International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Prof. Sumit Vitthal Patil, Suraj Balaso Patil, Akshay Arun Vibhute, Yash Bajirao Surve

ADCET College of Engineering & Technology, Ashta, Sangli

Abstract

This paper presents the designandperformanceevaluation of an automated viscous fluid filling system using Arduinobased control and proximity sensors. The system aims to address challenges in manually fillinghigh-viscosityfluidssuch as oils and gels, which typically result in inconsistent output and increased operator fatigue. The proposed setup integrates sensor-actuated pneumatic systems controlled by Arduino, ensuring precise fluid dispensing and improved ergonomics. Performance analysis was conducted using time and method study techniques. The system exhibited enhanced efficiency, consistency, and reduced cycle time, making it viableforsmallscale industrial applications.

Keywords: Arduino, Proximity Sensor, Pneumatics, Viscous Fluids, Time Study, Automation, Ergonomics

Introduction

IntroductionViscousfluidssuchasoils,gels,andsyrups areusedextensivelyinfood,cosmetics,pharmaceuticals,and lubrication industries. These fluids possess high internal resistance to flow, which makes their handling and dispensing more challenging compared to low-viscosity fluids. Manual filling of such fluids leads to several issues including spillages, inaccurate fill volumes, high rejection rates, and physical strain on operators. With increasing demandforspeedandconsistencyinindustrialoperations, manualprocessesarenolongerviableformedium-tohighvolume production. Automation in the form of microcontroller-basedfillingsystemspresentsasolutionto this problem. Arduino-based platforms offer flexibility, affordability, and ease of integration with sensors and actuators. This research focuses on the development of a semi-automated viscous fluid filling system controlled via Arduino,utilizingproximitysensorstodetectcontainersand pneumatic cylinders for fluid actuation. The primary objective is to enhance the accuracy, consistency, and ergonomicaspectsofthefillingprocess,ultimatelyimproving operationalefficiencyforsmalltomediumenterprises.

Literature Review

Literature Review The evolution of automated fluid dispensing has been extensively documented in both academicandindustrialliterature.Krainev(2010)discussed how traditional volume-based piston pump systems have

beenupgradedwithpneumaticdrivesandautomatedvalves to handle a wide variety of semi-liquid and viscous substances. These systems often include level sensors for improved control. Duncan and Redan (2018) highlighted contaminationrisksassociatedwithfood-gradelubricantsin piston filling machines, emphasizing the importance of hygieneandprecisioninfillingequipment,especiallyforfood andpharmaceuticalapplications.Meah(2010)proposedan Arduino-basedlow-costliquidfillingmachineaimedatsmallscale industries that cannot afford high-end PLCs. This system offered adequate precision while maintaining a simple design, making it accessible for educational and industrialuse.LadandLodewijks(2002)discussedthecostbenefit advantagesofsemi-automaticfilling machinesthat integrate stepper motors and non-return valves to ensure flowcontrolandaccuracyinviscousfluiddispensing.Guha and Ganzeer (2000) explored ways to reduce labour involvementinrepetitivemanufacturingoperationsthrough automation,identifyingfillingasoneoftheprocessesmostin needoftechnologicalintervention.Thesestudiescollectively supporttheneedforaffordable,flexible,andefficientfluid fillingsystemsindiverseindustrialsettings.

Manual filling of high-viscosity fluids is labor-intensive and leads to inconsistent volumes, ergonomic strain, and reducedproductivity.Conventionalsystemslackautomation, areinefficientforcontinuousoperations,andposechallenges in handling varying container sizes and fluid types. To addressthesegaps,thisprojectdevelopsasemi-automated fluidfillingsystemusingArduinoandpneumatictechnology

Objectives

• Redesign the workstation for ergonomic and continuousproduction.

• Integrate sensors with Arduino for automated control.

• Employ pneumatic cylinders for repeatable actuation.

• Validateperformancewithtimeandmethodstudies.

• Ensureaccuracyacrossdifferentfluidviscositiesand containerdimensions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

