International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Dr. P. P. Tapkire 1 , Mr. Vaibhav Jawalkote 2 , Mr. Atul S. Chandanshive3

1 H.O.D. Civil Dept., N.B. Navale Sinhgad College of Engineering, Solapur, Maharashtra, India-413255

2 Research Scholar at N.B. Navale Sinhgad College of Engineering, Solapur, Maharashtra, India-413255

3 Lecturer Civil Dept., Solapur Education Society’s Polytechnic Solapur, Maharashtra, India-413002

Abstract - In this study, the construction industry inIndiais undergoing a significant transformation with the growing adoption of prefabricated building techniques. While conventional construction remains dominant, prefabrication offers notable advantages such as reduced construction time, improved quality control, and enhanced safety. This study focuses on evaluating the effectiveness of different spans in prefabricated buildings under varying static and dynamic loading conditions. Dynamic loading, which includes forces such as wind and seismic activity, has become a crucial factor in modern structural design due to its impact on building stability and safety. A comprehensive literaturereviewreveals that most existing studies emphasize single-storyorindustrial prefabricated structures, often overlooking the influence of span variation under dynamiceffects. Addressingthisresearch gap, the present work aims to analyze the performance of prefabricated buildings across different spans and heights using structural analysis software. Both static and dynamic analyses are performed, considering variations in bracing systems to enhance structural response. The outcomes of this study include non-dimensional charts that correlate span effectiveness with building height, providing valuable design insights for engineers and architects. The findings supportthe feasibility of multi-story prefabricated construction and contribute to optimizing structural performance under realworld loading conditions

Key Words: Prefabricatedbuildings,Spanvariation,Bracing systems,Seismicperformance,ETABS/ANSYS,Construction efficiency

The construction industry plays a crucial role in India's economic growth and has traditionally relied on on-site, conventionalbuildingmethods.Recently,however,therehas been a notable shift toward prefabricated construction, which is emerging as a more modern and efficient alternative. This approach involves producing building components in a controlled factory environment and subsequently assembling them at the project site. Such a methodenhancesqualitycontrol,acceleratesconstruction timelines,andpromotesbettersafetystandards.Withrapid urbanizationandtheincreasingneedforquickandreliable infrastructure, prefabricated structures are becoming a

viable solution for both residential and commercial developments. Additionally, recent advancements have highlightedthesignificanceofaccountingfordynamicloads in structural design. Unlike static loads, which remain constantovertime,dynamicloads suchasthosegenerated bywind,seismicactivity,ormovingvehicles fluctuatein intensity and direction. Addressing these forces requires sophisticated analytical techniques to maintain structural integrity.Methodssuchasmodalanalysisandtime-history analysisenableengineerstoassesshowstructuresrespond to varying loads. This dissertation investigates the performanceofprefabricatedbuildingswithdifferentspan configurations under both static and dynamic loading conditions, aiming to optimize structural efficiency and ensuresafetyinpracticalapplications

To evaluate the effectiveness of varying spans in prefabricatedbuildingsunderdifferentstaticanddynamic loadingconditions.

1) Compare the static and Dynamic analysis of prefabricatedbuilding.

2) Dynamic analysis of various spans along with differentbracingsystem.

3) Preparation of non-dimensional comparative chart foreffectivespanforvariousheights

Buildings and houses are essential to human life, and construction methods have evolved significantly since ancient times. Modern construction demands not only structural strength but also aesthetic appeal, speed, costefficiency,andquality.Pre-engineeredbuildings(PEBs)have emergedasapracticalsolutiontomeettheseneeds,offering fasterconstructionandlowercostscomparedtotraditional methods. To gain deeper insight into PEB design and performance, various research studies and journal articles werereviewed,withkeyfindingssummarizedforreference.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Contributionsofresearchersarepresentedasfollows,

Jimin He [1] He presents a novel approach designed to pinpointspecificregionswithinananalyticalmodelwhere errors tend to cluster. Analytical models serve as mathematical representations of real-world systems, but their predictions often differ from actual experimental outcomes. What sets his method apart is its effectiveness evenwhenonlylimitedorincompleteexperimentaldatais available acommonissueinpracticaltestingenvironments. By examining this partial data, the technique enables researchers to identify which areas of the model are primarily responsible for the discrepancies. This focused strategymakesitpossibletorefineandimprovemodelsmore efficientlybytargetingonlytheproblematicsections,rather thanrevisingtheentiremodel.Ultimately,thisenhancesthe accuracyanddependabilityofsimulations,whichisvitalin fieldssuchasengineering,physics,andotherdomainswhere precisemodelingisessential

Jaillon, L., & Poon, C. S. [2] Intheir2009study,Jaillonand Poon carried out a comparative assessment of different buildingstructurestoexaminehoweffectiveprefabricationis within the construction sector. Their findings reveal that incorporating prefabricated components can significantly shorten the overall construction timeline compared to conventionalmethods.Byproducingstructuralelementsoffsite and assembling them on location, the construction process becomes more efficient and less vulnerable to setbackscausedbyadverseweatherorlabor-relateddelays. Additionally,thestudypointsoutthatprefabricationboosts efficiencybyoptimizingresourceusage,minimizingmaterial waste, and ensuring more uniform quality control. These insightsunderlinethegrowingrecognitionofprefabricated construction as a sustainable, efficient, and practical alternativeinthemodernbuildingindustry

Hui Min Xu, Yung Yang Li, Wei Xui [3] Researchers conducted on-site dynamic testing on four prefabricated housesbuiltusinglightweightsteelstructures.Byapplying theStochasticVibrationSignalAnalysis(SVSA)method,they were able to identify key dynamic characteristics of the buildings,includingnaturalfrequencies,dampingratios,and vibration modes.The resultsshowedthatthesestructures primarilyexhibitedshear-typevibrationmodes,whichreflect typical deformation behavior under dynamic loads. The dampingratiosobservedrangedfrom0.6%to2%,aligning withtheexpectedperformanceoflightweightsteelsystems. These findings offer valuable insights into the seismic and dynamic behavior of such prefabricated structures, reinforcingtheirsuitabilityforsafe,efficient,andresilientuse inmodernconstructionpractices.

