International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Nirmitee Gudekar1 , Mitali Dandage2

1Third Year student of B.Sc. Biotechnology, Dept. of Biotechnology, Modern college of Arts, Science and Commerce, Shivajinagar, Pune-05, Maharashtra, India

2Assistant Professor, Dept. of Biotechnology, Modern college of Arts, Science and Commerce, Shivajinagar, Pune-05, Maharashtra, India ***

Abstract - The rising demand for plastics has led to a significant growth in plastic waste, creating a substantial threat to the environment. In response to this, researchers are exploring an alternative, biodegradable plastic to replace traditional synthetic plastics. This study focuses on the development of bioplastics from Mierspenaeopsis hardwickii shrimp shells, a readily available and renewable resource. We extracted chitin from shells and converted it into chitosan via few steps like demineralization, deproteinization and deacetylation. Further, chitosan was characterized by studying its moisture content, solubility, degree of deacetylation and Fourier Transform Infrared Spectroscopy (FTIR) analysis. Then characterized chitosan was used to produce bioplastic films by adding components like starch, Glacial Acetic Acid and Glycerine. The resulting bioplastics exhibited excellent properties and biodegradability. One film without chitosan was also prepared and characterized with films which were made with chitosan. Our findings suggest that shrimp shell chitosan-based bioplastics have the potential to replace traditional plastics in various applications, reducing the environmentalimpactofplasticwaste.

Key Words: Biodegradable plastic 1 , Synthetic Plastic 2 , Mierspenaeopsishardwickii 3,Chitin 4,Chitosan 5

In today’s era of swift industrialization and economic growth,countrieslikeIndiaareemergingasmajorplayers in global economy. However, this progress is accompaniedbyasignificantincreaseinwasteproduction, especially plastic waste, which poses severe environmental issues. According to the report of the Central Pollution Control Board (CPCB) 2020-21, Maharashtra generates plastic waste approximately 3,11,254 tonnes per annum. Among the states, Maharashtra contributes the big share of plastic waste, with metropolitan cities like Mumbai and Pune identified as major contributors due to their dense populations, boomingindustries,andconsumer-drivenlifestyles.[1]

The widespread distribution and uncontrolled as well as unregulated deposition of plastic across land and water bodies have caused the environmental challenges. The poor practice of dumping and littering, especially in

coastal and urban zones, contribute to soil deterioration, water pollution, and disruption of ecological equilibrium. Despite these drawbacks, plastic is an integral part of modernlifeduetoitspropertieslikeflexibility,versatility, moistureresistance,lightweightandaffordability.[2] Asa resultofthesehealthandenvironmental effects,scientists havebeenexploringsubstitute,biodegradablematerialsto replace conventional synthetic plastics. To make this bioplastic,thereareseveralsourcesofrenewablebiomass like plants, algae, or microorganisms, which offer a promising solution to theissueof plastic waste. However, the production of bioplastics can be expensive and compete with food crops for land, water, and other food resources. Therefore, there is a need to explore alternative, non-food biomass sources for bioplastic production.

Shrimp shells, a waste byproduct of the seafood industry, are easily available and renewable resource which can be used to produce bioplastics. Shrimp shells are rich in chitin, a polysaccharide that can be converted into chitosan, a biodegradable and non-toxic polymer. [3] For this purpose, we can also use Mierspenaeopsis hardwickii which is popularly known as spear shrimp which are found mostly on seafloor at the depth of up to 90 meters andatsandymud.[4]Chitinisthesecondmostabundant naturalpolymeraftercellulose.Chitosaniswellknownfor itsmechanicalstrength,biocompatibility,biodegradability and thus explored for various applications, including biomedicaldevices,watertreatment,foodpackagingwhile some studies have shown that chitosan-based materials exhibit high tensile strength and thermal stability, which are essential for various industrial applications also. [5], [6]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

In the production of chitosan-based bioplastic, chemicals like Hydrochloric acid (HCl) and Sodium hydroxide (NaOH)areutilizedtoremovemineralsandproteinsfrom therawmaterial like chitin ofshrimpshells.Glacialacetic acid facilitates in dissolving chitosan, whereas starch, glycerine, and water serve as plasticizers and fillers, enhancingelasticityandflexibilityofthefinalproduct.[7], [8], [9] Such biopolymer development projects are significantly increasing due to properties like renewability, low cost, biodegradability, and low toxicity. The characterization of these bioplastic films involves techniques to evaluate solubility, chemical resistance and degradationprofiles.[10],[11]

