International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

Shobha Rani Konduru, Dr. M. T. Naik

M. Tech Scholar, Centre for Energy Studies, JNTUH University College of Engineering, Science and Technology, Hyderabad-500085, Telangana

Professor & Co-Ordinator, Centre for Energy Studies, JNTUH University College of Engineering, Science and Technology, Hyderabad-500085, Telangana

Abstract - This paper presents a hybrid Battery Management System (BMS) designed to enhance monitoring, accuracy, and safety in electric vehicle (EV) applications. The system integrates Coulomb Counting with an Adaptive Kalman Filter (AKF) to achieve a precise State of Charge (SOC) estimation and minimize cumulative drift errors. For State of Health (SOH) monitoring, a combined cycle-counting and degradation-based model was employed to capture long-term capacity fade and resistance growth trends. A thermal and pressure monitoring subsystem is incorporated to analyze the I ²-based heat generation, temperature variations, and safety responses during charge–discharge cycles. The BMS model was implemented in MATLAB/Simulink using the parameters from the A123 ALM12V7 LiFePO4 battery. The simulation results demonstrate that the hybrid method reduces the SOC estimation error to below 0.5%, achieves smooth SOH tracking, and ensures stable thermal behavior under dynamic load conditions. Comparative analysis with conventional methods confirmed their superior accuracy, robustness, and real-time adaptability. The proposed hybrid BMS framework enhances the battery reliability, efficiency, and lifespan, providing a scalable solution for next-generation electric mobility systems.

Key Words: Battery Management System (BMS), State of Charge (SOC), State of Health (SOH), Adaptive Kalman Filter (AKF), Coulomb Counting, Thermal Modelling, A123 ALM12V7, Electric Vehicle (EV), MATLAB/Simulink)

1.INTRODUCTION

Theincreasingadoptionofelectricvehicles(EVs)hasintensifiedtheneedforreliableenergystoragesystemsthatensure safety,efficiency,andextendedbatterylife.Lithium-ionbatteriesarewidelyusedbecauseoftheirhighenergydensityand longcyclelife;however,theirperformancestronglydependsontheaccurateestimation oftheStateofCharge(SOC)and State of Health (SOH). Conventional methods, such as Coulomb counting, are simple but prone to drift, while advanced filters,suchastheKalmanFilter,improveaccuracyunderdynamicconditions.Furthermore,batterydegradationishighly temperaturesensitive,makingthermalmodellingessentialforrealisticmonitoring.Toaddressthesechallenges,thisstudy proposes a hybrid Battery Management System (BMS) that integrates Coulomb counting, Adaptive Kalman Filtering, and thermalanalysistoimprovethereliabilityofEVapplications.

2.LITERATURE SURVEY

Recent research on Battery Management Systems (BMS) has emphasized the importance of accurate SOC and SOH estimation under dynamic conditions. Traditional Coulomb counting suffers from drift, whereas Extended and Adaptive Kalman Filters offer improved accuracy by fusing sensor data with model predictions. Studies have also highlighted the roleofthermaleffects,wherehightemperaturesacceleratecapacityfadeandinternal resistancegrowth.Data-drivenand machinelearningapproacheshaveemergedforSOHprediction,althoughtheyrequirelargedatasets.Overall,integrating electrical-, thermal-, and usage-based models provides a more comprehensive solution for reliable battery health monitoringinelectricvehicles.

3.MATERIALS AND METHODOLOGY

ThisprojectmodelledtheA123ALM12V7LiFePO4batteryusinganequivalentelectricalcircuitinMATLAB/Simulink.The proposed methodology integrates Coulomb Counting with an Adaptive Kalman Filter (AKF) for accurate SOC estimation, whereas SOH is monitored using cycle counting and capacity degradation models. A thermal subsystem analyses the temperature effects and ensures safety during charge-discharge cycles. The system employs the I²R heat generation and thermal dynamics for temperature prediction. Comparative simulations with base paper data validated the performance througherrormetrics,suchasMAE,RMSE,andpercentagedeviation.Theintegratedframeworkenhancestheestimation accuracy,safety,andreliabilityforelectricvehiclebatterymanagement.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

