International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Fidha Fathima P J1 , Dr. George K George2 , Muhammed Ajmal3, Lakshmy E G4

1M.Tech Student, Structural Engineering, KMEA Engineering College, Kerala, India

2Assistant Professor, Dept. of Civil Engineering, KMEA Engineering College, Kerala, India

3Assistant Professor, Dept. of Civil Engineering, KMEA Engineering College, Kerala, India

4Assistant Professor, Dept. of Civil Engineering, KMEA Engineering College, Kerala, India ***

Abstract - Stainless Steel Corrugated Core Plate Walls (SSCPWs) represent a novel class of structural wall systems composed of thin stainless steel face plates interconnected by stainless steel core tubes arranged orthogonally. In this study, a novel bi-directional corrugated SSCPWs is analyzed under axial compression. A parametric investigation is conducted to evaluate the effects of variables such as core tube spacing, tube diameter, and face plate thickness across two distinct wall geometries: L-shaped and T-shaped. Additionally, the study examines how core tube connectors and geometric configurations influence the ultimate load-carrying capacity of the corrugated SSCPWs. Finite Element Analysis (FEA) is carried out using ANSYS Workbench 2024 R2 to simulate the structural behaviour under compressive loads.

Key Words: Stainless Steel Core Plate Wall (SSCPW), bidirectionalcorrugatedSSCPW,axialcompression,coretubes, ultimateloadcarryingcapacity,AnsysWorkbench2024R2

Thebi-directionalstainlesssteelcoreplatewall(SSCPW)is intendedtooffersuperiorperformanceinbothseismicand non-seismic applications by enhancing lateral force resistance in two orthogonal directions. This multidirectional stability enables the system to efficiently distribute loads under varying conditions Typically, an SSCPWconsistsofdualstainlesssteelplatesconnectedby orthogonallyplacedcoretubes,withcopperbrazingusedto weldthecomponents.Thesewallscanbemanufacturedin various configurations, including T-shaped, L-shaped, or cross-shaped layouts, depending on architectural and structuralneeds.Bymodifyingthearrangement,SSCPWscan servemultiplestructuralpurposessuchasbeams,columns, floors,orwallcomponents.[1,2]

L-shapedcorewallsareparticularlysuitedforbuildingswith irregularorasymmetricfloorplans.Theyareoftenplacedat corners, where enhanced torsional rigidity is required, or usedtoencloseservicecoreslikestairwellsorelevatorshafts.

T-shapedcorewalls,ontheotherhand,aredeployedwhere structural resistance is needed in two perpendicular

directions.Thesearecommonlylocatedalongmajoraxesor centrally within buildings, integrating with vertical circulation elements. Their unique shape enables efficient force transfer and reduces reliance on moment-resisting frames,whichhelpsinachievingopenandflexibleinterior layouts.Theirconfigurationallowsthemtoactasacentral spine,providingstiffnessandstrengthintwodirections.[1,2]

The corrugated profile of SSCPWs, especially when using trapezoidalpatterns,contributessignificantlytoimproved mechanicalperformance.Comparedtoflatplatesystemsof equivalent thickness, corrugated designs offer superior ductility, energy dissipation, and load-bearing capacity. Thesecharacteristicsmakethemhighlysuitableforusein earthquake-pronezones,whereabsorptionanddissipation of seismic energy are critical. Moreover, the corrugations enhance impact resistance by absorbing local stresses through deformation, effectively limiting damage. This increasedstiffnessalsoallowsforthinnerpanelstobeused withoutcompromisingstrength,reducingtheoverallweight of the structure and potentially lowering foundation demandsandinstallationtime.

The main objective of this research is to conduct a comprehensivecomparativestudyontheaxialload-carrying capacities of T-shaped and L-shaped corrugated stainless steelcoreplatewalls,focusingontheirstructuralbehavior, load distribution mechanisms, and overall performance underaxialloadingconditions,inordertoidentifythemost efficientconfigurationforstructuralapplications.

Toevaluatetheaxialcompressiveperformanceofthenovel bi-directionalcorrugatedSSCPWs,advancedfiniteelement simulationswereconductedusingANSYSWorkbench2024 R2.Non-linearanalysisisemployedtoinvestigatetheplastic behaviour of bi-directional corrugated stainless steel core plate walls, specifically in T-shaped and L-shaped

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

configurations.Theincorporationofcorrugatedcoreplates significantly improves vertical stiffness, enhances loadbearingcapacity,andincreasesresistancetobuckling.

