International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Rohan V1, Srivani2

1Power Electronics ,RV college of Engineering, Bengaluru

2Power Electronics ,RV college of Engineering, Bengaluru

Abstract - A more sustainable approach to improvingship energy efficiency involves combining a heat recovery mechanism that utilizes waste energy with an electric propulsion setup based on Medium Voltage Direct Current (MVDC). This system uses an Organic Rankine Cycle (ORC) to capture and transform the heat from diesel engine exhaust into electrical energy. This recovered energy is then fedintotheMVDCbusthroughabuckconverter.Theoverall setup includes two independent zones, each powered by diesel generators connected to Permanent Magnet Synchronous Generators (PMSGs) and regulated by controlledrectifierstoensurevoltagestability.Acentralized controller manages power sharing and system regulation in real time. Simulations carried out in MATLAB/Simulink confirm that this configuration enhances total power output, enables balanced load distribution, and supports dynamicoperation.

Keywords: Buck Converter, Simulink, Organic Rankine Cycle (ORC), Marine Propulsion, Energy Efficiency, Permanent Magnet Synchronous Generator (PMSG), ControlledRectifier,MVDC,WasteHeatRecovery.

The need for creative energy solutions in the marine sector has increased due to the growing global concern over fuel usage, emission laws, and sustainability in transportation. Propulsion systems for ships, which are essential components of global trade, must be strong, dependable,energy-efficient,andecologicallybenign.This work's innovation is the incorporation of a WHRS based on an Organic Rankine Cycles into a dual-zone MVDC marine propulsion system with centralized PI control, which permits dynamic voltage stability, balanced power sharing,andeffectiveenergyrecovery.

Tomeetthesedemands,wasteheatrecoverytechnologies in conjunction with electric propulsion architectures are demonstrating promise as workable alternatives to conventional diesel-based systems. Examining one such option, a maritime propulsion system that combines a systemforrecoverinheatfromwaste(WHRS)designedto improve overall energy efficiency, reduce fuel usage, and loweremissions.

With a strong emphasis on integrating renewable energy sources and increasing overall system efficiency, the global energy sector is undergoing a significant transformation. In this changing landscape, the maritime industry which is essential to international trade is under growing pressure to cut down on fuel usage and reduce greenhouse gas emissions. Marine vessels, which still heavily depend on large diesel engines, are responsible for nearly 2% of the world’s CO₂ emissions. Only 45–50% of the fuel's energy is converted into useful mechanical work by these inefficient engines; the remaining energy is lost as heat through cooling and exhaustsystems.[5].

To tackle this issue, a promising approach is to combine electric propulsion systems with Systems for recovering heat from waste (WHRS) By capturing and transforming the otherwise wasted heat into more electrical power, these systems can greatly increase overall energy utilization. The Organic Rankine The cycle (ORC) is a uniqueWHRStechnologyformarineapplications.Itworks well with low-temperature heat sources, requires relatively little space, and operates efficiently [12], [18]. ORC systems recover energy via engine exhaust at moderate temperatures by using specific fluids at low boiling points. making them ideal for the compact and demandingconditionsaboardships.

At the same time, advances in power electronics and electricalsystemdesignaredrivingashiftfromtraditional alternating current (AC) systems to Direct Current (DC)based marine power networks. Medium Voltage Direct Current (MVDC) systems offer clear benefits: simpler power distribution, lower energy losses, and easy integration with renewable sources and energy storage [6], [8]. The development of marine propulsion is also being shaped by Voltage Source Converter (VSC)-based high-voltage DC systems, which enable two-way power flow,betterfaultmanagement,andindependentcontrolof voltage and frequency all of which are crucial in the challengingmarineenvironment[7].

The presented system introduces and simulates a marine electricpropulsionsetupthatcombinesaMediumVoltage Direct Current (MVDC) architecture with a System for

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Recovery of Waste Heat (WHRS) based on the cycle of organic Rankine (ORC).The configuration consists of two separategeneratorzones,eachpoweredbydieselengines andPermanentMagnetSynchronousGenerators(PMSGs), connected to a shared MVDC bus through controlled rectifiers. One of the zones includes an ORC-based WHRS that captures exhaust heat and converts it into electrical power via a microturbine generator. Before being sent to the MVDC bus, this recovered energy is controlled by a buckconverter.

