International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

Naresh Kumar Wagri 1, 4 Kamal Kishore2, Swastishree Jain3, Anurag Choubey4, Akashdeep Sahu5, Aseem C Tiwari4

1Department of Materials Science and Engineering, School of Industrial Engineering and Management, KTH Royal Institute of Technology, SE-10044 Stockholm, Sweden

2School of Civil, Mining, Environmental and Architectural Engineering, University of Wollongong, NSW- 2522, Australia

3Department of Forest, Government of Madhya Pradesh, Bandhavgarh National Park, Khitauli, Garhpuri, MP484661, India

4 Department of Mechanical Engineering, University Institute of Technology, Rajiv Gandhi Proudyogiki Vishwavidyalaya (UIT-RGPV), Bhopal, MP-462033, India

5Department of Police, Government of Madhya Pradesh, Patan, Jabalpur, MP-483113, India

Abstract - Irrigation in rural areas is essential for agricultural productivity and food security. However, several issues arise from improper or unsustainable irrigation practices, which canhavelong-termenvironmental,economic, and social impacts. Thus, proper supply of water with mechanical equipment is therefore essential to implementing and maintaining a cost-effective irrigation system. A treadle pump is a human-powered irrigation device designed to efficiently lift water from a lower to a higher elevation. Its basic structure consists of a pedal-operated lever, or treadle, connected to a pump mechanism. The user steps on the treadle, which activates a series of pistons or diaphragms, creating a pumping action that draws water from a source such as a well or a river. By performing this pump there are several challenges for the proper supply of water supply. It includes designing of whole treadle pump assembly. In this study, a treadle pump was constructed and operated with design parameters in order to estimate the outlet flow rate of water. The efficiency of the treadle pump was estimated to be around46.6 %andthe overallsystemcost has beenestimated at around ₹ 6000 (INR). Results from this study concluded that the Government of India should be urged to increase the availability and to promote this kind of technology to the market at a reduced cost by offering tax incentives to local manufacturers and by using an input voucher system to subsidize qualified poor smallholder farmers.

Key Words: Treadle pump, Flow rate, Mass flow rate, Water, Irrigation.

Indevelopingcountries,ruralvillagesfacemanychallenges likepoorinfrastructure,limitedhealthcare,

Nomenclature

M Massflowrate

g Accelerationtogravity

W Unitofpower

N Newton

h Headofthepump

ρ Densityofthewater

q Dischargeofthepump

l Lengthofthepipe

d Diameterofthepipe

f frictionfactor

m Meter

v Velocityoftheflow

Kg Kilogram

s Second kgf Kilogram-force

lackofcleanwater,pooreducation,longhoursofhousehold work, and few opportunities for business and economic growth1–5. Despite help from governments and organizations, rural poverty has not improved much. Market-based approaches, unlike traditional aid, aim to boosttheeconomybysupportingentrepreneurship6.These methods are often more effective because they help local businesses grow and increase income of people from the groundup7. Manyorganizationsoftenfocusonagriculture in developing nations as subsistence farming is the main activity in rural areas8–10. The Food and Agriculture Organization of the United Nations (2000) states that reliableirrigationmethodscanboostcropyieldsby100%to 400%11.Thisincreaseinagriculturaloutputleadstohigher salesandrevenue,allowingfarmerstogrowmorevaluable cropsandadoptnewtechnology.Withincreasedrevenue, farmers can expand their arable land, further boosting productivityandincomeeachseason.Thisimprovementcan

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

be achieved without expensive traditional pumping methods, which require significant financial investment12 . Forexample,whiledieselpumpsareeffectiveforirrigation, their high initial and fuel costs prevent many subsistence farmersfromusingthem 13

Human-powered pumps are popular among small-scale farmersduetotheirlowinitialandongoingcosts14.Thefootpowered treadle pump, designed by Norwegian engineer GunnarBarnesinthe1970s,iswidelyusedandrecognized. It was first presented in Bangladesh15. International Development Enterprises (IDE) and KickStart have since redesigned the treadle pump and developed new humanpoweredmodels.Thesepumpscandrawwaterfromdepths ofupto7metersandhave flowratesofupto 5litresper second. Human-powered pumps have helped many subsistencefarmersimprovetheireconomicsituationand escapepoverty16,17

