International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Nithish N1, S G Srivani2

1PG Student, Electrical and Electronics, RV College of Engineering, Bengaluru, India

2Professor and Head of the dept., Electrical and Electronics, RV College of Engineering, Bengaluru, India

Abstract - In recent years, the increasing demand for clean and reliable energy has accelerated the integration of renewable sources like solar photovoltaic (PV) systems into modern power networks. However, the intermittent nature of solar energy necessitates an efficient energy storage strategy to ensure stable and continuous power delivery. This paper presents a hybrid energy management system that combines a battery and a supercapacitor to enhance energy storage performance in solar PV systems. A boost converter is employed to regulate the output of the PV panel, while a bidirectional DC-DC converter facilitates twoway energy flow between the storage units and the DC bus. The proposed system is modeled and simulated using MATLAB/Simulink to validate the energy flow control strategy and system behavior under varying load and solar conditions. Intelligent energy management is achieved based on real-time load demand and state of charge (SOC) levels, ensuring optimal utilization of both storage elements. The battery supports long-duration energy supply, while the supercapacitor addresses short-term, high-power fluctuations. Simulation results confirm the system's ability to maintain a stable DC link voltage and deliver a consistent 500 W output to the load. The architecture is scalable, efficient, and suitable for standalone or off-grid solar energy applications.

Key Words: Hybrid energy storage system, Solar PV, Battery, Supercapacitor, MATLAB/Simulink, Boost converter, Bidirectional DC-DC converter, State of Charge (SOC),EnergymanagementController.

Solar photovoltaic (PV) systems are rapidly gaining popularity due to their sustainability, low environmental impact, and declining installation costs. However, the unpredictable nature of solar energy caused by varying irradiance and weather conditions leads to instability in energy output, making standalone solar systems insufficient for reliable power delivery. To overcome this limitation, energy storage systems have been integrated into PV systems to stabilize power supply and ensure energy availability during low-sunlight conditions. Conventional batterysystemscanstore energy efficiently, but they suffer from reduced lifespan when exposed to frequent and sudden power fluctuations. Supercapacitors

offer fast dynamic response and high power density, making them suitable for managing short-term load variations, though their energy density is comparatively lower. Therefore, a hybrid energy storage system (HESS) that combines batteries and supercapacitors is proposed asaneffectivesolutionforenhancedenergyreliabilityand systemflexibility[1].

Recent studies have highlighted the benefits of hybrid storage configurations in improving voltage regulation, reducing power losses, and ensuring fast transient response. The use of a boost converter helps to extract maximumpowerfromthePVpanelthroughMPPTcontrol, while a bidirectional DC-DC converter enables efficient energy exchange between the storage units and the DC link.MATLAB/Simulink-basedmodelingandanalysishave been extensively used to simulate hybrid systems and verifytheirdynamicperformanceundervaryingsolarand loadconditions[2]

The integration of an energy management controller (EMC) plays a key role in optimizing energy flow by monitoring real-time parameters such as state of charge (SOC), load demand, and PV output. This strategy enables intelligent switching between storage elements and enhancessystemperformance.Researchalsosupportsthe scalability of such architectures for higher-capacity or microgrid-level applications, and ongoing improvements in storage technology and control algorithms continue to expandthepotentialofhybridenergysystems[3].

The hybrid system not only extends the lifecycle of batteries by offloading fast dynamics to the supercapacitor, but also ensures minimal ripple in the output voltage, enhancing load compatibility. During periods of high solar irradiance, the excess energy is stored efficiently, while in low generation scenarios, storedenergyisdispatchedtomaintainloadsupply[4] This dual storage method supports both steady-state and transient load demands without compromising efficiency. The EMC ensures smooth coordination between the PV source, battery, and supercapacitor based on system priorities and conditions. Power sharing is dynamically adjusted to reduce stress on components, ultimately increasingreliability[5].