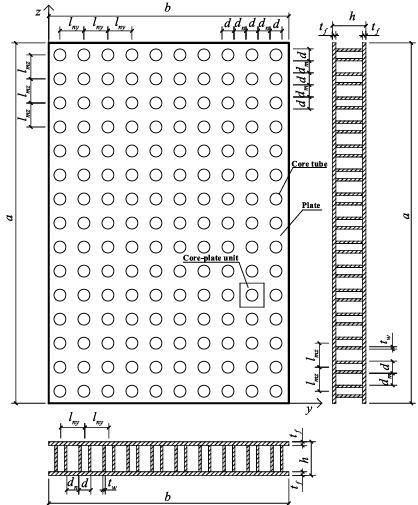

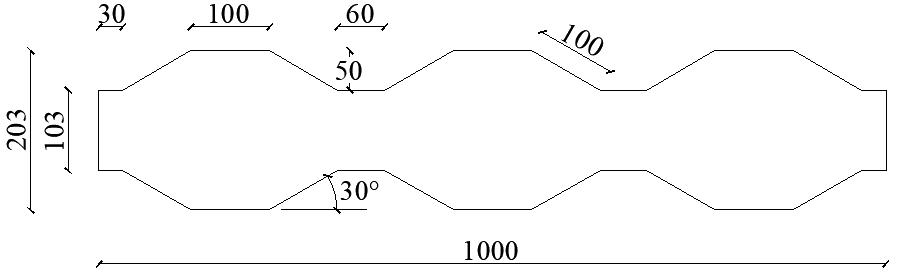

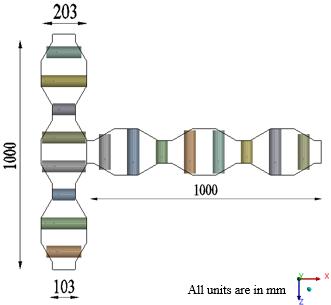

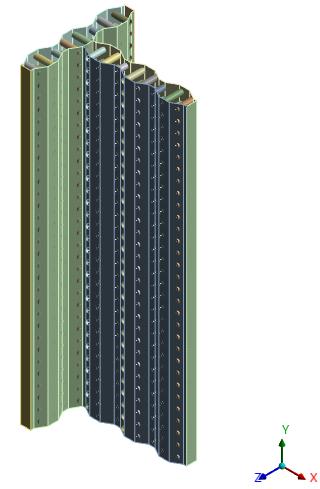

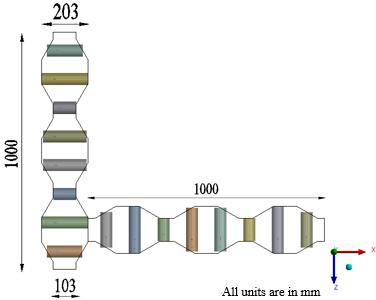

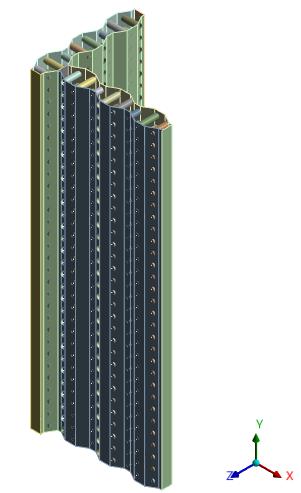

Thegeometryofthebi-directionalSSCPWwascreatedusing ANSYSDesignModeler.Boththefaceplatesandcoretubes weremodeledfromausteniticstainlesssteelgradeS30408. ThegeometricdetailsoftheSSCPWspecimenareillustrated in Fig -1, with corresponding parameters summarized in Table1.Theoverallheight,widthandthicknessofthewall are denoted by a, b and h, respectively, while b1 and b2 representsthewidthoftwowalllimbs.Theplatethicknessis indicated by tf. For the core tubes, d represents the outer diameter, and tw isthecore tube thickness.Thecenter-tocenter distance between the tubes is defined as lmz in the vertical direction and lny in the horizontal directions. Correspondingly, the clear spacing between adjacent core tubesisdenotedasdm anddn fortheverticalandhorizontal orientations, respectively. Fig -2 displays the geometric parametersofthetrapezoidalcorrugatedplate,whileFig-3 andFig-4representthetopandisometricviewsoftheTshapedandL-shapedSSCPWspecimens,respectively.The materialpropertiesforthestainlesssteelusedareprovided inTable2.Toaccuratelycapturetheplasticbehaviorofthe material, a multi-linear isotropic hardening model was employed[1,2]