Loss, C., Piazza, M., & Zandonini, R. [4] The study investigated the innovative use of mixed materials in prefabricated construction, with a particular emphasis on combiningwoodandsteel.Theresearchershighlightedthe

advantages of hybrid structural systems, which merge the aesthetic appeal, environmental friendliness, and thermal properties of wood with the strength, durability, and adaptability of steel. This material combination presents a promising direction for prefabricated buildings, aiming to enhancebothstructuralperformanceandsustainability.The study points out that such systems can optimize load distribution, increase seismic resilience, and enable more flexible and lightweight designs. This approach not only expandsthepotentialofprefabricatedarchitecturebutalso alignswiththegrowingneedforeco-consciousandefficient constructionpractices

Chandrashekhar B Adin, Raveesh R. M, Praveen J.V. [5] Theresearchersconductedacomprehensivestudytoassess how different bracing systems and dampers affect the dynamicbehaviorofindustrialsteelstructuressubjectedto seismicandwindloads.Themaingoalwastoevaluatehow variouscombinationsofbracingsanddampers,alongwith changesinmassratiosandheight-to-breadthratios,impact key dynamic parameters such as natural frequencies, dampingcharacteristics,andtheoverallstructuralresponse. Theresultshighlightthecriticalroleofcarefulselectionand placementofbracinganddampingcomponentsinenhancing structural stability and energy dissipation under dynamic forces.Thisresearchoffersvaluableinsightsforoptimizing the design of industrial steel structures to improve their resilienceagainstearthquakesandwind-inducedstresses.

Fard, M. M., Terouhid, S. A., Kibert, C. J., & Hakim, H. [6] This research centers on enhancing safety management practices during the construction phase of prefabricated buildings.Acknowledgingthespecificchallengesinvolvedin assembling and installing prefabricated components, the study identifies key safety risks linked to both off-site production and on-site construction activities. While prefabricationoffersbenefitssuchasimprovedefficiencyand reduced on-site labor, it also introduces unique safety concerns especiallyrelatedtothehandling,transportation, andassemblyoflargestructuralelements.Tomitigatethese risks, the authors propose several practical measures, including better project planning, comprehensive worker training,improvedcoordinationamongstakeholders,andthe implementationofsafetyprotocolstailoredtoprefabricated systems. These recommendations aim to strengthen the overallsafetyculturewithintheprefabricatedconstruction sector, ensuring greater worker protection and smoother projectexecution

Kasperzyk, C., Kim, M. K., & Brilakis, I. [7] The study introducesaninnovativeautomatedsystemdesignedforthe dismantlingandreconfigurationofprefabricatedbuildings, representing a major step forward in construction automationandsustainablebuildingpractices.Itrespondsto theincreasingdemandforadaptableandreusablebuilding systemsdrivenbychangingspatialneedsandenvironmental concerns. By incorporating advanced technologies such as

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

robotics and digital modeling, the system allows for the efficient disassembly of prefabricated components with minimal manual effort. These components can then be reorganizedorreusedinnewlayouts,significantlyreducing construction waste and extending material lifespans. The research emphasizes the system’s potential to improve flexibility, lower labor demands, and promote circular economy principles within the prefabricated construction industry

Teng, Y., Li, K., Pan, W., & Thomas Ng, S. [8] This study presents a thorough evaluation of the environmental performance of prefabricated buildings, with a particular emphasisoncarbonemissionsacrosstheentirebuildinglife cycle. By analyzing both the production and operational stages,theresearchfindsthatprefabricatedbuildingstendto generatesignificantlylowercarbonemissionscomparedto conventionalconstructionmethods.Thisreductionislargely due to more efficient use of materials, less construction waste,andimprovedenergyefficiencyduringoperation.The study also highlights the benefits of a streamlined construction process and the potential to recycle building components, further enhancing the environmental sustainabilityofprefabricatedsystems.Overall,thefindings position prefabricated construction as a more eco-friendly andsustainableapproach,offeringmeaningfuladvantagesin reducingenvironmentalimpactandadvancinggreenbuilding practices.

Li, Y. S., Hwang, B. G., Shan, M., & Looi, K. Y. [9] The researchersdevelopedadecisionsupportsystemdesignedto accurately calculate the volume of prefabricated building components.Theirapproachintegratesdetailedtheoretical analysiswithpracticalsimulationmethodstodeliverprecise volumeestimations,supportingmoreeffectiveplanning,cost forecasting, and resource management in prefabricated constructionprojects.Byincorporatingthissystemintothe design and manufacturing stages, stakeholders can better optimize material usage, reduce waste, and improve the overallefficiencyofcomponentproductionandassembly.

3.1 Introduction

To Do the Study of PEB Concept truss in different loading condition for different span. These can be achieved by designingatypicaltrussframeofproposedcommercialware houseusingboththeconceptsandanalyzingthedesigned frames using the Structural Analysis and Design Software package.

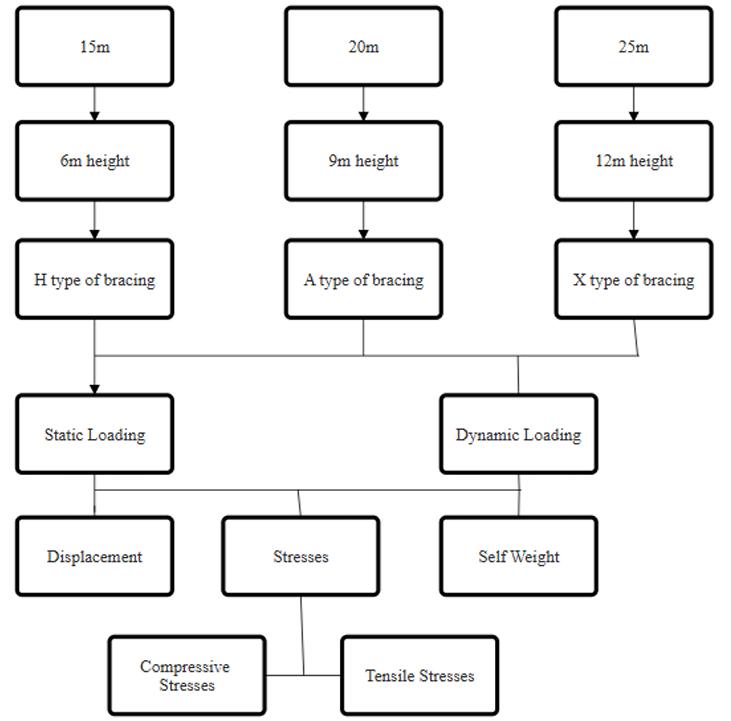

Fig. No. 3.1 span and height of ware house

Pre-EngineeredBuildings(PEB)arestructuresdesignedina factoryandputtogetheronlocation.Steelstructuresarethe normforPEBstructures.Built-upsectionsaremadetoexact measurements in the factory, transported to the site, and assembled there using bolted connections. Industrial structures such as warehouses, metro stations, and other structurestypicallyusethisstructuralconcept.Adoptingthe PEBdesignconceptoverthetraditionalconcretestructure designconceptproducesseveralbenefits,includingeconomy andmorestraightforwardfabrication.Thesestructurescan becompletedfromwithintoserveanypurposesthatbenefit the design of low-rise buildings. Warehouses, canopies, factories,bridges,andotherstructuresarepre-engineered buildings.