Such systems are particularly beneficial for off-grid and remote applications where grid access is unavailable or unreliable[3][4].Overall,thehybridconfigurationoffersa sustainable,stable,andsmartapproachtorenewable

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

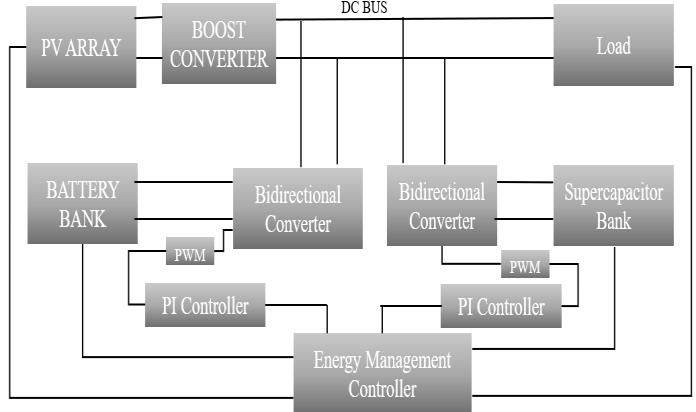

Fig -1:ArchitectureoftheHybridEnergyStorageSystem

energy utilization. This study explores advanced control algorithms and hybrid storage architectures to achieve a sustainable, stable, and intelligent energy management solutionforsolarPVapplications[6].

The block diagram shown in Fig. 1 illustrates a hybrid energy management system that integrates a solar PV array, boost converter, bidirectional converters, battery bank, and supercapacitor bank. The energy management controller (EMC) coordinates with PI controllers to regulate power flow using PWM signals, ensuring stable voltage on the DC bus while meeting varying load demands.

The solar photovoltaic (PV) array serves as the primary source of energy in the proposed hybrid system. It convertsincidentsolarirradianceintodirectcurrent(DC) electricity,whichisessentialforfeedingtheDCbus.Since the output of the PV array fluctuates with changes in sunlight intensity and ambient temperature, an MPPT (Maximum Power Point Tracking) algorithm is implemented to ensure optimal power extraction. In this project,thePerturbandObserve(P&O)methodisadopted duetoitssimplicityandeffectivenessinreal-timetracking of the maximum power point. The energy generated from the PV array is first used to meet the load demand. Any surplus energy is directed to charge the battery or supercapacitor, enhancing overall system efficiency and sustainability.During periodsoflowsolaravailability, the system intelligently switches to stored energy sources to maintain uninterrupted power supply. This integration of the PV array with intelligent power control ensures reduced reliance on the grid and promotes clean energy utilization. Additionally, real-time monitoring of PV voltage, current, and power supports dynamic energy management and system stability. Additionally, real-time

monitoring of PV voltage, current, and power supports dynamicenergymanagementandsystemstability.

Table -1: SolarPVSpecifications

Module Wareenergieswu-120

Parallelstrings 4

Series-connectedmodulesper string 2

Cells

module

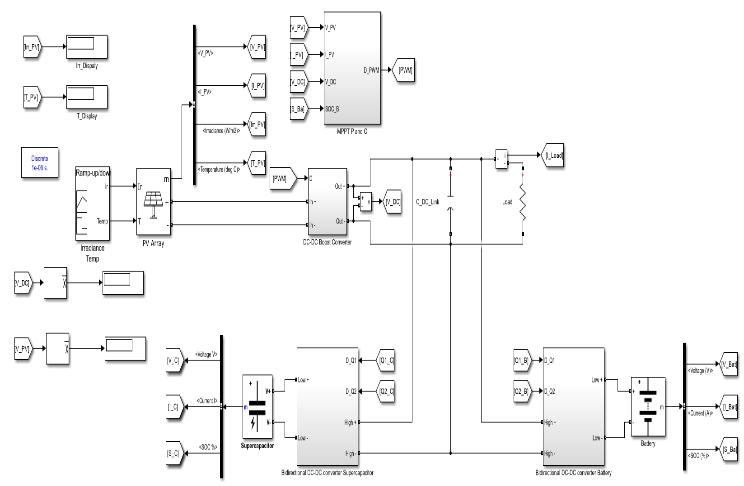

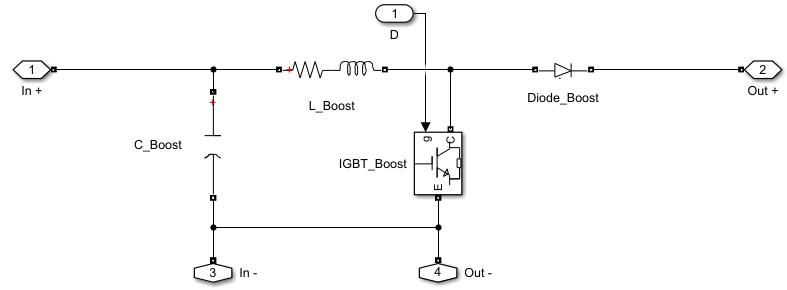

TheboostconverterisemployedtoelevatethevaryingDC voltagefromthesolarPVarraytoa stableDCbus voltage required by the system. As illustrated in Fig-3, the converter includes an inductor (L_Boost), a switching device (IGBT_Boost), a diode, and an output capacitor (C_Boost), forming a conventional step-up DC-DC topology. The switching action, controlled through a duty

