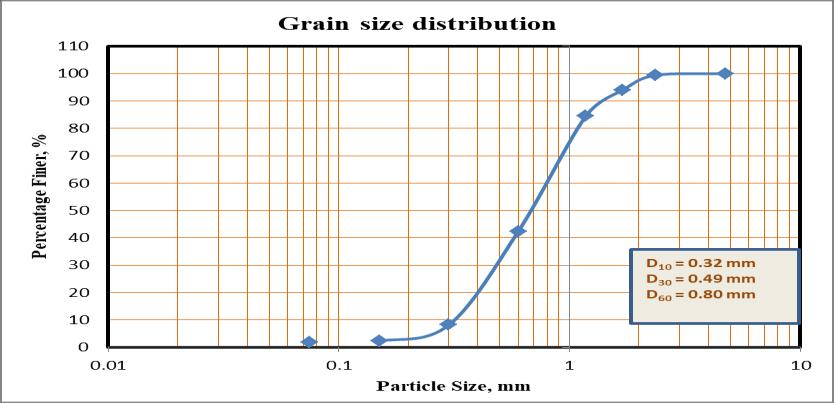

Chart -1:GrainSizeDistributionCurve.

Table -1: PropertiesofSand

EffectiveGrainsize,D10 0.32

Co-efficientofCurvature,Cc 0.94

Co-efficientofUniformity,Cu 1.53

SoilClassification PoorlyGradedSand

RelativeDensity 30%&60%

AngleofInternalFriction 29˚&34˚

Fivesmall-scalemodelsofaluminumhelicalpilesof380 mminlengthwereused,withahelixdiameterof46mmfor a 28 mm pile shaft diameter. Different configurations of helicalpileswereadoptedinthisstudy:thecylindricalpile, singlehelix,doublehelixandtriplehelixpileswithdifferent verticalspacing’sbetweenhelices.Theparametersofhelical pilesaresummarizedinTable-2,whereasFig-1showsthe modelrepresentationofhelicalpiles.

Table -2: Modelpilefeatures

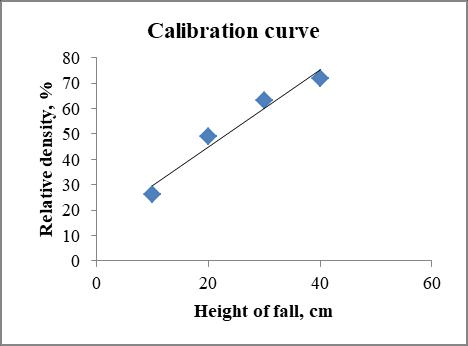

Prior to experimental work density of the sand bed is decided and the relative density of the bed is achieved by using the calibration chart of height of fall (Chart-2). A certainheightismaintainedduringpreparationofsandbed toachievethedesireddensity.Inthisstudy30%,60%and layered sand bed having both 30 and 60% is used to investigatethebehaviourofhelicalpileinvarioussandbed.

International

Volume: 12 Issue: 05 | May 2025 www.irjet.net

An experimental investigation is performed on a small-scalemodeltankmadeofmildsteel,measuring1.2m ×0.75m×1.5m,withathicknessof10mm.Thedimensions of the model tank are chosen to minimize the impact of boundary effects. Reaction frames are used and securely attached to the model tank on both sides. One end of the reaction frame is connected to a pulley and rope system, whilemodelpilesareattachedtotheotherend.Aproving ring is used to measure and record the force needed for extraction.Thereactionframeislabelledwithanglesof0°, 30°,and45°toshowanobliqueloadingarrangement,with theverticalaxisservingasareference.Twodialgaugesare employedformeasurements:oneispositionedverticallyat thetopofthepiletomeasureverticaldeformation,whilethe other is fixed horizontally to measure horizontal deformation. Fig -2displays theactual imageshowing the axialandobliquepull-outloadingarrangement.