Reduced Construction Time: Buildings are typically delivered in just a few weeks after approval of drawings. Foundationandanchorboltsarecastparallelwithfinished, readyforthesitebolting.OurstudyshowsthatinIndiathe useofPEBwillreducetotalconstructiontimeoftheproject byatleast50%.Thisalsoallowsfasteroccupancyandearlier realizationofrevenue.

Lower Cost: Due to the systems approach, there is a significant saving in design, manufacturing and on-site erection cost. The secondary members and cladding nest togetherreducingtransportationcost.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Flexibility Of Expansion: Buildingscanbeeasilyexpanded inlengthbyaddingadditionalbays.Also,expansioninwidth andheightispossiblebypredesigningforfutureexpansion.

LargeClearSpans:Buildingscanbesuppliedtoaround80M clearspans.

Quality Control: Asbuildingsaremanufacturedcompletely in the factory under controlled conditions the quality is assured.

Low Maintenance : Buildingsaresuppliedwithhighquality paint systems for cladding and steel to suit ambient conditionsatthesite, whichresultsinlong durabilityand lowmaintenancecoats.

Energy Efficient Roofing and Wall Systems:Buildingscan besuppliedwithpolyurethaneinsulatedpanelsorfiberglass blanketsinsulationtoachieverequired“U”values.

Architectural Versatility: Building can be supplied with varioustypesoffascias,canopies,andcurvedeavesandare designed to receive pre cast concrete wall panels, curtain walls,blockwallsandotherwallsystems.

Single Source Responsibility: As the complete building packageissuppliedbyasinglevendor,compatibilityofall thebuildingcomponentsandaccessoriesisassured.Thisis one of the major benefits of the pre-engineered building systems.

3.4 Diversified Applications of Pre-Engineered Buildings (PEB)

Applicationsofpre-engineeredsteelbuildingsinclude(but arenotlimitedto)thefollowing

1. WAREHOUSES

2. FACTORIES

3. WORKSHOPS

4. OFFICES

5. GASSTATIONS

6. VEHICLEPARKINGSHEDS

7. SHOWROOMS

8. AIRCRAFTHANGARS

9. METROSTATIONS

10. SCHOOLS

11. RECREATIONAL

12. INDOORSTADIUMROOFS

13. OUTDOORSTADIUMCANOPIES

14. BRIDGES

15. RAILWAYPLATFORMSHELTERS

3.5 Requirement of ware house and span and heights

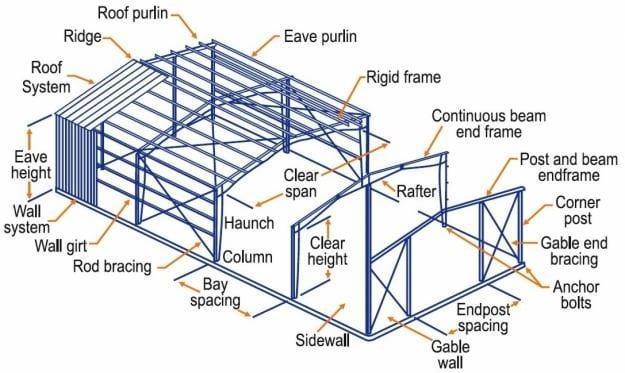

3.6 Components of PEB

Main Components

There are following major components in a preengineeredbuilding:

PrimaryorMainframe

GableEndframingorWindcolumns

SecondaryframeorPurlins,girtsetc.

Roof&WallSheeting

Bracingsystem

Cranesystem

Mezzaninesystem

Insulations

Attachmentslikecanopies,fasciaetc.

Doors,Windows,Ventilators

AccessorieslikeTurbovents,RidgeVents,Skylights etc.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

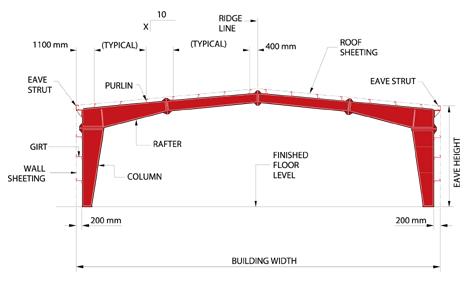

3.6.1 Main Framing

Mainframingbasicallyincludestherigidsteelframesofthe building. The PEB rigid frame comprises tapered/straight columnsandtaperedrafters(steelplatefabricated'I'or'H' sectionsarereferredtoasbuilt-upmembers).Theframeis erected by bolting the end plates of connecting sections together.

3.6.2 Secondary frame or Purlins, girts etc.

Purlins,girtsandeavestrutsarealsoknownassecondary cold-formedmembers.Thereisnoweldinginvolvedintheir preparation. They are prepared by press bending the HR steelcoilgivingitthedesiredshape(Z-orC-shape).

3.6.3 Roof & Wall Panels

Metallicplainorcolourcoatedprofiledsteelsheetsareused as roof and wall sheeting. The steel sheets are generally madefromZincalumeorGalvalumecoilsinthicknessrange of 0.47mm to 0.55mm. The base steel is either galvanized havingazinccoatingvaryingfromaminimumMassof120 gsm./m2toamaximumof275gsm./m2(totalofbothsides) or a base steel coating of zinc – aluminum (zinc 45%, aluminum55%)oftotalMassof150gsm./m2(totalofboth sides) are available with permanent colour coating. The colour coating is also available in various options in polyester paint coating like regular modified polyester, silicon modified polyester and super polyester coatings. SpecialorganiccoatingslikePVF2(PolyVinylFluoride)are also made available. These various colour coatings on the base steel with galvanized or zinc aluminum coating provides suitable resistance for various kinds of environmenthazards.Metalroofingandsidingprofilescan be manufactured to any length – limited only by transportation constraints (usually to 12 meters). To eliminatewateringress,generaloverlapjointconsideredis 15 cm to 20 cm. It also has a major advantage for the designersasitallowsroofingwithminimumpitchwhichisa rare case in conventional buildings. This happens due to joint-less run of roofing as it has flexibility in cutting of lengths.Slopesasshallowas1:20arepossiblewhichallows

sufficient drainage of water thereby improving long term performance of the panels. These profile steel sheets are conventionallycategorizedintotwotypesdependingupon the type of fine-tuning arrangement followed. These two types are Through Fastened and second one is Standing Seam.Installationofthistypeofroofing&claddingsystem canprovide30yearsormoreoftrouble-freeaccommodation inmostenvironments.

