International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Pratham Mankar1 , Soham Mhalagi2 , Tejas Karpe3 , Shailesh Mehendre4,Shreyash Gosavi5

1B.E. Mechanical student PES’s Modern College of Engineering, Pune-05

2B.E. Mechanical student PES’s Modern College of Engineering, Pune-05

3B.E. Mechanical student PES’s Modern College of Engineering, Pune-05

4B.E.Mechanical student PES’s Modern College of Engineering, Pune-05

5Assistant Professor,Department of Mechanical Engineering, PES’s Modern College of Engineering, Pune-05, Maharashtra, India

Abstract – Industrial lifts play an important role in modern industries which helps to move raw materials vertically in a safe and efficient way. The elevators are specially designed to carry heavy loads and to work in tough and critical conditions. These are widely used in different sectors like manufacturing, agriculture, mining, pharmaceuticals and construction, where raw materials need to be lifted from one floor to another in large quantities in less time. The industrial lift makes the process faster and reduces the manual work and saves time. This project covers the detail design and manufacturing of an industrial lift system model for lifting raw materials along with humans. It also includes installation of control system to operate the lift safely and efficiently by preparing small scale model.

Key Words: Industrial lift, Material handling, two floor lift system, load lifting mechanism, control system, Lift Automation, Safety

1.

Theintegrationofindustrialliftsisaimedatenhancingthe efficiency, safety and overall productivity of raw material handling within our facility. Given the increasing scale of operations and the need for streamlined vertical transportation of materials, implementing industrial elevators provides a strategic solution to address the limitation of manual and horizontal handling methods. Traditionalmaterialhandlingmethodsoftenresultindelays, increased labour costs and heightened safety risks, especially when transporting heavy and bulky materials betweendifferentlevelsofaplantorfacility.

The lift model has to be designed considering the load capacityandotherdesignconsiderations.Forthisdifferent literatureswerestudied.Theliftdesignedfora ratedload capacity of 10 kg which required 1 hp electric motor. The powertransmissionwasachievedusing beltpulley,worm gearandchain sprocket mechanisms;and the automation system was achieved using contactors and limit switches [2].Thedesignofelectricliftingmotorforanelectrichoistof thesinglegirderbridgecranewiththe500kgloadcapacity.

It represents the design of the electric lifting motor according to a commonly used scheme for the design of electric motors, from the power at a uniform load to the relativeloadofthemotor[1].theanalysisofascissorlifting mechanismbasedontheleadscrewmechanismconceptwas studiedinordertokeepthelift’scostdown,thedesignmight make the lift smaller and which becomes appropriate for mediumprojects[4].

The experimental work typically involves the analysis, design and fabrication of the industrial raw material lift modelwhichhasliftingcapacityof 4215Nloadattherateof 0.63 m/sec. It also includes the design of rope and pulley calculatingforceanalysisofpowertransmissionmechanism andselectionfactorforspecifiedmotorpowerwithworking loadlimittoactualload(5:1).

3.1 Components of Lift

01)Motor

02)Battery

03)DoublepoledoublethroughDPDTswitch

04)LimitSwitch

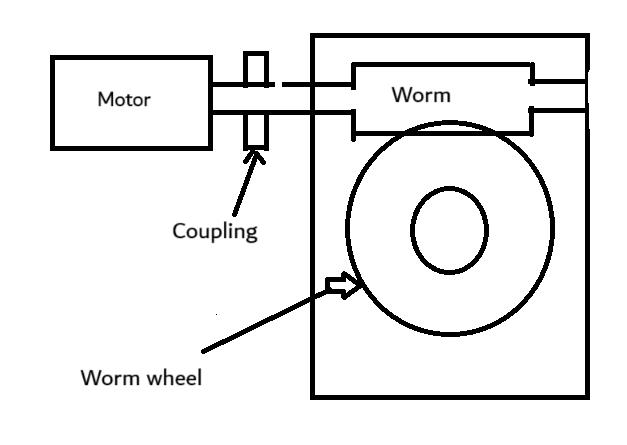

05)Wormandwormgear

06)ON/OFFswitch

07)Wireandconnectors

08)Insulatingtape

09)SheetMetal

10)Others

3.2 Data and designing

Designanelevatorforanindustrialusewhichhasanlifting loadcapacityof4215N(430kg.)for1floorheight. Selection of Gear - Selecting Worm and Worm wheel gear becauseofitsselflockingproperty.