Ultimately, incorporating bioplastics into waste managementstrategiescanplayamajorroleinalleviating the plastic crisis. With research focused on cost efficiency and performance, and biodegradation capacities, bioplastics especially chitosan-based films represent an important step towards environmentally sustainable development. This research provides a novel approach to developing sustainable bioplastics and underscores the importance of exploring alternative to synthetic plastic, renewable resources for a more environmentally friendly future. The results of such research will provide insights into the potential of shrimp-based bioplastics to replace traditional plastics and reduce the environmental impact ofplasticwaste.

2.1 Preparation of raw material:

Shrimpsampleswerecollectedfromthelocalfishmarket. Shellsofcollectedshrimpsampleswereremovedandthen washedthoroughlywithtap watertoremoveexoskeleton orflesh.Furthershellsweredriedinsunfor3-4daysand groundedintofinepowderusingmortarpestle.Driedshell powderwassievedandplacedinopaquebottletostoreat ambient temperature. Meanwhile representative shrimp sampleswereidentifiedas Mierspenaeopsishardwickii.

2.2 Demineralization:

For this step, shrimp shell powder was demineralized using 5% HCl at room temperature for 24 hours. Here, ratio for shell powder to 5% HCl was taken as 1:6 (w/v). After completion of 24 hours, the shells were quite squashy and were rinsed with water to remove acid and CaCl2.FurthershellsweredriedinHotairovenat60°C of for 8 hours. To ensure completion of demineralization of shells, small amount of HCl treated shell powder was reacted again with 10% HCl solution. Absence of bubble productionintubeprovedsuccessfuldemineralization.[5]

Demineralized shell powder was further deproteinized using 5% NaOH solution at 60°C for 48 hours at the ratio of 1:10 (w/v). After deproteinization, the residue was washed with distilled water to remove NaOH. Then it is dried for 2-3 days and the residual solid mass obtained waschitin.[5]

Deacetylation is the process used to convert chitin into chitosan via removal of acetyl group. After rinsing with distilled water, the decalcified chitin was added to a 60% NaOH solution for 2 hours. Then it was rinsed with distilled water and dried at 60-650C for overnight in Hot air oven. Product obtained after deacetylating chitin was chitosan.[5]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

2.5.1 Moisture content:

Estimation of moisture content of produced chitosan is crucialasthisparametercanaffectthequalityofchitosan. Gravimetric method described by [3] was used which involved calculating weight of chitosan before and after drying, where water mass loss was estimated. Lost water mass was the difference between the wet and dry sample weights.

Moisturecontent=Wetweight–Dryweight × 100 Dryweight

2.5.2 Degree of deacetylation (DD %):

Degree of deacetylation refers to percentage of acetyl groupsremovedfromchitintoconvertitintochitosan.To determine the degree of deacetylation, acid-base titration of the generated chitosan was performed as per protocol given by [12] where 0.125g chitosan was weighed and mixed with 30ml of 0.1M std HCl solution. Methyl orange (stock solution of indicator) was prepared by mixing 0.05gram in 100ml water; 5-6 drops of indicator were addedtothesolutionandthenstirredfor30minutesuntil thehomogeneouschitosanHClmixturewasattained.This was done on magnetic stirrer at room temperature. Then homogenized mixture was titrated against 0.1M NaOH solution until the red-coloured solution turns orange. Using thegiveneq.theDD%ofchitosanwasdetermined.

DD% = C1V1-C2V2 × 0.016 × 100

M × 0.0994

where; C1 and C2 are the mol/L concentrations of standardHClandNaOHaqueoussolutionsrespectively,V1 isthevolumeof0.1MHClsolutionutilizedduringtitration (mL), V2 is the volume of 0.1M NaOH solution consumed during titration (mL), and M is the weight of derived chitosan (g). The weight of the NH2 group in 1mL of std 1M HCl solution, expressed in grams, is a standard factor anddirectproportionalratiooftheNH2groupbyweightin theresultingchitosanis0.0994.

