International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Mrs. Dhanashree D.Pise1, Dr. Himadri Majumder2

1Student M.Tech. (CADME), Department of Mechanical Engineering, G H Raisoni College of Engineering & Management Pune, India

2 Guide, Department of Mechanical Engineering, G H Raisoni College of Engineering & Management Pune, India

Abstract The primary objective of this study is to analyze and simulate the effects of fin geometry and material selection on the temperature distribution and heat flux of the Honda SP 125 engine cylinder fins. Various fin geometries were considered, including rectangular, slotted rectangular, circular, slotted circular, angular, and longitudinal fins, all with a uniform thickness of 2.5 mm. Among these, the circular fins with perforations demonstrated superior heat transfer efficiency and an advantageous power-to-weight ratio. Based on this optimal geometry, different materials Aluminum 6082, AL204, Cast Iron, Magnesium Alloy AZ31, and Beryllium Oxide were evaluated. 3D models were developed using SolidWorks and subsequently analyzed using ANSYS 16.2 under steady-state conditions. Finite Element Analysis (FEA) was performed to examine heat distribution and heat flux across all models. The findings indicate that Beryllium Oxide exhibits the highest thermal performance. The results were compared to determine the geometry and material combination that yields the maximum heat flux.

Keywords- Fins, Heat transfer, Aluminium 6082, Berylliumoxide,Ansys.

Managingheateffectivelyininternalcombustionenginesis especially important in two-wheelers to maintain efficiency, dependability, and long-term performance. Aircooling is the most commonly used method in these vehicles because of its simple construction, low cost, and high durability. In such systems, heat produced during combustion is mainly dispersed through fins attached to thecylinderhead.

Engine cooling performance is heavily influenced by fin design, including their geometry, quantity, size, and the material selected. Optimizing these elements involves a trade-off while adding more fins or enlarging their surface area can enhance heat dissipation, it can also increase the engine’s overall weight, which negatively affects the crucial power-to-weight ratio in two-wheelers. Furthermore, aspects like fin thickness, spacing, and alignment need to be carefully designed to ensure unobstructed airflow and efficient convective heat transfer.Recent research highlights that adding perforations to fins can enhance cooling by inducing turbulence and breaking up thermal boundary layers. Circular perforations, in particular, have demonstrated better heat transfer performance and weight reduction

compared to other shapes like rectangular or triangular ones. Additionally, selecting materials with high thermal conductivity such as aluminum alloy 6063-T6 has been found to significantly improve cooling effectiveness while preservingthestructuralstrengthofthefins.

Considering these factors, the objective of this study is to conduct a comprehensive analysis of cylinder head fin designs in two-wheeler engines by examining different geometries and materials. Using computational modeling and simulation tools, the research evaluates multiple fin shapes,materialoptions,andperforationlayoutstoidentify configurationsthatenhance heatdissipation whilekeeping weight and production complexity low. The outcomes of this work aim to support advancements in engine cooling technologies and contribute to wider goals such as improved fuel economy, lower emissions, and environmentallysustainabletransportationsolutions.

1.1 Fins: A fin is an extended surface added to a component to enhance heat transfer between the object anditssurroundings,primarilybyboostingconvectiveheat exchange.Therateatwhichheatistransferreddependson conduction,convection,and radiation.Heattransfercanbe improved by increasing the temperature difference between the surface and its environment, enhancing the convective heat transfer coefficient, or expanding the surface area. Since adjusting the temperature difference or convection coefficient may not always be practical or costeffective, incorporating fins offers a more feasible and economical alternative by enlarging the surface area. Common applications include circumferential fins on motorcycleenginecylindersandfinsoncondensertubesin refrigerators.Maintaining an appropriate temperature distributionwithinasparkignition(SI)engineiscrucialfor ensuring efficient operation and maximizing thermal efficiency. Engines must operate within specific thermal limits to perform optimally. Fins play a key role in this process by facilitating heat dissipation and preventing the enginefromoverheating.Theyactasaheatsink,protecting the engine from thermal damage. The number and size of fins on an engine cylinder generally correlate with the engine’s capacity higher-capacity engines typically require more fins to manage the increased heat. This cooling mechanism is essential for preventing thermal failure of both the engine and the lubricating oil, ensuring long-termreliabilityandperformance.

