International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

SURIYA R1, SUGANTHI K2

1M. Tech Student, Department of Computer Science and Engineering, PRIST Deemed to be University, Thanjavur, Tamil Nadu, India.

2M.E., Assistant Professor, Department of Computer Science and Engineering, PRIST Deemed to be University, Thanjavur, Tamil Nadu, India.

Abstract - The influence a hazardous workplace has on worker well-being and efficiency has led numerous companies to put extreme focus on workplace safety. Workers are continuously subjected to numerous hazards at all times and locations when laboring in today's large construction/manufacturing plants and other hazardous industrial sites. The accident occurrence is thus higher compared to other sectors because the number of variables of risk is higher, and it is also a requirement for employees to don personal protective devices (PPE) in order to protect their bodies against unsafe causes. The accidents that have occurred because employees failed to put on personal protection equipment, such as hard hats, are the most common types of safety occurrences at the worksites. In reality, most existing safety inspection processes rely on the manual observation and reporting of inspectors. Hand observation of construction sites can be time-consuming, error-prone, costly, and inappropriate for large projects with several simultaneous operations. There have been numerous publications of studies on automatic detection of helmet wearing and human identity recognition, which have been aimed at helping safety inspectors on construction sites in monitoring workers' safety. Another study asserts that the computer vision-based person identification could be combined with helmet wear. In other words, in helmet testing, we usually do not have the capability to recognize individual people, and vice versa. We propose a computer vision approach to automatically recognize workers' identity and helmet wear to resolve the issues discussed above. First, our method involves two applications: identification and detection of helmet wear. Second, we tested the accuracy and recall rate of the algorithm under different visual environments to establish its use in the real construction site conditions. This was carried out as per the differing visual conditions at the construction site.

Key Words: Accident Occurrence, Computer Vision, Helmet Detection, Personal Protective Equipment, Safety Inspection, Worker Identification

In order to reduce the risks involved with working under such circumstances, it is important to maintain worker safetyonbuildingandconstructionsites.Itisadvisablethat all employees undergo extensive training programs regarding key standards and be given frequent refresher

courses.Safetyfromexposuretoarangeofhazardscanbe providedbyworkersthroughthefrequentuseofPersonal Protective Equipment (PPE), including hard hats, safety glasses, gloves, and appropriate footwear. Fall protection devices, including guardrails and personal fall arrest equipment, demand special attention, especially when undertaking work at heights. Routine maintenance and checksarenecessarytoensurethesafeusageofequipment andmachinery.Trainingsessionsthateducateemployeeson properusearealsorequired.Properhazardcommunication assistsinenhancingawarenessandensuresworkersknow aboutpotentialhazards.Itcanbeattainedthroughlabelling, signage,andfrequentsafetymeetings.Additionally,havinga systematicapproachtorecordingandfixingsafetyproblems ensures a proactive safety culture on construction sites. Construction industry stakeholders could significantly enhanceworkplacesafetyandhelpminimizetheprobability of accidents and injuries by catering to these essential factors.

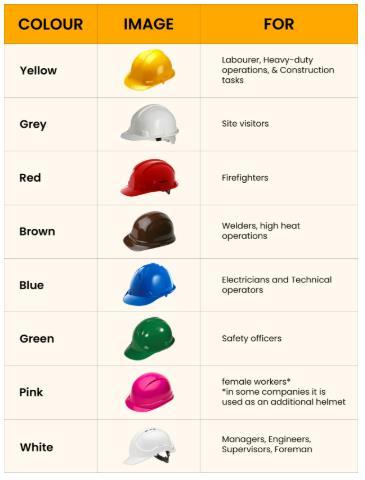

Inmostsectors,particularlyconstructionwherethereisa high risk of head injuries, helmets are a critical part of employee safety. The primary function of helmets is to prevent the risk of severe head injury by serving as a protective barrier against possible threats such as falling objects, debris, or impact. Additionally, helmet usage is in linewithoccupationalhealthandsafetyregulationsinmany locations, which demonstrates the importance as an obligatoryprotectionmeasure.Thehelmetsconsistofahard exterior, typically made from fiber glass or high-density polyethylene.Thisouterhardsurfaceservestospreadforce ofimpactacrossabiggersurfacearea,therebymakingthe helmetmoreeffective.Suspensionsystem,withstrapsand headband,istypicallyintegratedintheinteriorinorderto facilitate a comfortable as well as a secure fit around the headofthewearer.Thereareavarietyofhelmettypesthat existandarecreatedforspecificsortsofworkconditions. Industrialhelmets,forinstance,aremanufacturedtobeable to withstand electricity conductivity, as well as brimmed constructionhelmetsthathelpprotectagainstsunshineand rain.Protectingworkersfromrisksassociatedwithheads, thecombinationofdifferenthelmets'featuresanddesigns togetheraimstoprovideanimprovedworkcondition.Fig1 illustratesdifferentcolorsofconstructionsitehelmetswith code.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Fig 1:Helmetwithcolorcodes (https://www.reddit.com/r/coolguides/comments/42saf b/difference_between_different_safety_helmets_colors/?rd t=54588)