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

cyclesignal,enablesenergystorageintheinductorduring the ON period and subsequent energy transfer to the output during the OFF period, effectively increasing the output voltage. This configuration ensures that the PV systemdeliverssufficientandregulatedpowertosupport theloadandenergystorageelements.Theboostconverter also operates in conjunction with an MPPT algorithm to maintain optimal energy extraction from the PV array. Its role is crucial in maintaining voltage stability and enhancing the efficiency of the overall hybrid energy system.

TheboostconverterstepsupthevoltagefromthePVpanel to the DC bus. Input Parameters: - PV maximum power voltage(V_in):17V-DesiredDCbusvoltage(V_out):32VDutycycle,

Inductor Design: Let switching frequency f=20KHz and ripplecurrentΔIL=0.3×Iin=2.1A

CapacitorDesign:Outputcurrent(I_out)=P/V=964/32 ≈30.1A,AssumingΔV=1V

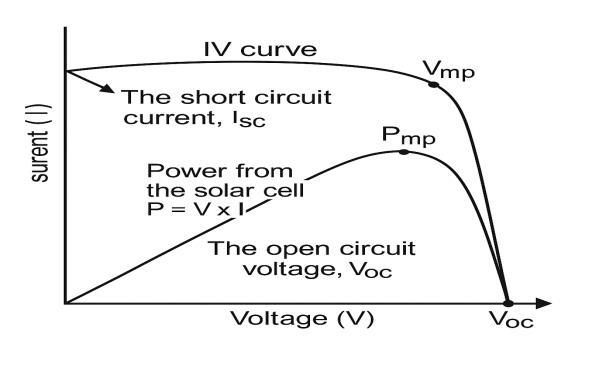

The Maximum Power Point Tracking (MPPT) algorithm is a crucial component in photovoltaic systems, enabling them to operate at peak efficiency under varying solar irradianceandtemperatureconditions.AsshowninFig-4, the power-voltage (P-V) curve of a PV module exhibits a distinct maximum point, known as the Maximum Power Point (MPP), where the product of current and voltage reaches its highest value. The MPPT controller dynamicallyadjuststheoperatingpointofthePVarrayto trackthisoptimalpointbymodifyingthedutycycleofthe DC-DCconverter.

TheimplementationoftheMPPTalgorithminthissystem involvesthefollowingsteps:

1. MeasuretheinitialPVvoltageV[k]andcurrentI[k].

2. Calculatethepower:P[k]=V[k]×I[k]

3. Slightlyperturbthevoltageeitherbyincreasingor decreasingit:V[k+1]=V[k]±ΔV

4. MeasurethenewvoltageV[k+1, currentI[k+1]and computethenewpower:P[k+1]=V[k+1]×I[k+1]

5. Comparethecurrentandpreviouspowervalues:

•IfP[k+1]>P[k]:

–Continueadjustingthevoltageinthesame direction

•IfP[k+1]<P[k]:

–Reversethedirectionofthevoltageadjustment

6. Updatethereferencevaluesforthenextcycle: P[k]=P[k+1],V[k]=V[k+1]

7. Repeatsteps3to6continuouslytoensuremaximum powerextractionfromthePVsource.

Krepresentsthecurrenttimesteporiterationindexused totrackandcomparevoltage,current,andpowervaluesof thesolarPVsystemforMPPT.