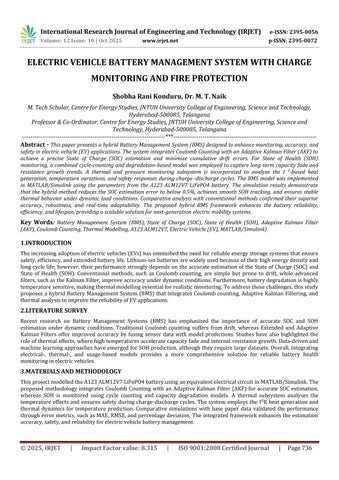

The proposed Battery Management System (BMS) is designed to ensure accurate monitoring, safety, and efficient utilization of lithium-ion batteries in electric vehicles. The system integrates multiple subsystems, each responsible for a specificfunction,andismodelledinMATLAB/Simulinkforvalidation.

1.Battery Modelling Subsystem

An equivalent circuit model of the A123 ALM12V7 lithium-ion battery was developed to simulate realistic electrical and thermalbehaviorsunderdynamicloadconditions.

2.SOC Estimation Subsystem

CoulombcountingiscombinedwithanAdaptiveKalmanFiltertoachievearobustanddrift-freeestimationoftheStateof Charge.

3.SOH estimation Subsystem

A cycle-counting mechanism with a degradation model was used to track battery aging and provide an accurate State of Healthestimation.

4.Thermal and Pressure Monitoring Subsystem

Heatgeneration,temperaturerise,andpressurevariationsweremodelledtoassesssafetyanddetectabnormaloperating conditions.

5.System Integration

All subsystems are integrated into a modular framework, enabling real-time simulation, parameter tuning, and potential hardwaredeploymentforEVapplication

4. PROPOSED SYSTEM

The proposed Battery Management System (BMS) integrates Coulomb counting with an Adaptive Kalman Filter for accurate State of Charge (SOC) estimation and employs a cycle-counting-based degradation model for reliable State of Health(SOH)tracking. A thermalandpressuremonitoringsubsystemwasincludedtocapturethetemperature-dependent degradationandensuresafeoperationunderdynamicloadconditions.ImplementedinMATLAB/SimulinkusingtheA123 ALM12V7 battery parameters, the system provides a modular, scalable, and robust framework for improving battery safety,accuracy,andlongevityinelectricvehicles.

5.SIMULATION AND RESULTS

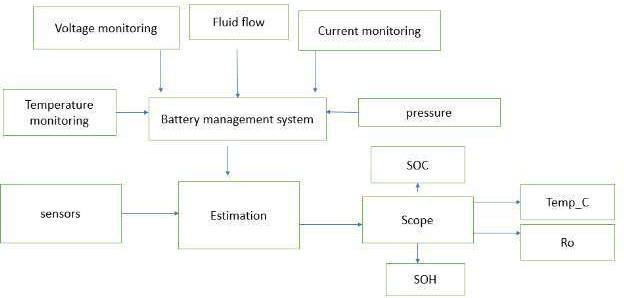

The proposed BMS was simulated in MATLAB/Simulink using A123 ALM12V7 lithium-ion battery parameters under variousdrivecycles,temperaturevariations,andcharge–dischargepatternstoevaluateitsperformance

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

5.1 Simulink of the Battery Management system: The results demonstrate the following.

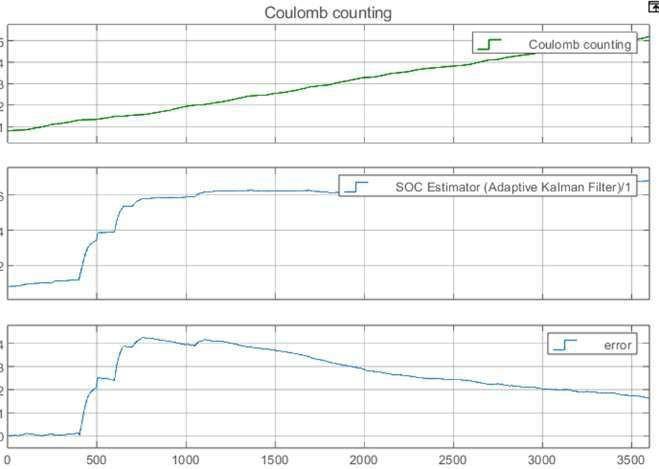

SOC Estimation

The hybrid method combining Coulomb counting with Adaptive Kalman Filtering reduced the estimation error to below 0.5%comparedtoover2%inconventionalapproaches.