Desu Fu, et.al,…[1] A helmet detection algorithm based on improved YOLOv5 is put forward in this paper. First, the structure of the YOLOv5 network is changed. With the enlargementofthefeaturemapsize,onescaleisaddedtothe initial three scales, while also using the added 160*160 feature map to detect small targets. Second, K-means clusteringisusedtore-clusterthehelmetdatasettoyield more suitable prior anchor boxes. It was observed from experimentalresultsthattheaverageprecision(mAP)ofthe improvedYOLOv5algorithmislargerby2.9%,reaching95% ascompared to the base model, while the mAP for helmet recognitionisincreasedby2.4%,reachingalevelof94.6%. The algorithm reduces the rates of missed detection and misdetectionwhiletheoreticallysupportingthehardtoscale detectionofsmalltargetswhilebeingofhighpracticalitywith advanced features. It meets the demand for real-time detectionandcontributessignificantlytowardsafetywithin the electrical industry. In realizing their daily activities, powerworkersareeasilyrecognizedbytheirsafetyhelmets, whetheritissunny,rainy,orsnowy.Ifthepowerworkerfails

tousesuchhelmetsduringoperations,hecanbehitonthe headbyobjectsfallingfromabove,sufferheadinjuriesdueto high falls, or get an electric shock on the head. Therefore, safety helmets serve as the safeguard for the staff in this industry.Safetyhelmetsaremandatoryforpowerworkersto enter the operation areas. However, manual inspection is time-consuming and labor-intensive, with some work scenarios being risky in terms of close-range supervision. Hence, the development of the intelligent real-time safety helmet detection system for power workers has gained tremendous importance. This intelligent safety helmet detection system can not only bring the supervision and monitoringworkofsafetyintoautomaticanddigitalpractice but will also augment workers' safety in this industry, thereforehavingsignificanceinpracticaldevelopments.

ShuaiWang,et.al,…[2]Thepresentworkinvestigatesasmart vision-basedmethodforidentificationofworkers,whichin turnisdevelopedontheGMMmodelformotionextraction, based on MHOG and SVM techniques for personnel recognition,andisfurtherbuiltuponOpenPoseandtransferlearning CNN techniques for helmet identification. The method can very well identify the worker type in construction sites, factory workshops, power construction sites, and interior decorations, among many others. The methodisapplicabletosmall-scaledatasets,andaccuracyof worker identification does not suffer much for occluded helmets, varying sizes of workers, and lighting conditions. Theresultsoftheexperimentperformedonourself-collected dataset demonstrate that the accuracy values vary little underdifferenttypesofidentification-relatedcircumstances, withonefigurereaching99.43%asthemeanaccuracyvalue. It is worthwhile to mention here that the visual characteristics of the self-collected dataset in the present study are rather ideal, and this explains the better identification result in this study. Our following, larger schemeofworkwouldbetocollectsomeworkervideosin realindustrialenvironments,includingacarefulanalysisof theworkers'imagesrelativetoapplicationofvision-based identificationofworkers.

Yi-Jia Zhang, et.al,….[3] Design an algorithm for helmetwearing detection for the construction workers, based on contour andcolor features. Image preprocessing involving image smoothing and image enhancement is adopted to eliminateinterferenceintheimage.Thecombinationofface detection,skincolordetection,andhelmetcontourdetection procedures helps extract the two-stage ROI based on the result of image preprocessing. Safety helmet-wearing detectionisimplementedbycolorspaceconversionandcolor featurerecognitionbasedontheoutputfromtheregionof interestextraction,statingwhethertheworkersweartheir helmets.Thewearingofhelmetsdoesbeargreatsignificance in most contexts, thus rendering the detection of helmetwearing a matter of some intérêt in providing safety in construction.Thealgorithmproposedhereisrealizedmainly for batch image helmet-wearing detection that can satisfy

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

some detection requirements, although some real-time detection is not covered in this study. In the direction of future research, real-time helmet-wearing detection, along witha promptfornon-wearingalarm,will berealizedand assistance in constructing a safety helmet-wearing system thatcouldbepracticallyapplied.

