International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

David Atadious1 , Ikechukwu Patrick Onwuamaeze2 , Onyekachi Tochukwu Dennar3 , Anthony Chijioke Aneke4

1,2,3,4Mechanical Engineering Department, Petroleum Training Institute, Effurun, Delta State, Nigeria

Abstract - This study involves the design andfabrication ofa four – hopper (4-H) feed, horizontally inclined system (HIS) plantain slicing machine in order to optimize throughput capacity andefficiency at low cost, reduce total time of slicing and produce hygienic and quality chips for small scale plantain chips producers. The materials for the machine include stainless steel plates and mild steel angle iron. The machine consists of a cutting disc having two cutting blades, cutting chamber, 4-H plantain feed, the main frame and a 750W electric motor power transmission unit. The machine was evaluated for performance using raw plantain with an average diameter of 50mm andlength 150mm,whichsourced from markets in the vicinity of Petroleum Training Institute, Effurun, Nigeria. The results obtained from the fabricated plantain slicing machine gave a cutting force of 37.67N, and velocity of the cutting disc of 4.2m/s. It is not totally free of noise andvibration, the slicing method is continuous withtwo slicing blades provided inside the cutting chamber and the energy for loading and unloading is reduced since four feed hoppers and a large discharged outlet were provided. The performance evaluation gave the efficiencyforasinglehopper feed (1-H), double (2-H) , triple (3-H) and quadruple (4-H) hopper feeds, as 89.66%, 91.67%, 91.21% and 90.98% respectively, and their throughput capacities were 50.52g/s, 100.13g/s, 141.85g/s and 183.00g/s respectively. The maximum slicing time obtained was 3.6m/s.

Keywords: Plantain chips, Hopper, Cutting disc, throughput capacity, Efficiency and Cutting Chamber.

Plantainisabasicstaplefoodcropindevelopingcountries, especiallyAfricaandSouthAmerica[1].Theharvestedcrop whenprocessedprovidesavarietyoffoodandrawmaterials for fast moving consumer goods (FMCG) factories and for over70millionpeopleinNigeria[2][1].Plantainisasemiperishable crop and large quantity is wasted due to deteriorationduringthepeak ofharvest [3][4]. Toensure food security and to reduce wastage, the adoption of an effective processing into chips for preservation and availabilitythroughouttheyearisnecessary[3][4].Modern methodsofslicinghavegreatlyimprovedproductionrates andreducedslicingtime[3][4][5].Theplantainbelongsto thefamilyMUSASPP,andthespeciesinsomepartsofAfrica suchasNigeria,Cameroon,BeninandGhanaplantainsare alsodried andmadeintoflour(bananamealsforms),when

ripeplantainisfried,whichisgenerallycalleddodo(doughdough)[4][6][7].

Plantain is important food stuff with the followingconstituents:water10.62%protein3.55%calcium 1.15%carbohydrates81.67%[1][4].

Theprocessofmanualpeelingandslicingusingtheknifecan beinjurious,timeconsuminganddoesnotproduceuniform size of sliced chips, possibility of food contamination and inevitablyleadsto lowoutputbyfarmers withlittleor no incomemargin[3][8][9][10][11]

Provisionofamotorizedslicingmachinewillcontributeto food security, export earnings and economicgrowth and reduction in the slicing time [5][8][9]. Farmers are faced with post-harvest losses since the plantain perish or get rotteneasilywhenripe[5].Forthisreasonmanymethodsof processing are being introduced like(roasting and frying) afterharvest[5][12]