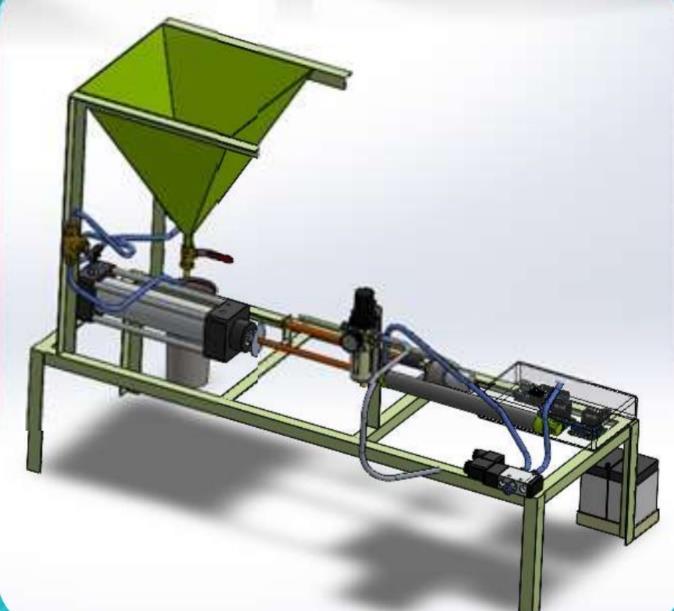

The viscous fluid filling system comprises several essential components working in synchrony to achieve automation and accuracy. At the heart of the setup is the Arduino Uno microcontroller, which governs all logical operations, including reading sensor inputs and triggering actuators.Arelaymoduleactsasaninterfacetoswitchhighvoltage deviceslike the solenoid valveusingtheArduino’s low-voltage signals. A proximity sensor detects the container’spresenceandinitiatesthefillingprocesswithout physical contact. The pneumatic FRL unit ensures the compressedairusedinthecylindersisclean,regulated,and lubricated,enhancinglongevityandperformance.A12VDC gear motor provides high torque at low RPM to operate auxiliary mechanisms like a lead screw or rotating parts. Limit switches installed along the cylinder path act as feedbacksensors,restrictingpistontravelandhelpingreset eachcycle.The5/2solenoidvalveservesasthedirectional controllerforthepneumaticactuator,alternatingairflowto achieveforwardandbackwardstrokes.Themainpneumatic cylinder,witha50mmboreand150mmstroke,handlesthe suction and discharge of viscous fluid from the hopper. A secondary support cylinder assists in maintaining stroke stability.Allcomponentsareassembledonamildsteelframe, and the hopper, fabricated from stainless steel, stores the fluidpriortodispensing.Together,thesecomponentsforma reliable, accurate, and ergonomic system for small-scale industrial applications allowing successful fundamental investigationsandexperimentoutputrecording.

The design of the system is a hybrid of pneumatic and electronic automation, coordinated through a microcontroller. The system’s core mechanism involves filling viscous fluid from a hopper into containers using a double-actingpneumaticcylinder.Whenacontainerisplaced

beneath the fill nozzle, a proximity sensor detects its presenceandsignalstheArduinoUno.Themicrocontroller then triggers a 5/2 solenoid valve via a relay, allowing compressedairtoactivatethemainpneumaticcylinder.The forwardstrokeofthepistondrawsfluidfromthehopperinto thedeliverytube,andthereturnstrokepushesthefluidinto thecontainer.Thelimitswitchesdetectthepiston’sextreme positionstoconfirmstrokecompletionandtriggerthenext operation. All components are housed in a sturdy frame fabricated from C-45 mild steel to withstand repeated pneumaticoperationswithoutdeformation.

TheHopper,fabricatedfromstainlesssteel,holdsthefluid under gravity. Its design supports multiple cycles of operation without requiring frequent refilling. Pneumatic pressureismaintainedbyaproperlycalibratedFRLunitto ensuresafeandconsistentactuation.Theelectricalcircuitry is wired on a breadboard and simulated in Tinker cad to validatesignalflowandlogicsequence.

Cylinder Volume:

Given:Borediameter=50mm,Strokelength=150mm

• Radius=25mm

• V=π×r2×h=3.1416×252×150=294,524.3mm3≈294.5 ml

This is sufficient for a 200 ml target fill witha marginforpressurelossesordelay.

Hopper Capacity:

• Dimensions:260mm×260mm×255mm

• V=260×260×255=17,238,000mm3=17.2L

• The volume allows up to 85 full cycles before requiringarefill.

• Given:Power=10W,RPM=1000

• T=60×P/2π×N=60×10/6.2832×1000

≈95.5Nmm

Thisconfirmsthattheselectedmotorprovidessufficient torquetodriveanymechanicalsupportmotionsuchasalead screwifrequired.

These calculations informed the component sizing, especiallyinensuringthepneumaticstrokeandvolumecould reliably meet the fill quantity under variable viscosity conditions.Eachparameterwasoptimizedforperformance, repeatability,anddurability,makingthesystemrobustand adaptabletoreal-worldapplications

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Thedevelopedautomaticviscousfluidfillingsystemwas rigorouslyevaluatedusingindustrialengineeringtechniques suchasTimeStudy,MethodStudy(includingTwo-Handed ProcessChartandMultipleActivityChart),andobservations of real-time operation. These tools helped determine the improvementsachievedinefficiency,accuracy,ergonomics, andoverallproductivitycomparedtomanualfillingmethods.