Estimation of solubility of extracted chitosan was determined using method suggested by [5]. 0.1 gram of chitosan powder was taken in centrifuge tube of known weight, and then dissolved in 10 ml of 1% acetic acid for 30 minutes using an incubator shaker operating at 240 rpm and 25°C. The mixture in the centrifuge tube was heated for 10 minutes using boiling water bath and then

cooled to 25°C and centrifuged at 5000 rpm for 10 minutes.Thesupernatant wasdiscarded,andundissolved particleswere washed in distilledwater(25 ml)and then undissolved matter was dried at 60°C for 24 h and by weighing the mass of particles, the percentage solubility wasdeterminedusingthefollowingequation:

Solubility(%)=

(Initial weight of (tube+ chitosan)) – (final weight of (tube+chitosan))X100

(Initial weight of (tube + chitosan))–(weight of empty tube)

FTIR analysis provides insight into the chemical composition and molecular structure of sample by detecting and analyzing the functional groups present in the sample. It also provides important information about characteristics and functionality. FTIR analysis was done by the model named BRUKER Tensor II, single reflection diamond ATR. Sample's FTIR spectrum was recorded at a wavelengthbetween400and4000cm-1 .

2.6

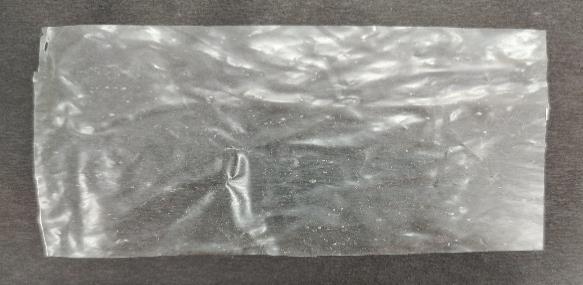

Components were added into heat resistant container as per table no.1. Each mixture was heated using a hot plate at around 70-80°C until the mixture thickens. During this step, mixture was continuously stirred to prevent the formation of lumps and to provide even distribution of heat. Further, heated bioplastic mixture was poured and rolled onto flat, non-stick surfaces like glass or metal sheets or petri-plate until it forms thin layer. All the bioplastic films were allowed to air dry at room temperature for several hours until it becomes solid and rigid. Lastly, films were scraped out from surfaces and characterizationwasdone.[10]

Bioplasticfilms

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

2.7 Characterization and biodegradation of bioplastic:

2.7.1

A handheld micro-meter screw gauge (0–25mm, Mitutoyo, Japan) was used for measuring the thickness of bioplastic films. The bioplastic films were cut into 3cm × 3cm dimension for testing. At random four positions, the thicknessof eachfilmsamplesmeasuredandvalues were noted. The mean values of thickness were used as final valuesinthefurthertests.[6]

2.7.2

Swelling test was performed using method described by [6]. All the bioplastic films were cut into 3cm x 3cm dimension and dried at 60°C in hot air oven. Initial thickness of each samples was measured. The films were kept immersed in water for 24hours. Thickness of the samplesafterimmersionweremeasured.

Swelling(%)= Th1−Th0 ×100

Th0

(where Th0, Th1 = Thickness of the sample before and afterimmersioninwater,respectively)

2.7.3 Water absorption test:

All the bioplastic films were cut into 3cm × 3cm dimension and dried at 60°C in hot air oven. Initial mass of the films was noted. The films were immersed in the water for 24hours. The mass after immersion was measured.

Waterabsorption(%)= M1−M0 ×100 M0

(where M0, M1 = mass of the sample before and after immersionofthesample,respectively)[6]

2.7.4

The bioplasticfilms were cutinto1cm× 3cm inorder to match the width and height of cuvette. The films were attached to the side of the cuvette. Synthetic plastic film made from polyethylene was used as control. Absorbance was recorded at 600nm using UV-1800 Shimadzu 240V UV spectrophotometer. Transmittance was calculated usingbelowmentionedequation.