Anexperimentaltestingprogrammewascarriedout tostudythebehaviourmonopile,single(HP1),double(HP2) and triple (HP3) helical piles with different helix spacing ratio (S/Dh) of 1.5 & 3. Helical piles are embedded in homogenous dry sand bed at relative density of 30% and 60%andalsoinlayeredsandbed.Inordertodeterminethe ultimatepulloutandobliquepulloutcapacity(30˚and45˚)of eachmodelpileatotalof54laboratoryexperimentswere performed.Foreachmodeltest,thesoilwasremovedfrom thetankandwasreplacedbytherequireddensity.

The summarized model pile load test program is illustratedinTable-3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

This section compares the ultimate pull-out capacities of helicalpileswiththoseofconventionalpiles.Italsoexplores how helical piles respond to different load inclinations in terms of displacement. Key factors such as the number of helices, load angle, sand density, and spacing between helicesareanalyzed.Thegoalistobetterunderstandhow thesevariablesaffectpileperformance.Overall,thefindings aimtoimprovetheaccuracyandpracticaluseofnumerical modelsingeotechnicalengineering

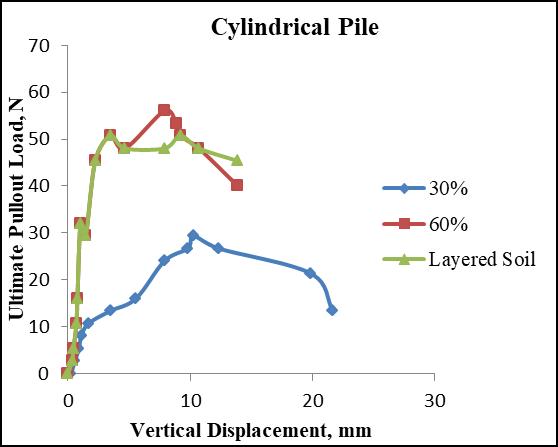

Chart -3:LoadDisplacementCurveforCylindricalPile underAxialLoading.

Chart-3 presents the pullout behavior of a cylindricalpileinthreesoilconditions:loosesand,medium dense sand and layered sand. The ultimate pullout loads recorded were 29.34 N, 56.05 N and 50.71 N for the respectivesoilconditions.Thecorrespondingdisplacements at peak load were 10.3 mm, 7.89 mm, and 9.22 mm, respectively. Among the three, the medium dense sand provided the highest resistance to uplift, highlighting the strong interaction between the pile and the surrounding dense material. The layered soil also performed well, offering significantly more resistance than the loose condition. This improvement is largely due to the dense layer beneath, which engages effectively during uplift and supportsthepiledespitetheweakertoplayer.Theseresults emphasizetheimportanceofunderlyingsoilconditionsin determiningtheoverallpulloutperformanceofpiles.