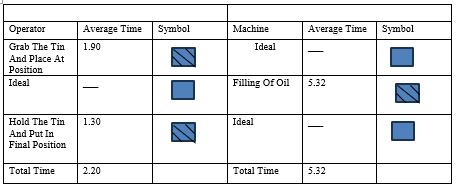

TimeStudyisasystematictechniqueusedtodetermine thetimerequiredbyaqualifiedworkertoperformataskata definedlevelofperformance.Itisbasedondirectobservation andtimemeasurementofworkcyclesusingastopwatch.In this project, time study was essential to quantify the efficiencygainsachievedthroughautomation.Byanalyzing bothmanualandautomatedprocesses,thestudyprovideda clearcomparisonoftimesavingspercycle,leadingtoamore reliableestimationofsystemthroughput.Allowancesforrest, fatigue, and delays were included to calculate a realistic standard time. This method served as a performance benchmarktoevaluatewhethertheautomationsignificantly improvedthesystem’soperationalspeed.

Time study is a work measurement technique used to establish a standard time for completing a task. In this project, the stopwatch flyback method was employed to record the time taken for manual vs. automated filling operations.

Thetaskwasbrokenintodistinctelements.

Eachelementwastimedover30cyclestomaintain accuracyandreducevariability.

A performance rating factor (based on operator speed)and15%allowances(forfatigue,delay,etc.) wereapplied.

The automated system reduced cycle time by 43%, increasingproductivityandthroughput

Ontheotherhand,isusedtoimprovethewayataskis performedbyanalyzingthesequenceandnatureofactivities involved.Itincludesdetailedexaminationofhandmotions, material handling, and workspace layout to eliminate unnecessary or inefficient actions. In this project, method studywasconductedusingtwospecifictools

This chart records the simultaneous motions of both handstoidentifyredundantmovementsandimbalances.It revealedinefficienciesinmanualfillingthatweremitigatedin theautomatedsystem.

1. Taskselected:Viscousfluidfillingoperation.

2. Both hands were observed for motion types (operation,transport,hold,delay).

3. The chart recorded each second-by-second movementusingstandardsymbols.

4. Post-analysisrevealedexcessiveidletimeinmanual operationduetohandlingthecontainer,operating thenozzle,andadjustingthefill.

Benefits Realized:

Reduced awkward hand positions and excessive movement.

Increasedcoordinationandrhythm.

Improvedworkercomfortandreducedfatigue

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net

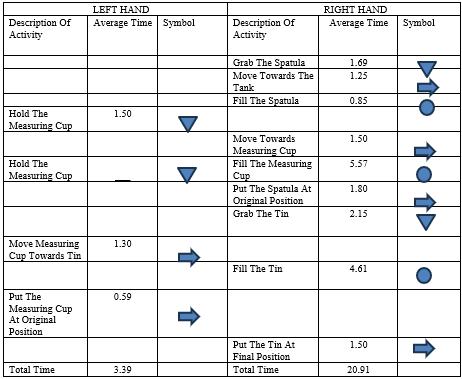

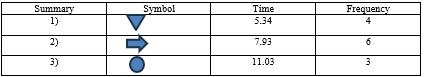

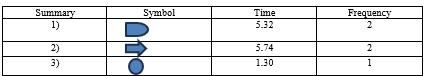

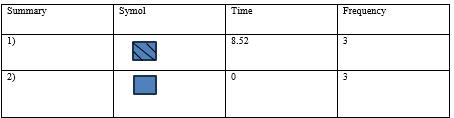

Table2.TwoHandedProcessChartForAutomaticFilling

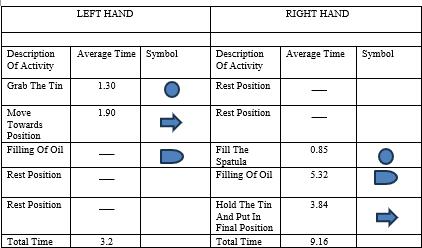

Table4.TwoHandedProcessChartForAutomaticFilling Multiple Activity Chart

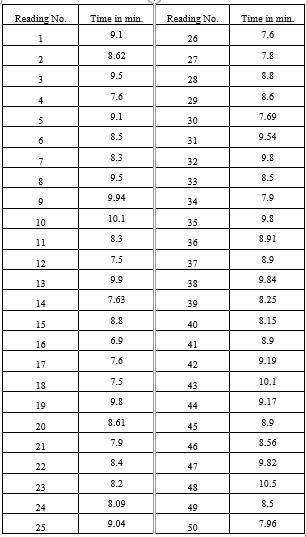

Thistoolisusedtoevaluateandcoordinateactivitiesof boththeoperatorandthemachineovertime.Ithelpedassess worker-machine interaction and highlighted improved synchronizationintheautomatedprocess.