International Research

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Chandrakant R et al. conducted a numerical study to enhance the heat dissipation efficiency of an engine cylinder equipped with fins. The 3D model was created using Autodesk Fusion 360, and steady-state thermal analysiswasperformedusingANSYSsoftware.Simulations were carried out using two different materials for the fins: Aluminum alloys 204 and 6061. The study also examined how variations in fin geometry such as changes in thickness, spacing (pitch), and orientation affect thermal performance.Acomprehensivecomparisonoftemperature distribution and total heat flux was made. The results indicated that Aluminum alloy 6061 outperformed the other configuration, offering noticeable improvements in bothheattransferefficiencyandpower-to-weightratio.

Sroka ZJ et al. conducted heat transfer modeling and simulations on a single-cylinder, four-stroke, air-cooled engine to assess the heat transfer characteristics of the engineblock.UsingtheSolidWorksplatform,theymodeled cylinders featuring varying numbers of fins and different fin geometries. The components tested were made from 6063-T6 aluminum alloy castings. The study examined the effects of fin count and geometry, including circular and rectangular perforations. The findings indicated that increasing the number of fins improves heat transfer but can reduce overall engine efficiency due to added weight. Among perforation shapes, circular designs proved superior to rectangular ones of the same cross-sectional area, offering a reduction in cylinder mass and over a 4% improvementinheattransfer rate.Perforationsizestested included diameters of 7.14 mm, 8.5 mm, and 10 mm. The 7.14 mm perforations slightly enhanced heat transfer compared to larger sizes, while the 10 mm perforations achievedthegreatestweightreduction.

S.K.MohammadShareefetal.conducteda numericalstudy focusedonevaluatingthethermalcharacteristicsofengine cylinders by altering the geometry, material, and profile of thecylinderfinsusingANSYSWorkbench.Themodelswere developed using SolidWorks software. This research involvedthenumericaloptimizationofenginecylinderfins made from cast iron, copper alloy, and Aluminum 6082, considering different fin shapes such as rectangular, circular,andangularprofiles.

Nihal Chavan et al. conducted a study focused on identifying the most efficient fin materials and geometries to optimize heat transfer. Through thermal analysis of the chosenmaterialsandshapes,averageheatfluxvalueswere determined and compared. The results indicated that Aluminum 7075 exhibited the highest average heat flux amongthevariousaluminumalloysevaluatedinthestudy.

P.L.Rupeshetal.focusedtheirstudyondesigningfinswith circular and tapered profiles for a two-stroke engine. They conducted steady-state thermal analysis to observe temperature distribution and heat dissipation on both fin

shapes. The materials chosen for the fins were Alusil and Silumin, and computational evaluations were performed using the Finite Element Method (FEM). Based on the FEM results and comparisons with existing fin designs and materials, the study identified the most effective fin shape andmaterialcombination.

N. Muthuram et al. aimed to improve the efficiency of engine cooling systems by optimizing fin design, including the addition of slots to increase surface area and enhance heat dissipation. The study analyzed two fin shapes rectangular and cylindrical both fabricated from Aluminum 1100. The designs were developed using PTC CREOParametric6.0,whilesteady-statethermalandmodal analyseswereconductedwithANSYS2023R1.Thethermal analysis revealed that the slotted cylindrical fins achieved the highest heat transfer rates compared to traditional fin designs. These findings are expected to contribute significantlytoimprovedcoolingperformance.

Sk. Avinash Kapil et al. aimed to investigate the thermal performance of cylinder fins by experimenting with different materials. In their study, cast iron was replaced with Aluminum alloy and Gray cast iron for comparison. TheresultsshowedthatAluminumalloy outperformedthe other materials as the most suitable choice for engine fins. The thermal analysis was conducted based on the dimensionsoftheBAJAJ150CCengineblock,thoughitwas noted that material changes could indirectly lead to increasedmanufacturingcosts.