Power sharing between the zones is controlled by a centralized Proportional–Integral (PI) control system, which also keeps the DC bus's voltage stable. System dynamics such as voltage stability, power flow, rotor speed, and heat recovery efficiency are simulated using MATLAB/Simulink.Theproposedsystemaimstoincrease the efficiency and performance of marine propulsion systems while reducing emissions and fuel consumption. Additionally, it encourages adherence to the environmental guidelines established bytheInternational MaritimeOrganization(IMO)[10].

1.2

MVDC systems are increasingly adopted in marine applications due to their advantages in power flow control, reduced cable weight, and integration flexibility [6]. Controlled Pulse Width Modulation (PWM) rectifiers, paired with centralized controllers, provide effective means to manage power sharing and ensure DC bus voltage stability [15], [20]. The incorporation of Proportional–Integral (PI) controllers enhances dynamic response and improves operational efficiency [16].ResearchinVSC-basedconvertershighlightstheneed for advanced control strategies to handle varying marine loads and ensure stability under dynamic conditions [7], [13].

Controlled PWM rectifiers address the shortcomings of passive diode-based designs and allow for efficient loadfollowingandfaulttolerance[14],[20].StudiesbyYuanet al.,D’Agostinoetal.,andNguyenandLeedemonstratethe viability of ORC-based WHRS for marine applications [9], [13], [18]. These systems are effective at utilizing lowgrade heat with minimal maintenance, thereby improving energy conversion efficiency and reducing emissions [12].When it comes to verifying marine propulsion designs, simulation tools such as MATLAB/Simulink are essential. They allow accurate modeling of electrical machines, converters, and control strategies, significantly reducing implementation risks and costs [19].The study builds upon the existing literature by proposing a unified simulation model that integrates MVDC propulsion, ORCbased WHRS, and centralized control. The approach aims to deliver a low-emission, high-efficiency marine power systemalignedwithglobalsustainabilitytargets[1],[2].

The proposed marine power system integrates a Medium Voltage Direct Current (MVDC) architecture with an Organic Rankine Cycle (ORC)- System for Recovery of Waste Heat (WHRS) to lower emissions and increase energy efficiency. Two diesel generators (DG1 and DG2), each coupled with Permanent Magnet Synchronous Generator (PMSG), supply electrical power through controlled three-phase rectifiers into a common MVDC bus. One of the diesel generators is also connected to an ORCunitthatutilizesexhaustheattodriveamicroturbine. Thisadditionalpowerisrectifiedandregulatedviaabuck converter before being injected into the MVDC network. Proper load sharing and system-wide voltage regulation areguaranteedbyacentralizedcontroller.

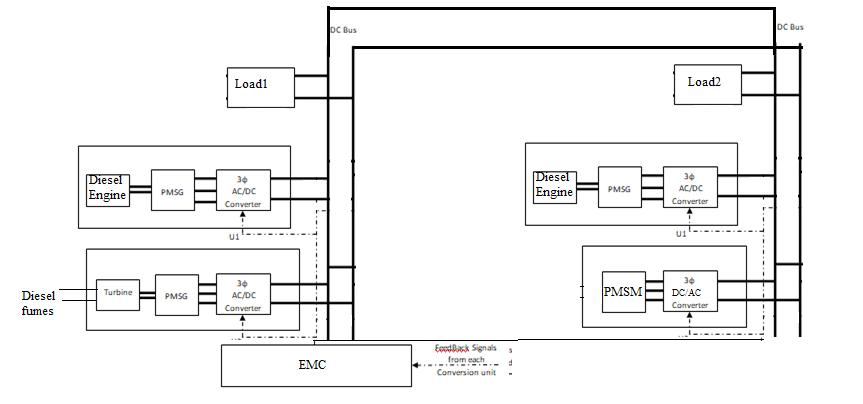

Fig -1:BlockDiagramoftheProposedMarinePropulsion SystemwithMVDCArchitectureandIntegratedWHRS