Materialselection.

For worm: Cast hardened alloy steel (16Ni80Cr60) {Sut=710N/mm2}

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

Forwormwheelgear:Gunmetal{Sut=250N/mm2}

Sut =ultimatetensilestrength

Calculations

1) Power output required (P) = work done * lifting velocity=(5000-2000)*0.63=1890W

Considerationofthepowertransmissionas85%

2) Input power required = Po/p/n= 1890/0.85 = 2362.5W

3) Speedofgear(N gear)=D*pi*N/60000=38rpm

Speedofmotor(Nmotor)=1440rpm

4) Gearratio(G)-Nw/Ng=1440/38=37.1007nearly 38Asspeed(gear)ratioisgreaterthan30,

Zw=1

HenceG=zg/zw=38

i.e Zg=38

�� b =(Sut)g/3=250/3=83.33N/mm2

Where�� b =permissible/allowablebendingstress

TheLewisformfactor(20o fulldepthinvolute)

Y=0.484-2.87/z(38)

(Y)is0.40847

Tan��=Zw/q where, q= diametrical quotient, ��=lead angle

Tan��=1/14=4.0856 Tan��=��g=4.0856 o

��w=(90o –4.0856 o)=85.91438 o

Now,dw=m*qi.e.dw=14mAlso,b=7.7459m

i) Beam Strength

Fb=(�� b)g*b*m*y*cos �� = 83.33 * 7.7459m*m*4.0856*

cos(4.0856o)

Fb=262.9960m2 N

ii) Wear Strength

Fw=dg*b*k where,dg=m*Zg=38m,

K=0.8249=toothformfactor, b=facewidth

Fw=242.8339m2 N

As,Fw<Fb

Considerdesignforwearstrength

iii) Effective Load

Feff=(Ka*Fgt)/Kv where,ka=Servicefactor,Kv=Velocty factor

Fgt=tangentialforce

Pitchvelocityofgear(v)–v = (��*dg*ng)/60000=0.07722mm/s

Kv=6/6+v=6/6+0.07722m, Fgt=P/v=2362.5/0.07722m

Assuming,Ka=1.5Now, Feff=((76489.401/m)+984.3027)N

Forsaftyagainstwearfailure

Fw=FOS*Feff takingfatorofsaftyas1.5

Wegetmodulem=8.0384⩯8mm

iv) Calcuation for input motor power

��=tan��/tan(��v+��)buttan(��v)=��v=��/cos(��n)

Coefficientoffriction��=0.07��v=0.0749

Hence,tan��v=4.2602 o

��=tan��/tan(��v+��) =48.6898%<50%

Hence,thewormgearisself-locking

�� = output power/ inputpower = 48.6898% = 2362.5/Pinput

Therefore,Pinput=4852.2103W

Hence , standard motor of 5.5KW is to be selected (Accordingtodesigndatabook)

v) Calculation of new module

Calculatenewmoduleforinputrpmof1500(Nw=1500 rpm)

Gearratio(G)=N_w/N_g

WeassumingratioG=1500/38=38.64⩯39

1/G=Zw/Z_g

1/Zg=Zw/Gi.e.Zg=39

Thereisnochangeinleadangle��=4.0856o

Beam strength

Fb=(��*b*m*y*cos��

Where,Y=0.484-2.87/z(39) Y=0.41041

Fb=83.33*7.7459m*m*0.41041*cos(4.0856o)