-1: SpecificationofdesignparametersofSSCPW GeometricParameters

Lengthofwall(b)

ofwall(a)

ofwall(h)

ofsteelplate(tf)

ofcoretube(d)

ofcoretube(tw)

Spacingofcoretubesinhorizontaldirection(lny)

mm

mm

Spacingofcoretubesinverticaldirection(lmz) 100mm

Material Poisson’s ratio

Fig -3:TopviewandisometricviewofT-shaped corrugatedSSCPW

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Fig -4:TopviewandisometricviewofL-shaped corrugatedSSCPW

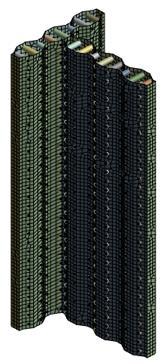

3.3 Meshing

Meshingdividesthewholecomponentintoafinitenumber ofsmallelementsasperrequirement.Adaptivesizemeshing of50mmsizeisusedforthemeshingofthespecimenmodel. TheelementtypeusedforconnectorisBEAM188,andfor the plates SHELL 181 is used. The element shape used is quadrilateral.

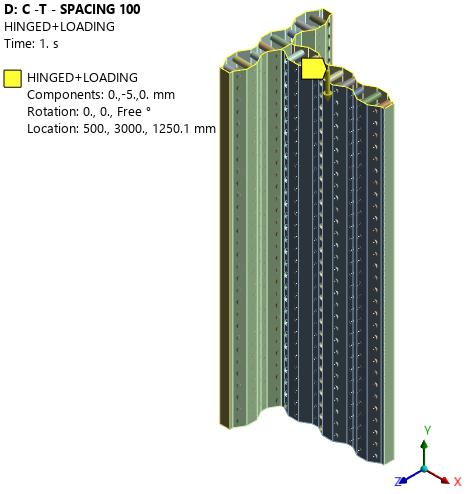

The boundary conditions are set to simulate realistic constraints: the bottom of the SSCPW model is fully fixed, restrainingalldegreesoffreedom,whilethetopishinged, allowing rotation but restricting horizontal movements in the X and Y directions. A displacement-controlled compressiveloadisappliedalongthecentroidalaxisofthe modeltoreplicateaxialcompression.Fig -5illustratesthe meshingpatternandtheapplicationpointofaxialloadon theT-shapedcorrugatedSSCPW.

Fig -5:TotaldeformationofT-shapedandL-shaped corrugatedSSCPW

4.1 Comparative Study of the Axial Load Carrying Capacity of T And L-Shaped Corrugated SSCPW

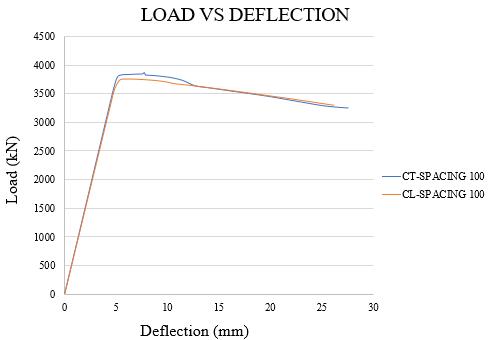

AcomparativestudyofTandL-shapedcorrugatedSSCPW under axial loading was done In this study, models of 2.5 mmplatethickness,51mmcoretubediameterand100mm verticalspacingofcoretubeswereconsidered.Thicknessof thecoretubesweretakenas0.5mmforallthemodels.Chart -1showstheloadvsdeflectiongraphoftheTandL-shaped corrugated SSCPW. Table 3 shows the ultimate load and deformationvaluesoftheSSCPW.CT-SPACING100andCLSPACING 100 represents corrugated T-shaped and corrugatedL-shapedcorewallswith100mmverticalspacing ofcoretubesrespectively.