UsingORCTechnology

Fig. 1 illustrates the overall structure of the proposed balancing, and optimized control under varying marine operatingconditions.

marine power system. Two diesel engines, each coupled with Permanent Magnet Synchronous Generator (PMSG), feedtheMVDCbusviathree-phaseAC/DCconverters.One engine’s exhaust gases are routed to a turbine, which drives an additional PMSG that contributes recovered energy to the same bus. The DC bus powers dual propulsion loads and auxiliary DC loads, with all components monitored and coordinated by a centralized Energy Management Controller (EMC). Feedback signals from each conversion unit ensure voltage regulation, load

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

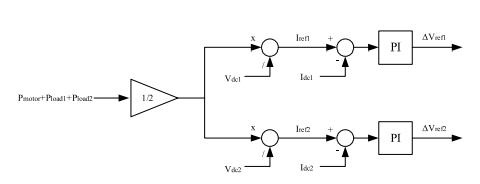

The fig. 2 centralized controller ensures balanced power sharing between the two generators by assigning each PWM rectifier half of the total load power. The reference current is calculated by dividing this power by the measured output voltage. A PI controller compares the reference and actual currents to generate a corrective voltage ref , which adjusts the rectifier’s output. If the measured current is higher, ref decreases the reference voltagetoreduceoutputcurrent,andviceversa.

The power generated from both PMSGs is rectified using PWM-based controlled rectifiers and delivered to the MVDCbus.Acentralizedcontrollermonitorsthetotalload and calculates the reference power to be shared equally between both generator zones. It then adjusts the output voltage of each rectifier is regulated to maintain uniform current flow, ensuring balanced power contribution from bothsidesandmaintainingbusvoltagestability.

The PMSGs are modeled using d–q axis equations. The stator voltages in the rotating coordinate frames are applied to determine internal machine dynamics and torque generation. A speed PI controller regulates the rotorspeed,generatinga torquereferenceforthecurrent controlloop.

Inverse Park transformation is used to transform the d-q axis current references into three-phase signals for converter control. Subsequently, hysteresis current controller is employed to produce PWM signals for the switchingdevices

This reference voltage is applied to the controlled rectifierstoregulatecurrentflow.

The exhaust heat from DG1 is captured by the ORC-based WHRS, which drives a microturbine connected to a generator. The generated AC power is converted to DC using an uncontrolled rectifier and then processed throughabuckconverter.Thebuckconverterstepsdown the voltage to match the MVDC bus level. A voltage-mode PIcontrollerregulatestheconverterbyadjustingtheduty cycle.