Pulasari Srinivas and Vadlamudi Ravikumar examined the extended surfaces, or fins, of Honda Shine and Bajaj Discovertwo-wheelerstostudytheimpactofcross-section, fin pitch, material, and thickness on heat transfer rates. A parametric 3D model of the engine block fins was created usingCATIAsoftware,andthermalanalysiswasperformed onfinsbothwithandwithoutperforationstoevaluateheat flux and temperature distribution. Currently, cylinder fins aremanufacturedusingAluminum2014andgreycastiron, while Aluminum 6061 was proposed as an alternative material. This study analyzed all three materials with variations in geometry, including perforations, to assess their effect on heat dissipation. The results concluded that Aluminum 6061 is the most suitable material for cylinder finsduetoitssuperiorheatfluxperformance.

MohanDas etal.aimed to investigate the effectofcylinder fin thickness on cooling efficiency. Their study revealed that fins with a thickness of 3 mm exhibited higher heat transfercomparedtofinswiththicknessesof2.5mmand2 mm.Theyconcludedthatincreasingthefinthicknessleads toanimprovementintherateofheattransfer

MukeshKumarSinghandH.S.Sahuaimedtodeterminethe most effective fin shape and material for engine cooling. Their study concluded that pin fins with slanted edges are themostsuitabledesignforheatsinks,astheyenhancethe rateofheattransfer.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

M.S.V. Kartheek et al. focused on modifying the fin profile, thickness, spacing between fins, and fin material in their study. They developed the models using Pro/Engineer software and performed the analysis with ANSYS. Their findings indicated that altering the fin geometry leads to improvedthermalperformancecurvywecanenhancemore coolingefficiencythanstraightfinsbutthedrawbackisthat themanufacturingofcurvegeometryfinisdifficult,

Rahul Gupta et al. aimed to identify the most suitable material for engine cylinder fins by conducting thermal analyses on both aluminum alloy and magnesium alloy. Theircomparisonshowedthatmagnesiumalloy,beingless dense than aluminum, reduces the overall weight while providingcomparableheattransferperformance.

R. Suresh et al. conducted a study where the engine cylindermaterialwaschangedfromcastirontoAluminum Alloy 6082, and thermal analyses were performed on both materials.TheirresultsdemonstratedthatAluminumAlloy 6082 provides higher heat transfer rates and heat flux compared to cast iron. The material substitution in the model took into account the differences in density and thermalconductivity.

G. Babu and M. Lava Kumar aimed to investigate the thermal characteristics of engine cylinder fins by varying their geometry and material. Their thermal analysis included Aluminum alloy 606, Aluminum alloy 204, and Magnesium alloy. The study concluded that curved fin geometries enhance heat transfer, and they recommended furtherresearchinthisarea.

3.1 ENGINE MODEL SELECTION-

This research focuses on conducting a thermal analysis of thecylinderheadfinsoftheHondaSP125engine,awidely usedtwo-wheelermodel.Theenginehasaborediameterof 50 mm and a stroke length of 70 mm. Its cylinder head includessevencoolingfins,eachwithathicknessof2.5mm and spaced at a pitch of 10 mm. These fins are manufactured using Aluminum 6061 alloy, known for its goodthermalconductivity.