Ahatsham Hayat, et.al,…[4] developed machine and deep learning-based helmet detection systems, but few have focusedonmosthelmetdetectionatconstructionsites.Inthis paper, the authors proposed a safe, real-time computer vision-basedautomaticsafetyhelmetdetectionsystemona constructionsite.TheYOLOarchitectureisveryfast,withthe capabilitytoprocess45framespersecond,makingitsuitable touseitforreal-timehelmetsafetydetection.Inthisstudy,a benchmarkdatasetof5000imagesofhardhats,whichwas further subdivided in a ratio of 60:20:20 (%) for training, testing, and validation respectively, was used. Backed by experimental results,theYOLOv5xarchitecturescoredthe bestmeanaverageprecision(mAP)of92.44%,establishing excellentsuccessinsafetyhelmetdetectionunderlow-light conditions.Themonitoringofconstructionworkers'safetyis of paramount importance. Monitoring the use of safety equipmentisacriticalcomponentofsafetymanagementat constructionsites.Inmostfallingaccidents,aworkermayfall fromaheightandthenhithisheadonthehardground.Safety helmetsaredesignedtoabsorbanddissipateimpactenergy and minimize injury to the worker in case of a fall from a height.Hardhatsarealsodesignedtolessentheriskofshock fromfallingobjectsorcutbysharpobjectsorcontactwith electricalhazards.Ifhardhatsareusedproperly,halfofall deaths from falls might be avoided and most deaths from slips,trips,andbeingstruckbyfallingobjects.

Han Liang, et.al,…[5] GhostNet, a lightweight network, is proposedtobeutilizedasthebackbonefeatureextraction networkinthehelmetdetectionnetwork.Itmakesthemodel lighter overall through its cheap operation, while guaranteeing efficient automatic feature extraction. In the feature processing stage, we designed multiscale segmentation and feature fusion network (MSFFN) to improvetherobustnessofanobjectdetectionalgorithmfrom different scales. On the other hand, the feature fusion networkbringsoutthediversityofthehelmetfeaturesthat wouldhelptoincreasetheaccuracyofhelmetdetectionin thedistancechanges,viewinganglechanges,andocclusion phenomena.Theproposedlightweightresidualconvolutional attention network version 2 (LRCA-Netv2) is basically the improvementofanattentionmoduleofspatialfeaturesfrom LRCA-Netthatweproposedinthepreviouswork.Themain ideaofimprovementisthatbyfusingthecombinedfeatures, both horizontal and vertical, while using their weights for attention,thisoperationcanestablishdependenciesbetween those features further apart with accurate location-based information. The improvement clearly shows better performance as compared to the previous module. The proposed lightweight helmet-wearing detection network,

evaluatedonthecombineddataset,achievedmAPandFPSof 93.5% and 42, respectively, which improves our model in executionspeedandaccuracycomparedtoexistingmethods.

Usually,conventionalvideomonitoringtechniquesareused tosupervisethewearingofsafetyhelmetsonconstruction sites.Thesetechniquesmostlyrelyonhumanjudgmentabout finalclearances.Essentially,conventionalmethodsmaynot beasgoodagaugeinrecordingcompliancetosafetyhelmet use compared to fully automated versions. This is why conventionalmethodsofobjectdetectionaremultitudinous. They commonly use sliding window approaches to select regions,whichinvolvesconductingameticulouspassoveran entireimage.Choosingtherightaspectratioandscalesofa sliding window, however, may easily be difficult when dealingwithhelmetsofvarioussizesandorientations.Also, sliding windows can cause navigational delays while scanningthroughtheentireimagefordetection.Becauseof this, methods advanced by human management may experience issues of accuracy and efficiency. There is increasing interest in looking for more sophisticated technologies like automated visual processing systems coupledwithmachinelearningtechniquestoaddressthese challenges.Suchtechnologiescanimmenselyreducehuman interventionforaccuratereal-timeusedetectionofhelmets; anefficientmeansofensuringsafetycomplianceinbuilding sites.Embracingtheseautomatedsystemscouldsupplyan excellentsimmeringsolutionforimprovingtheefficiencyof buildingsafetymonitoringprocedures.Adoptionoftop-end technological solutions is becoming increasingly popular towards solving these challenges. Promising substitutes includeautomatedcomputervisionsystemsthataredriven by machine learning algorithms. In real time, these algorithms may be trained to identify safety helmets with accuracy,eliminatingtheneedforhumanmonitoring.Deep learningtechniques,whichacquirecomplexpatternsfroma varietyofdatasets,offeramoreflexiblemethodforhelmet detection.