ThisalgorithmeffectivelytrackstheMPPbymonitoring thechangeinpowerrelativetovoltageperturbations, allowingthesystemtomaintainoptimalenergyharvesting evenduringpartialshadingorfluctuatingenvironmental conditions

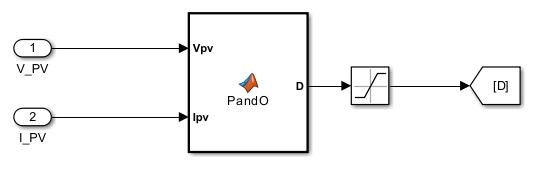

Fig-5:a)PWMsignalgenerationfromPandO b)PWMsignalgenerationfromBattery

ThesupportingMATLABcodeembeddedinsidetheMPPT block (Fig-5: a) is written using a persistent variable structurethatretainsthevaluesofthepreviousdutycycle (Dold),voltage(Vold),andpower(Pold)acrosssimulation steps. Initially, these variables are assigned default values toestablishastartingpointforcomparison.Thealgorithm computes the present power (Ppv) by multiplying the input voltage (Vpv) and current (Ipv). It then compares thisvaluewiththepreviouspowertodecidethedirection ofperturbation.

If the current power increases compared to the previous step, the code checks the direction of voltage change to decide whether to increment or decrement the duty cycle(D).Conversely,ifthepowerdecreases,thealgorithm reverses the direction of voltage change accordingly. The a) b)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

calculateddutycycleisthenstoredbackasDoldforusein thenextiteration,along withupdatedvaluesforVoldand Pold.Thisstructureensuresaresponsive,adaptivecontrol that helps the system quickly reach and maintain operation near the Maximum Power Point (MPPT) under the varying environmental conditions like varying temperatureandsolarirradiance.

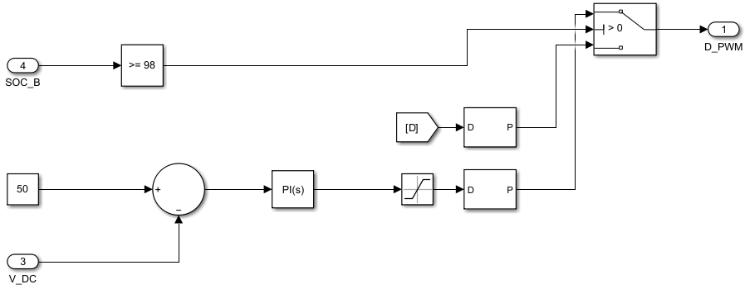

Fig-5:b) showsthecontrol logic thatdeterminestheduty cycle (PWM signal) for the boost converter based on the batterystateofcharge(SOC)andtheDClinkvoltagelevel. The PWM signal is only provided by this control block when the battery SOC reaches or exceeds 98%, which implies the battery is fully charged and cannot absorb furtherenergy.Insuchacase,thePIcontrollertakesover, comparing the reference DC link voltage (50 V) with the actual DC voltage (V_DC) and generating the appropriate dutycycleneededtoregulatetheoutputthroughtheboost converter.

In contrast to the MPPT-based control logic shown in the Fig- 5: a), which operates under normal charging conditions to maximize solar energy extraction, the logic inFig-5:b)becomesactiveonlywhenthebatteryisunable to store more energy. While the MPPT algorithm continuously perturbs the voltage to track maximum powerfromthePVpanel,thecontrollogicinFig-5ensures that excess energy is diverted appropriately by adjusting the converter’s operation to maintain voltage stability across the DC bus when storage is full. This ensures the system prioritizes safe and efficient power regulation, adaptingdynamicallytoenergystorageavailability.

2.4 Bidirectional Converter

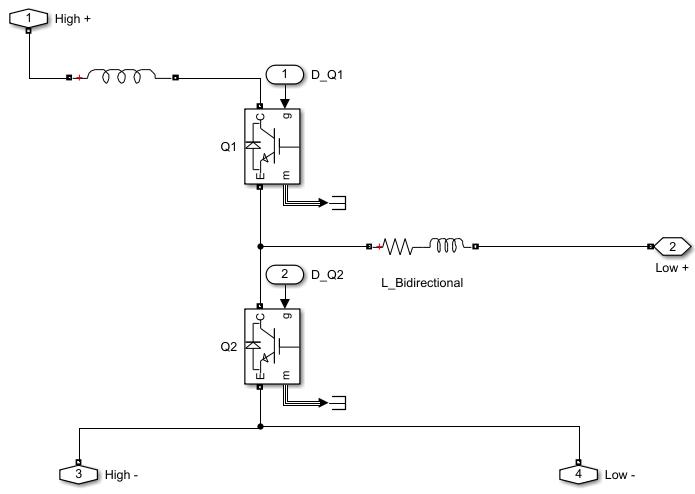

Fig-6: BidirectionalConverterforbothBatteryand Supercapacitor

Fig-6 illustrates the bidirectional DC-DC converter topologyusedforboththebatteryandthesupercapacitor energystorageunitsinthesystem.Theconverteroperates in two modes charging and discharging depending on the system’s power demand and storage availability. It

consists of two IGBT switches (Q1 and Q2) controlled by separate PWM signals (D_Q1 and D_Q2), and a central inductor (L_Bidirectional) that facilitates energy transfer between the high-voltage DC bus and the low-voltage storageunits.