Following the rise in popularity of Treadle Pumps, many organizations began testing their efficiency18. The initial testing was conducted by IRRI, Mennonite Central Committee (MCC), and Bangladesh Rural Development Board (BRDB). These tests examined the technical, sociological,andergonomicaspectsofthepump,including water discharge rate, pumping depth, tube well length, piston-cylinder diameter, operator characteristics, adaptability,andpowerinput19.Theconceptofthetreadle pumpwasexplainedbyBarnesin198620,whohighlighted itssimplicity,lowcost,andsustainableproduction.However, the original design had limitations, such as the frequent malfunctions, lack of pressurized output, and limited durability.Toaddresstheseissues,variousimprovements were tried using alternative materials like glass linings, concrete and cast iron21. In 1989, Kroeker19 proposed furtherdesignenhancementsbyadjustingpistondiameters andvalvesbasedonlabandfieldtests.In2000,theFoodand AgricultureOrganizationoftheUnitedNations11provideda comprehensive analysis of treadle pumps used in Africa, detailing their specifications, marketing strategies, production processes, and socio-economic impact in countries like, Zimbabwe, Zambia, Kenya, and Niger. The reportnotedthatlocalagriculturalpracticesinfluencedthe designofpump.UnlikeBangladesh,wherecanalfarmingis common, African farmers mainly use drippers, hoses, and overheadtanksforirrigation.Thus,thetreadlepumpwas modifiedtoincludeapressurizedoutletchannel,leadingto thedevelopmentofthepressurepump.In2004,Srinivasand Jalajakshi22 studiedtreadlepumpsinIndia,assessingtheir performance with consumption data. They found that treadle pumps outperformed other manual pumps in discharge and were more efficient than diesel pumps. In 2006,Pereira etal.investigatedtheergonomics oftreadle pumps, body motions, analysing foot placement, and operator comfort. They recommended specific foot angles foroptimalandcomfortableuseofthepumps23 .

Treadlepumpsarehuman-poweredwaterpumpsusedfor crop irrigation in rural areas of developing countries24,25 . Theyoperatelikeastairmastermachine,usingarepetitive up-and-downmotiontodriveapiston-cylinderarrangement that pumps water. Typically made of alloy steel26–29 for durability and strength in harsh, corrosive environments, therearetwomaintypesoftreadlepumps:suctionpumps andpressurepumps.Suctionpumpsaremoreaffordablebut lesseffectiveforirrigatinglargeareas.Thetreadlepumpisa pressure pump, which is more suitable for extensive irrigation25. Treadle pumps can significantly improve the lives of rural farmers. Access to water is the main factor distinguishing rich farmers from poor ones in developing countries.Byusingtreadlepumps,farmersinIndiacangrow crops year-round, potentially tripling their income30. The pressure treadle pump can lift 30-60 litres of water per minutefromwellsandboreholesupto8mdeep,compared to suction treadle pumps that only reach 4.5 meters. This pump provides irrigation and drinking water in areas without electricity31-35. Treadle pumps are designed to lift waterfromwells,rivers,orothersourcesforirrigationand domestic use. They are especiallybeneficial in rural areas where electricity and motorized pumps are scarce. These pumpshavebecomevital toolsforsmallholderfarmersin manydevelopingcountries.Byprovidingasustainableand affordablesolutionforsmall-scaleirrigation,treadlepumps improve agricultural productivity and support farmers in water-scarceregions 36-41.Theirsimpledesignandreliance onhumanpowermakethempracticalandenvironmentally friendlyforenhancingwateraccessinruralcommunities17 .

Inthisstudy,acosteffectivetreadlepumpisdevelopedfor low-income farmers to plough their fields and for wide farmingapplications.Thedevelopedpumpisanimproved configuration which provide maximum pump flow, and minimizesthematerialsconsumptionforpreparation.The configureddimensionsoftreadlepumpallowittoworkwith maximumefficiency.

