International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Dr. P. Senthamilselvi 1 , A. Aakash 2

1Associate Professor, Department of Civil Engineering, Government College of Engineering, Salem, Tamil Nadu, India

2P.G. Student, Department of Civil Engineering, Government College of Engineering, Salem, Tamil Nadu, India ***

Abstract - This experimental study evaluates the mechanical and durability characteristics of Geopolymer Concrete (GPC) formulated with Fly Ash and Ground Granulated Blast Furnace Slag (GGBS) as binders. The study further investigates the enhancement provided by varying contents of steel fibers (0%, 0.25%, 0.5%, 0.75%, and 1%). Mechanical performance was assessed through compressive, split tensile, and flexural strength tests at 7 and 28 days. Durability was evaluated using water absorption, acid and sulphate resistance, and sorptivity tests. Reinforced GPC beams (with and without fibers) were tested under two-point loading and validated using ANSYS finite element analysis. The results showed 0.75% steel fiber yielded the highest improvements in strength and durability, proving its potential in structural applications.

Key Words: Geopolymer Concrete, Fly Ash, GGBS, Steel Fiber, Compressive Strength, Durability, Flexural Strength, ANSYS, Ambient Curing

Therapidgrowthofinfrastructuredevelopmenthasledtoa massive increase in the production of Ordinary Portland Cement (OPC), which is a major contributor to global CO₂ emissions.Toovercometheenvironmentalissuescausedby cementproduction,geopolymerconcrete(GPC)hasemerged as a sustainable alternative. GPC utilizes industrial byproductslikeflyashandGroundGranulatedBlastFurnace Slag (GGBS) as binders, activated by alkaline solutions, eliminating the need for traditional cement. Geopolymer concrete is known for its high early strength, low permeability,andexcellentresistancetochemical attacks. However, like conventional concrete, it suffers from brittleness and low tensile strength. To address this, steel fibers are incorporated into the mix, which help improve ductility,crackresistance,andtoughness.Thisstudyfocuses onM30-gradegeopolymerconcretewithvaryingsteelfiber contents (0% to 1%) under ambient curing conditions. Mechanicalpropertiessuchascompressive,splittensile,and flexuralstrengthweretested,alongwithdurabilitytestslike waterabsorption,acidresistance,sulphateresistance,and sorptivity.Reinforcedgeopolymerbeamswerealsotested underflexuralloadingandvalidatedthroughANSYSfinite element analysis. The aim is to identify the optimal fiber content that enhances both strength and durability,

promotinggeopolymerconcreteasasustainableandhighperformancematerialforstructuralapplications.

Ganesan et al. (2014) – Influence of Steel Fibres on Tension Stiffening and Cracking of Reinforced Geopolymer Concrete

Thisstudyinvestigatedthebehaviorofgeopolymerconcrete (GPC) reinforced with varying volumes of crimped steel fibersanditseffectontensionstiffeningandcracking.The resultsshowed thatas fiber content increased, the tensile stiffness improved significantly, and crack widths and spacingreduced.Theauthorsconcludedthattheinclusionof steel fibers greatly enhanced the ductility and post-crack performanceofGPC,makingitsuitableforstructuraluse.In the current study, a similar improvement in crack control and first crack load was observed in the fiber-reinforced beams, particularly at 0.75% fiber dosage, validating the findingsofthisresearch.

Rashad et al. (2020) – Effect of Steel Fibers on Geopolymer Properties

This paper presents a comprehensive review of previous workontheinfluenceofsteelfibersonthemechanicaland durability properties of geopolymer concrete. The study highlightsthattheadditionofsteelfibersresultsinhigher compressive, flexural, and tensile strengths while also enhancingductility,energyabsorption,andtoughness.The authors also noted that fiber content beyond a certain threshold (typically around 1%) may lead to workability issuesorreducedperformance.Thisdirectlysupportsthe current research, where the optimum performance was recordedat0.75%fibercontent,whileaslightreductionwas seen at 1%, suggesting a balance is required between strengthgainandworkability.

Almutairi et al. (2021) – Potential Applications of Geopolymer Concrete in Construction

In this study, the environmental and practical benefits of geopolymerconcretewereexplored,withafocusonlargescale applications. The authors emphasized the use of ambient curing as a practical alternative to heat curing,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

makingGPCmoreviableforin-situconstruction.Theyalso stressedtheimportanceofintegratingreinforcingfibersto overcome the brittle nature of GPC. The present study closely follows this recommendation by using ambient curingconditionsandincorporatingsteelfibers,resultingin improved mechanical performance and field applicability. Theuseofambient-cured,steelfiber-reinforcedGPCbeams further affirms its structural potential as outlined in this literature.