When the storage device (battery or supercapacitor) needstobecharged,theconverteroperatesinbuckmode. Inthiscase,Q2isactivated, allowingcurrenttoflowfrom the high-voltage bus through the inductor to the storage device. Conversely, when the load demand increases and additional power is required, the converter switches to boost mode by turning on Q1. This enables the stored energy to be discharged back to the DC bus. The bidirectional converter thus ensures efficient power exchange in both directions, maintaining voltage regulation and energy balancing between the PV source, storageunits,andtheload.

The bidirectional DC-DC converter implemented in this project is designed to perform energy transfer between the DC bus and the energy storage units (battery and supercapacitor) in both charging (buck mode) and discharging (boost mode) operations. In boost mode, the converter steps up the lower voltage from the storage elementtotheDClinkvoltage(~50 V)tosupporttheload. In buck mode, it steps down the higher DC bus voltage to safelychargethestorageunits.Thedesignconsidersboth operating conditions to ensure proper inductor and capacitorsizing,ripplecontrol,andtransientresponse.

A) During boost mode (Discharge to load), the inductor L(Lboost)isselectedbasedon:

( )

Assume: Vin=12V, Vout=50V, , , fs=25kHz ( )

B)Duringbuckmode(ChargingfromPVthroughDClink), theinductorL(Lbuck)isselectedbasedon: ( )

Assume:Vin=50V,Vout=12V,d=0.24 ( )

A small series resistance of 0.05 Ω is included in the bidirectional converter circuit to limit inrush currents during mode transitions. It also helps dampen highfrequency oscillations, improving system stability and

International

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

protectingsensitivecomponents. Inductorvaluesin boost andbuckmodesareselectedbasedonvoltagelevels,duty cycle, switching frequency, and current ripple to ensure efficientandstablepowerconversion.

The battery plays a crucial role in the hybrid energy storage system by providing backup power during low solar irradiance and maintaining energy balance under steady-state conditions. Among various types, a LithiumIon battery is selected for its high energy density, longer cyclelife,andsuperiorcharge-dischargeefficiency.

Table -2: BatterySpecifications

Nominal

As shown in Table-2, the selected battery has a nominal voltage of 24 V, a cut-off voltage of 18 V, and reaches a fullychargedvoltageofapproximately27.94V.Itfeatures a rated capacity of 14 Ah, a nominal discharge current of 6.087 A, and a battery response time of 0.1 seconds, making it well-suited for dynamic power support. The internal resistance is 0.017143 ohms, minimizing energy lossduringcharginganddischargingcycles.

The initial state of charge (SOC) is set to 50%, and the battery operation is controlled through a bidirectional converter interfaced with the energy management controller(EMC).DuringperiodsoflowPVoutputorhigh demand, the battery discharges to stabilize the DC bus. When excess solar energy is available, the EMC directs powertochargethebattery.Thisensuresoptimalbattery usage and contributes to maintaining a consistent power supplytotheload.

To evaluate the performance of the lithium-ion battery in the proposed hybrid energy storage system, several key parameterswereconsideredbased on the manufacturer's specifications. These include nominal voltage, current ratings, capacity, internal resistance, and response time. The battery is designed to assist in maintaining DC bus voltage stability by discharging when solar output drops andchargingwhenexcesspowerisavailable.

The total energy stored in the battery can be calculated using:E=Vnominal×CapacityAh=24 V×14 Ah=336 Wh

This implies the battery can supply 336 W for 1 hour, or proportionally different power for shorter/longer durations.

Todeterminethedischargetimewhenpoweringa500 W load:

The battery charging time depends on the charging current.Assumingaconstantchargingcurrentof6A:

Taking into account efficiency (typically 90% for lithiumioncharging),effectivechargetimeis

The battery’s internal resistance, 0.017143 ohms, results in minimal internal voltage drop and power loss. The powerlossduringdischargeatnominalcurrentis:

Ploss=I2 R=(6.087)2 0.017143 0.64W

Thislowpowerlossensuresefficientenergydelivery.The response time of 0.1 seconds enables the battery to quickly support the load or absorb power fluctuations, whichiscriticalinhybridenergymanagement. Thus, the battery system is well-suited for intermediate energy storage and backup power delivery, complementing the fast-response supercapacitor and the intermittentnatureofsolarPVinput.