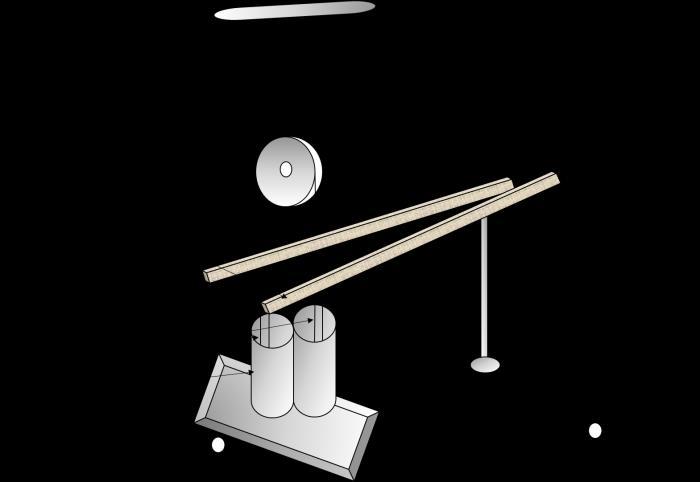

Inthisstudy,twoalloysteelpumpcylinderswereusedto provideproperpressureforcontinuouswaterflowfromthe outlet of the treadle pump. While this is less critical for gravityirrigation,itisbeneficial forpressurizedirrigation, where maintaining pressure is important. The schematic view of treadle as shown in Figure 1. The Pump cylinder lengthwaschosen230mm.Theinletandoutletdiametersof thepumpcylinderwereassumedtobe64mmand68mm respectively.Additionally,othergeometricconstantvalues canbeseeninTable1.

Pistons move up and down in the cylinders when the operatorpressesthetreadles.Steelrodsconnectthepistons to the treadles. Pistonscan be made of steel, wool, plastic, leather,orrubber,withcupsorringsformingthesealwith thecylinder.Thissealmustwithstandthecontinuousmotion against the cylinder wall. The manifold is a steel box in a

International

Volume: 12 Issue: 07 | July 2025 www.irjet.net

pressurepumpthatconnectstheinletandoutletpipestothe pumpcylinder.Itcomprisestwoparts:theinletside,which allows water into the cylinder, and the outlet side, which allowwatertoexitfromthecylinderintoadeliverypipe.This canbeseeninFigure1.

Figure-1. Aschematicillustrationoftreadlepump.

Thevalveboxisdividedintothreesections:oneforinlet and outlet attachment, and two cylindrical sections in the middle.Partingplates,drilledforwaterflow,separatethese sections.Syntheticrubberpads,actingasNon-ReturnValves (NRVs),areboltedontoonesideoftheplatestoenableonesidedflow.ThevalveboxdimensioncanbeseeninTable1.

Table-1: Dimensionsofthevalvebox(squarecrosssection)

supportfortheoperator.Whilecertainpumpsutilizewooden framesforenhancedportability,anironframeisemployed here to accommodate the weight of two adults. Wooden frames may be preferable in security-sensitive situations wherepumpscannotbeleftunattendedovernight.However, the use of a sturdy metal frame, as implemented in this design,ensuresdurabilityundersustainedusage.

Theoperatorutilizesthetreadlestooperatethepumpby pushing them up and down. Typically, these treadles are around1meterinlength,hingedatoneend,andsupportedat theotherendbyaropeorchainrunningoverapulley.They arelinkedtothepistonrods,enablingthemovementofthe treadles to be transferred to the piston. Treadles can be constructedfrommaterialssuchassteel,wood,orbamboo (withsteel beingpreferable).Theymustpossesssufficient strength to withstand the forces exerted by the operator's weight.

A treadle pump consists of a cylinder with a closely fitted piston,operatedbyamechanismthatmovesthepistonup and down. A pipe connects the pump to the water source, endingwithanon-returnvalvethatallowswatertoenterthe pipebutpreventsitfromflowingback.Whenthepistonis raised,itcreatesavacuuminthecylinder,drawingwaterinto the pump. When the piston is pushed down, water passes throughasmallvalveinthepiston,fillingthespaceaboveit. Onthenextupwardstroke,thepistonliftsthiswater,which then flows out over the rim of the cylinder and into an irrigationchannelortank(forasuctionpump).Inapressure pump, the water is compressed as the piston is raised, moving it to the next cylinder and then to the outlet pipe, wheretheprocessrepeats.