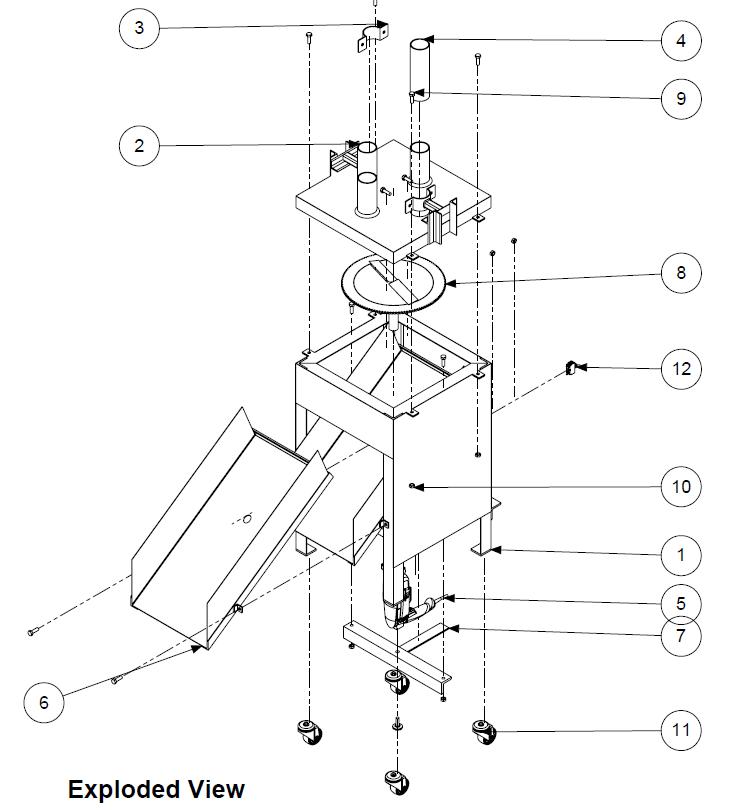

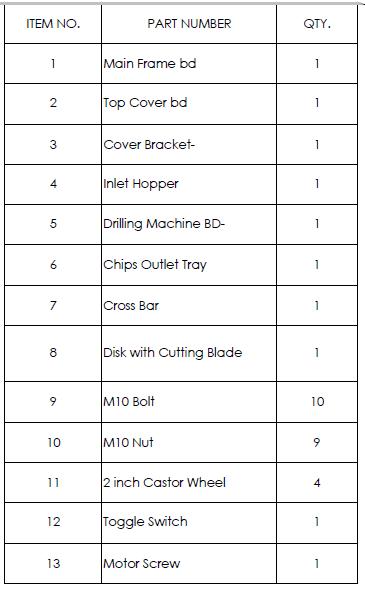

In this design a 4-H horizontally inclined slicer (HIS) machine was constructed with the aim of increasing total throughputandperformanceofthedesignascomparedwith otherdesignswiththreeorlessfeedhoppers.

Theslicingequipmentconsistsofrotatingbladesdrivenby centrifugalforceprovidedbyanelectricmotorthatperforms thecuttingactionastheplantainisfedthroughthehoppers undergravity.

2.1 Materials

Thematerialsemployedintheconstructionwerecarefully selected to ensure proper hygiene of sliced plantain, durability,reliability,safety,portabilityandefficiencyofthe machine. Other materials include the motor selection and angleironfortheframeandstand.

The plantain chips are produced in a chamber fabricated fromstainlesssteelplatewhiletheframewasconstructed usingmildsteel.

2.2

The modifications introduced in this design involved incorporatinganadditionalhoppertohavea4-Hdesignas