This model comprises helmet detection with facial recognition. This form of intelligent safety involves the mergerofcutting-edgetechnologyandattemptstoprovide reliable means by which surveillance and enforcement of safety procedures may occur simultaneously. Camera placements are made at critical locations in the operation through the Grassmann algorithm-a visual features extraction technique. This gives an essential and adroit foundation on which further identification can be built by extractingthefeaturesuniquetotheface.Then,comparison ofidentifiedfacefeaturesforstreamingdataismadewithan authorized personnel database to ensure real-time and accurateidentification.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

YOLO (You Only Look Once) algorithm enables helmet detection and further augments safety measures. This algorithm specifically aims to identify people not wearing helmets,allowingforfastandaccurateobjectdetection.By integrating facial recognition and helmet detection, the solution provides a holistic approach to ensuring helmet usage and access with an adherence to safety protocols. Uponidentifyingnon-helmetuseorunauthorizedaccess,the technologyisdesignedtosoundalarms.Theproactivealarm system allows for rectifying any deviation from safety requirements.Theproposedtechniqueenhancesworkplace safetythroughreal-timemonitoringandquickresponsein combinationofbothfacerecognitionandhelmetdetection algorithms.Theproposedframeworkisdepictedinfig2.

Thediagramfig2illustratesasystemforverifyingworkers' identity and construction helmet usage before granting accesstoacompany.Theprocessinvolvesseveralstages:

Basic Employee Details: An administrator inputs basic employeedetailsintothesystem.

FacialFeatureExtraction:Thesystemextractsfacialfeatures using the Grassmann algorithm and stores them in a database.

Helmet Dataset Training: The system trains a dataset of constructionhelmetsusingYOLO(YouOnlyLookOnce),an objectdetectionsystem.

Surveillance Camera Verification: When a worker approaches,asurveillancecameracapturestheirimage.

Authorized Person Verification: The system verifies the worker'sidentitybycomparingtheirfacialfeaturestothe database.

If verified, the system proceeds to check for a constructionhelmet.

Ifnotverified,accessisdenied,andanotificationis senttotheadministrator.

ConstructionHelmetDetection:Thesystemchecks iftheworkeriswearingaconstructionhelmet.

Ifahelmetisdetected,theworkerisallowedaccess tothecompany.

Ifnohelmetisdetected,accessisdenied.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Thissystemaimstoenhancesecurityandsafetybyensuring thatonlyauthorizedpersonnelwearingappropriatesafety gear can enter the company premises. The use of facial recognitionandhelmetdetectiontechnologyautomatesthe verificationprocess,improvingefficiencyandreducingthe riskofhumanerror.

The YOLO (You Only Look Once) algorithm is a powerful real-time object detection system that works in a single forwardpassofaneuralnetwork.Here’showitprocessesan imagestepbystep:

Splitting the Image into a Grid

Theinputimageisdividedintoagridofcells.Thesizeofthe grid depends on the specific YOLO version for example, YOLOv3typicallyusesa13×13or19×19grid.Eachcell in thegridisresponsiblefordetectingobjectsthathavetheir centerwithinthatcell.

Predicting Bounding Boxes

Eachgridcellpredictsmultipleboundingboxes(usuallytwo orthree)thatdefinethepotentiallocationofobjects.These boxes include details such as width, height, and the (x, y) coordinatesofthebox’scenter.Additionally,eachboxcomes with a confidence score, indicating the likelihood that an objectispresent.

Classifying Objects

For every predicted bounding box, the model assigns probabilitiestodifferentobjectcategories(suchas"person" or"car").Thisisdoneusingsoftmaxactivation,meaningthe highest probability indicatesthe mostlikely object in that box.