%T=Antilog(2−Absorbance)

Thetransparencywasdeterminedusingtheformula, Transparency=Log%T/b

(where %T is transmittance at 600nm and b is the thicknessofbioplastic(mm).[6]

2.7.5 Organoleptic properties:

Organoleptic features describe a substance's sensory qualities, specifically those that can be detected by the sensesofhumans.Theevaluationoforganolepticqualities is crucial when analyzing bioplastics for a report in order to analyze their sensory components and potential influence on consumer acceptability. Some of the factors assessedareodour,colour,durabilityetc.[10]

2.7.6 Water solubility:

All the bioplastic film samples were cut into 3cm × 3cm pieces, dried at 60°C for 2hours and weighed. The dried pieces of films were immersed in 20ml of distilled water in petri plate and kept on a rocker for 24hours at room temperature. After 24hours, the films were observed for solubility. The residues were dried and then weighed to calculatethepercentageofthesolubilityofthefilms.

Solubility%=W0−W1 ×100

W0

(whereW0=initialdryweight,W1=finaldryweight)[6]

2.7.7 Chemical resistance:

Thebioplasticfilms(3x3cm)wereimmersedindifferent solvents (0.1N HCl, 0.1N NaOH, NaCl solution) for 48hours, and their resistance was determined by observingchangesinappearance.[6]

2.7.8 Soil burial testing:

Pre-weighted bioplastic films (3 × 3 cm) were dried in an ovenat70°Cfor24hours,andburiedintosoilatdepthof 10 cm. The possible natural landfill biodegradation was determined by weighing the bioplastic films every 5 days till 45 days. In each stage, the samples were rinsed with

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

running tap water to remove any soil residues and then dryinginanovenat70°Cfor3htoremoveanymoisture. The weight loss was determined by the following equation:

Weightloss(%)= W0−��1 ×100

(where, W 0 is the weight before test and W 1 is the weightaftertest)[11]

3. RESULTS AND DISCUSSION

Moisturecontentofchitosanisveryimportantasitaffects thermal, mechanical and barrier properties of chitosan films.Italsoaffectsstabilityandshelflifeofchitosan.[13] According to [14], commercial chitosan can have 10% moisture content. In present work, Table no. 2 demonstrates that moisture content of produced chitosan was8.4%.

Chitosan is a derivative of chitin produced via deacetylation procedure. It has more solubility and wide rangeofapplicationsascomparedtochitin.DDofchitosan may range from 30% to 95% depending upon the available source and procedure. [9] According to sigmaAldrich, the extracted chitosan and commercial chitosan were observed to be 86 and 75-85 percent deacetylated, respectively. While in this investigation, degree of deacetylationwasfoundtobe85%.

Duetorigidcrystallinestructureofchitosan,itisinsoluble in most of the solvents. [7] Then [15] have studied that lower solubility of chitosan indicates incomplete removal ofprotein.Accordingto[16],chitosanhasahighsolubility, varying from 83.28 to 99.05 %., and [17] found that chitosan solubility ranges between 48.3 to 97.65 percent at different temperatures and NaOH concentrations. However, Table no. 3 shows that solubility of extracted chitosanwas93%.

Sr.No. Propertiesofchitosan Results

1 Moisturecontent 8.4%

2 Degreeofdeacetylation 85%

3 Solubility

TableNo.2:Propertiesofchitosan

FTIRanalysisofproducedchitosansamplei.e.Tableno. 3 and Fig no. 5 showed the presence of various functional groups like Ether, Hydroxyl and Amines. Ether bonds can improve flexibility, solubility, and mechanical strength of bioplastic.Hydroxyl group enableshydrogen bondingand influencesfilm’sstructure.While,Aminegroupofchitosan usedforbioplasticproductioncontributetotheflexibility,

thermal degradation resistance, thus helps in improving theirbiodegradabilityandmakingitsafeforhumanuseas wellasforenvironment.[10]

FigNo.5:FTIRGraph

Sr No. Frequency range Peak assignment Remarks 1 1013-1055 R-O-R EtherGroup 2 2826-3006

2 AmineGroup 3 3665-3706 OH HydroxylGroup

TableNo.3:FTIRResults

Characterization of formulated bioplastic films:

Thicknessisanimportantfactorasitaffectstransparency, density and mechanical properties while formulating bioplastic film. Among all the formulated bioplastic films, wefoundthatincreasingconcentrationoftheglycerineor plasticizer led to increasing thickness (Films E, F and G). Higher swelling % were observed in films A, C and F. It was possibly due to the higher hydrophilicity and water absorptioncapacityofstarchandplasticizer.Additionally, bioplastic without chitosan showed higher thickness and increased water absorption. Films B and G showed more solubility.