Steel fibers are added to concrete to improve its tensile strength,crackresistance,andoverallductility.Inthisstudy, hooked-end steel fibers were used due to their better bondingandanchoragewithinthegeopolymermatrix.These fibershadatensilestrengthof1620N/mm²andaspecific gravityof7.85.Theywereincorporatedinvaryingdosages (0% to 1%) to evaluate their effect on strength and durability. The optimum performance was observed at 0.75%,showingsignificantimprovements incompressive, tensile, and flexural strength, as well as enhanced crack controlandpost-crackbehavior.

4.1 Literature Review and Problem Definition

Anextensiveliteraturereviewwascarriedouttounderstand theexistingresearchongeopolymerconcreteandtheeffects ofsteel fibersonitsmechanical anddurabilityproperties. The review highlighted the growing interest in replacing cementwithindustrialby-productslikeflyashandGGBSto produce eco-friendly concrete. However, limited studies wereavailableontheperformanceofsteelfiber-reinforced geopolymer concrete under ambient curing conditions, especially with full-scale structural elements like beams. Thisgapservedasthefoundationforthecurrentstudy.

4.2

TheprimarymaterialsusedinthisstudyincludeClassFfly ash and ground granulated blast furnace slag (GGBS) as binders.Analkalineactivatorcomposedof12molarsodium hydroxide(NaOH)andsodiumsilicate(Na₂SiO₃)ina1:2.5 ratiowasprepared24hoursinadvance.M-sandconforming to Zone II was used as fine aggregate, and 20 mm size crushedgranitewasusedascoarseaggregate.Hooked-end steelfiberswithatensilestrengthof1620N/mm²andan aspect ratio of 60 were selected to enhance ductility and crack resistance. The steel fibers were incorporated in varying dosages: 0%, 0.25%, 0.5%, 0.75%, and 1% by volumeofbinder.

TheconcretemixwasproportionedtoachieveM30grade strengthusingIS10262:2009andIS456:2000guidelines

Thefinalizedmixratiowas1partbinder(FlyAsh+GGBS), 1.6partsfineaggregate,2.9partscoarseaggregate,and0.45 partsalkalineliquid.Thealkalineliquid-to-binderratiowas keptconstantat0.45forall mixestomaintainuniformity. Trialmixeswereconductedtoconfirmtheworkabilityand strengthcharacteristicsbeforecastingthefinalspecimens.

Concrete specimens were cast for both mechanical and durability tests. The specimen types included cubes (100×100×100 mm) for compressive strength, cylinders (150×300 mm) for split tensile strength, prisms (100×100×500 mm) for flexural strength, and reinforced beams (1000×150×150 mm) for structural analysis. All specimensweredemouldedafter24hoursandcuredunder ambient environmental conditions (open air, room temperature) for a period of 28 days. No water or heat curingwasapplied,simulatingreal-timefieldapplication.

Mechanical testing was conducted at 7 and 28 days. Compressive strength was determined using cube specimens,whilesplittensilestrengthwasmeasuredusing cylindrical specimens. Flexural strength was assessed on prismspecimensundertwo-pointloadingasperIS516.All testswereperformedinaccordancewiththerespectiveIS code procedures using calibrated digital compression and flexuretestingmachines.

Durabilitybehavioroftheconcretewasevaluatedthrough water absorption, acid resistance, sulphate attack, and sorptivitytests.Waterabsorptionwascalculatedbasedon themassdifferencebeforeandafterimmersion,following ASTM C642-81. For acid resistance, specimens were immersedin5%hydrochloricacidsolutionfor28days,and their strength and weight loss were recorded. Sulphate resistance was assessed by exposing samples to sodium sulphate solution, and sorptivity was evaluated by measuringtherateofcapillarywateruptakefromonefaceof thespecimen.

Twofull-scalereinforcedgeopolymerconcretebeamswere cast, one without fibers (GPC–SF 0%) and the other with 0.75%hooked-endsteelfibers(GPC–SF0.75%).Thebeams weretestedundertwo-pointloadingusingahydraulicjack. Linear Variable Differential Transformers (LVDTs) were placedatL/3,L/2,and2L/3positionstomeasuremid-span deflections.Thefirstcrackload,ultimateload,crackpattern, andmaximumdeflectionwererecordedforanalysis.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