3.6.4

Longitudinalcrossbracing,usedtoprovidelateralstability to the structure against wind, seismic or other forces, comprisesofrods,pipes,anglesorcableswithaneyebolt and an adjusting nut at both ends, located near the outer flangeofcolumnsorraftersandattachedatthewebofthe rigidframe.

3.6.5

These pre–engineered buildings can be equipped with Overhead EOT cranes, Semi-gantry cranes, wall mounted cranes, Mono rails and under slung cranes for various materialandequipmenthandlingoperationsinside.These buildings are being designed for crane capacities ranging from 1MT to 250MT. The crane runway beams (Gantry Girders) are simply supported built-up sections with/withoutcapchannelsandwithmaintenanceplatforms and ladders. Catwalks for crane maintenance are usually mountedalongsidethecranebeams,suspendedunderrigid frameraftersorelevatedabovethetopofthebuildingroof. Cranesatvariouslevelscanalsobeprovided.PEBvendors generally do not keep the supply of rail and Crane Bridge withcraneintheirscope

5.1 General

InthedesignofPre-EngineeredBuildings(PEBs)asperIS codes, key parameters such as span variation and height variation play a crucial role in determining the structural efficiency and cost-effectiveness of the building. height variation influences the structural stability and load distribution, affecting factors like wind resistance and mezzanine floor provisions. In this chapter parameters consideration for PEB as well as variation in models has beendiscussed.Followedwithloaddesign,sectionselection hasbeencarriedoutinseparatespreadsheet

4.2 Parameter considered

1. Deformation

2. Self-Weight

3. CompressiveStresses

4. TensileStresses

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

4.3 General Philosophy of PEB design as per IS code DESIGN CRITERIA

a) Loads

Loads Live

Loadonroofandframeshallbe0.75kN/m^2asperIS-875 Part-2

Dead load

Deadloadonroofshallbemin.0.15kN/m^2

Earthquake load

AsperIS1893(Part-1)–2002.

ImportanceFactor&ResponsereductionasperIS1893Part IV.

WindloadasperIS875Part3,1987

Other Loads

Designofallstructuresshallalsoconsideranyotherrelevant stressesimpartedtothestructureduetovariationindaily and seasonal temperature, water label, erection and maintenanceloads,creepshrinkageetc.

Wind and seismic forces shall not be considered to act simultaneously.

Individualmembersoftheframeshallbedesignedforthe worstcombinationofforcessuchasbendingmoment,axial force,shearforce,torsionetc.resultedfromthemostcritical combinationsofloadsasspecifiedbelow.

b) LOAD COMBINATON:

Strength load combination for buildings with or without equipmentshallbe:

1.5*DeadLoad+1.5*Live/ImposedLoad

1.5* Dead Load + 1.5* Live / Imposed Load + 1. 5*

Piping/FirefightingLoad

1.5*DeadLoad+1.5*(Wind/SeismicLoad)

0.9*DeadLoad+I.5*(Wind/SeismicLoad)

1.2* Dead Load + 1.2* Live/Imposed Load + 1.2*

Piping/Firefighting+1.2*(Wind/Seismicload)

Serviceloadcombinationsforgeneralbuildingsshallbe:

1.0*DeadLoad+1.0*Live/ImposedLoad

1.0* Dead Load + 1.0* Live/Imposed Load 1.0*

Piping/FirefightingLoad

1.0*DeadLoad+1.0*(Wind/SeismicLoad)

1.0*DeadLoad+1.0*Piping/FirefightingLoad+0.8*(Wind/ SeismicLoad)

1 .0 * Dead Load + 0.8* Live/Imposed Load + 0.8*

Piping/FirefightingLoad+0.8*(Wind/SeismicLoad)

Permissiblestressesfordifferentloadcombinationsshallbe takenasperrelevantISCodes.

c) GENERAL

Angle/Rodbracingforroofandwallisconsidered.

Mainframecolumnbaseconsideredaspinnedsupport.

Builtup&HotrolledsectionstobedesignedasperManual ofSteelConstruction,9thedition,AmericanInstituteofSteel Construction(AISC)&IS:800.

Coldformedmemberstobedesignedasper1996Editionof Cold-FormedSteelDesignManual,AmericanIronandSteel, Institute(AISI),IS:801&IS:513.

Welding shall be applied in accordance with: American WeldingSociety(AWSD1.1.98)StructuralWeldingCode–Steel.IS:800,IS:813&IS:816.

d) PERMISSIBLE

The permissible vertical deflection for structural steel membersshallbeasspecifiedbelow: a.ForPrimary Span /180

b.ForSecondary Span/150

SteelStructuresimplespanBeamshallbeSpan/240.

SteelStructureforcantileverspanBeamshallbeSpan/120.

Permissiblehorizontaldisplacementatcranelevel/eaves levelshallbeHeight/150. PermissibleDeflectionforPurlin shallbeSpan/150.

PermissibleDeflectionforSideRunnerShallbeSpan/150

e) Design of Pre-Engineered Buildings (PEB)

ThemainframingofPEBsystemsisanalyzedbythestiffness matrix method. The design is based on allowable stress design (ASD) as per the American institute of Steel ConstructionspecificationortheIS800.thedesignprogram provides an economic and efficient design of the main framesandallowstheusertoutilizetheprogramindifferent modestoproducetheframe designgeometryandloading

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

and the desired load combinations as specified by the building code opted by the user. The program operates throughthemaximumnumberofcyclesspecifiedtoarriveat anacceptabledesign.Theprogramusesthestiffnessmatrix methodtoarriveatanacceptabledesign.Theprogramuses the stiffness matrix method to arrive at the solution of displacements and forces. The strain energy method is adopted to calculate the fixed end moments, stiffness and carryoverfactors.Numericalintegrationisused.