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

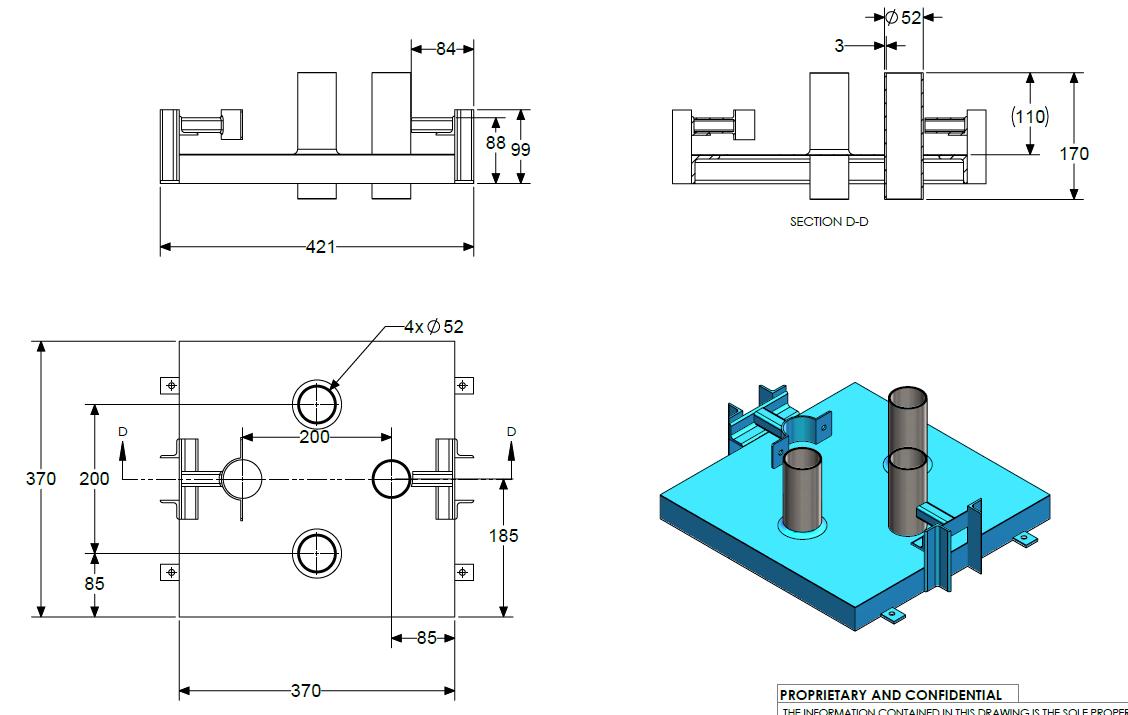

againstexistingdesignwhichhasone(1-H)orthreehoppers (3-H). The cutting disc is mounted on a direct drive shaft connected to the electric motor. The cutting disc was also modifiedtohavetwocuttingbladesasagainstoneinother designs[4] ThedesigndiagramsarepresentedinFigures1 and2

AkandeandOnifade(2015)[3]andTawakalitu(2016)[4] presented other factors to be considered in the design to includethefollowing;

1. Hygiene:Theslicingblademustbewashablesothat quality chips can be obtained therefore the blade must be made of stainless steel as approved by worldhealthorganization(WHO)toguideagainst corrosion,

2. AcceptableColour:Thecolouroftheslicedproducts mustnotchange,thoughitdependsonthecolourof theplantaintobesliced,

3. Aesthetics: The machine physical appearance should look good, attractive and not looking odd, this would make it attractive by choosing a streamlined frame design, choosing light but durable materials, wirings should also be done neatly and an attractive paint colour must be selected,

4. Sizeandweightofthemachine:Theoverallsizeand weight of the machine is an important factor that governsthesizeoftheselectedmaterialsandtheir components such as electric motor. The easy movementofthemachineisanimportantfactor,so thatanywherethemachinewillbeneeded,itcanbe easilyconveyedtotheplace,

5. Compactness:thisisimportantwhenthemachineis built as small as possible without removing basic componentsandfeatures,

6. EaseofOperation:Themachineisdesignedinaway that it is easy to assemble, disassemble, load, operateandoff-load,

7. Safety: The wires of the electric motor are all insulated and the electrical switch is carefully selected to ensure complete power cut from the mainswhenswitchoffandtopreventelectricshock in case the neutral wire becomes the live when pluggedtoawronglyconnectedsocket.Thecasing on the electric motor was also insulated, while sharpedgesweremadeblunt.Rotatingpartswere alsoshielded,

8. Ease of Maintenance: The machine must also be easily maintained either by routine or weekly cleaning, retightening of bolts, and lubrication of necessarypartse.g.bearingandjoints,

9. Toensurethatthemachinedoesnotgetwetafter the plantain has been sliced in order to prevent rustingofthemovingparts.

p-ISSN: 2395-0072

The plantain chipping machine employs the principle of shearingoperationtocut(slice)througha givenlength of plantain that is fed by gravity through a hopper onto a rotating cutting blade mounted on a disc; the rotational motion is provided by an electric motor whose power is transmittedthroughashaft(Tawakalitu,2016).

The following analyses were used to determine the parts parametersoftheplantainchippingmachine.