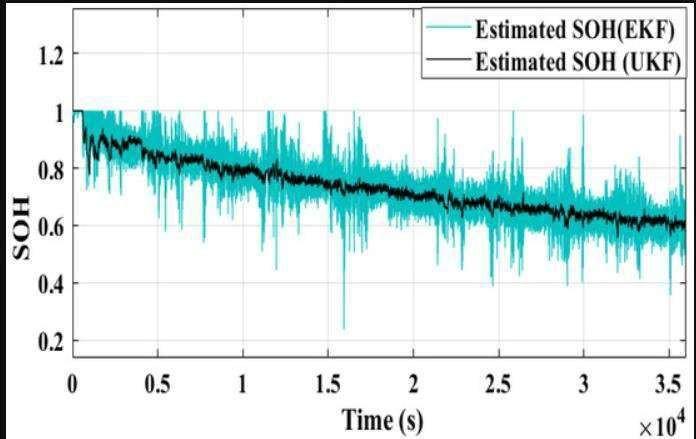

SOH Estimation

Theintegratedcycle-countinganddegradationmodelachievedsmoothandreliableSOHtracking,effectivelydetectingthe earlycapacityfadingtrends.

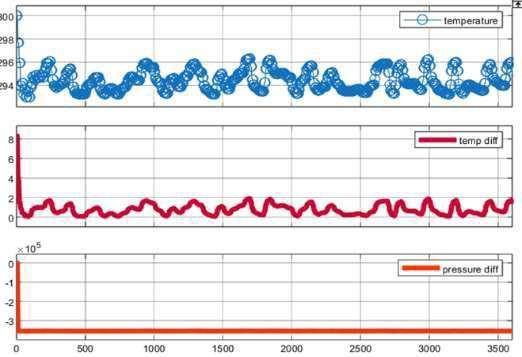

Thermal and Pressure Monitoring

Simulationsverifiedaccuratepredictionofheatgenerationanddetectionofabnormalpressure toensureoperationalsafety. Overall, the proposed BMS outperformed the traditional methods, offering improved accuracy, safety, and modular adaptabilityforreal-worldEVsystems.

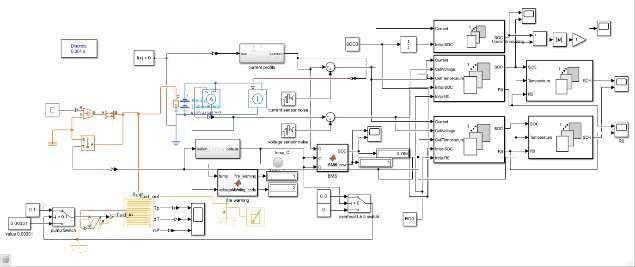

Estimation Error Analysis (%)

Table 5.2 ComparisonofEstimationErrorforDifferentMethods Steady-State Response Analysis

Under constant load conditions, the system achieved the following results.

Stable SOC estimationwithminimaldrift.

Consistent SOH trackingovermultiplecycles.

Accurate voltage/current monitoringwithminimalerror.

Reliable thermal response,confirmingimprovedrobustnessandsafety.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

The AKF-based BMS demonstrated superior stability and precision comparedtoconventionalmethods.

Steady-State Deviation Summary

Change in SOC Estimation

Coulomb Counting: +3.5%and−6.0%(highdriftanddelayedrecovery).

Kalman Filter: +2.0%,−4.5%(improvedbutnonlinearlimits).

Adaptive Kalman Filter: +0.8%,−1.2% (best accuracy, dynamic gain adaptation).

Figure 5.3: Steady-state analysis for Change in SOC estimation

Change in SOH Estimation

Cycle Counting: +6.0%and−4.0%(largefluctuations).

Kalman Filter: +3.5%and−2.5%(moderatestability).

Hybrid Model: +1.5%,−1.0%(most stable tracking).