Chart -1:LoadvsdeflectioncurveofTandL-shaped corrugatedSSCPW

Table -3: FEAresultsofTandL-shapedcorrugated SSCPWunderaxialload

Fromthejournals,theaxialloadcapacityofTandL-shaped flat type SSCPW were 1400 kN and 1180 kN. Axial load capacity of T-shaped corrugated SSCPW increased by 2.76 times and for the L-shaped wall the axial load capacity increasedby2.18times,whencomparedwiththeflattype SSCPWofTandL-shapes.[1,2]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

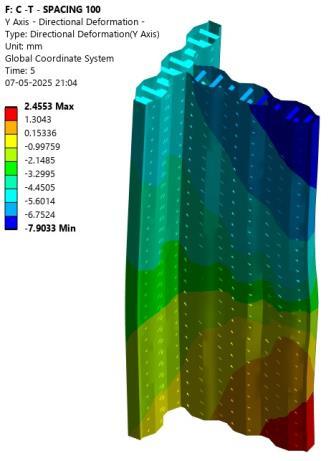

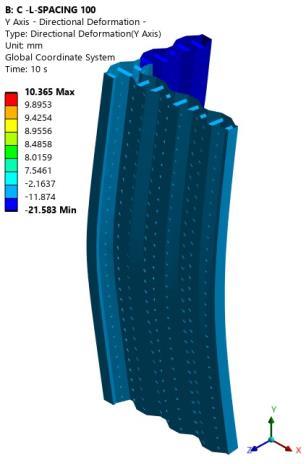

Underaxialloading,T-shapedwallsexhibitedconsistently higher load-bearing capacity than L-shaped walls under similar configurations. There was an approximately 3.1% increaseintheloadcarryingcapacityinT-shapedwallsthan in L-shaped walls. This is attributed to the geometric efficiencyoftheT-shapedcross-section,whichhasagreater momentofinertiaandsectionaldepth,leadingtoenhanced bucklingresistanceandbetteraxialforcedistribution.TheTshapedwallstendtohavemoresymmetricallateralstiffness, minimizingstressconcentrationsatre-entrantcornersand promotingamoreuniformstressflowundercompression. Fig-6showsthetotaldeformationdiagramsoftheTandLshapedcorrugatedSSCPWs.

Fig -6:DeformationshapesofT-shapedandL-shaped corrugatedSSCPW

5. CONCLUSION

TheloadcarryingcapacityoftheSSCPWswereincreasedby introducingcorrugationstotheplatesofthecorewall.These bi-directional corrugated walls were tested under axial loadingconditionsbyvaryingdifferentparameterssuchas platethickness,coretubediameterandverticalspacingof thecoretubes.Also,theinfluenceofthecoretubesandthe efficiencyofthegeometricshapeofthecorewallswerealso studied.

Themainconclusionsobtainedfromtheanalysisare:

• Axial load capacity of T-shaped corrugated SSCPW increasedby2.76timesandfortheL-shapedwalltheaxial loadcapacityincreasedby2.18times,whencomparedwith theflattypeSSCPWofTandL-shapes

• AxialloadcapacityofT-shapedcorrugatedSSCPWis3.1% morethantheL-shapedwall.Thisincreaseisattributedto the geometric efficiency of the T-shaped cross-section, leading to enhanced buckling resistance and better axial forcedistribution.

• The T-shaped corrugated SSCPW with 2.5mm plate thickness,51mmouterdiameterofcoretubesand100mm

vertical spacing of cores provided the maximum load carryingcapacityunderaxialloading.

[1] X.P.Shu,H.B.Wang,Y.Li,Z.S.Yuan,K.Li(2021),“Study on the bearing resistance of axially compressed Lshaped stainless steel core plate wall based on the stabilityloss”,EngineeringStructures,249,113264.

[2] X.P.Shu,S.Yan,Y.Li,B.R.Lu(2021),“Strengthdesignof T-shaped stainless steel core plate wall under axial compression”,Journal of Constructional Steel Research,186,106891.

[3] Z. X. Li, C. X. Guo (2008), “Nonlinear finite element analysisofL-shapedcolumnunderaxialcompression”, SteelConstruction,23(5),11-13.

[4] F.Emami,M.Mofid,A.Vafai(2013),“Experimentalstudy on cyclic behavior of trapezoidally corrugated steel shearwalls”,EngineeringStructures,48,750-762.