In this hybrid energy storage management system, a supercapacitor is integrated alongside the lithium-ion batterytoenhancedynamicresponseandhandletransient powerdemands.Supercapacitorsareknownfortheirhigh power density, fast charge-discharge cycles, and long operational life, making them ideal for short-term energy buffering. Unlike batteries, which are better suited for sustained energy supply, supercapacitors respond almost instantaneously to sudden changes in load or PV output, thereby improving system stability and reducing voltage fluctuationsontheDCbus.

Table -3: SupercapacitorSpecifications

Ratedcapacitance(F) 20.83

EquivalentDCseriesresistance(Ohms) 0.003

Ratedvoltage(V) 32

Numberofseriescapacitors 1

Numberofparallelcapacitors 1

Initialvoltage(V) 32

Operatingtemperature(Celsius) 25

To effectively support transient load conditions and stabilize the DC link voltage, the sizing of the supercapacitor is based on its ability to supply or absorb energy over a short duration. The required capacitance canbeestimatedusingtheenergyequationforcapacitors:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

( )

Where: E is the required energy in joules, C is the capacitance in farads, V1 and V2 are the initial and final voltagesofthecapacitorduringdischarge Forinstance,assumingthesupercapacitorneedstosupply 500 W for 5 seconds during a sudden load event, the energyrequiredis:E=P×t=500 W×5 s=2500 J

Assuming the voltage drops from 32 V to 28 V during discharge: ( ) ( ) ( )

Therefore, a capacitance of 20.83 F is sufficient to deliver the required energy during short bursts. This value ensuresreliableperformanceduringrapidloadvariations whilemaintainingvoltagestabilityattheDCbus.

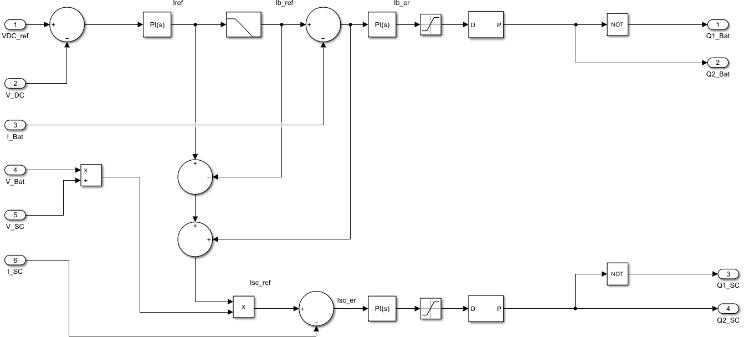

Fig-7: PIcontrollerImplementedtogenerategatepulses forBidirectionalConvertersofbothStorageSystem

TheFig-7showsthePIcontrollerlogicusedforgenerating gate pulses for the bidirectional DC-DC converters in the hybrid storage system. It compares the reference DC link voltage with the actual voltage to produce a current reference, which is then processed to control battery and supercapacitor currents. The controllers adjust the duty cyclesandgenerateappropriateswitchingsignals(Q1,Q2) to manage charge/discharge modes. This control ensures stable DC link voltage and effective coordination between batteryandsupercapacitorinreal-time.

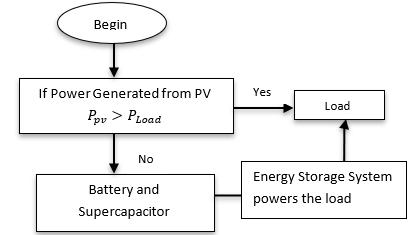

The flowchart shown in Fig-8 represents the decisionmaking logic of the Energy Management Controller (EMC) used in this project to manage energy flow between the solar PV, battery, and supercapacitor based on real-time operating conditions. It begins by reading key parameters suchasPVpower(Ppv),loadpower(Pload),batterypower (Pb), supercapacitor power (Psc), and the State of Charge (SOC)ofboththebatteryandsupercapacitor.

1. The system starts by reading all necessary input values:

solar power from the PV panel, load power, power from the battery and supercapacitor, and the SOC valuesofbothstorageunits.