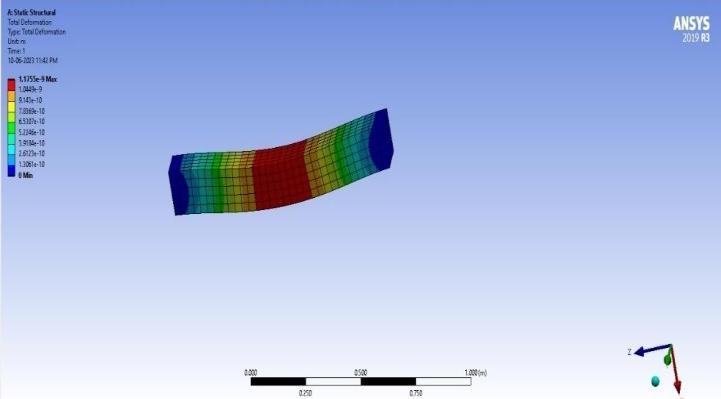

4.8 Finite Element Analysis (ANSYS

In parallel with the experimental program, finite element analysis of the reinforced beams was carried out using ANSYSWorkbench.Theconcreteportionsofthebeamwere modeled using SOLID185 elements, while the internal reinforcementwasmodeledusingLINK180elements.The same loading and boundary conditions used in the experimentalsetupwerereplicatedinthesimulation.The resultsincludingload-deflectioncurves,crackpropagation, andstressdistributionwereextractedandcomparedwith experimentaldatatovalidatetheaccuracyofthesimulation model.

rise.Thecompressivestrengthincreasedfrom32.56MPain thecontrolmixto46.65MPaat0.75%fiberdosage.Thesplit tensile strength followed a similar trend, increasing from 1.874 MPa to 3.538 MPa, while the flexural strength rose from 2.839 MPa to 5.360 MPa over the same fiber range. However,at1%fibercontent,aslightdropinallstrengths was observed, which is attributed to reduced workability andpotential clustering offibers withinthematrix. These results confirm that the optimum steel fiber dosage for maximizingstrengthis0.75%.

The incorporation of steel fibers also enhanced the durability performance of geopolymer concrete. Water absorptionvaluesdecreasedprogressivelywithincreasing fiber dosage, indicating improved matrix density and impermeability. At 0% fiber, the water absorption was recordedat5.2%,whichreducedto3.7%forthe0.75%fiber mix.Acidresistancewasevaluatedbyimmersingspecimens in hydrochloric acid solution, where the strength loss droppedfrom13.3%inthecontrolmixto9.2%inthe0.75% fibermix.Similarly,thesulphateresistancetestshowedthat strength degradation due to exposure to sodium sulphate wasreducedfrom17.1%to11%.Sorptivity,whichmeasures capillary water ingress, decreased from 0.0335 mm/√s in thecontrolmixto0.0312mm/√sintheoptimizedfibermix. These findings demonstrate the role of steel fibers in reducing permeability, refining pore structure, and improvingtheoveralldurabilityoftheconcrete.

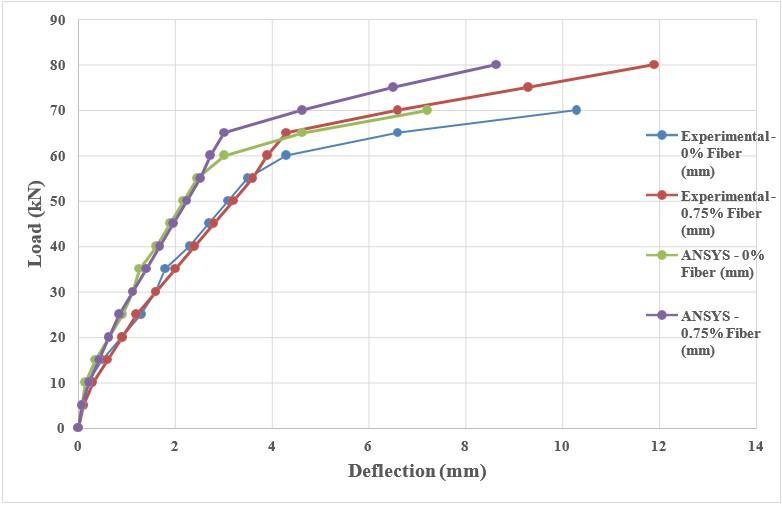

Two reinforced geopolymer concrete beams were tested under two-point loading to study flexural behavior, one without fibers and another with 0.75% steel fibers. The fiber-reinforcedbeamexhibitedimprovedfirstcrackload, higherultimateload,andbetterpost-crackingperformance. Crackpropagationinthecontrolbeaminitiatedearlierand extendedrapidly,whileinthefiberedbeam,thecrackswere narrower and more distributed. The load-deflection response showed that the beam with 0.75% steel fiber sustainedhigherloadswithgreaterdeflections,indicating betterenergyabsorptionandductility.Theincorporationof steel fibers effectively enhanced the beam’s structural integrityanddeformationcapacityunderflexuralstress.