[5] M.R.M.Rejab,K.Ushijima,W.J.Cantwell,(2014),“The shear response of lightweight corrugated core structures”, Journal of Composite Materials,48 (30), 3785-3798.

[6] E. Hosseinpour, S. Baharom, Y. Yadollahi, (2015), “Evaluationofsteelshearwallsbehaviorwithsinusoidal and trapezoidal corrugated plates”, Advances in Civil Engineering,1,715163.

[7] M.Bahrebar,M.Z.Kabir,M.Hajsadeghi,T.Zirakian,J.B.P. Lim,(2016),“Structuralperformanceofsteelplateshear wallswithtrapezoidalcorrugationsandcentrally-placed square perforations”, International Journal of Steel Structures, 16(3),845–855.

[8] L. Hosseinzadeh, F. Emami, M. Mofid, (2017), “Experimental investigation on the behavior of corrugated steel shear wall subjected to the different angleoftrapezoidalplate”, The Structural Design of Tall and Special Buildings, 26(17),e1390.

[9] A. Farzampour, I. Mansouri, J. W. Hu, (2018), “Seismic behaviorinvestigationofthecorrugatedsteelshearwalls considering variations of corrugation geometrical characteristics”, Structures,16,1–10.

[10] H. Fadhil, A. Ibrahim, M. Mahmood, (2018), “Effect of CorrugationAngleandDirectiononthePerformanceof Corrugated Steel Plate Shear Walls”, Civil Engineering Journal, 4(9),2063–2074.

[11] Y.L.Guo,J.S.Zhu,M.Z.Wang,X.Yang,P.Zhou(2018), “Overall instability performance of concrete-infilled double steel corrugated-plate wall”, Thin-Walled Structure,130,372-394.

[12] Y.Wang,Z.Gao,Q.Han,L.Feng,H.Su,N.Zhao,(2018), “Experimentalstudyontheseismicbehaviorofashear

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

wall with concrete-filled steel tubular frames and a corrugatedsteelplate”, The Structural DesignofTalland Special Buildings, 27(15),e1509.

[13] M. M. Wang, Y. L. Guo, J. S. Zhu, X. Yang, J. Z. Tong, (2019), “Sectional strength design of concrete-infilled double steel corrugated-plate walls with T-shaped”, Journal of Construction Steel Research,160,23-44.

[14] S Yan(2019),“StudyonBearingCapacityofStainless Steel Core T-Shaped Wall under Axial Compression”, MasterDissertation,HunanUniversity,Changsha.

[15] Aswathy Mathew & Aju Sankarathil (2021), “AssessmentofSingleandDoubleCorrugatedSteelPlate Shear Walls for Seismic Performance” Revista ElectronicadeVeterinaria,22,37-44.

[16] A.Suresh,P.Dilip,(2021),“EffectofPlateThicknessof StainlessSteelCorePlateWallonLoadCarryingCapacity under Pure Shear and Compression Shear Conditions”, Journal of Civil and Building Materials Engineering,5(2), 1–8.

[17] S. M. Ghodratian Kashan & Maleki Shervin (2021), “Numerical Investigation of Double Corrugated Steel Plate Shear Walls”, Journal of Civil Engineering and Construction,10(1),44-58.

[18] Y.Liu,X.Xue,(2021),“Nonlinearbehaviorofstainless steelcoreplateshear wallssubjectedtocyclicloading”, Journal of Constructional Steel Research,182,106698.

[19] Z. Chen, Z. Zi, T. Zhou, Y. Wu, (2021), “Axial compression stability of thin double-steel-plate and concrete composite shear wall”, Structures, 34, 38663881.

[20] K A HibaFarhana,Dr.SSyedIbrahim,P K Rashida (2022),“StructuralPerformanceofOrthogonalandFlat Type Stainless-Steel Plated Shear Wall”, International JournalofEngineeringResearch&Technology,11,07.

[21] F. Wang, G. Chen, H. Zhang, (2022), “Stability and strengthanalysisofstainlesssteelcompositeshearwalls under axial compression”, Thin-Walled Structures, 173, 108598.

[22] J Li, Z Wang, F Li, B Mou & T Wang, (2022), “Experimental and numerical study on the seismic performance of an L-shaped double-steel plate compositeshearwall”, Journal of Building Engineering, 49,104015.