All formulated bioplastic films were less transparent as compared to synthetic one but film B showed maximum transparency. On the contrast, film without chitosan i.e. film G was least transparent. Most of the films showed change in dimension upon treatment with HCl and NaOH while there was no change observed in presence of NaCl. All bioplastic films were soft after chemical treatments. Surprisingly, film C was found to be slightly dissolved in NaOHsolution.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Texture and extensibility of all the bioplastic films were goodexceptinfilmwithoutchitosan.FilmCandGshowed slightly pungent odour. This could be because of higher concentration of glacial acetic acid. During degradation experiment, it was found that degradation rate was quite high for initial 7-9 days. Film E showed maximum biodegradation among the formulated bioplastic films. While other bioplastic films showed approximately 2540%degradationwithin28days

1

2

3

4

TableNo.4:ThicknessandSwellingPercentage

TableNo.7:FilmTransparencyTest

TableNo.5:WaterAbsorptionTest

TableNo.6:SolubilityTest

i b,c,f,g,j 5 E a,c,f,g,j a,d,f,g,i b,c,f,g,j 6 F a,c,f,g,j a,c,f,g,i b,c,f,g,j 7 G a,c,f,g,j a,c,f,g,i b,c,f,g,j

TableNo.8:ChemicalResistanceTesting

(a= Change in dimension, b= No change in dimension, c= Absorption, d= No Absorption, e= Dissolved, f= Not dissolved, g=Softened, h= Brittle, i= Disruption, j= No disruption) Sr

1 A Off-white No odour Moderate Moderate

B Off-white No odour Smooth Moderate 3 C Very Pale yellow Slightly Pungent Hard High 4 D Translucen tOff-white No odour Hard High 5 E Off-white No odour Smooth Moderate

6 F Very light beige No odour Very Smooth Less

7 G Whitishyellow Slightly Pungent Very Smooth Poor

TableNo.9:OrganolepticProperties

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

SoilBurialTesting

Beforeaddingintosoil

After7days

After14days

After21days

After28days

Collected shrimp shells were treated according to standard protocols and chitosan was produced from treated shell waste. Aim behind this study was to synthesize eco-friendly bioplastic from waste animal resources. In the present work, we have formulated six bioplastic films using same chitosan powder, starch source, plasticizer and cross-linker. While, one bioplastic film was synthesized without chitosan. Each film was characterized and showed different properties with respect to thickness, strength, chemical resistance, degradation potential and appearance also. After comparingbioplasticmadefromchitosanwithabioplastic made without chitosan, it was observed that chitosan playedasignificantroleinmaintainingthickness,strength, water resistance and transparency levels. Additionally, degradation rate was found to be fast in formulated bioplasticfilmsascomparedtosyntheticplastic.

We would like to express our heartfelt gratitude to everyone who contributed in the completion of this project. Our deepest thanks to Head of the Department (Biotechnology), Progressive Education Society’ s Modern College of Arts, Science and Commerce (Autonomous) Shivajinagar, Pune 05 – Dr. Rama Phadke for her continuous guidance and support throughout the project. SpecialthankstoZoologicalSurveyofIndia(ZSI)-Punefor species identification. We are also grateful to Central Sophisticated Analytical Instrumentation Facility (CSAIF),

funded by DST-FIST, New Delhi, India at Progressive Education Society’ s Modern College of Arts, Science and Commerce (Autonomous) Shivajinagar, Pune 05 for FTIR analysis. Lastly, we extend our appreciation to the Department of Biotechnology- Progressive Education Society’ s Modern College of Arts, Science and Commerce (Autonomous) Shivajinagar, Pune 05 for giving us this valuablelearningopportunity.

1) https://cpcb.nic.in/

2) M.Subba Reddy, et al. (2014), “Effect of plastic pollution on environment”, Journal of Chemical andPharmaceuticalSciences.