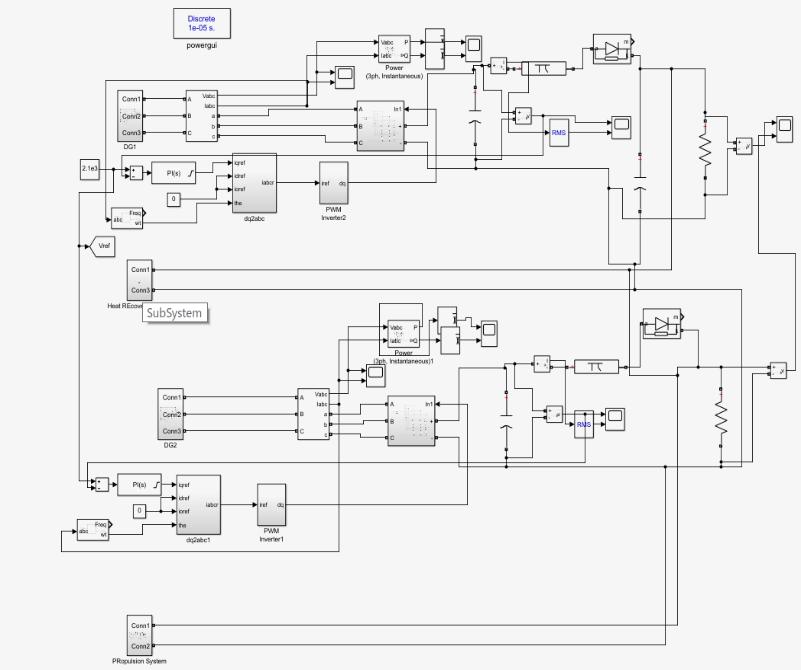

The complete system is modeled and simulated in MATLAB/Simulink.SimscapeElectricalblocksareusedfor machines, converters, and controllers. The simulation evaluates system behavior under load changes, speed reversal, and waste heat recovery scenarios. The focus is on MVDC bus voltage stability, power sharing, and effectiveutilizationofrecoveredheat.

The proposed MVDC-based marine propulsion system integrated with a heat recovery mechanism was modeled and simulated using MATLAB/Simulink. The simulation environment replicates the complete power and control structure, including dual diesel generator (DG) zones, controlled rectifiers, centralized PI-based load sharing, andanORC-basedWHRSwithbuckconverterintegration. The model was designed to operate under both steadystate and dynamic load conditions, capturing transient responses, voltage regulation, power balancing, and efficiencyvariation.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

Fig -3:SimulinkImplementationoftheProposedMVDCBasedMarinePropulsionSystemwithWHRSIntegration

Standard marine load profiles were used to verify the system's dependability under actual operating circumstances. The complete system model was implemented in MATLAB/Simulink using the Simscape Electrical and Power Systems toolboxes. The simulation environment replicates all major components of the proposed MVDC system including diesel generators, PIbased rectifier control, a Waste Heat Recovery Subsystem (WHRS), and the propulsion drive An overview of the model's structure is provided in Fig. 1, which highlights the structured integration of control and power modules acrossthesystem.

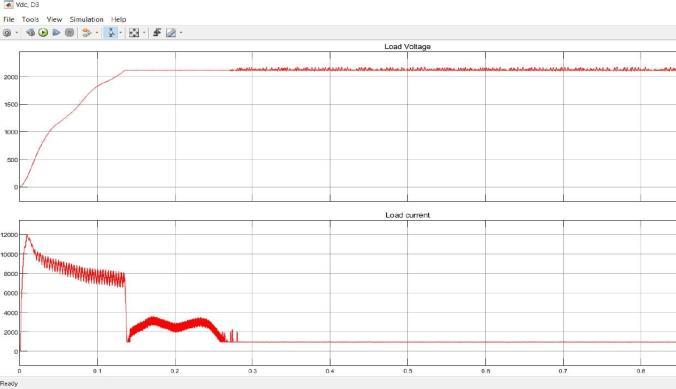

TheMVDCbusvoltagewaseffectivelymaintainednearthe 800 V reference, demonstrating strong voltage regulation. Bothdiesel generatorssharedtheload equally,producing 195–200 kW each, while the WHRS contributed an additional30–40 kWtothesystem.

Table -1: SimulationParametersandObservedOutputfor theProposedMVDCMarinePropulsionSystem

Component/ Parameter

DG1Power Setpoint

DG2Power Setpoint

WHRSTurbine Output(AC)

MVDCBus

During load transients, the PI controller ensured fast stabilization within 0.2–0.4 seconds. Rotor speeds were well regulated at around 500 rpm. With WHRS enabled, overall system efficiency improved from 82–84% to approximately92%,highlightingthebenefitsofreclaiming energyandensuringsteadypowercontrol.