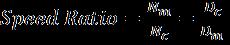

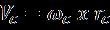

The speed of the cutting disc can be calculated using Equation(1)[13] (1)

where;Nmisthespeedofthemotor(rpm),Ncisthespeedof thecuttingdisc(rpm),

Dm isthediameterofthemotorshaft(m),Dc isthediameter ofthecuttingdisc(m)

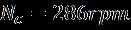

Givenadiameterofmotorshaft=20mm,andDc =280mm

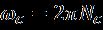

TheangularspeedofthecuttingdiscisgivenbyEquation(2) as;

where; istheangularvelocityofcuttingdisc(rad/s)

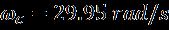

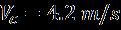

Linear Velocity,

The linear velocity of the cutting disc ( is given by Equation(3),[14]as;

where; Vc isthe velocity of thecutting disc (m/s), rc isthe radiusofthecuttingdisc(m)

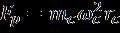

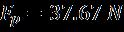

Thecentripetalforce( requiredtosliceplantainisgiven byEquation(4)as;

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

where; Fp isthecentripetalforcerequiredtosliceplantain (N), m isthemassofthecuttingdisc=0.3 kg

Obeng, 2004 reported that the average force required to shearrawplantain of diameters rangingfrom30 – 70mm 33.15N.

Power required at the Cutting Disc

Thepowerrequiredbythecuttertoslicetherawplantain maybeobtainedfromtheexpressioninEquation(5)[4] (5)

Theplantainchippingmachinewaspreparedforoperation, therotatingpartsofthemachinewerelubricatedtoreduced friction;rotatingforcewassuppliedtothebladethroughthe shaftconnectedtotheelectricmotor[3][4][15].Testingof themachinewithfreshfingersofplantainwasthencarried out. The electric powerwas supplied to the machine via electric motor and the machine was allowed to run for tenminutessoastostudyitsbehaviour;noise,vibrationof themachine[15].Theplantainpeelwaspeeledwithaknife toexposethefruit;equallengths(150mm)ofthefruitwas verticallyfedintothefeedhopper,duringthisprocess,sliced plantain (chips) passed through the discharged outlet [4]. Fivesampleseachweretestedusingthe1-H,2-H,3-Hand4Harrangementrespectively. Theaverage weightandtime taken to completely slice through the given lengths were recorded. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

where; isthepowerrequiredatthecuttingdisc(watts)

Power required by the Electric Motor

The power requirement for the electric motor is given in Equation(6)accordingtoTawakalitu,(2016)[4]as; (6)

Where; isthepowerrequirementofelectricmotor(W), isthepowerfactor=(0.5)

Anelectricmotorwithapowerrating750 W and4000rpm isselectedbasedonsafetyandavailability.

Throughput capacity

Throughput capacity is the rate of slicing, which is the quantity(g)ofslicedplantaindividedbythetimetaken(s) asshowninEquation(7)[6] (7)

Efficiency of the machine

TheefficiencyofthemachinewascalculatedusingEquation (8)asshownbelow[6];

Efficiency (8)

where;W1 =totalweightofplantain

W2 =weightofdamagedplantainchips

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

The results of the performance test are shown in Table 1 below.

Theresultshowsthattheaveragetimetakentocompletethe slicing operation using the 1-H, 2-H, 3-H and 4-H arrangement are 3.1secs, 3.2secs, 3.4secs and 3.6secs respectively.Thisshowsthatbyincreasingthenumbersof hoppers,thereisaminimaleffectontheaverageslicingtime.