Thedesigncycleconsistsofthefollowingsteps:

1. Setupsectionsizesandbracelocationsbasedonthe geometryandloadingspecifiedfortheframedesign.

2. Calculate moment, shear, and axial force at each analysispointforeachloadcombination.

3. Compute allowable shear, allowable axial and allowablebendingstressincompressionandtensionateach analysispoint.

4. Computethecorrespondingstressratiosforshear, axialandbendingbasedontheactualandallowablestresses andcalculatethecombinedstressratios.

5. Designtheoptimumsplicelocationandchecktosee whether the predicted sizes confirm to manufacturing constraints.

6. Using the web optimization mode, arrive at the optimum web depths for the next cycle and update the memberdatafile.

7. Attheendofalldesigncycles,ananalysisisrunto achieveflangebraceoptimization.

Theprogramhasthecapabilitytohandledifferenttypesof framegeometryasfollows

Frames of different type’s viz. rigid frames, frames with multiple internal columns, single slope frames, lean to framesetc.

Frames with varying spans, varying heights and varying slopes etc. Frames with different types of supports viz. pinnedsupports,fixedsupports,sinkingsupports,supports withsomedegreesoffreedomreleased.

Unsymmetrical frames with off centric, unequal modules, varyingslopesetc.Userspecifiedpurlinandgirtspacingand flangebracelocation.

Frame design can handle different types of loadings as describedbelow:

Allthebuildingdeadloadsduetosheeting,purlins,etc.and theself-weightoftheframe.Imposedliveloadontheframe withtributaryreductionsaswell.

Collateralloadsuchasfalseceiling,lightfixtures,ACducting loads,sprinklersystemsandmanyothersuspendedloadsof similarnature.

Following are the main design codes generally used:

AISC : Americaninstituteofsteelconstructionmanual

AISI : Americanironandsteelinstitutespecifications

MBMA : Metalbuildingmanufacturer’scode

ANSI : American national standards institute specifications

ASCE : Americansocietyofcivilengineers

UBC : Uniformbuildingcode

j) Types of Bracing

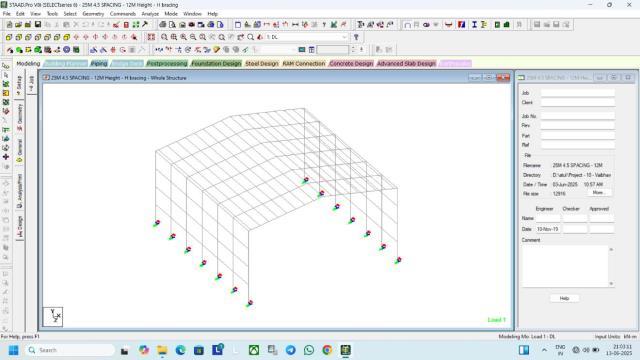

H type

Fig. No. 4.1 H type Bracing

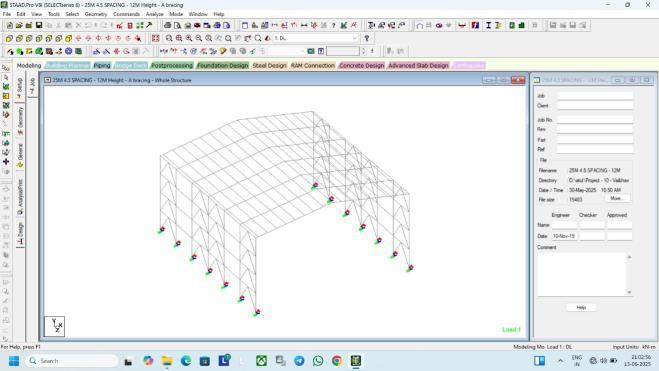

A type

Fig. No. 4.2 A type Bracing

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

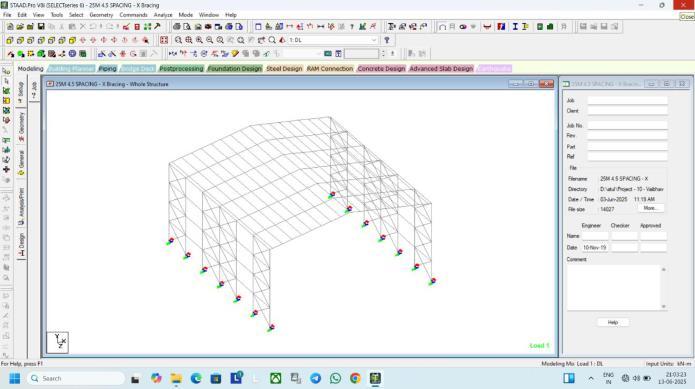

No. 4.3 X type Bracing

5. RESULTS AND DISCUSSION

5.1 General

ThecurrentprojectworkistostudyofEffectivenessofspan forPrefabricatedbuildingfordifferentloadingasperflowof project mentioned in the theoretical Formulation chapter. Heights and span of PEB warehouse truss and parameter consideredforanalysisofPEBwithexerciseasdiscussedin previouschapter. Thischaptercontainsdiscussionofresults ofanalyzedPEBtrussesasfollows,

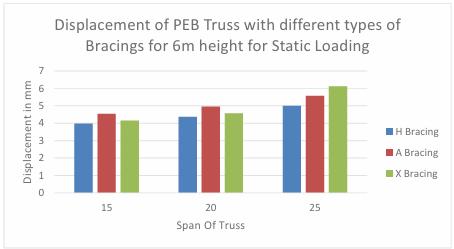

5.2 Displacement of PEB Truss with different types of Bracings for 6m, 9m and 12m height for Static Loading

no.1 Displacement of PEB Truss with different types of Bracings for 6m height for Static Loading

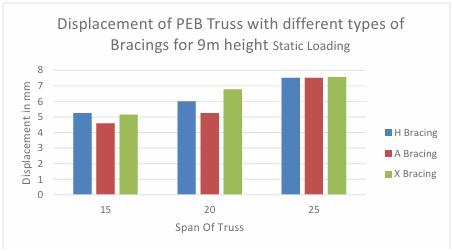

Graph no.2 Displacement of PEB Truss with different types of Bracings for 9m height Static Loading

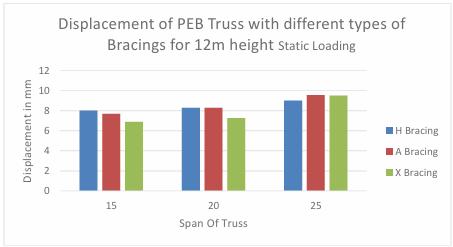

Graph no.3 Displacement of PEB Truss with different types of Bracings for 12m height Static Loading

VariationofdeformationofPEBtrussfor6M9Mand12m of height of trust and plotted against span referring to appendixa.