Table3.TwoHandedProcessChartForManualFilling

Table5.MultipleActivityChartForAutomaticFilling

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Thecomparisonbetweenthemanualandautomaticfilling processesrevealssignificantimprovementsinoperational efficiencyand worker well-being.Oneofthemostnotable differences is in the total time taken to complete each process.Themanualfillingprocessrequiresatotalof 24.30 seconds, with 3.39 seconds for the left hand and 20.91 seconds for the right hand. In comparison the automatic filling process takes only 12.36 seconds, In which 3.20 secondsforthelefthandand9.16secondsfortheright.This results in a time reduction of approximately 49.14%, highlightingtheefficiencyachievedthroughautomation.The right-handworkloadisreduced.

In terms of worker fatigue, automation offers advantages. Manualfillinginvolvesfrequentuseofbothhands,repetitive motions, and a moderate level of mental effort to ensure accuracy during filling. This increases the risk of physical strain.Ontheotherhand,theautomaticprocessminimizes physicalmovementbyincorporatingidleorrestperiodsfor therighthandandreducestheneedforconstantattention. Asaresult,workerfatigueisminimized,leadingtoamore ergonomicandsustainableworkingenvironment.

Process simplicity is another way where automation is leading.Manualfillingconsistsofmultiplemicro-stepsthat involvetheuseofvarioustoolssuchasspatulas,measuring cups, and tins. This requires high coordination and consistent hand movement throughout the task. The automaticprocesssimplifiestheworkflowbyreducingthe numberofstepsandtoolsrequiredprimarilyinvolvingthe tinandallowingthemachinetohandlemostoperations.This makes the task easier to learn, reduces the error, and becomefastertrainingfornewoperators.

The manual process depends heavily on labour, with no involvementofmachinery.Thisnotonlylimitsscalabilitybut also increases operational costs due to longer processing timesperunit.Incomparisontheautomaticprocessreduces

labour dependency by using a machine for the oil filling, making the operation more efficient for high-volume productionenvironments.

ThedesignanddevelopmentofanArduino-basedautomatic viscous fluid filling system successfully addressed key limitations associated with manual filling methods. By integrating proximity sensors, pneumatic actuation, and microcontroller-basedlogic,thesystemachievedsignificant improvements in cycle time, accuracy, repeatability, and ergonomics. Time study results demonstrated a 43–49% reduction in operation time, while method study techniques through two-handed and multiple activity charts confirmedenhancedcoordination,reducedmanual involvement,andminimizedoperatorfatigue.

Thesystemconsistentlydeliveredaccuratefillvolumeswith deviations within ±5 ml, confirming its reliability across more than 100 test cycles. Furthermore, the simplified design reduced operator workload and dependency on manual labour, making it highly suitable for small to medium-scale industries aiming to semi-automate fluid fillingoperations.Thecombinationoflow-costcomponents, modular design, and industrial engineering principles validated the system’s effectiveness, scalability, and userfriendliness.

Future scope includes integrating IoT-based monitoring, digital HMI controls, and conveyor-based automation to furtherenhanceproductivityandprocesscontrol.

1. A. F. Krainev, Mashinovedenie na yazyk eskhem, Moscow:Mashinostroenie,2010.

2. T.DuncanandB.Redan,“FoodGradeLubricantsin PistonFillers,” J. Food Equip. Eng.,vol.22,no.4,pp. 145–152,2018.

3. K.Meah,“Arduino-basedAutomatedLiquidFilling System for Small-Scale Industry,” Int. J. Emerg. Technol. Adv. Eng.,vol.1,no.3,pp.56–60,2010.

4. Y.LadandG.Lodewijks,“Semi-AutomaticViscous FluidFillingSolutionsinDevelopingMarkets,” Proc. Int. Conf. Ind. Autom.,vol.35,no.1,pp.22–28,2002.

5. A. Guha and A. Ganveer, “Low-Cost Automation Techniques for Repetitive Manufacturing Processes,” Ind. Eng. J., vol. 18, no. 2, pp. 32–39, 2000.

6. T.KalaiselviandR.Praveena,“ArduinoIntegration inPneumaticSystems,” Proc. Natl. Conf. Embedded Control Syst.,vol.3,no.1,pp.88–94,2012.