Sr.No Type

1 Displacement 124cc

4Stroke,SI

2 MaxNetPower 8kW@7500rpm

3 MaxNetTorque 10.9N-m@6000rpm

4 FuelSystem PGM-FI

5 CompressionRatio 10.0:1

6 BoreXStroke 50.0X70mm

Table-1:HondaSP125

StandardEnginefinmodelspecification

Sr. No Engine parameter Value

1 BoreDiameter 50mm

2 StrokeLength 70mm

3 Finthickness 2.5mm

4 FinPitch 10mm

5 Numberof fins 7

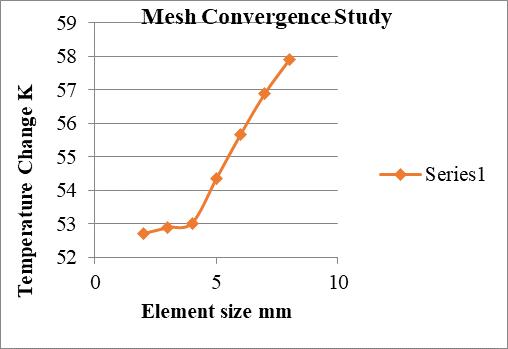

To identify the optimal element size for finite element analysis, a mesh convergence study was conducted. Mesh sizes varying from 2 mm to 8 mm were assessed, with corresponding temperature variations recorded for each. The results indicated that temperature differences were negligible for mesh sizes of 2 mm, 3 mm, and 4 mm. Consequently, a 3 mm mesh size was chosen for subsequent simulations as it offered a good compromise betweencomputationalefficiencyandaccuracy..

Chart -1:Meshconvergencestudy

Sixdifferentfingeometriesweremodelledandanalysed:

Rectangularfins

Rectangularfinswithslots

Circularfins

Circularfinswithperforations

Angularfins

Longitudinalfins

All finswere modelled with a uniformthicknessof2.5 mm usingAluminium6061asthebasematerial.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

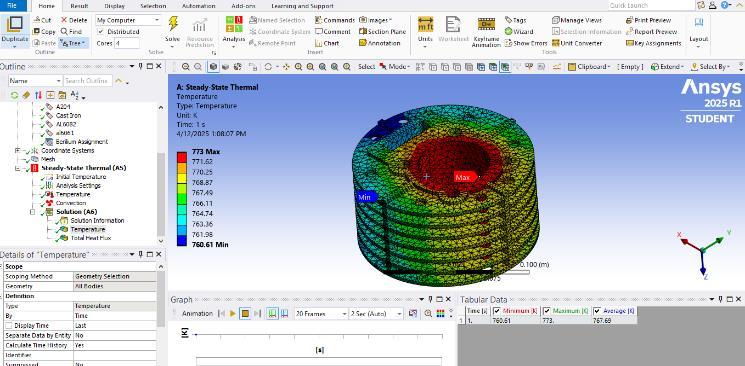

The thermal simulations were conducted in ANSYS Workbench, applying specific boundary conditions. The internal surface of the engine was set to a temperature of 500 °C, while the surrounding ambient temperature was maintained at 25 °C. A convective heat transfer coefficient was used based on stagnant air conditions. Transient thermalanalysiswasemployedtoobservethetemperature distributionandheatfluxacrossvariousfindesigns.

Eachfinconfigurationwasevaluatedbasedon:

Temperaturechange(ΔT)

Heatflux(W/m²)

Heattransferrate(W/m²K)

Mass(ingrams)

Power-to-weightratio(calculatedasheattransfer ratedividedbymass)

Following the results of the geometrical analysis, the circular fin design featuring perforations was chosen for further material evaluation, as it exhibited a high heat transferratealongwithafavorablepower-to-weightratio.

Thematerialsevaluatedincluded:

Aluminium6082

AluminiumA204

CastIron

MagnesiumAlloyAZ31

BerylliumOxide

The performance of each material was evaluated by simulating parameters such as heat flux, temperature variation, heat transfer efficiency, and the resulting weight ofthecomponent

Fig-1TemperatureContourofCircularFinwithhole BeO BerylliumOxide

The simulation outcomes were assessed using the previously mentioned evaluation criteria. The optimal fin and material combination was determined by balancing thermal efficiency reflectedin a high heat transfer rate and mechanical factors such as reduced weight and enhanceddurability.

Table-2 ThermalPerformanceofDifferentFinShapes

Among the fin designs evaluated, the circular fin with perforations provided the most effective balance between thermalperformanceandpower-to-weightratio.Whilethe angular and longitudinal fins showed relatively higher power-to-weight ratios, they fell short in terms of overall heattransferefficiencywhencomparedtothecircularfin.