PlotG1,G2,G3showsthatfor6m,9m,12mheightofcolumn of truss comparison respectively of deformation in PEB Trussesinvariationwithdifferenttypesofbracingwhichare htypebracing,atypebracingandXtypebracing.

Followingobservationsarenoted,

As observed in plot G1, G2, G3 plotted with respect to differenttypesofdressingsdeformationvalues,

1. AsweseefromPlotG1,G2,G3thevaluesofdeformation oftrussesfromdifferenttypesofbracingsvariesasthe heightchanges.

2. In plot G1 for span 15 M and 20 m A bracing shows higherdisplacementthanothertwotypesofbracings.

3. In plot G1 for span 25 m the value of displacement is higherforxbracing.

4. In plot G2 A bracing shows less displacement as comparedtoothertwotypesofbracingfor15Mand20 mspan

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

5. In plot G2 for span 25 m the value of displacement showsapproximatelysamevalueforalltypesofbracing.

6. InplotG3forheight12minspan15Mand20mthe expressingshowslessvalueofdisplacementotherthan twobracing.

7. In plot G3 for height 12 m in span 25 m the values of displacementnearlysame.

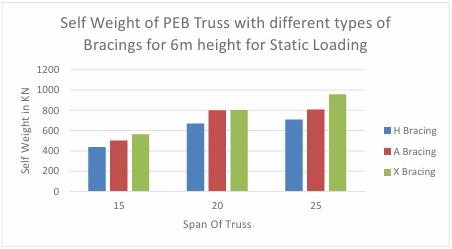

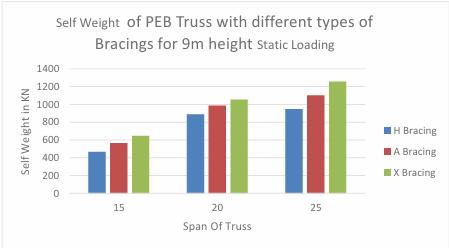

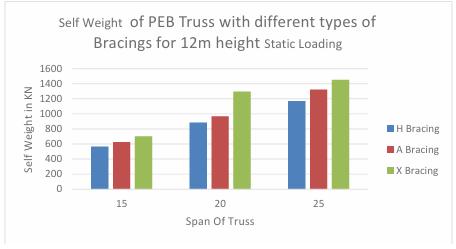

5.3 Self-Weight of PEB Truss with different types of Bracings for 6m, 9m and 12m height for Static Loading

Variationofself-weightinkNofPEBtrussfor6M9Mand 12mofheightoftrustandplottedagainstspanreferring toappendixa.

PlotG4,G5,G6showsthatfor6m,9m,12mheightofcolumn of truss comparison respectively of self-weight in PEB Trussesinvariationwithdifferenttypesofbracingwhichare htypebracing,atypebracingandXtypebracing.

Followingobservationsarenoted,

AsobservedinplotG4,G5,G6plottedwithrespectto differenttypesofdressingsself-weightvalues,

1. AsweseefromPlotG4,G5,G6thevaluesofself-weight oftrussesfromdifferenttypesofbracingsvariesasthe heightchanges.

2. Asweseeingraph,asthenumberofmembersincreases theself-weightoftheTrussalsoincreases.Inallheight thevalueofweightofbuildingincreasesuniformly

3. Maximum self-weight of the truss in this research is 1453kN for 12m height and 25m span for X type of bracing.andtheminimumself-weightofthetrussinthis research is 438kNfor 6m height and 15m span for H typeofbracing

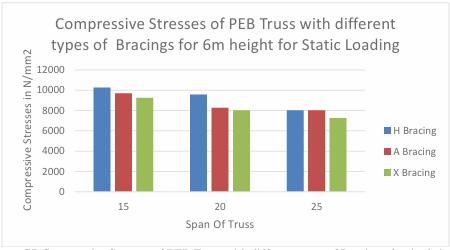

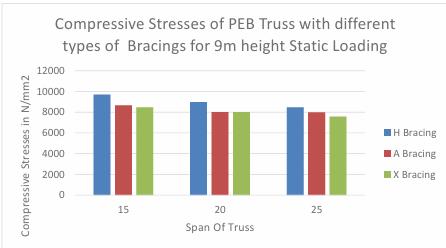

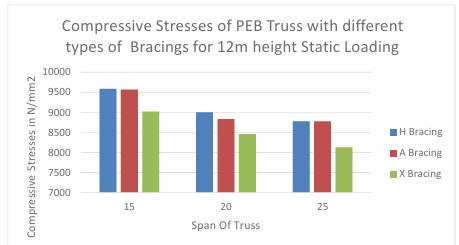

5.4 Compressive Stresses of PEB Truss with different types of Bracings for 6m, 9m and 12m height for Static Loading

Graph no.7 Compressive Stresses of PEB Truss with different types of Bracings for 6m height Static Loading

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Graph no.8 Compressive Stresses of PEB Truss with different types of Bracings for 9m height Static Loading

Graph no.9 Compressive Stresses of PEB Truss with different types of Bracings for 12m height Static Loading

VariationofCompressiveStressesinN/mm2ofPEBtrussfor 6M9Mand12mofheightoftrustandplottedagainstspan referringtoappendixa.

PlotG7,G8,G9showsthatfor6m,9m,12mheightofcolumn oftrusscomparisonrespectivelyofCompressiveStressesin PEB Trusses in variation with different types of bracing whicharehtypebracing,atypebracingandXtypebracing.

Followingobservationsarenoted,

AsobservedinplotG7,G8,G9plottedwithrespectto differenttypesofdressingsCompressiveStressesvalues,

1. As we see from Plot G7, G8, G9 the values of CompressiveStressesoftrussesfromdifferenttypesof bracingsvariesastheheightchanges.

2. In plot 7 for 6 M height in 15 M plan the value of compressivestressesaregraduallydecreasing.In20m spanthestressesbetweenabracingandxbracingare nearlysame,butinhbracingthevalueisabithigher.