Fig-8: EnergyManagementController(EMC)Flowchart

2. It then calculates the available power by subtracting the load demand from the generated solar power is givenbytheequationof(Pav=Ppv−PL).

3. If the available power equals zero, the system keeps monitoring and waits for any change in input conditions.

4. If there is excess solar power (Pav > 0), the system checks whether the supercapacitor is eligible for charging based on its SOC being below the maximum safelimit.

5. If there is no excess solar power (Pav < 0), the controller checks if the battery has enough charge to bedischargedandsupporttheload.

6. Ifthebatteryisunabletofulfilltheremainingdemand, the system then evaluates the supercapacitor’s SOCto decidewhetheritcansupplythepower.

7. Ifboththebatteryandsupercapacitorcannotmeetthe load, the controller disconnects the load to prevent undervoltageandprotectsystemstability.

8. When all power sources are insufficient, it loops back tobeginmonitoringagainandavoidsdrawingunstable power.

9. IfthesupercapacitorisnotfullychargedandexcessPV power exists, the controller initiates supercapacitor charging.

10. If,aftercharging the SC, extra powerstill remains, the controller checks if the battery also needs to be charged.

11. If the battery SOC is not yet full, it allows charging to continue; otherwise, it stops MPPT to prevent unnecessaryenergytransfer.

12. Finally,ifpowerbalanceconditionsaresatisfied,MPPT stays on; if not, the control logic returns to its monitoringanddecisioncycle.

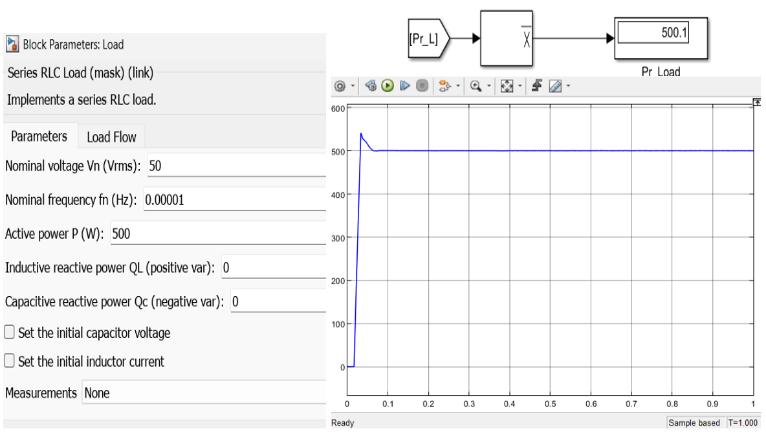

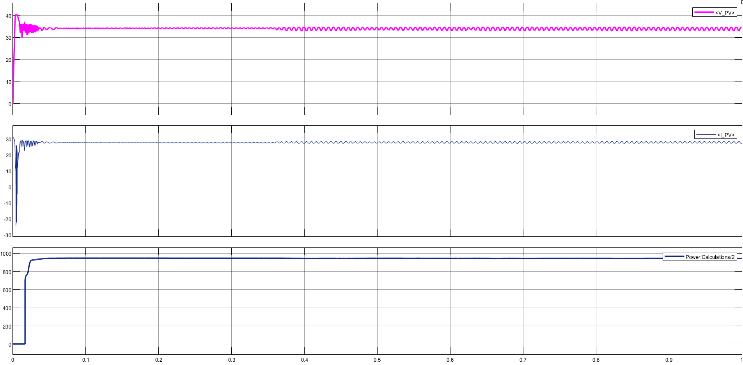

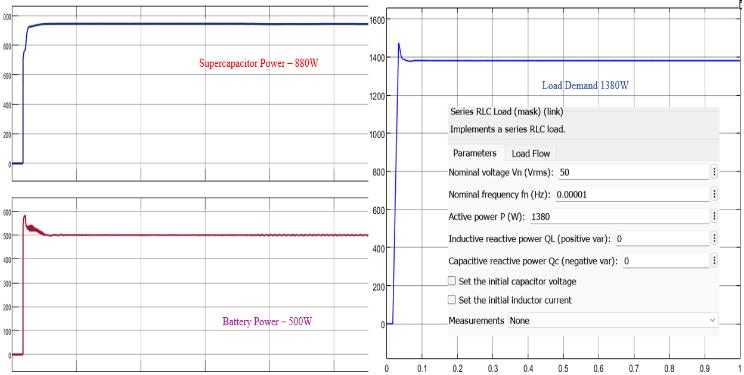

The simulation results show that when the 500 W load demand occurs, it is first met by the solar PV, which can

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

supply up to 950 W; the surplus is used to charge the battery and supercapacitor. When the load increases to 1380 W and solar is disconnected, the battery supplies 500 W and the supercapacitor provides the remaining 880 W.