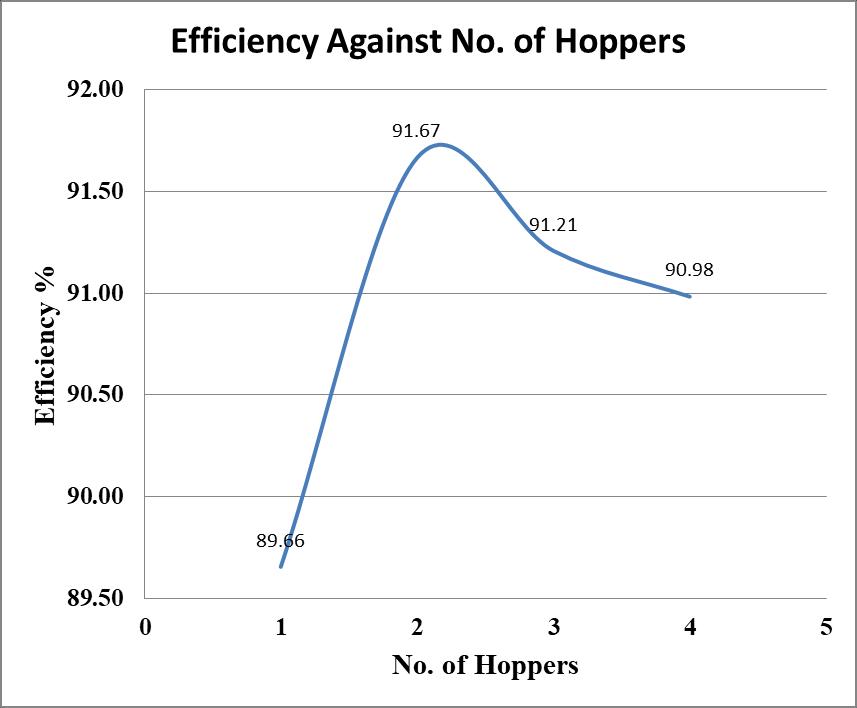

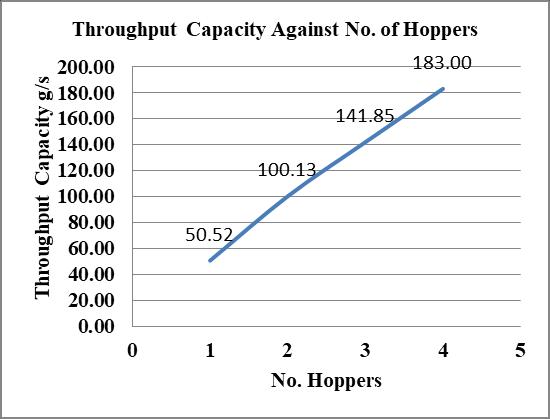

The throughput capacity increases as the number of feed hoppers were increased, this is reflected in the results obtained for the 1-H, 2-H, 3-H and 4-H arrangement as 50.52g/s,100.13g/s,141.85g/sand183.00g/srespectively. Further analyses indicated an increase in the throughput capacities of 49.60% between 2-H and 1-H arrangement, 64.40% between 3-H and 1-H arrangement and 72.40%

between4-Hand1-Harrangements.Also,byincreasingthe feed from 3-H to 4-H gave an increase of 22.50% in the throughputcapacity.Theseresultswereplottedasshownin Fig.3.

The machine slicing efficiency was calculated as 89.66%, 91.67%,91.21%and90.98%respectivelyforthe1-H,2-H,3Hand4-Harrangementsrespectively.Theresultwasplotted asshowninFig.4.

Table2,showsthecomparisonofresultsobtainedfromthis studywiththeresultsfromliteraturesconsulted.Theresult for the 3-H from this study shows an increase in the throughputcapacityof64.40%comparedwiththeresultof AkandeandOnifade(2015)[3],itwashigherby17.6%when comparedwiththeresultobtainedbyTawakalitu(2016)[4] The 4-H slicer from this study gave a higher throughput capacity of 72.41% and 33.13% when compared with AkandeandOnifade(2015)[3]andTawakalitu(2016)[4] respectively.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Thefour–hopperhorizontallyinclinedslicerwasdesigned, fabricatedusinglocallysourcedmaterialsandevaluatedto determineitsthroughputcapacityandefficiency.

Theresultofthetestgavea throughputcapacityof50.52, 100.13,141.85and183.00g/sforthe1-H,2-H,3-Hand4-H arrangementsrespectively.Themachineslicingefficiencyfor thearrangementswasalsocalculatedtobe89.66%,91.67%, 91.21%and90.98%.

Acomparisonofthe3-Hwithliteraturesconsultedgavean increasedthroughputcapacityof64.40%and17.60%over AkandeandOnifade(2015)[3]andTawakalitu(2016)[4] respectively; while the 4-H gave an increased throughput capacity of 72.41% and 36.13% over Akande and Onifade (2015)[3]andTawakalitu(2016)[4]respectively.