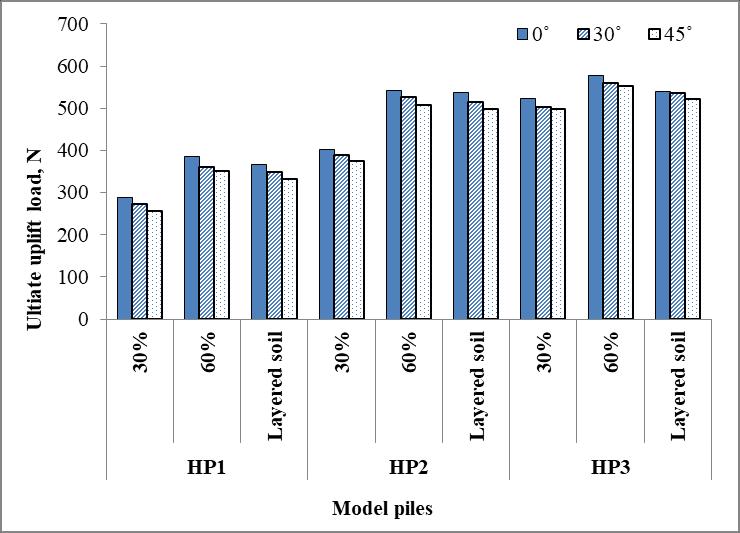

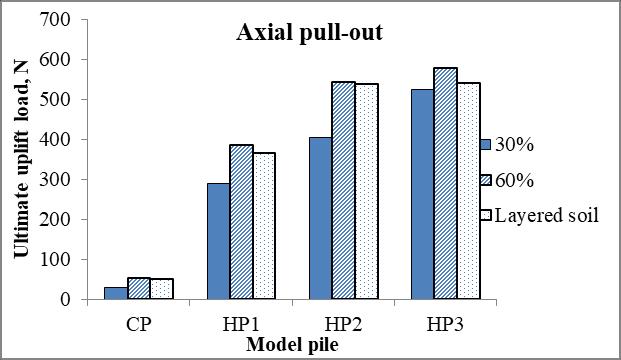

Chart-4 illustrates effect of relative density of homogenousandlayeredsandbedonaxialandobliquepullout capacities of model piles. The uplift capacity of model pileshasbeenfoundtoincreaseastherelativedensityofthe sand bed increases. This is because dense sand mobilized

higherfrictionalresistancealongthefailuresurfaceleading toanincreaseintheoverallperformanceofthesystem.

Chart -4:Effectofhomogenousandlayeredsandonuplift andobliquepulloutcapacityofhelicalpile.

When helical pile results of layered sand bed is comparedwithloose&mediumdensehomogeneousstate (30%&60%)ultimatepull-outloadcarriedbythelayered sandismorethanthehomogeneouslayerofloosestatesand bed and marginal difference with that of 60% relative densitywasobserved.Thisisduetomobilization ofmore passiveresistancebyincreasingthedensityatthebottom layerinadditiontothehelixatbottomleadstomovementof point of rotation towards the tip of the pile and this movementoffersmorepassivewedgeareawhichultimately leadstomoreupliftresistance.

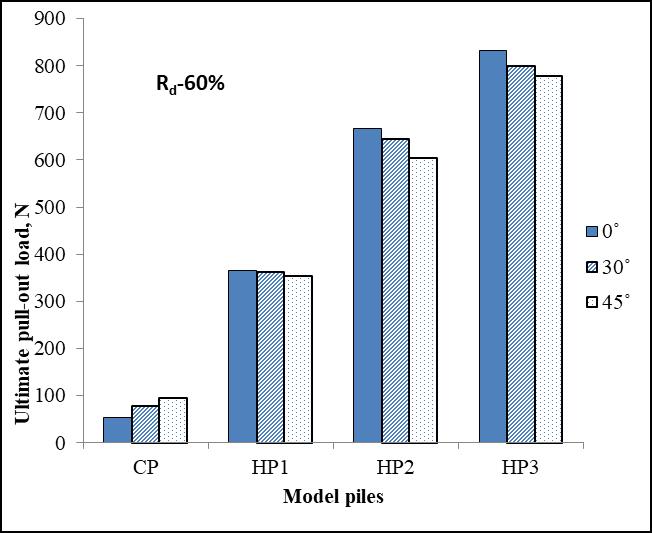

Chart -5: Variationofaxialupliftcapacitywithnumberof helixesfordifferentsandrelativedensities,(S/Dh=1.5)