Foratreadlepump,theforceappliedisusedtoliftwatertoa certain height. Therefore, calculation of the gravitational potential energy (GPE) per unit time gained by the water, whichisgivenbythepoweroutputformula:

Poweroutput=Mxgxh=ρxqxgxh (1)

Where,

Densityofwater=1000kg/m3 ,

Thepulleywheelandropelinkthetwotreadles,allowing theoperatortomovethemupanddowninareciprocating motion.Typically,thepulley,madeofwoodsoakedinoilfor preservationandlubrication,isutilized,butinthiscase,an iron pulley is employed. An alternative to the pulley is a rockingbar,whichispivotedinthemiddle.

Thecomponentsofthetreadlepumpweremountedona frame, which keeps all the parts together and provide

Gravitationalacceleration=9.81m/s2 ,

TotalHead=7m,

In this study, the head losses in a system were not considered because of the negligible effect and due to unknownvalueofthefrictionfactor.

Totaldischarge=0.5-0.7liter/s.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Thus,

Poweroutput=1000x9.81x0.7x10-3W=48.069~48W and,

Powerinput=[weightoftheoperator+forceappliedbythe operator(10–20%oftheweightofthewater)]xvelocityof thepiston.

Weightoftheoperator=53kgx9.81m/s2 =519.93N=520N

Forceappliedbytheoperator=0.2x520=104N

Velocityofthepiston=2strokespersecond,strokelength= 8cm=0.08m

So,velocityofthepiston=2x0.08=0.16m/s

Therefore,powerinput=(540+104)x0.16 =103W

Efficiency:Theefficiencyofatreadlepumpcanbecalculated bythebelowformula.

Thus, the efficiency of the system = output power/ input power =48/103 =0.466=46.6%

3.2 Cost estimation

Thecostestimationaroundofeachpartofthetreadlepump canbeseeninTable2.Estimatingthecostofatreadlepump involves considering several factors, including manufacturing, materials, labor, distribution, and maintenance.Here’sadetailedbreakdown:

Table-2: Costestimationofthetreadlepump.

Variable Description

Value

ValveBox Weightofthesheetper squaremeter =7.85kgf

Costofironsheetperkg =₹55

Areaofflange =119850mm2

Areaofcoverplate =312050mm2

Areaofvalveboxwalls =161000mm2

Areaoftrisectionplate =71300mm2

Areaofsmallerplate = 11883.33 mm2~11884 mm2

Totalareaofironsheetused invalvebox = 676084 mm2~0.68m2

Therefore,theareaofthe sheetbought =1m2

Costofironsheet = 7.85 x 55 = ₹

Cylinder and Piston

Assembly

431.75~₹430

Cylinderandpistoncost =₹1200

Extrapistonrod =₹200

Frame Weightoftreadlebase =4kgf

Weighofsupportingbar =1kgf

Weightofhandlebars =6kgf

Costofbarperkg =₹70

Therefore,totalcostofframe =770

Pulley Weightofpulley =3kgf

Costofpulleyandrope+ball bearing =₹500

Inlet and Outlet

Pipes

Suction

Pipe and Float

Valve

Inletandoutletpipecost =₹200

Hardsuctionpipelength =10ft costperft. =₹30

Costofsuctionpipe =₹300 costoffloatvalve(=2inches) =₹400

LaborCost =₹2000

Overall Cost = ₹ 6000 INR

Thissystemdoesnotrequirefueltoliftwater,resultingin negligiblerunningcostsandlowinstallationexpenses.Itis easytooperate,install,assemble,andmaintain.Thesystem is noiseless, vibration-free, and environmentally friendly, producing no pollution. Solely powered by manpower, it ensurescontinuousoperationwithoutpowerinterruptions. Its operational characteristics allow multitasking, such as reading, while it functions. The water flow is almost continuous,notintermittent,andthesystemcandrawwater fromadepthof3-5metersanddischargeitataheightof3-4 meters.

The water flow is partially intermittent rather than continuous,duetothepistonsmovinginoppositedirections. WhenonepistonreachesTDC(topdeadcenter),itdoesnot draw in water. The system, designed for multiple users, is bulkyandnoteasilytransportable.Whiletheinitialcostis relativelyhigh,itisnotprohibitive.However,theoperationis labor-intensive.