Fb=264.2429m2 N

Wear strength

Fw=dg*b*k

Where,dg=m*Zg=39m, K=0.8249=toothformfactor,

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

B=7.7459m

Substitutingthevalues,

Fw=249.2243m2 N

As,Fw<Fb

Considerdesignwearstrength

Effective Load

Feff = (Ka*Fgt)/Kv where , Ka = service factor, Kv = Veloctyfactor

Fgt=tangentialforce

PitchVelocityofgear(v)-

V=(��*dg*Ng)/60000=0.07925mm/s

Kv=6/6+v=6/6+0.07722m, Fgt=P/v=5500/0.07925m

AssumingKa=1.5Now, Feff = 1.5 * ((5500/0.0792m)+(6+0.7925m/6))N ......eq1.2

Forsafetyagainstwearfailure

Fw=FOS*Feff Takingfactorofsafetyas1.5 Onsolvingeq1.2wegetmodulem=8.8791 ⩯10mm

3.3 Dimensions of gear pair

1)d_g=m*Z_g=10*39=390mm

2)dw=m*q=10*14=140mm

3)a-centerdistancebetweenwormandwormwheel =dg+dq/2=265mm

4)b=facewidth =7.7459m =77.459mm

5) Pa=axialpitch =��m=��*10 =31.145mm

6) L=leadofworn =Pa*zw=31.145*1=31.145mm

7) Ha=1m =10mm

8) Hm=1.25m =12.5mm

9) Lw=lengthofworm =��*m*z(4.5=zg/50)=165.8760mm

3.4 Control / operating mechanism

Thisliftisoperatedbymanualcontrolduetosafety reasons. Upanddownswitchforupanddownmovementwhichis handoperatedforlift.Movementliftoperatorshouldholdup anddownbuttonforgoingupanddownshereleasesbutton liftwillstopmoving.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN: 2395-0072

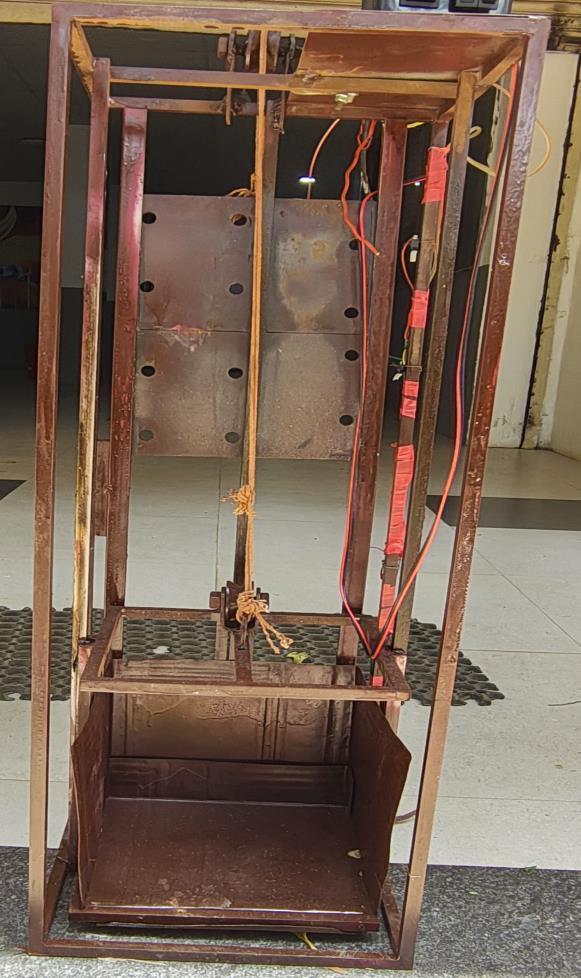

TheIndustrialRawMaterialliftwassuccessfullydeveloped with a secure self locking mechanism which has lifting capacityof4215N(430Kg)for1floorheight.Thecartwas successfully manufactured with dimension of 1.524 m x 1.524mand1.828mdeeptocarrytherawmaterialfrom groundtothefirstfloor.

[1] DenisM,MBlatnicky,“Designofthepowerofanelectric lifting motor for a single girder bridge crane with a 500kgloadcapacity,”TransporttechnicandTechnology, vol.XVII Issue 2 year 2021.DOI: 10.2478/TTT-20210010

[2] Peter Kayode Farayibi,Taiwo E, “Development of an automated mechanical lift for material handling process” FederalUniversity Akure,African Journal of ScienceTechnologyInnovationandDevelopment-June 2020

[3] Dr.Harish Hasurkar,Husain Shaikh, “Design and development of Pneumatic Scissor Lift,” IJCRT Vol.12 Issue3March2024

[4] Karthik SK,Vinodkumar Patil,”Design and Analysis of Scissor lift using leadscrew mechanism,IJRAR Jan 2023,Vol10Issue1