Calculating the Confidence Score

To determine how reliable a prediction is, the confidence score is computed by multiplying the abjectness score (whichindicateswhetherthere’sanobjectinthebox)with thehighest-classprobability.

Removing Duplicate Detections (Non-Maximum Suppression - NMS)

Sincemultipleboxesmaypredictthesameobject,afiltering process called Non-Maximum Suppression (NMS) is used. The algorithm sorts the boxes based on their confidence scores and removes any overlapping boxes with lower scorestoavoidredundantdetections.

Filtering Low-Confidence

Any bounding boxes with confidence scores below a predefinedthresholdarediscarded,ensuringonlythemost reliabledetectionsarekept.

Intheend,YOLOprovidesalistofdetectedobjects,including theirboundingboxcoordinates,confidencescores,andclass labels.Thisallowsustoseewhatobjectsarepresentinthe imageandwheretheyarelocated.

By processing the entire image in a single pass, YOLO achievesreal-timeperformance,makingitapopularchoice for applications like self-driving cars, surveillance, and robotics.

GrassmannmanifoldsGn,pisaresetsoflinearsubspacesof Rn(p-planesinRn),where

0 < p ≤ n. This manifold has a natural quotient representationGn,p =Vn,p/Op,whereVn,pisaStiefelmanifold(thesetofn×p orthonormalmatrices)andOp istheorthogonalgroup.Thismeansthattwosuchmatricesif and only if their columns span the same p-dimensional subspace. Thus, an entire equivalence class can be representedasthespacespannedbythecolumnsofsome matrixY.

[Y]={YQ_p:Q_p∈O_p}

In other words, a point on the Grassmann manifold is a linear subspace which may be specified by any arbitrary orthogonalbasis.

Useeyecoordinatestodeterminetheinitialaffine registrationparametersforeachimage.

Sample the affine registration manifold by perturbingtheaffineparameters

Compute the k nearest neighbors from the registrationmanifold

Applycolorequalizationandfilterfeaturesvalues

Constructthetangentspace

Embed the approximated tangent space and computecanonicalangles

Computethesubspacedistance

Obviously, in order to test the system some faces are required. There are so many standard face databases for testing and rating a face detection algorithm. A standard database of face imagery is essential to supply standard

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

imagery to the algorithm developers and to supply a sufficient number of images to allow testing of these algorithms.Withoutsuchdatabasesandstandards,therewill be no way to accurately evaluate or compare facial recognitionalgorithms.Alltheexperimentsdescribedhere havebeenexecutedmainlyonthefacesprovidedbythereal timefacedatabase.

Accuracy(ACC)isfoundasthefractionoftotalnumberof perfect predictions to the total numberof testdata. Itcan alsoberepresentedas1–ERR.Thefinestpossibleaccuracy is1.0,whereastheveryworstis0.0.

ACC= (TP+TN)/(TP+TN+FN+FP)x100

True positive (TP): number of true positives - perfect positiveprediction.

False positive (FP): number of false positives - imperfect positiveprediction.

True negative (TN): number of true negatives - perfect negativeprediction

False negative (FN): number of true negatives - imperfect negativeprediction

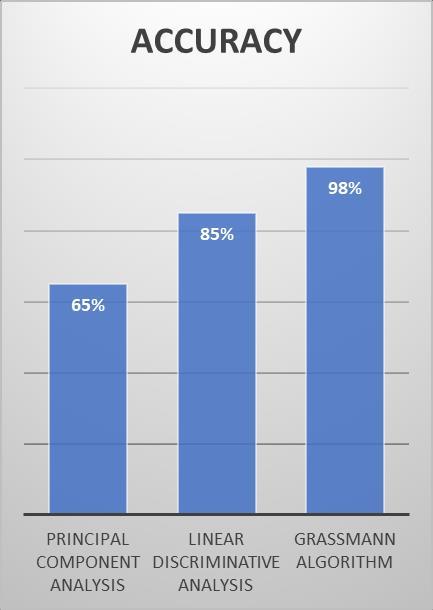

Table 1:Performancetable

ALGORITHM

PRINCIPALCOMPONENTANALYSIS 65%

LINEARDISCRIMINATIVEANALYSIS 85%

GRASSMANNALGORITHM 98%

From the graph given in Fig:3, proposed system provides improved accuracy rate than the existing PCA and LDA algorithm