Thetreadlepumpisavaluabletoolinthearsenalofsmallscale farmers, particularly in developing regions. Its costeffectiveness,easeofuse,andenvironmentalbenefitsmake itanattractiveoptionforenhancingagriculturalproductivity andensuringfoodsecurity.However,addressingchallenges related to physical labor, water depth limitations, and durability is essential for maximizing its potential and ensuring widespread adoption. Through continued innovationandsupport,treadlepumpscanplayasignificant role in sustainable rural development and poverty alleviation.

In this study, the efficiency of the treadle pump was estimatedtobearound46.6%. However,theefficiencyof

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

thetreadlepumpcandependonotherfactors,includingits mechanical efficiency, water delivery rate, and the energy expenditurerequiredbytheuser.

The overall cost has been estimated based on local resourcesandworkmanshipfortheyearof2014whichwere around₹6000INR(Indianrupees).Thisstudydescribeda rough estimation, and the actual cost can vary based on location (e.g. depend on country), scale of production, efficiencyofoperations,andotherfactors.Foramoreprecise cost,adetailedanalysistailoredtothespecificcircumstances andlocalmarketconditionswouldberequired.

We would like to express our deepest gratitude to the UniversityInstituteofTechnology,RajivGandhiProudyogiki Vishwavidyalaya (UIT-RGPV), Bhopal, M.P. India, for providing the opportunity and resources to pursue this research.Theacademicenvironment,facilities,andsupport from the faculties have been invaluable in shaping and enrichingouracademicjourney.Wearealsogratefultothe DepartmentofMechanicalEngineeringanditsstafffortheir assistanceandcooperation,whichsignificantlycontributed to the smooth progress of our research. Furthermore, we want to acknowledge the Central Workshop, UIT-RGPV, Bhopal for the resources and the technical support which madethisresearchpossible.

Naresh Kumar Wagri: Methodology, Conceptualization, Writing–original draft, Formal analysis, Writing–review & editing, Visualization Kamal Kishore: Writing–review & editing. Swastishree Jain: Datacuration. Akashdeep Sahu: Investigation. Anurag Choubey: Resources. Aseem C Tiwari: Supervision.

The authors declare that they have no known competing financialinterestsorpersonalrelationshipsthatcouldhave appearedtoinfluencetheworkreportedinthispaper.

[1] Johnson NG, Bryden KM. Energy supply and use in a ruralWestAfricanvillage.Energy.2012;43(1):283-292. doi:10.1016/j.energy.2012.04.028

[2] Johnson NG, Bryden KMBTMEC. Clearing the air over cookstoves: improved cookstoves won’t save fuel or reducepollutioniftheycan’tbeincorporatedintodaily life. Gale Acad OneFile. 2013;135(11):S8+. https://link.gale.com/apps/doc/A350677235/AONE?u =anon~e688d8ce&sid=googleScholar&xid=5a448867

[3] McComb C, Johnson NG, Santaeufemia PS, et al. Multiobjective optimizationandscenario-based robustness analysis of the MoneyMaker Hip Pump. Dev Eng. 2018;3(December 2015):23-33. doi:10.1016/j.deveng.2018.01.001

[4] KalraG,KishoreK,KumarA,RajoriaYK,YadavA,Boadh R. FIS-Based Prediction and Estimation of Health Insurance for Workers in the Manufacturing Sector. J Pharm Negat Results. 2022;13(8):2636-2645. doi:10.47750/pnr.2022.13.S08.331

[5] Kishore K, Gupta N. Role of Water Containing Variant Total Dissolved Solids on Cement Mortar : Overview , andBehavior.In:AIPConferenceProceedings.Vol2721. ; 2023:020023-11. doi:https://doi.org/10.1063/5.0154034

[6] PolakP,WarwickM.TheBusinessSolutiontoPoverty: DesigningProductsandServicesforThreeBillionNew Customers. Vol 30.; 2015. https://jurnal.ugm.ac.id/v3/jieb/

[7] Cooney K, Shanks TRW. New Approaches to Old Problems:Market-Based Strategies forPoverty Alleviation. Soc Serv Rev. 2019;(March):29-55. http://www.journals.uchicago.edu/t-and-c

[8] Magistro J, Roberts M, Haggblade S, et al. A model for pro-poorwealthcreationthroughsmall-plotirrigation andmarketlinkages.IrrigDrain.2007;56(2-3):321-334. doi:10.1002/ird.300