5. RESULTS AND DISCUSSION

5.1 Strength Results

The mechanical strength of geopolymer concrete was evaluated through compressive, split tensile, and flexural strengthtestsconductedat28daysformixeswithvarying steelfibercontent.Asthefibercontentincreasedfrom0%to 0.75%,all threestrength parametersshoweda significant

FiniteelementanalysiswasperformedinANSYSWorkbench to model the same reinforced beams that were tested experimentally.TheconcretewasmodeledusingSOLID65 elementsandreinforcementusingLINK180elements.The simulation used the same material properties, loading conditions,andsupportconstraintsasinthephysicaltests. Theload-deflectionresultsobtainedfromtheANSYSmodel were in good agreement with experimental data. For the GPC-SF(0%) beam, the maximumloadobservedin ANSYS

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

was 52 kN compared to 55 kN experimentally, and the midspandeflectionwas3.2mmcomparedto3.5mm.Inthe caseoftheGPC-SF(0.75%)beam,theANSYSmodelpredicted amaximumloadof68kNandadeflectionof4.4mm,closely matchingtheexperimentalvaluesof70kNand4.6mm.The deviationbetweenexperimentalandsimulatedvalueswas within5%,whichvalidatestheaccuracyandreliabilityofthe finiteelementmodel.ThecorrelationconfirmsthatANSYS can be effectively used to predict flexural performance of steelfiberreinforcedGPCbeams.

Table -1: 28DaysStrengthTestResultsofGPCwith VaryingSteelFiberContent

The main objective of this study is to evaluate the mechanicalandflexuralperformanceofflyashandGGBSbased geopolymer concrete (GPC) incorporated with hooked-end steel fibers. Parameters such as compressive, tensile, and flexural strengths, durability against chemical attack,crackpropagationbehavior,andsimulationaccuracy wereassessed,leadingtothefollowingconclusions:

1. Theadditionofsteelfiberssignificantlyenhancesthe mechanical properties of geopolymer concrete, with 0.75%fibercontentyieldingthehighestcompressive, tensile,andflexuralstrengths.

2. Fiber reinforcement improves crack bridging and ductility, allowing GPC beams to sustain higher deflectionwithoutfailureunderflexuralloading.

3. Theincorporationoffibersreduceswaterabsorption and sorptivity, thereby improving the concrete’s impermeability and resistance to acid and sulphate attack.

4. Fiber-reinforcedbeamsexhibitdelayedcrackinitiation, increased energy absorption, and improved postcrackingbehaviorundertwo-pointloadingconditions.

Table -2: ComparisonofExperimentalandANSYSLoadDeflectionResults

Chart -1: LoadvsDeflectionComparisonGraph (ExperimentalvsANSYS)

5. Theoptimumfibervolumeof0.75%providesabalance between mechanical performance and workability, while fiber content above this threshold leads to marginalreductionsduetopoordispersion.

6. Finite element modeling using ANSYS shows strong correlation with experimental results, validating the simulationapproachforpredictingflexuralresponsein steelfiber-reinforcedGPCbeams.

7. The study confirms that geopolymer concrete with 0.75% steel fibers is a viable, eco-friendly, and structurally efficient alternative to conventional cement-based concrete for durable construction applications.

[1] P. Thamilselvi, Geopolymer concrete: Overview, 2018

[2] R.Abraham,Strengthandbehaviourofgeopolymer concretebeams,2013.

[3] A.M. Rashad, Effect of steel fibers on geopolymer properties,2020

[4] M.M.A.B.Abdullah,etal.,Studyonthegeopolymer concrete properties reinforced with hooked steel fiber,2017.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

[5] Takekar, et al., Experimental study on mechanical properties of fly ash and GGBS based geopolymer concrete,2017.

[6] G.SrinivasaRao,etal.,Experimentalinvestigationof GGBSbasedgeopolymerconcretewithsteelfibers, 2019.

[7] N.Ganesan,etal.,Influenceofsteelfibresontension stiffening and cracking of reinforced geopolymer concrete,2014.

[8] N. Ganesan,Durability characteristics of steel fibre reinforcedgeopolymerconcrete,2015.

[9] Bureau of Indian Standards, IS 10262:2019, IS 456:2000,IS13311(Part1andPart2),India.

[10] Ghaffar,Steelfibrereinforcedconcrete,2014.

[11] H.A.Goaiz,etal.,Evaluationofsteelfiberreinforced geopolymer concrete made of recycled materials, 2022.2003;34:663–77.

[12] Islam, Influence of steel fibers on the mechanical properties and impact resistance of lightweight geopolymerconcrete,2017.

[13] M.M.A.B.Abdullah,etal.,Performanceandcharacterizat ion of geopolymer concrete reinforced with short steelfiber,2017.

[14] M.R.Manikantha,Mechanicalperformanceofsteel fiberreinforcedgeopolymerconcrete,2005.

[15] F.U.A. Shaikh, Mechanical propertiesof stee lfibre reinforced geopolymer concretes at elevated temperatures,2016.