Theresultsofthe4-Hplantainslicingmachineprovedtobe abetterdesignduetothefollowing;

i. Theaverageproductiontimeforplantainchips wasreducedsincefourfeedingchutesareprovided, ii. Easeofmaintenancewithshortassemblyand disassemblytime

iii. Easeofoperation,

iv. Easyloadingandunloadingofplantainfruits andchips

v. Ripeandunripeplantainscanbeproduced

vi. Littlediscolorationoftheslicedchips produced with provision of stainless blade and airoutletsontheframe

vii. Rotatingpartsareenclosedandelectricmotor casingwasinsulatedforsafety.

[1]DirisuO.Joseph,SalawuY.Enesi,AzetaJoseph,FajobiA. Muyiwa, Okokpujie P. Imade and Ajayi O. Oluseyi. “Development of a Time - Saving Precision Plantain Cutter.” AIP Conference Proceedings. Published Online: AIPPublishings,2019.1-7.

[2]Seydou, T., Georges, A. L., Elisee, C. B., Sibirina, S., Fatogoma,S.,Kouabenan,A.,andDaouda,K.“Assessment of Banana and Plantain Behavior under Natural Infestation by Mycosphaerella fijiensis, Morelet in SouthernCoted'Ivoire.” Journal of Agronomy 15,no.4 (2016):151-164.

[3] Akande F. B., Onifade T. B. “Modification of a Plantain Slicing Machine.” Innovative Systems Design and Engineering 6,no.10(2015):41-52.

[4] Tawakalitu, B O. “Design and Fabrication of a ThreeHopper Plantain Slicing Machine.” American Scientific Research JournalforEngineering,TechnologyandSciences (ASRJETS) 17,no.1(2016):61-80.

[5] Adedipe J. O., Ibiyeye D. E., Ekaun A. A., Olatunji B. T., Afolabi R. T., Ajiboye O. O. “Development of a Simple Plantain Slicer for Small Scale Plantain - Chips Producers.” Global Scientific Journals 9, no. 1 (2021): 1972-1984.

[6] Adedipe J. O., Owolaja A. O., Ekaun A. A., Olatunji B. T., Adedipe D., Ajiboye O. O. “Compariso of Two Locally Made Motorized Plantain Slicers.” Engineering and Technology Journal 6,no.3(2021):833-837.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

[7]ArisaN.U.,AdelekanA.O.,AlamuA.E.,andOgunfowora E. J. “The Effect of Pre-Treatment of Plantain (Musa Parasidiaca) Flour on the Pasting and Sensory CharacteristicsofBiscuits.” International Journal of Food and Nutrition Science 2,no.1(2013):10-24.

[8]Awoliyi,O.O. Design and Construction of Plantain Slicer . UnpublishedThesisDissertation,DepartmentofDesign andFabrication,FederalInstituteofIndustrialResearch, Oshodi:FIIRO,2003,20-21.

[9] Obeng, G Y. “Design and Fabrication and Testing of a Mechanized Plantain and Carrot Slicer.” Technology consultancy center Kwame Nkrumah University of science for WestAfrican schools, Ghana 24, no. 2 (2004): 126133.

[10]UgwuokeI.C.,IkechukwuI.B.,MuazuZ.O.“Designand FabricationofanElectricallyPoweredRotarySlicerfor Raw Plantain Chips Production.” American Journal of Engineering Research 3,no.4(2014):38.

[11] Consorcio, S. N. Jr. and Cerilo, B. Jr. “Perfomance Evaluation of Manually Operated Banana Slicer for Small Scale Food Processing Industries.” Science International (Lahore) 34,no.1(2022):45-48

[12] Okafor, B.E. and Okafor, V.C. (2013):. “Design of a PlantainChipsSlicingMachine.” InternationalJournalof Engineering andTechnology 3,no.10(2013):928-932.

[13]KachruR.P.,Balasubramanian,D.,NachiketK.“Design, DevelopmentandEvaluationofRotarySlicerforRaw Banana Chips.” Journal of Agricultural Mechanization, 1996:61-64.

[14] Khurmi, R.S. and Gupta, J.K. Theory of Machines. New Delhi,India:EurasiaPublishinghouse,2010.

[15] Okoh, P. A., Eze, J. N and Ademiju, T. A. “Design and Fabrication of Improved Motorized Plantain Slicing Machine for Chips Production.” World Journal of Advanced Engineering Technology and Sciences (WJAETS) 11,no.1(2024):395–401.