[9] Tomar R, Kishore K, Singh Parihar H, Gupta N. A comprehensivestudyofwastecoconutshellaggregate as raw material in concrete. Mater Today Proc. 2021;44:437-443.doi:10.1016/j.matpr.2020.09.754

[10] GudainiyanJ,KishoreK.Areviewoncementconcrete strength incorporated with agricultural waste. Mater Today Proc. 2022;(xxxx). doi:10.1016/j.matpr.2022.10.179

[11] MelvynKay,BrabbenT.TreadlePumpsforIrrigationin Africa.FoodandAgricultureOrganizationoftheUnited Nations;2000.

[12] KishoreK,PandeyA,KumarN,SaxenaA.Technological challenges in nanoparticle-modified geopolymer concrete : A comprehensive review on nanomaterial dispersion , characterization techniques and its mechanical properties. Case Stud Constr Mater. 2023;19(July):e02265.doi:10.1016/j.cscm.2023.e02265

[13] PolakP,NanesB,SampleJ.OpeningAccesstoAffordable Micro-Plot Irrigation for Small Farmers. Published online1985:1-9.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

[14] NepalIDE.NaturalResourceManagementApproaches and Technologies in Nepal. ICIMOD; 2013. doi:https://doi.org/10.53055/ICIMOD.580

[15] OrrA,IslamAN,BarnesG.TheTreadlePump:Manual Irrigation for Small Farmers in Bangladesh. First. RANGPUR DINAJPUR RURAL SERVICE; 1991. http://pdf.usaid.gov/pdf_docs/pnabx290.pdf

[16] PolakP,YoderR.Creatingwealthfromgroundwaterfor dollar-a-dayfarmers: Wherethesilent revolutionand the four revolutions to end rural poverty meet. HydrogeolJ.2006;14(3):424-432.doi:10.1007/s10040005-0011-2

[17] Mangisoni JH. Impact of treadle pump irrigation technologyonsmallholderpovertyandfoodsecurityin Malawi:AcasestudyofBlantyreandMchinjidistricts. Int J Agric Sustain. 2008;6(4):248-266. doi:10.3763/ijas.2008.0306

[18] BhatS,SahaSK,GuptaV.StudyandAnalysisofTreadle Pump.ISMEJMechDes.2020;4(2):27-35.

[19] KroekerMG.Thetwin-treadlepump:manualirrigation in Bangladesh. In: University of British Columbia. ; 1989:1-96.doi:https://dx.doi.org/10.14288/1.0062828

[20] G.Barnes.Thetwin-treadlepump:manualirrigationin Bangladesh.In:SmallFarmEquipmentforDeveloping Countries:ProceedingsoftheInternationalConference on Small Farm Equipment for Developing Countries: Past Experiences and Future Priorities. International RiceResearchInstitute;1985:181-194.

[21] KishoreK,PandeyA,AbedAS.CoralConcrete :Overview ,CompositionanditsBehaviorinEnvironment.Mater SciForum.2023;1085:55-65.doi:10.4028/p-lh2v12

[22] Srinivas SN, Jalajakshi CK. Alternatives to MicroIrrigation:Evaluationof the TreadlePump.Econ Polit Wkly.2004;39(38):4271.

[23] PereiraC,MalçaJ,GasparMC,VenturaF.Humanmotion analysisintreadlepumpdevices.In:IFIPInternational Federation for Information Processing. Vol 221. ; 2006:135-145.doi:10.1007/978-0-387-36792-7_8

[24] Santaeufemia PS, Johnson NG, McComb C, Shimada K. Improving irrigation in remote areas: Multi-objective optimization of a treadle pump. Proc ASME Des Eng TechConf.2014;2A.doi:10.1115/DETC2014-35463

[25] AdeotiA,BarryB,NamaraR,KamaraA.TheImpactof Treadle Pump Irrigation Technology Adoption on PovertyinGhana.JAgricEducExt.2009;15(4):357-369. doi:10.1080/13892240903309611

[26] KumarWagriN,PetareA,AgrawalA,etal.Anoverview of the machinability of alloy steel. Mater Today Proc. 2022;62:3771-3781.doi:10.1016/j.matpr.2022.04.457