3) Mohamed Ismail, et al. (2023), “Extraction of Chitosan from Aristeus antennatus Shells as a Prior for Biodegradable Plastic Production”, Alfarama Journal of Basic & Applied Sciences, Vol 4(1),pp155-170.

4) R. V., Borichangar, Parmar J. N., Bharda S. K., and KotadiyaD.P.2024.“ANewDistributionalRecord and Taxonomic Descriptions of Mierspenaeopsis Hardwickii(Miers,1878)fromtheArabianSeaon the Gujarat Coast, India”. Annual Research & Review in Biology 39 (9):130-34. https://doi.org/10.9734/arrb/2024/v39i92127

5) Mashuni Mashuni, et al. (2022), “Synthesis of Antibacterial and Biodegradable Bioplastic Based on Shrimp Skin Chitosan and Durian Skin Cellulose with the Microwave Assistance”, Jurnal KimiaValensi,Vol8(1),pp113-123.

6) Akshaya Krishnamurthy, et al. (2019), “Synthesis and characterization of eco‑friendly bioplastic fromlow‑costplantresources”,ASpringerNature Journal, https://doi.org/10.1007/s42452-0191460-x.

7) Suneeta Kumari, et al. (2016), “Chitosan from shrimp shell (Crangon crangon) and fish scales (Labeorohita): Extraction and characterization”, African Journal of Biotechnology, Vol 15(24), pp 1258-1268

8) Arafat A., et al. (2015), “Preparation and Characterization of Chitosan from Shrimp shell waste”, International Journal of Scientific & EngineeringResearch,Vol6(5),pp538-544.

9) P. Premasudha, et al. (2017), “Extraction and Characterization of Chitosan from Crustacean Waste: A Constructive Waste Management Approach”, International Journal of Science and Research(IJSR),Vol9(7),pp1194-1200.

10) Dr. vishishtta Nagaraj, et al. (2023), “Characterization of bioplastic prepared from composites of food waste”, International Journal ofNovelResearchandDevelopment,Vol8(8).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

11) Shashwat Nigam, et al. (2021), “Synthesis, characterization and biodegradation of bioplastic filmsproducedfrom Partheniumhysterophorus by incorporating a plasticizer (PEG600)”, Elsevier Journal,EnvironmentalChallenges5.

12) Ayaat R. El Feky, et al. (2024), “Biodegradable plastic formulated from chitosan of Aristeus antennatus shells with castor oil as a plasticizer agent and starch as a filling substrate”, Nature Scientific Reports, https://doi.org/10.1038/s41598-024-61377-9

13) Sreelekshmi R S, et al. (2022), “Shelf-life specific moisturevariationinchitosan ofgenus fenneropenaeus distributedalongarabian sea,India” doi:https://doi.org/10.1101/2022.05.15.491996

14) Li, Q., Dunn, E. T., Grandmaison, E. W., & Goosen, M. F. A. (1992). Applications and Properties of Chitosan. Journal of Bioactive and Compatible Polymers, 7(4), 370–397. https://doi.org/10.1177/088391159200700406.

15) BrineCJ,AustinPR(1981). Chitinvariabilitywith species and method of preparation. Comp. Biochem.Physiol.69(2):283-286

16) M.M.Samar,M.El-Kalyoubi,M.Khalaf,andM.Abd El-Razik, "Physicochemical, functional, antioxidant and antibacterial properties of chitosan extracted from shrimp wastes by microwavetechnique,"Ann.Agric.Sci.,vol.58,pp. 33-41,2013,doi:10.1016/j.aoas.2013.01.006

17)M. Hossain and A. Iqbal, "Production and characterization of chitosan from shrimp waste," J. Bangladesh Agric. Univ., vol. 12, pp. 153-160, 2014,doi:10.3329/jbau.v12i1.21405.

BIOGRAPHIES

Nirmitee Gudekar, Third year student of BSc. Biotechnology, Dept. of Biotechnology, Modern college of Arts, Science and Commerce, Shivajinagar, Pune05. Emailnirmiteegudekar@gmail.com

Mitali Dandage, Assistant Professor,Dept.ofBiotechnology, Modern college of Arts, Science and Commerce, Shivajinagar, Pune-05. Emailmitalimarathe1@gmail.com