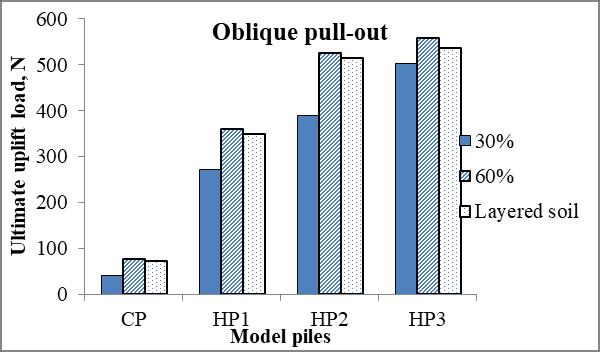

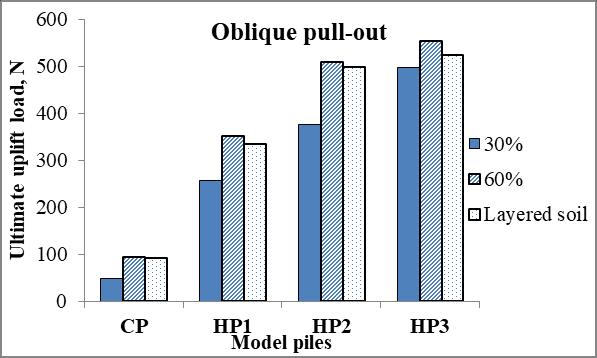

Chart-5,6and7illustrateultimateupliftresistancewith varyingnumbersofhelicesindifferentsanddensitiesunder axialpulloutandobliquepulloutloadwith30˚&45˚.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Chart -6: VariationofObliqueupliftcapacity(30˚)with numberofhelixesfordifferentsandrelativedensities, (S/Dh=1.5)

Chart -7: Variationofobliqueupliftcapacity(45˚)with numberofhelixesfordifferentsandrelativedensities, (S/Dh=1.5).

The ultimate pull-out loads obtained for the pile embeddedinloosesandsubjectedtoaxialtension(Chart-5) areapproximately29.36N,288.25N,403.02N,and523.14N with the largest capacity being that of the pile with three helicalplateshavingtheinterhelixspacingratioof1.5.The single-helixpileincreaseditscapacitybyapproximately10 timescomparedtothecylindricalpile,whilethetwohelix pile increased its capacity by 14 times. By increasing the numberofhelicalplatestothree,acapacityincreaseof18 timeswasobtained.

From Chart-6, it is evident that the ultimate pull-out capacityunder30˚obliqueloadinginloosesandincreases with the number of helices on the pile. The observed capacitiesareapproximately40.04 Nforthecylindricalpile (CP),272.38 NforHP1,389.67 NforHP2,and502.74 Nfor HP3,allwithaspacingratio(S/Dₕ)of1.5.Whenthespacing ratioisincreasedto3,thecapacitiesforHP2andHP3rises further to 468.12 N and 690.11 N respectively. This corresponds to an increase of about 20.13% for HP2 and 37.26%forHP3whenthehelixspacingisincreasedfrom1.5 to 3, highlighting the beneficial effect of larger spacing on pull-outresistanceunderobliqueloading.

A similar trend is observed under 45˚ oblique loading, further confirming the positive influence of increased numberofhelicesonoverallpull-outperformance.

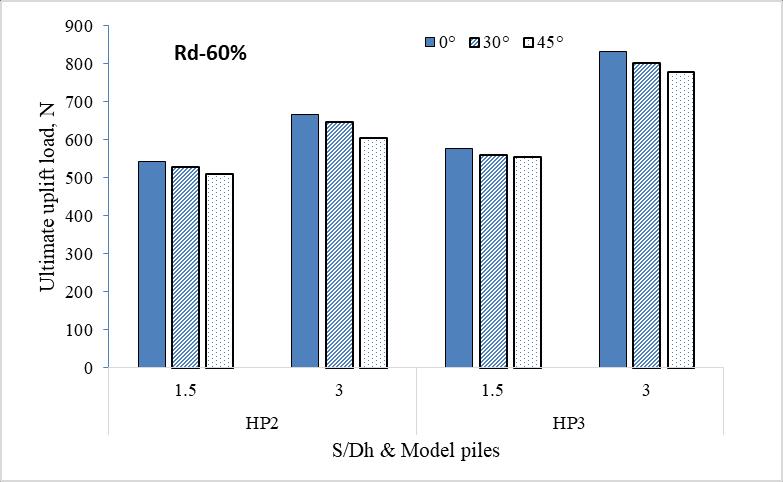

Many researchers concluded that the transition from cylindricaltoindividualfailuremechanismdependsonthe S/Dh ratio and is almost independent of the soil strength, unitweight,andshaftdiameter.Also,improvementinpullout capacity beyond the critical S/Dh ratio was relatively small.Hence,inthisstudyanattemptismadetoinvestigate theeffectofinterhelixspacingratio(S/Dh)of1.5and3on upliftcapacityofmodelhelicalpiles(HP2&HP3).