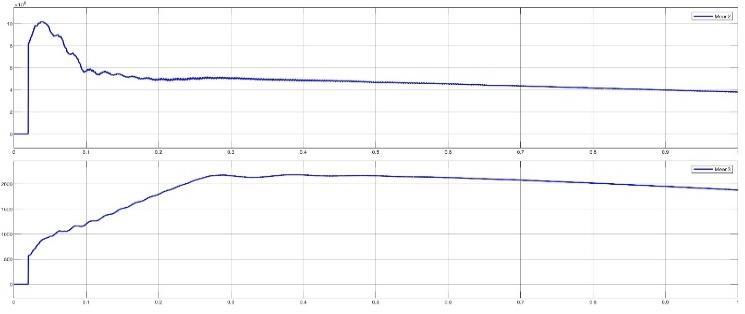

ThePowerfromeachunit isprovidedbelow:

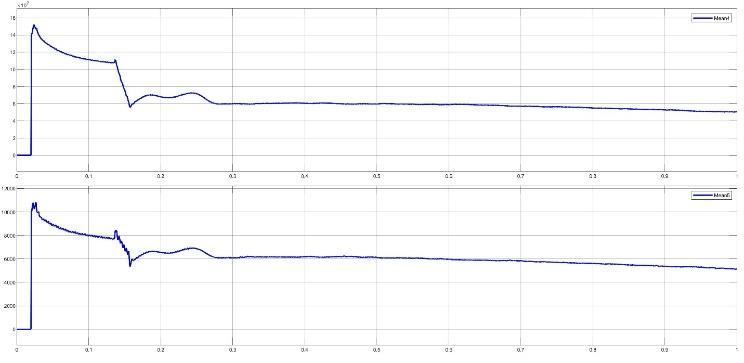

Fig -4:graphicalrepresentationofpower fromeachunit.

DG1 and DG2 each produce 4 MVA of power, making a totalof8MVA,andtheSystemforRecoveryofWasteHeat contributes around 6 MVA. The system controls power generation by adjusting the reference DC bus voltage. Belowisalistofeachunit'svoltageandcurrentvalues:

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

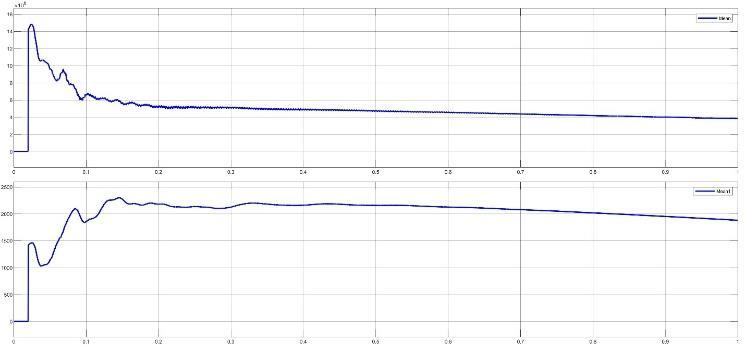

Fig -5:graphicalrepresentationvoltageandcurrentof eachunitofthedcbus.

The dc voltages generated from inverters connected to DG1 and DG2 is around 2.4KV and current is around 3KA and the output voltage of buck converter from heat recoverysystemis2.1KVandcurrentis1KA.

B. TestPerformanceEvaluation

Simulation results confirmed the capability of the MVDCbased system when they used together with WHRS (Waste heat recovery system) integration. DG1 and DG2 each delivered 4 MVA, while the WHRS added 6 MVA, increasing total power. The DC bus voltage remained stable at 2.4 kV with 3 kA current, and the WHRS buck converter maintained 2. kV at kA. Rotor speed smoothly reversed from 1500 to – 500 rpm, with stator

currents realigning effectively and minimal torque ripple. Controlled rectifiers ensured balanced power sharing, confirming improved energy efficiency and dynamic stability.