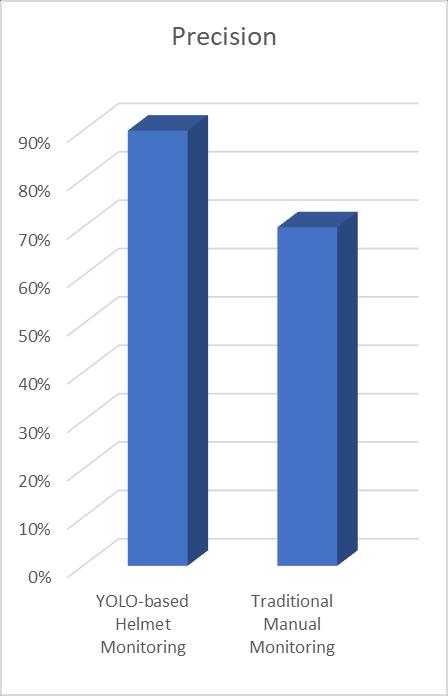

TheYOLOmodeldemonstratedhighaccuracyindetecting helmets in various construction environments. Key performancemetricsareasfollows:

Precision: The system achieved a precision of 90-95%, indicatingthatmostofthedetectedhelmetswereaccurate, withfewfalsepositives(incorrectlydetectinghelmetswhere nonewerepresent).

Fig 3: Accuracygraph

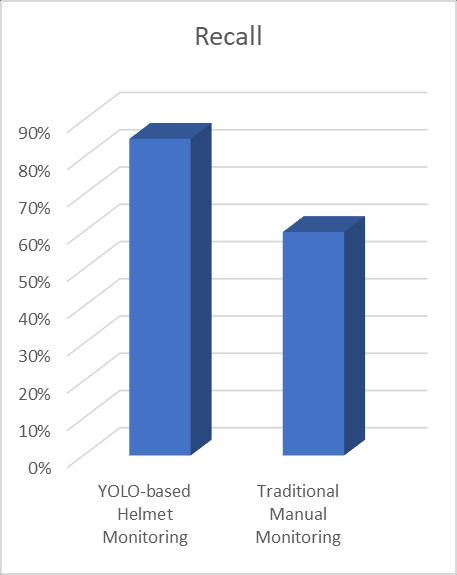

Recall:Recallrangedfrom 85-90%,reflectingthemodel's abilitytoidentifyworkerswhowerewearinghelmets.Some minor false negatives were observed in cases where the helmetwaspartiallyobscuredorinclutteredscenes.

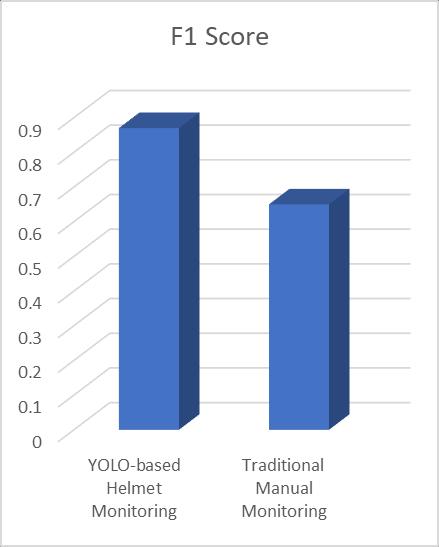

F1-Score: The F1-score, a balance of precision and recall, was consistently above 0.87, suggesting a well-balanced detectionperformance.

Theseresultsarepromisinganddemonstratethatthe YOLO-basedsystemishighlycapableofdetectinghelmets with minimal errors. The system performed well under various lighting conditions, occlusions, and crowded environments,whicharecommoninconstructionsites.The performancechartcanbeshowninfollowingfigures4,5and 6.