-8: Thevariationofultimateupliftloadwith differentS/Dhratios.

Similar trend is observed in layered sand also. Summarizedresultsforaxialandobliquepulloutcapacityof PilesHP2andHP3havingdifferentinterhelixspacingratio isgivenintheTable-4below.

Table -3: AxialPull-outandObliquepull-outloadofHP2 &HP3pileswithvaryingS/Dhratios(Ds=28mm, Dh=46mmandRd=60%)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

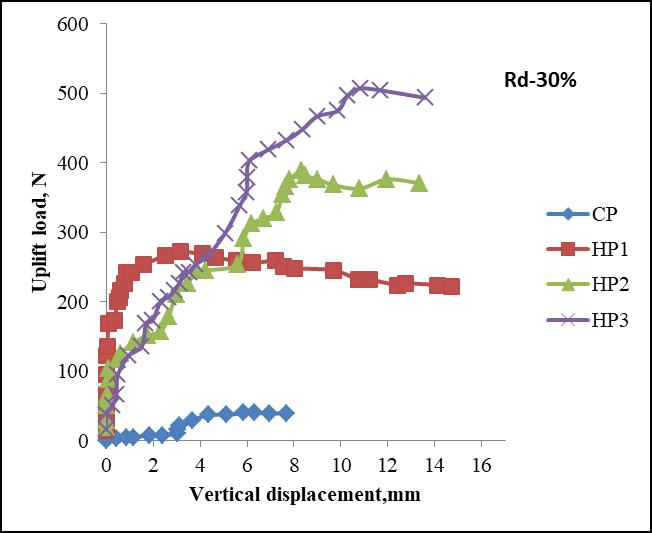

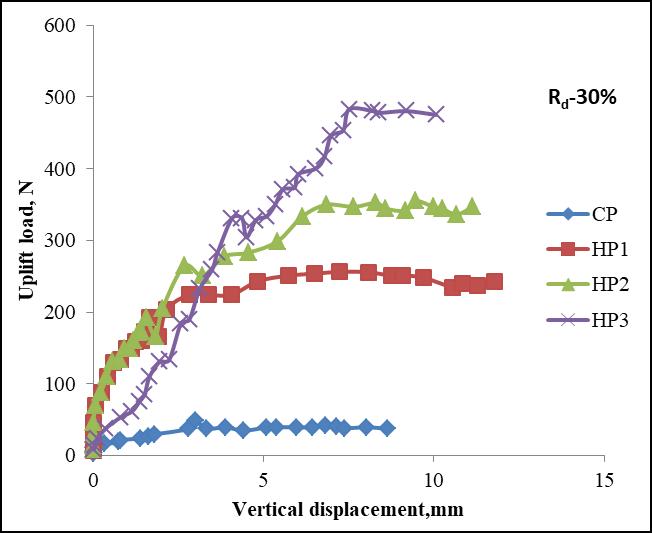

Theload-displacementcurvesforhelicalpilesofvarious configurations under inclined loading conditions were plottedfromtheExperimentinvestigation.

Chart -9:Comparisonoftheload-displacementcurvefor 30°loadinclinationtovertical.

Chart -10: Comparisonoftheload-displacementcurvefor 45°loadinclinationtovertical.

The provided Chart-9 illustrates the load-displacement curves for helical piles (HP1, HP2, and HP3) under a 30° inclined loading condition, along with a conventional pile (CP) for reference. Chart-10 illustrates the loaddisplacementcurvesforhelical piles(HP1,HP2,andHP3) under a 45° inclined loading condition, along with a conventionalpile(CP)forreference. Theloaddisplacement curve for the cylindrical and helical pile embedded in homogenoussandbedwithrelativedensityof30%under 30˚&45˚obliqueloadingexhibitsimilarbehaviortothatof cylindricalandhelicalpileunderaxialpulloutloading.