[27] Padhan S, Wagri NK, Dash L, et al. Investigation on SurfaceIntegrityinHardTurningofAISI4140Steelwith SPPP-AlTiSiNCoatedCarbideInsertunderNano-MQL. Lubricants. 2023;11(2). doi:10.3390/lubricants11020049

[28] WagriNK,JainNK,PetareA,etal.Investigationonthe PerformanceofCoatedCarbideToolduringDryTurning ofAISI4340AlloySteel.Materials(Basel).2023;16(2). doi:10.3390/ma16020668

[29] Wagri NK. Improving machinability of alloy steel. 2016;(July). https://dspace.iiti.ac.in/handle/123456789/328

[30] FandikaIR,KadyampakeniD,ZingoreS.Performanceof bucket drip irrigation powered by treadle pump on tomatoandmaize/beanproductioninMalawi.IrrigSci. 2012;30(1):57-68.doi:10.1007/s00271-010-0260-2

[31] Kamwamba-Mtethiwa J, Namara R, De Fraiture C, Mangisoni J, Owusu E. Treadle pump irrigation in Malawi: Adoption, gender and benefits. Irrig Drain. 2012;61(5):583-595.doi:10.1002/ird.1665

[32] Kishore, K., Sheikh, M.N. and Hadi, M.N., 2025. Functionalization of Carbon Nanotubes for Enhanced Dispersion and Improved Properties of Geopolymer Concrete: A Review. Journal of Building Engineering, p.113096.

[33] Kishore, K., Sheikh, M.N. and Hadi, M.N., 2024. Doped multi-walled carbon nanotubes and nanoclay basedgeopolymer concrete: An overview of current knowledgeandfutureresearchchallenges.Cementand ConcreteComposites,p.105774.

[34] Gudainiyan,J.,Gupta,P.K.andKishore,K.,2023,August. A Base Isolated Building Under Seismic Loading at VariousAngleofIncidence.InInternationalConference on Construction, Real Estate, Infrastructure & Project Management (pp. 1-9). Singapore: Springer Nature Singapore.

[35] Kishore,K.,Sheikh,M.N.andHadi,M.N.,2024.Acritical analysisofelectricarcfurnace(EAF)slagforsustainable geopolymer concrete production. Materials Today Sustainability,p.101064.

[36] Kishore,K.andGupta,N.,2019.Experimentalanalysis oncomparisonofcompressivestrengthpreparedwith steel tin cans and steel fibre. Int. J. Res. Appl. Sci. Eng. Technol, 7(4),pp.169-172.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | July 2025 www.irjet.net p-ISSN: 2395-0072

[37] Kishore, K., Gupta, N., Saxena, K.K. and Lade, J., 2022. Development and characterisation of bacteria as a potential application in enduring the mechanical and durabilitycharacteristicofcementcomposite. Advances in Materials and Processing Technologies, 8(sup3), pp.1604-1621.

[38] Sharma, S., Vaishali, Pandey, A., Garg, A., Sharma, P., Bhatrola,K.,Irfan,A.,Devi,N.,Rubab,L.,Mishra,K.and Dubey, K., 2025. Reusable Magnetic Nanoparticles: A GreenSystemforSynthesisofPyrroleScaffolds. Journal of Heterocyclic Chemistry, 62(2),pp.164-191.

[39] Sharma, S., Vaishali, Pandey, A., Rani, S., Sharma, P., Mishra,K.,Kumar,A.,Kumar,H.andDhyani,A.,2025.An Untold Story of Ionic Liquid for the Isatin Derivative Synthesis. Current Organic Chemistry, 29(16),pp.12401255.

[40] Jain, S., Jain, R., Wagri, N.K., Sikarwar, A.S., Khaire, S.J., Dewangan, S.K., Jeon, Y. and Ahn, B., 2025. Reducing experimental dependency: Machine-learning-based predictionofCoeffectsonthemechanicalpropertiesof AlCrFeNiCox high-entropy alloys. Materials Today Communications, 44,p.112055.

[41] Jain, S., Wagri, N.K., Bhowmik, A. and Park, N., 2025. MachineLearningApproachesforPredictingMechanical Performance and Reducing Experimentation in RefractoryHigh‐EntropyAlloys. Advanced Engineering Materials, 27(12),p.2403052.