Additionalanalysiswascarriedoutonthetop-performing design circularfinwithperforations bytestingitwith variousmaterialoptions.

Table-3 ThermalPerformanceforDifferentMaterials (CircularFinwithPerforations)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Beryllium Oxide demonstrated the highest heat transfer rate (14,954.8 W/m²K) but came at a highercostandmoderateweightpenalty.

Aluminium 6082 emerged as a highly suitable material offering an excellent balance of high heat transferrate,moderatecost,andlowweight.

Magnesium Alloy AZ31, although very lightweight, exhibited a comparatively lower heat transfercapability.

Taking into account thermal efficiency, ease of manufacturing, weight, and cost-effectiveness, the perforated circular fin constructed from Aluminium 6082 emergedasthemostsuitableandefficientchoiceforusein two-wheelerenginesystems.

This study aimed to enhance the design of cylinder head finsfortheHondaSP125two-wheelerenginebyexploring both geometric and material modifications, using comprehensive simulations in ANSYS. Among the different fin shapes assessed, the circular fin with perforations delivered the best results, offering a high rate of heat dissipation along with a superior power-to-weight ratio. Theadditionofperforationsimprovedairflowandinduced greater turbulence, which significantly increased cooling effectiveness. In the material evaluation phase, Aluminum 6082 emerged as the most appropriate option due to its excellent thermal conductivity, mechanical strength, low weight, and cost-efficiency. While Beryllium Oxide showed better thermal characteristics, its high cost and handling challengesmake itlesspractical.Asa result,the optimized design circular perforated fins made from Aluminum 6082 proves to be a highly efficient and affordable solution for enhancing thermal regulation in two-wheeler engines, thereby improving performance, lowering emissions,andboostingfueleconomy

While the simulation findings provide strong support for the suggested fin design improvements, there are stillmultipleaspectsthatwarrantadditionalresearch:

Experimental Validation: Performing live engine experiments to confirm the simulation results under real-worldconditions,includingchangesinspeed,load, andenvironmentaltemperature.

Advanced Materials: Investigating advanced lightweight materials and composite options, like

graphene-enhanced alloys or hybrid materials, to furtherenhancethermalconductivity.

3D Printed Fin Structures: Examining the use of additive manufacturing techniques to produce intricate, biomimetic fin designs that maximize airflow whileminimizingweight.

Forced Convection Analysis: Expanding the research to incorporate forced convection conditions to better represent the cooling effects during high-speed operationoftwo-wheelers.

Vibration and Fatigue Analysis: Analyzing the durability of the optimized fin designs by examining their mechanical performance under prolonged engine vibrationsandrepeatedthermalcycling.

Pursuingthesefutureresearchavenuescouldpavetheway for innovative cooling solutions, driving improvements in two-wheeler engine performance and promoting sustainability.

[1]SonawaneChandrakantR, Rath,PratyushNishantVats, Shreyas Patekar, Prakhar Verma, Anand Pandey 2022,” Numerical simulationto evaluatethethermal performance of engine cylinder Fins: Effect of fin geometry and fin material”,MaterialsToday,.

[2] Sroka ZJ, Sufe G, Kejela E 2024.,” Improving heat transfer in an air-cooled engine by redesigning the fins”, CombustionEngines,

[3]S.K.MohammadShareef,MSaiVikas,A.L.NArunKumar , Abhishek Dasore , Sanjay Chhalotre ,Upendra Rajak , Trikendra Nath Verma, 2021” Design and thermal analysis of engine cylinder fin body using various fin profiles”, MaterialsToday,.

[4]NikhilChavan;RushikeshPote;DishantBhor;S.Senthur Prabu, (2023).” Comparative thermal analysis on the extended surface of an automobile engine cylinder using ANSYSsimulation”,AIPConf.Proc.2869,040006

[5]P.L.Rupesh,K.Raja,N.V.SaiDeepakRaj,M.Pruthviraj Bharmal , Pandey Aditya Ramjatan, ,2021” Computational investigation of heat transfer on the surface of engine cylinder with fins of different shapes and materials”, MaterialsToday.