Ingeneralaxialpull-outcapacitiesofmonopilearesmaller when compared to its oblique pull-out capacity. When monopilesubjectedtoaninclined/obliqueloadingwillhave displacementinbothhorizontalandverticaldirection,the horizontal movement will be resisted by the adjacent soil mediainturnshowsamaximumriseinultimateupliftload. From Chart-11 it was observed that the cylindrical pile

achieve its maximum pull-out capacity of 94.38N at an obliqueinclinationangleof45˚.

Chart -11: Ultimatepull-outcapacityofcylindricalpile& helicalpileversusobliqueangle.

Where as in case of helical pile, as the oblique capacity tendstodecreasessignificantlyduetothedevelopmentof passivezoneswhichtendstoincreaseswithincreaseinload inclination angle and results in significant reduction in lateralcomponentofaninclinedload.FromChart-11,itwas observedthatsignificantchangeinthepulloutcapacitiesof HP2andHP3pileswhilefortheHP1pile,pulloutcapacities were nearly similar for all load inclinations. When load inclinationangleisincreasedfrom30˚to45˚,theultimatepulloutloaddecreased from 667.08N to603.5N in case of HP2and832.7Nto776.2Nincaseofhelicalpile(HP3).

The group effect of helical pile on the axial uplift resistanceofthehelicalpilesgroupwasstudiedfordifferent groupsof2and3pileswithdifferentspacing’s.Nineseries oftestswereperformedinlooseandmediumdensesand.

Theresultsofthetestsmaybedescribedintermsofthe efficiency of the piles in the form of axial capacity of the singlepileinthegroupoverasinglepilecapacityofthesame conditions.Theefficiencymaybedefinedas:

Where:

η = X100%

η=Efficiency,%

QMU =UltimateUpliftCapacityofMulti-Helixpile,N

QIU =UltimateUpliftCapacityofIndividualSingle-Helix pile,N

The performed tests allowed for the evaluation of the influenceofhelicalpilesspacingconstantnumberofpileson

International Research Journal of Engineering and

Volume: 12 Issue: 05 | May 2025 www.irjet.net

thegroup efficiencyandfor the evaluationofefficiency of helical piles of a constant diameter. Calculated values of efficiencyfromthemeasuredloadsaregiveninTable-4.

Table -4: SummaryofEfficiencyofthemodelpiles

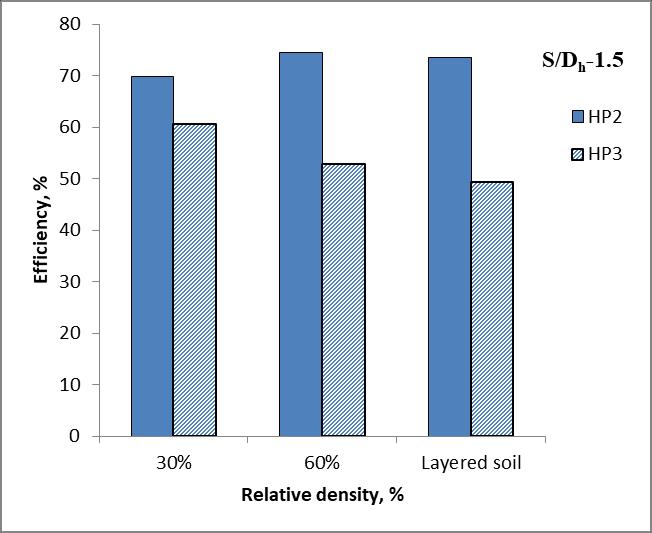

Chart -12:VariationofEfficiencyofMulti-helixpilewith relativedensityofsoilforHP2andHP3forS/Dh-1.5.