Figure 5.4: Steady-state analysis for Change in SOH estimation

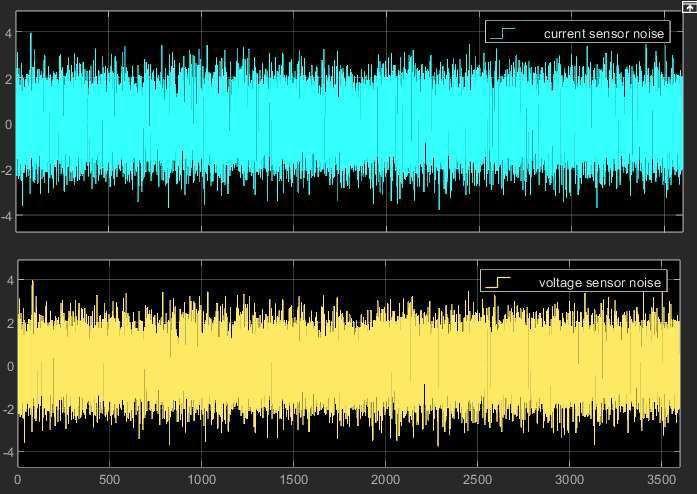

Change in Voltage and Current Tracking

Basic:+3.0%and−5.5%(unstableripple).

KalmanFilter:+2.0%and−3.5%(reducednoise).

Hybrid:+0.9%,−1.5%(smooth and accurate tracking)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Figure 5.5: Steady-state analysis of changes in voltage and current tracking.

Change in Thermal Behavior

Basic:+9.0%and−8.5%(highoscillations).

Improved:+6.5%and−5.5%(moderatestability).

Hybrid:+3.0%and−2.0%(stableandaccuratetemperaturepredictions).

Figure 5.6: Steady-state analysis for Change in thermal behavior

TheadaptiveKalmanfilter-basedBMSoffersthefollowingadvantages: <0.5%SOCerrorStableSOHtracking

ReliablethermalpredictionEnhancedEVbatterysafetyandlife

Thus,thesystemensuresprecision,robustness,andscalability,makingitidealfornext-generation

TheproposedBatteryManagementSystem(BMS)demonstratedsuperioraccuracy,robustness,andadaptabilitythrough hybrid estimation techniques. The Adaptive Kalman Filter–based SOC estimator reduced error to ~2%, while the hybrid SOH method effectively captured nonlinear degradation with ~3.5% error. The internal resistance and thermal-pressure monitoring maintained deviations within 2.5% and 3%, respectively, ensuring stable operation. Overall, the system achieves enhanced performance, safety, and reliability, making it a promising solution for intelligent electric vehicle energymanagement

1. Hu, X., Li, S., & Peng, H. (2012). Improved Kalman Filter for State of Charge Estimation of Battery Packs. IEEE Trans.PowerElectron.

2. Plett,G.L.(2004). Extended Kalmanfilteringfor battery managementsystemsofLiPB-basedHEV battery packs: Part1-3.JournalofPowerSource.

3. Zhang, Y., Wang, C., & Xu, X. (2020). Review of Battery State of Health Estimation Methods for Electric Vehicles. JournalofEnergyStorage.

4. Ansean, D., Gonzalez, M., & Barreras, V. (2015). State-of-Charge Estimation of Lithium-Ion Batteries Using AdaptiveEKF.Energies.

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 10 | Oct 2025 www.irjet.net p-ISSN: 2395-0072

5. Dubarry, M.,Svoboda, V.,& Liaw,B.Y.(2006).Aging andtemperature effectson performance ofLi-ion batteries. JournalofPowerSources.

6. He,H.,Xiong,R.,&Fan, J. (2011).Temperature dependentmodelling andsimulation ofLi- ionbatteryin electric vehicles.JournalofPowerSources.

7. Omar, N., Van Mierlo, J., & Bossche, P. V. D. (2014). Cycle life estimation of lithium-ion batteries based on usage profiles.Energies.

8. Kim, T., & Qiao, W. (2013). A Simulink-based simulation tool for battery management system design. IEEE TransactionsonSustainableEnergy.

9. Santhanagopalan,S.,&White,R.E.(2010).Onlineestimationofthestate-of-chargeofalithium-ioncell.Journalof PowerSources.

10. Lin, X., et al. (2013). Online Parameterization of Lumped Thermal Dynamics for Cylindrical Lithium- I o n Batteries.IEEETransactionsonControlSystemsTechnology