[6] N. Muthuram , Brajesh Kumar Kanchan, K. U. Ajith Kumar, 2024” Improving Engine Cooling Performance throughSlottedFinDesign:ASteady-StateThermalAnalysis Study”,journalofheatandmasstransferresearch,.

[7] Sk. Avinash Kapil, Ch. O. Rameshvamsi, Allu.Vamsi, D.Jaswanth,V.GVishalVarma

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

[8] Pulasari Srinivas Vadlamudi Ravikumar 2021, “Experimental And Investigation Of Cylinder Fins With DifferentMaterialsUsingFiniteElementMethod”,

[9] A N Das Mohan, G Suraj 2021 “Thermal analysis of different types of IC engine cylinder fins by varying thickness”,Volume12,.

[10] Mukesh Kumar, H S Sahu 2020 “A review on internal combustionenginefins”,Volume9,Issue8,

[11] M S V Kartheek, Reddy A Divakar 2017 “Optimization of engine cylinder fins of varying geometry and material”, Volume2,Issue5,.

[12] Rahul Gupta, Ranjeesh Kumar 2016. “Heat transfer analysis of engine cylinder fins by different materials”, Volume7,

[13]RSuresh,KLalith2014“Designandanalysisofcylinder fins”,Volume3,Issue1,.

[14]GBabu,MLavaKumar2013“Heattransferanalysisand optimizationofenginecylinderfinsofvaryinggeometryand material”,Volume7,issue4,

[15] K. Sivaramakrishnan, G. Ramakrishna, S. Selvaprakash, A. Sunil Kumar Gir, 2016 “Design and Thermal Analysis on Engine Cylinder Fins by Modifying its Material and Geometry”, International Journal of Creative Research Thoughts,

[16] S. Durgam, Aniket Kale,Nikhil Kene, 2021 “Thermal analysis of fin materials for engine cylinder heat transfer enhancement”,MaterialScience&Engineering,.

[17] Waghulde Devendra J. Prof. V H Patil, Prof. Koli T. A. 2017, “Effect of geometry, material and thickness of fin on engine cylinder fins”, International Research Journal of EngineeringandTechnology,.

[18] Tianci xie, Hui shi, Qun Luo, Qian Li, Kuo-Chih Chou 2021“Thermodynamicpredictionofthermal diffusivity and thermalconductivityinMg-Zn-La/Cesystem”,.

[19]MSVreddy Kartheek,ADivakar2017“Optimizationof engine cylinder fins of varying geometry and material”, Volume2,Issue5,

[20] Waghulde Devendra J, , Koli T.A. 2017 “Effect of geometry, material and thickness of fin on engine cylinder fins”,Volume4,Issue7,

[21] Kolhe Rushikesh ., Kashid Saurabh D., 2020 "Static, Modal & Thermal Analysis of Engine Block", International Journal of Engineering Research & Technology (IJERT), Vol. 9Issue08,August-

[22]Ahirwar,MahendraKumar,AsstProf,RavindraMohan, Asst Prof, and Jagdish Prasad 2018.. “IC Engine Cylinder FinsTransientThermalAnalysisByUsingANSYSSoftware.” International Research Journal of Engineering and Technology(IRJET)05(02):1085–91.

[23] Alam, Manir, and Assoc Prof M. Durga Sushmitha 2016.. “Design and Analysis of Engine Cylinder Fins of Varying Geometry and Materials.” International Journal of ComputerEngineeringInResearchTrends3(2):76–80.

[24]M.rajesh,s.rahamathullah,andg.Nagamalleswararao 2017.“DesignAndOptimizationOfEngineCylinderFinsBy Varying Geometry And Material With Thermal Analysis.” International Journal of Core Engineering & Management 424–32.

[25] Rahul Gupta, Ranjeesh Kumar 2014 “Heat transfer analysis of engine cylinder fins by different materials”, Volume 7. R Suresh, K Lalith “Design and analysis of cylinderfins”,Volume3,Issue1