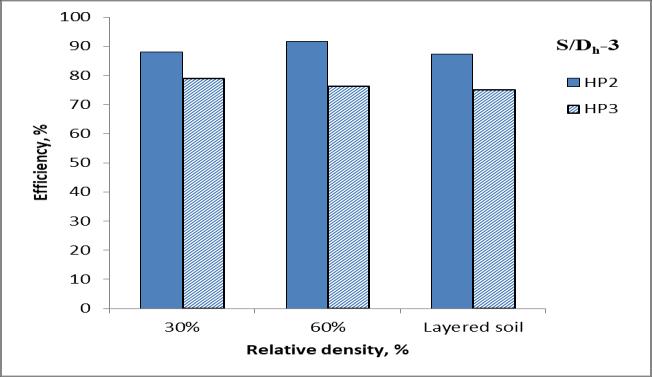

Chart -13: VariationofEfficiencyofMulti-helixpilewith RelativedensityofsoilforHP2andHP3forS/Dh-3.

From the Chart -12 & 13 it can be observed that the efficiencyofthegroupsdecreasesforgroupsofhelicalpiles embedded in medium dense sand as compared with the efficiency of the same groups in loose sand. It can also be seenthatasthenumberofplatesinthegroupincreasesthe efficiencydecreases.

From the other hand, it can be also noticed that the efficiency of multi-helix piles in medium dense sand and layeredsoilfoundtohavemarginaldifference.

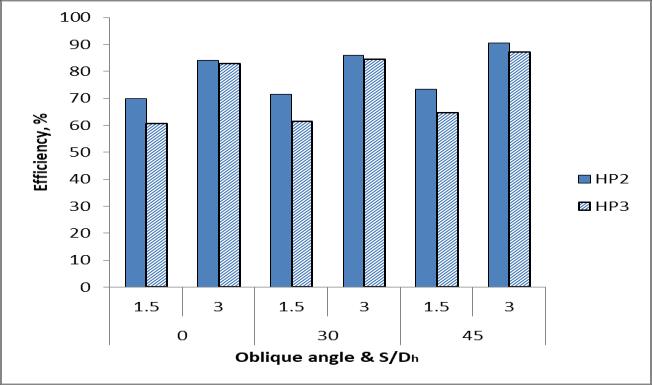

Chart -14:VariationofEfficiencyofMulti-helixpilewith obliqueangle&Inter-helixspacingratio(S/Dh-1.5&3)for HP2andHP3.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Fig 5.20 illustrates the efficiency of multi-helix piles compared to single-helix anchors based on ultimate uplift capacity, evaluated at relative helix spacing of 1.5 and 3. Ideally,whenhelixplatesarespacedfarenoughaparttoact independently, the efficiency should approach 100%. The results for pile HP-2 indicate that the transition from cylindrical shear behavior to individual plate behavior occursaroundaspacingratioof3,astheoreticallyexpected. However,theefficiencyatthisspacingremainsbelow100%, implying that installation effects might inhibit full load mobilization,evenwhenplatesarewidelyspaced.

Furthermore,itcomparesefficiencyvaluesforHP-2and HP-3pilesusingconsistentplatespacingof1.5and3.Itis observedthatefficiencydecreasesasthenumberofhelices increases,regardlessofspacing.Whilehigherspacing(S/Dh =3)resultsinbetterefficiencythancloserspacing(S/Dh = 1.5),therateofdecreaseismoregradual.Theseresultsalign with the expected transition from group interaction (cylindricalshear)atsmallerspacingtomoreindependent behavior(individualplate)atlargerspacing.

4. CONCLUSIONS

Thestudyaimstoenhancetheunderstandingofhelicalpile performance,particularlyunderverticalpulloutandinclined loads,usingacombinationoflaboratoryexperiments.The primaryeffectsinvestigatedincludetheinfluenceofvariable parameters. These effects were rigorously analyzed using experimental tests,offering a robustunderstandingofthe behaviorofhelical pilesundervariousloadingconditions. Thefollowingconclusionsaremadebasedontheobtained results:

The failure pattern in helical piles depends upon the embedmentdepth,spacingbetweenthehelices,andthe soilconditions.