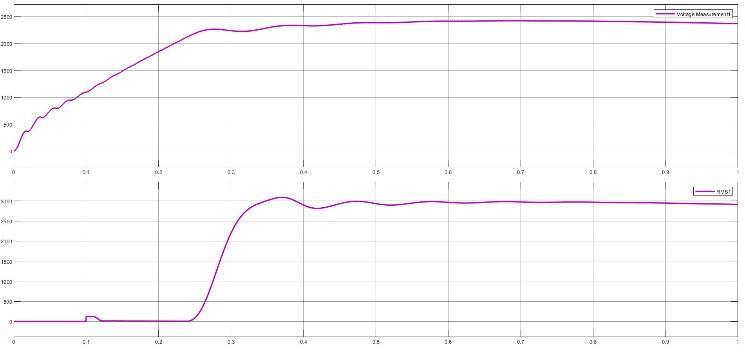

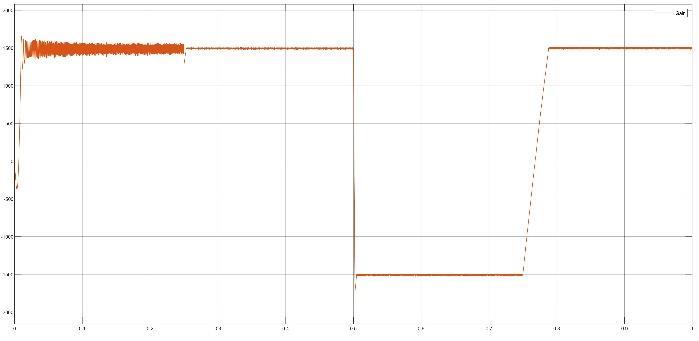

Thepropulsionsystem’srotorspeedisshownbelow:

Fig -6:graphicalrepresentationofpropulsionsystem’s rotorspeed

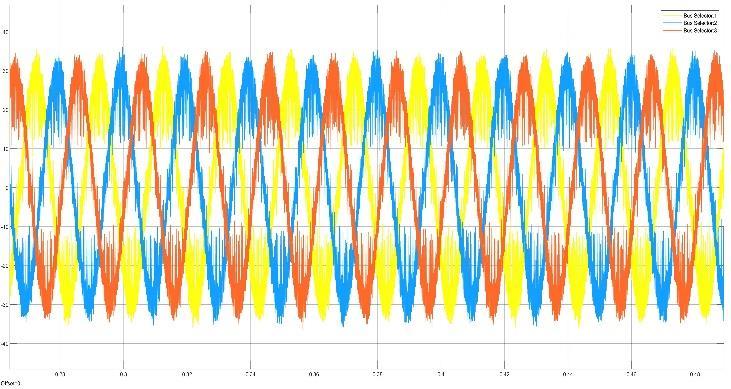

The rotor speed is initially 1500 rpm and at t=0.5s, it is reversed to -1500 rpm and again at t=0.75s, the speed is increased to 1500 rpm. The stator current during the speedreversalisprovidedbelow:

Fig -7:graphicalrepresentationofstatorcurrentduring thespeedreversal.

Thephaseisrealignedinordertoreversethespeedfrom1500rpmto1500rpmatt=0.75s.

A Medium Voltage DC (MVDC) propulsion system combined with an Organic Rankine the Cycle(ORC)-based Waste Heat Recovery System (WHRS) was designed and simulated to improve energy efficiency in marine applications. Using MATLAB/Simulink, the system demonstrated stable voltage regulation near 800 V, balanced power output from dual diesel generators, and quickPIcontrollerresponseduringtransients.TheWHRS recovered 30–40 kW of exhaust energy, boosting system

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page810

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

efficiency from 84% to approximately 92%. These results highlight the potential of integrating advanced control with energy recovery to enhance the reliability and sustainabilityofmodernmarinepropulsionsystems.

In the future, work could focus on developing a hardware prototype to test and confirm the simulation results in real-time. Power stability may also be enhanced by the additionofenergystoragedeviceslikebatteriesorsupercapacitors. Advanced control methods such as machine learning can be explored for better optimization. Detailed thermal modeling of the ORC system, fault protection mechanisms, scalability for larger ships, and environmental impact studies would further strengthen thesystem’spracticalvalueandsustainability.

[1] Hou, Jun & Sun, Jing & Hofmann, Heath. (2018). Mitigating Power Fluctuations in Electric Ship Propulsion WithaHybrid Energy Storage System: Design and Analysis. IEEE Journal of Oceanic Engineering.43.93-107.10.1109/JOE.2017.2674878

[2] J. Hou, Z. Song, H. Park, H. Hofmann, and J. Sun, "Implementation and evaluation of real-time model predictive control for load fluctuationsa mitigation in all-electric ship propulsion systems," Applied Energy, vol. 230, pp. 62–77, 2018, doi: 10.1016/j.apenergy.2018.08.079.