3. In Plot 8 for 9 M height the value of compressive stressesareagaingraduallydecreasing.

4. In plot 9 for 12 m height compressive stresses are reducinginalargenumber.

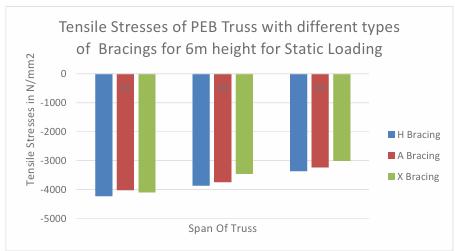

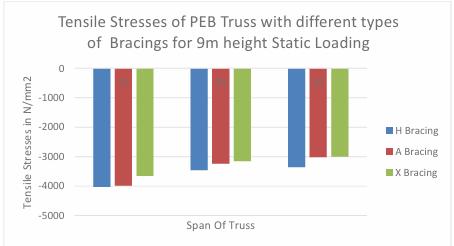

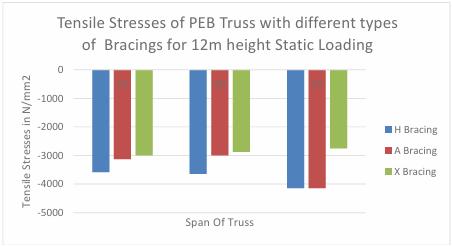

5.5 Tensile Stresses of PEB Truss with different types of Bracings for 6m, 9m and 12m height for Static Loading

Graph no.10 Tensile Stresses of PEB Truss with different types of Bracings for 6m height Static Loading

Graph no.11 Tensile Stresses of PEB Truss with different types of Bracings for 6m height Static Loading

Graph no.12 Tensile Stresses of PEB Truss with different types of Bracings for 6m height Static Loading

VariationofTensileStressesinN/mm2ofPEBtrussfor6M 9 M and 12 m of height of trust and plotted against span referringtoappendixa.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

PlotG10,G11,G12showsthatfor6 m,9m,12m height of columnoftrusscomparisonrespectivelyofTensileStresses inPEBTrussesinvariationwithdifferenttypesofbracing whichareHtypebracing,AtypebracingandXtypebracing.

Followingobservationsarenoted,

Asobservedin plotG10,G11,G12 plotted with respect to differenttypesofdressingsTensileStressesvalues,

1. AsweseefromPlotG10,G11,G12thevaluesofTensile Stresses of trusses from different types of bracings variesastheheightchanges.

2. In plot 10 for 6 M height in 15 M plan the value of compressivestressesaregraduallyincreasing.

3. In Plot 8 for 9 M height the value of compressive stresses are again gradually decreasing. In 15 m span thestressesbetweenAbracingandHbracingarenearly same,butinXbracingthevalueisabitlower.

4. In plot 9 for 12 m height compressive stresses are gaininginalargenumber.

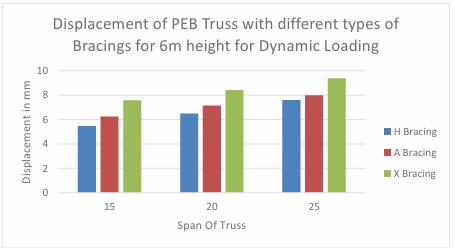

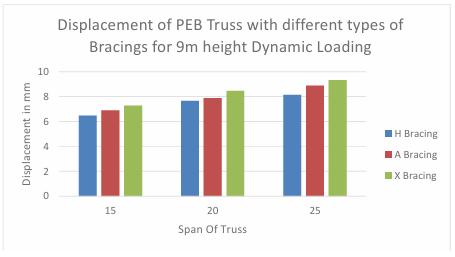

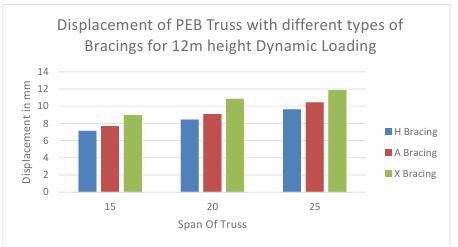

5.6 Displacement of PEB Truss with different types of Bracings for 6m, 9m and 12m height for Dynamics Loading

Graph no.15 Displacement of PEB Truss with different types of Bracings for 6m height Dynamic Loading

PlotG13,G14,G15showsthatfor6 m,9m,12mheight of columnoftrusscomparisonrespectivelyofdeformationin PEB Trusses in variation with different types of bracing whicharehtypebracing,atypebracingandXtypebracing.

Followingobservationsarenoted,

Asobservedin plotG13,G14,G15 plotted with respect to differenttypesofdressingsdeformationvalues,

1. As we see from Plot G13, G14, G15 the values of deformationoftrussesfromdifferenttypesofbracings variesastheheightchanges.

2. Inplot G13, G14,G15 for6 Mheightin15 M planthe valueofdeformationaregraduallyincreasing.

3. As the span increases the value of displacement increases.

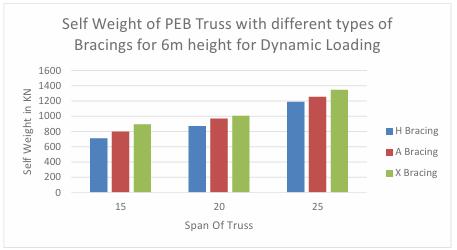

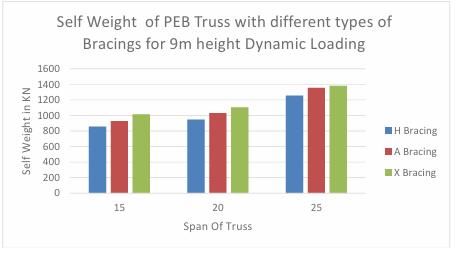

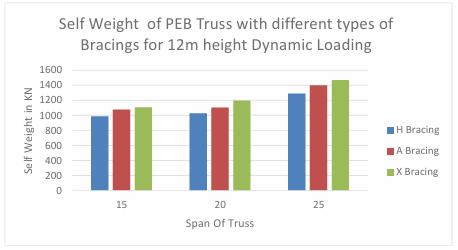

5.7 Self-Weight of PEB Truss with different types of Bracings for 6m, 9m and 12m height for Dynamics Loading

Graph no.16 Self-weight of PEB Truss with different types of Bracings for 6m height Dynamic Loading

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

Graph no.17 Self-weight of PEB Truss with different types of Bracings for 6m height Dynamic Loading

Graph no.18 Self-weight of PEB Truss with different types of Bracings for 6m height Dynamic Loading

Variationofself-weightinkNofPEBtrussfor6M9Mand 12mofheightoftrustandplottedagainstspanreferringto appendixa.