Helicalpilessignificantlyoutperformcylindricalpilein both axial and oblique pullout resistance due to their largerbearingareanddeeperembedment.

Anincreaseinrelativedensityofcohesionlesssoilfrom 30%to60%substantiallyimprovestheupliftcapacity across all pile configurations. Dense sand mobilizes greaterfrictionalresistanceandenhancesloadbearing performances.

Layered soil with dense bottom layer proves better pulloutresistancethanahomogenousloosesandbed. The shift in failure mechanism due to soil layering increasespassivezonemobilizationatthepiletip.

Asignificantpositiveeffectofnumberofhelixesonthe axialupliftresistanceofthehelicalpileswasfoundto exist.

The triple helix configuration showed the highest performancewithupliftloadsincreasingbyover90% comparedtocylindricalandsinglehelicalpiles.

Wider helix spacing (S/Dh=3) leads to transition from cylindricalsheartoindividualplatebearingenhancing thepulloutcapacity.

The ultimate pullout load for single helix pile have marginaldifferencewithanincreaseinobliqueangle, whereas in the case of multi plate helical piles, it is foundtodecreasewithanincreaseinobliqueangle.

Despitearelativespacingof3ormorebetweenhelices, the efficiency of multi-helix anchors remains below 100%, indicating that installation effects such as soil disturbanceorincompleteengagementmayinfluence performanceinsandysoils.

Theefficiencyofmulti-helixanchorstendstodeclineas the number of helices along the shaft increases. This reduction in efficiency is more significant when the helices are closely spaced, likely due to increased interactionbetweentheplatesandoverlappingstress zonesinthesoil.

MaximumefficiencywasrecordedatS/Dh=3fordouble helicalpileindensesand.

From all these results it can be conclude that helical piles are suitable for varied geotechnical conditions particularlywherehighupliftcapacityresistanceand rapid installation are required (e.g. Solar farms, Communication Towers, offshore-onshore platforms etc.)

[1] AbdrabboandElWakil,“Laterallyloadedhelicalpilesin sand”, Alexandria Engineering Journal, 2016. https://doi.org/10.1016/j.aej.2016.08.020.

[2] Howard A Perko, “Helical Piles: A Practical Guide to DesignandInstallation”.WileyPublishing:Hoboken,NJ, USA.2009.

[3] MamdouhNasr,“Performance-BasedDesignfor HelicalPiles”,2009.ASCELibrary. https://doi.org/10.1061/41021(335)62.

[4] Meyerhof G.G and Adams J.I (1968) “Ultimate Uplift Capacity of Foundations”. Canadian Geotechnical Journal,5(4):225-244.

[5] MitschM.P,ClemenceS.P(1985)“Upliftcapacityofhelix anchors in sand”. In: Proceedings of a session held in conjuction with the ASCE convention, Detroit, MI, England.

[6] RajuandVanishreeP.S(2017)“Lateral LoadCarrying CapacityofHelicalPilesinSand”.InternationalJournal of Advances in Scientific Research and Engineering (ijasre);E-ISSN:2454-8006Vol.3

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

[7] RaoandPrasad(1991)“EstimationofUpliftCapacityof Helical Anchors in Clays”, Journal of Geotechnical Engineering,119(2):352-357.

[8] SakrM(2018)“Performanceoflaterallyloadedhelical pilesinclayeysoilsestablishedfromfieldexperience”. DFIJournals12:28–41. https://doi.org/10.1080/19375247.2018.1430481.

[9] Vignesh Venkatesan and Muthukumar Mayakrishnan (2022) “Experimental and Numerical Study of Group EffectontheBehaviorofHelicalPilesinSoftClaysunder Uplift and Lateral Loading”. Journal of Ocean Engineering. http://dx.doi.org/10.1016/j.oceaneng.2022.113500.

[10] YuanC,HaoD,Zhang(2023)“NumericalInvestigationof Uplift Failure Mode and Capacity Estimation for Deep Helical Anchors in Sand”. Journal of Marine Science Engineering.https://doi.org/10.3390/jmse11081547.