[3] F. D’Agostino et al., “Development of a multiphysics real-time simulator for model-based design of a DC shipboard microgrid,” Energies, vol. 13, no. 14, p. 3580,Jul.2020.

[4] J. N. Forestieri and M. Farasat, “Energy flow control and sizing of a hybrid battery/supercapacitor storage in MVDC shipboard power systems,” IET Electrical Systems in Transportation, vol. 10, no. 3, pp. 275–284, Sep.2020.

[5] S. Castellan et al., “A review of power electronics equipmentforall-electricshipMVDCpowersystems,” International Journal of Electrical Power & Energy Systems,vol.96,pp.306–323,Mar.2018.

[6] Z.Wang,J.He,Y.XuandF.Zhang,"DistributedControl ofVSC-MTDCaSystemsConsideringTradeoffBetween Voltagea Regulation and Power Sharing," in IEEE Transactions on Power Systems, vol. 35, no. 3, pp. 1812-1821, May 2020, doi: 10.1109/TPWRS.2019.2953044.

[7] U. Javaid et al., “Stability analysis of multi-port MVDC distribution networks for all-electric ships,” IEEE Journal of Emerging and Selected Topics in Power Electronics,vol.8,no.2,pp.1164–1177,Jun.2020.

[8] D.Paul,“Ahistoryofelectricshippropulsionsystems,” IEEE Industry Applications Magazine,vol.26,no.6,pp. 9–19,Nov.2020.

[9] Y. Yuan et al., “A review of multienergy hybrid power system for ships,” Renewable and Sustainable Energy Reviews,vol.132,Oct.2020,Art.no.110081.

[10] Hou, Jun & Sun, Jing & Hofmann, Heath. (2018). Control development and performance evaluation for battery/flywheel hybrid energy storage solutions to mitigate load fluctuations in all-electric ship propulsion systems. Applied Energy. 212. 919-930. 10.1016/j.apenergy.2017.12.098

[11] S. Castellan, R. Menis, A. Tessarolo, F. Luise, and T. Mazzuca, "A review of power electronics equipment for all-electric ship MVDC power systems," Int. J. Electr. Power Energy Syst.,vol.96, pp.306–323, 2018, doi:10.1016/j.ijepes.2017.09.040.

[12] L. Xu and L. Yao, “ORC-based waste heat recovery for marine applications,” Energy Conversion and Management,vol.133,pp.347–361,Feb.2017.

[13] M. Martelli et al., “Advanced simulation of shipboard ORC systems integrated with propulsion,” Energy Procedia,vol.129,pp.828–834,Sep.2017.

[14] Farhadi, Mustafa & Mohammed, Osama. (2015). Performance Enhancement of Actively Controlled Hybrid DC Microgrid with Pulsed Load. IEEE Transactions on Industry Applications. 51. 1-1. 10.1109/TIA.2015.2420630

[15] R. Menis et al., “Control and protection of MVDC systems in all-electric ships,” IEEE Transactions on Transportation Electrification, vol. 5, no. 2, pp. 427–439,Jun.2019.

[16] K.H.Kimetal.,“Real-timesimulationofMVDCpower systemsformarinepropulsion,” IEEEAccess,vol.8,pp. 44735–44744,2020.

[17] Y. Wang et al., “Multi-source power system control usingpredictiveoptimizationforhybridvessels,” IEEE Transactions on Transportation Electrification, vol. 6, no.1,pp.45–55,Mar.2020.

[18] T. T. Nguyen and H. Lee, “Design of power converters for ORC-based energy recovery in marine applications,” Energies,vol.12,no.22,p.4381,2019.

[19] F. J. Arias, “Thermal integration of ORC units in shipboardsystems,” Applied Thermal Engineering,vol. 157,p.113675,Oct.2019.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN:2395-0072

[20] B. H. Khan, Electrical Power Systems, McGraw-Hill Education,2017.(fortheoretical support on rectifiers andconverters)

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page812