The YOLO-based Helmet Monitoring system performs significantlybetterthanTraditional Manual Monitoring in terms of Precision, Recall, and F1 Score, providing more reliable, accurate, and comprehensive helmet detection. TraditionalManualMonitoringissubjecttohumanerrorand fatigue, leading to lower Precision, Recall, and F1 Score, which can affect the overall effectiveness of safety monitoringonconstructionsites.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Tosummarize,thetechnologytransformedsafetypatterns inconstructionsitesthroughcomplianceandsurveillance. The system proposed utilizes the Grassmann and YOLO algorithmsforhelmetdetectionandfacerecognitiontoyield preciseresults.Thesystemwasabletonotonlychecksafety protocolsfortheuseofsafetyhelmetsbutalsoallowentry basedonfacialrecognitionwiththehelpofreal-timedata processingandstrategicallypositionedcameras.TheYOLO algorithm tailored helmet detection efficiently while Grassmannrealizescorrectextractionoffacialfeaturesand givesanaptstepforidentification.Thecombinationofthese advanced technologies affords a novel approach to workplacesafety,allowingrapidresponsestounauthorized entryandnon-compliancewithhelmetregulationsthrough proactivealarmsystems.Itsstrongandflexiblemethodof riskreductionputstheproposedsystemattheforefrontof innovationintheconstructionindustry,stillhighlycentered on safety. Joining automated technology with traditional safetytechniquesrealizesmoreaccuracyandeffectiveness, furthermore creating a safer working environment. The acceptance of such innovations is a pledge to improve workplacesafety,protectemployees,andminimizehazards onconstructionsites.

[1] Fu, Desu, et al. "Research on safety helmet detection algorithm of power workers based on improved yolov5." JournalofPhysics:ConferenceSeries.Vol.2171.No.1.IOP Publishing,2022.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

[2]Wang,Shuai,etal."Anintelligentvision-basedmethodof workeridentificationforindustrialinternetofthings(IoT)." Wireless Communications and Mobile Computing 2022 (2022).

[3] Zhang, Yi-Jia, Fu-Su Xiao, and Zhe-Ming Lu. "Safety Helmet Wearing Detection Based on Contour and Color Features."JournalofNetworkIntelligence:Taiwan,China7 (2022):516-525.

[4] Hayat, Ahatsham, and Fernando Morgado-Dias. "Deep learning-basedautomaticsafetyhelmetdetectionsystemfor constructionsafety."AppliedSciences12.16(2022):8268.

[5] Liang, Han, and Suyoung Seo. "Automatic detection of construction workers’ helmet wear based on lightweight deeplearning."AppliedSciences12.20(2022):10369.

[6] Li, Yange, et al. "Deep learning-based safety helmet detection in engineering management based on convolutional neural networks." Advances in Civil Engineering2020(2020):1-10.

[7] Cheng, Rao, et al. "Multi-scale safety helmet detection basedonSAS-YOLOv3-tiny."AppliedSciences11.8(2021): 3652.

[8] Hayat, Ahatsham, and Fernando Morgado-Dias. "Deep learning-basedautomaticsafetyhelmetdetectionsystemfor constructionsafety."AppliedSciences12.16(2022):8268.

[9]Deng,Lixia,etal."AlightweightYOLOv3algorithmused forsafetyhelmetdetection."Scientificreports12.1(2022): 10981.

[10]Huang,Li,etal."Detectionalgorithmofsafetyhelmet wearing based on deep learning." Concurrency and Computation:PracticeandExperience33.13(2021):e6234.

[11] Lin, Bingyan. "Safety helmet detection based on improvedYOLOv8."IEEEAccess(2024).

[12] Wu, Xiao, et al. "A remote-vision-based safety helmet and harness monitoring system based on attribute knowledgemodeling."RemoteSensing15.2(2023):347.

[13]Hao,Chang,etal."Multiplecomplex weathertolerant andlowcostsolutionforhelmetdetection."IEEEAccess11 (2023):50264-50271.

[14]Huang,Bingqiang,etal."AnImprovedYOLOv5s-Based Helmet Recognition Method for Electric Bikes." Applied Sciences13.15(2023):8759.

[15] Siebert, Felix Wilhelm, et al. "Computer vision-based helmetuseregistrationfore-scooterriders–Theimpactof themandatoryhelmetlawinCopenhagen."Journalofsafety research87(2023):257-265

Suriya R is currently pursuing an M.Tech in Computer Science and Engineering at PRIST Deemed to be University, Thanjavur, Tamil Nadu, India. She serves as a Lecturer in the Department of ComputerEngineeringatKaraikal Polytechnic College, Karaikal, Puducherry, India, with an extensive teaching experience of 18 years in the field of Computer Science and Engineering. She continuallystrivestoenhanceher knowledge through research and advancedstudies

SuganthiKiscurrentlyworkingas an assistant professor in the department of Computer Science andEngineeringat PRISTDeemed tobeUniversity,Thanjavur,Tamil Nadu, India with an extensive teachingexperienceof13yearsin thefieldofComputerScienceand Engineeringshecontinuestoguide students and support their learning.