[23] Lv Y., (2022), “Corrugated Steel Plate Shear Wall ConsideringtheGravityLoad”, SteelPlateShearWallswith Gravity Load: Theory and Design,165–188.

[25] Z. Xu, H. Chen, Z. Qu, C. Zhu, X. Wang (2022), “Nondestructive testing of local incomplete brazing defect in stainless steel core panel using pulsed eddy current”,Materials,15(16),5689.

[26] ChaithanyaandC Nijesh(2023),“NumericalStudyon Cross-shaped Stainless Steel Core Plate Wall”, International Journal of Engineering Research & Technology,11,02.

[27] S. Kim, S.Lee,(2023), “Effectof stiffenersontheaxial and lateral load capacity of stainless steel core plate walls”, Journal of Structural Engineering, 149 (2), 04023005.

[28] ZandSeyedeh,KalatjariVahidReza,AttariNader,(2023), “Cyclic Behavior of New Steel Plate Shear Walls ReinforcedwithTrapezoidalCorrugatedPlates, Periodica Polytechnica Civil Engineering,68(1),141–153.

[29] E.Ghorbani,M.Mofid,(2024),“Bi-directionalcorrugated stainlesssteelshearwalls:Energydissipationandfailure modes”, Journal of Building Engineering, 85,107123.

[30] M.Y.AbdEl-Latif,M.Yossef,A.Chen,M.Elsayad,(2024), “Behavior of stressed skin corrugated sheet under hydrostatic loads”, Case Studies in Construction Materials,20,03343.

[31] X. Mo, Z. Yuan, Y. Jia, L. Lu, X. Wei, N. Ke, (2024), “An Experimental and Numerical Parametric Study on a Novel T-Shaped Steel–Concrete Composite Shear Wall”, Buildings,14(7),2148.

[32] Y.Zhang,C.Wu,Y.Huang,(2024),“Seismicperformance evaluationofstainlesssteelcoreplatewallswithdifferent corrugationgeometries”, Soil Dynamics and Earthquake Engineering,157,107498.

[33] Z.Q.Jiang,A.L.Zhang,L.Su,J.J.Wang,H.Zhang,(2024), “Experimentalstudyofaxialcompressiveloadcapacityof internallystiffeneddoublesteelplateshearwall”, Journal of Constructional Steel Research,216,108566.

[34] Hu Yuanyuan & Yan Xianhui (2025), “Investigation of the lateral performance of trapezoidal double corrugated steel shear walls with two different corrugationangles”,JournalofEngineeringandApplied Science,72(1),21

[35] Khadka Binod, He Liusheng, (2025), “Experimental investigationonthecompressivebehaviorofcorrugated steel plate reinforced concrete shear walls”, Structural Concrete,1-13.

[24] M.Chen,J.Tang,X.Zhou,(2022),“Finiteelementanalysis ofstainlesssteelcoreplate wallsundercombinedaxial and lateral loading”, International Journal of Steel Structures,22(4),1321–1333.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

[36] L.Wu,Q.Nie,X.Wang,H.Cui,H.Wu,(2025),“Numerical investigation on out-of-plane behavior of unilateral stainless steel double-steel-plate composite shear walls”, Structures,72,108307.

[37] S.D.Li,X.G.Liu,(2025),“Experimentalinvestigationof innovativehigh-bearingandlarge-deformationsteelplate shearwallutilizingtrapezoidalcorrugatedpanel”, ThinWalled Structures,209,112950.

[38] Y.Lai,L.Xu,Y.Zhang,J.Zhang,B.Wang,Y.Chen,(2025), “Theoreticalandnumericalanalysisofbucklingstability ofbi-directionalcorrugatedsandwichpanels”, Ships and Offshore Structures, 20(3),347–363.

[39] L.Wu,Q.Nie,X.Wang,H.Cui,H.Wu,(2025),“Numerical investigation on out-of-plane behavior of unilateral stainlesssteeldouble-steel-platecompositeshearwalls”, Structures,72,108307.

[40] S.D.Lie,X.G.Liu,(2025),“Experimentalinvestigationof innovativehigh-bearingandlarge-deformationsteelplate shearwallutilizingtrapezoidalcorrugatedpanel”, ThinWalled Structures,209,112950.