PlotG16,G17,G18showsthatfor6 m,9m,12mheight of column of truss comparison respectively of self-weight in PEB Trusses in variation with different types of bracing whicharehtypebracing,atypebracingandXtypebracing fordynamicsloading.

Followingobservationsarenoted,

Asobservedin plotG16,G17,G18 plotted with respect to differenttypesofdressingsself-weightvalues,

1. As we see from Plot G16, G17, G18 the values of selfweightoftrussesfromdifferenttypesofbracingsvaries astheheightchanges.

2. Asweseeingraph,asthenumberofmembersincreases theself-weightoftheTrussalsoincreases.Inallheight thevalueofweightofbuildingincreasesuniformly

3. Maximum self-weight of the truss in this research is 1467kN for 12m height and 25m span for X type of bracing.andtheminimumself-weightofthetrussinthis

research is 707kNfor 6m height and 15m span for H typeofbracing.

This study presents a comprehensive analysis of PreEngineeredBuilding(PEB)trussesandboxgirderbridges undervariousstaticanddynamicloadingconditions.Two types of box girder cross-sections rectangular and trapezoidal were evaluated, highlighting the impact of span-to-depthratioondeflectionandstressdevelopment. ForPEBtrusses,theeffectsofdifferentbracingtypes(H,A, andX)werestudiedacrossvaryingcolumnheights(6m,9 m, and 12 m) and spans. Results show that bracing type significantly affects deformation, self-weight, and stress distribution.X-typebracinggenerallyoffersbettercontrolof displacement and tensile stresses, especially in taller structures, but results in higher self-weight due to its complex configuration. H-type bracing, while lighter, may notperformaseffectivelyinstresscontrol.Compressiveand tensile stresses vary with height and span, with taller structures showing reduced compressive stresses but increased tensile forces. Under dynamic loading, deformation increases with span length, emphasizing the needforoptimalbracinginlarge-spandesigns.Overall,the studyconcludesthattrussheight,spanlength,andbracing configurationarecriticalfactorsinoptimizingthestructural performanceandefficiencyofPEBsystems

[1] JiminHe(1987),”IdentificationOfStructuralDynamic Characteristics”, Department of Mechanical EngineeringImperialCollege,LONDONSW7

[2] Jaillon, L., & Poon, C. S. (2009). The Evolution of Prefabricated Residential Building Systems in Hong Kong: A Review of the Public and the Private Sector. Automation in Construction, 18, 239-248. https://doi.org/10.1016/j.autcon.2008.09.002

[3] Hui Min Xu, Yung Yang Li, Wei Xui(2014),”Dynamic characteristicanalysisofprefabricatedhouseoflight weight steel structure”, Applied mechanics material 578-579:483 487 DOI: 10.4028/www.scientific.net/AMM.578-579.483

[4] Loss,C.,Piazza,M.,&Zandonini,R.(2016).Connections forSteel-TimberHybridPreFabricatedBuildings.Part I: Experimental Tests. Construction and Building Materials, 122, 781- 795. https://doi.org/10.1016/j.conbuildmat.2015.12.002

[5] Chandrashekhar B Adin, Raveesh R. M, Praveen J.V.(2016),” Dynamic Analysis of Industrial Steel StructurebyusingBracingsandDampersUnderWind Load and Earthquake Load”, Dept. of CIVIL Sri SiddharthaInstituteofTechnologyTumkuru,India

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 08 | Aug 2025 www.irjet.net p-ISSN: 2395-0072

[6] Fard, M. M., Terouhid, S. A., Kibert, C. J., & Hakim, H. (2017). Safety Concerns Related to Modular/Prefabricated Building Construction. InternationalJournalforConsumer&ProductSafety, 24, 10-23. https://doi.org/10.1080/17457300.2015.1047865

[7] Kasperzyk, C., Kim, M. K., & Brilakis, I. (2017). Automated Re-Prefabrication System for Buildings Robotics. Automation https://doi.org/10.1016/j.autcon.2017.08.002 in Construction,83,184-195.

[8] Teng, Y., Li, K., Pan, W., & Thomas Ng, S. (2018). ReducingBuildingLifeCycleCarbonEmissionsthrough Prefabrication: Evidence from and Gaps in Empirical Studies. Building and Environment, 132, 125-136. https://doi.org/10.1016/j.buildenv.2018.01.026

[9] Li, Y. S., Hwang, B. G., Shan, M., & Looi, K. Y. (2019). Developing a Knowledge-Based Decision Support System for Prefabricated Prefinished Volumetric Construction. IOP Conference Series Earth and Environmental Science, 385, Article ID: 012002. https://doi.org/10.1088/1755-1315/385/1/012002.

BIOGRAPHIES

Mr. Vaibhav Jawalkote

B.E.(Civil),MTech(Civil-Structure) (pursuing)ResearchScholaratN.B. Navale Sinhgad College of Engineering,Solapur,Maharashtra, India

Dr. Pradeep. P. Tapkire

Working as Head of Department, Civil Engineering, N B Navale Sinhgad College of Engineering, Solapur, Maharashtra, India

Graduatedincivilengineeringand did masters in structure from ShivajiUniversity,Ph.D.fromS.P. Pune University and having experienceofmorethan18years inteachingaswell asinindustry. PG recognized teacher of Solapur University. Has selected as Board of Study Member for Solapur University,Solapur Guided22PG studentsand16areworkingunder theguidance HandledIITMCband radar installation project as structural and execution expert.

Nominatedasmemberfordistance learning syllabus formation committee IGNOU, Delhi. Also worked as committee member to identify centers for IGNOU for distance learning courses. Receivedappreciationawardfrom ULTRATECH, Cement Solapur for contributioninM-sandProject.

Mr. Atul S. Chandanshive

Working as Lecturer in, Civil Engineering, Solapur Education Society’s Polytechnic, Solapur, Maharashtra, India. Graduated in civil engineering and did masters in structure from Solapur University,andhavingexperience ofmorethan4yearsinteachingas wellasinindustry