Fig-9: LoadPowerWaveformwhenLoaddemandis500W

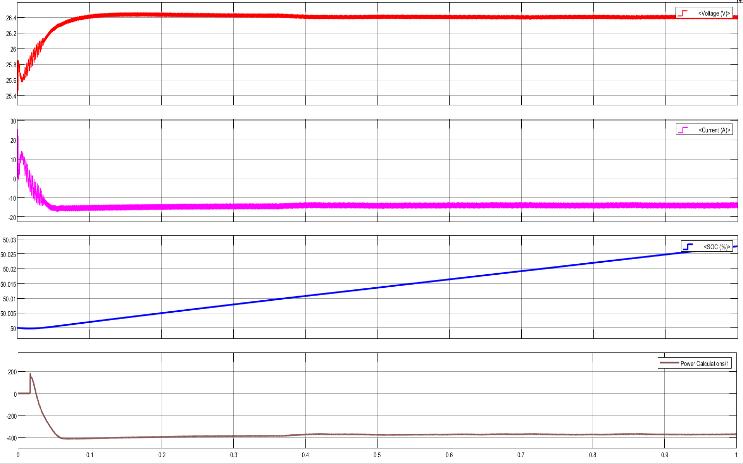

Fig-11: BatteryWaveformsofV,I,SOC(%)andPduring charging

Fig-12: LoadWaveformswhenpowerdemandis1380W

4.

The proposed hybrid energy management system effectively integrates a solar PV array, battery, and supercapacitor to ensure stable and reliable power delivery under varying load and generation conditions. The implementation of a boost converter with MPPT control optimizes solar energy extraction, while the bidirectional converter enables efficient charging and discharging of the storage units. Simulation results confirm that the system maintains a stable DC link and successfully manages load sharing based on power availability and SOC levels. Overall, the architecture demonstrates enhanced energy utilization, system flexibility, and support for standalone or remote applications.

[1] N. Arawwawala, N. Kularatna, and D. C. U. Sirimanne, “Future Directions of Commercially Available Supercapacitors,” IEEE Power Electronics Magazine, vol. 10, no. 3, pp. 18–24, Sep. 2023. doi: 10.1109/MPEL.2023.3309682

[2] T. Ariyarathna, N. Kularatna, K. Gunawardane, D. Jayananda, and D. A. Steyn-Ross, “Development of Supercapacitor Technology and Its Potential Impact on NewPowerConverterTechniquesforRenewableEnergy,” IEEE Journal of Emerging and Selected Topics in Industrial Electronics, vol. 2, no. 1, pp. 25–34, Mar. 2021. doi: 10.1109/JESTIE.2021.3061317

[3] K. Sudharshan, V. Vigneshkumar, and P. Sankar, “Comparative Analysis of P&O, Incremental Conductance MPPT with a Boost Converter for Solar PV Systems,” in Proc. IEEE Int. Conf. on Advances in Energy Systems and Environmental Engineering (ASEE), 2020. doi: 10.1109/ASEE.2020.9245587

[4] S. S. Kalingamudali and N. Abhayasinghe, “Solar PoweredMicroGridforDaytimeHighPowerApplications AssistedbySupercapacitor,”in Proc. IEEE ICECIE,2019.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page819

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[5] A. Smith, B. Johnson, and C. Lee, “Advanced Control Strategies for Hybrid Energy Storage Systems in Renewable Energy Applications,” IEEE Transactions on Smart Grid, vol. 14, no. 2, pp. 1234–1242, Mar. 2024. doi: 10.1109/TSG.2024.1234567

[6]K.W.Subasinghage,K.Gunawardane,andN.Kularatna, “Supercapacitor-Assisted Low-Dropout Regulator Technique for Low Output Ripple DC-DC Conversion,” IEEE Journal of Emerging and Selected Topics in Industrial Electronics, vol. 3, no. 2, pp. 382–391, Jun. 2022. doi: 10.1109/JESTIE.2022.3167803

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page820